-

0 items in quote

No products in the Quote Basket.

Knowledge Center

UKAM Industrial Superhard Tools is committed to helping you improve and optimize your slicing, dicing, and drilling operation to the outmost level of efficiency.

On our web site you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond tools, diamond drilling, cutting, grinding, & polishing. We believe that the best client is a well-informed client. The more you understand about what we can do for you, the better our partnership will be Superior Performance requires not only high quality diamond tools, but Proper Understanding & Experience on how to properly use them.

LET US HELP YOU

We Are A Partner In Your Success

We highly suggest exploring our Knowledge Center, which contains valuable information, where you will find answers to most of your questions. This valuable resource is offered to you FREE of charge, which is a rare benefit as many companies charge for similar information. We urge you to take advantage of this resource.

- Silicon Manufacturing

- Metallography / Sample Preparation

- Diamond Blade Articles

- Diamond Lapidary Blade Articles

- Diamond Drill Articles

- Dicing Blade Articles

- Diamond Wire

- Diamond Band Saw Blades Articles

- Diamond Articles

- CBN Articles

- Coolants Articles

- Diamond Bonds Articles

- Technologies Articles

- Diamond Wheels Articles

- Metallography Articles

- Diamond Core Bits Articles

- Diamond Hole Saws Articles

- Composites Articles

- Lapidary Articles

- Semiconductor Articles

- Sample Preparation Articles

- Concrete Articles

- Construction Articles

- Wafering Blade

Selecting Right Diamond & CBN Tools for your Application

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

08

May

Key Variables in Diamond & CBN Tool Performance that affect your ROI

Understanding the variables that play an important role diamond tool performance is important for achieving optimal results & improving your return on investment (ROI). This article dives into essential factors such as selecting the appropriate...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

How Diamond & CBN Tools Work

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

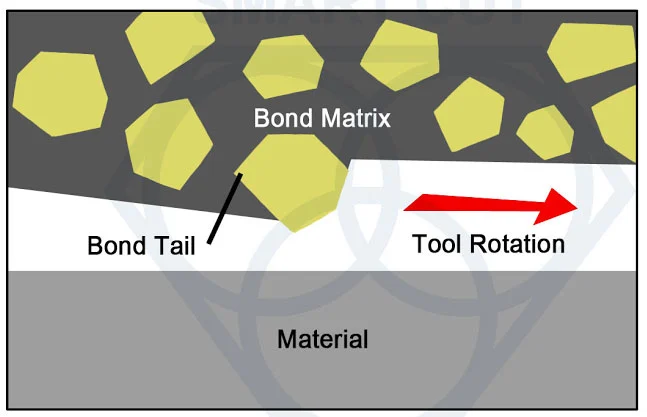

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

How Diamond Tools Work

Diamond & CBN Tools represent the highest engineering of cutting and grinding technology. These tools use their unparalleled hardness and durability of diamonds to perform tasks beyond the capabilities of conventional tools.

Share this Article with...

02

Jun

What is SMART CUT Technology

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT Diamond Bond, immediately penetrate into the material, grinding and polishing as they cut.

Share this Article with Friend or Colleague...

02

Jun

Diamond Tool Bond Hardness & wear resistance

Performance of Diamond or CBN Tools is not solely dependent on the diamond grit itself but also on the bond matrix that holds the diamonds in place. The bond matrix serves a dual function: retaining...

04

Aug

What are diamond dressers and their application

In the world of manufacturing, precision and efficiency are paramount. Among the various processes that contribute to achieving these objectives in abrasive grinding operations, truing and dressing stand out as critical steps. These...

04

Aug

How Diamond Tools are Manufactured

Manufacturing diamond tools involves a series of technological processes to impregnated manmade or natural diamond into various diamond tools. Find info on how these types of tools are made.

This article outlines...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...

Diamond & CBN Specifications

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Which to use for your application?

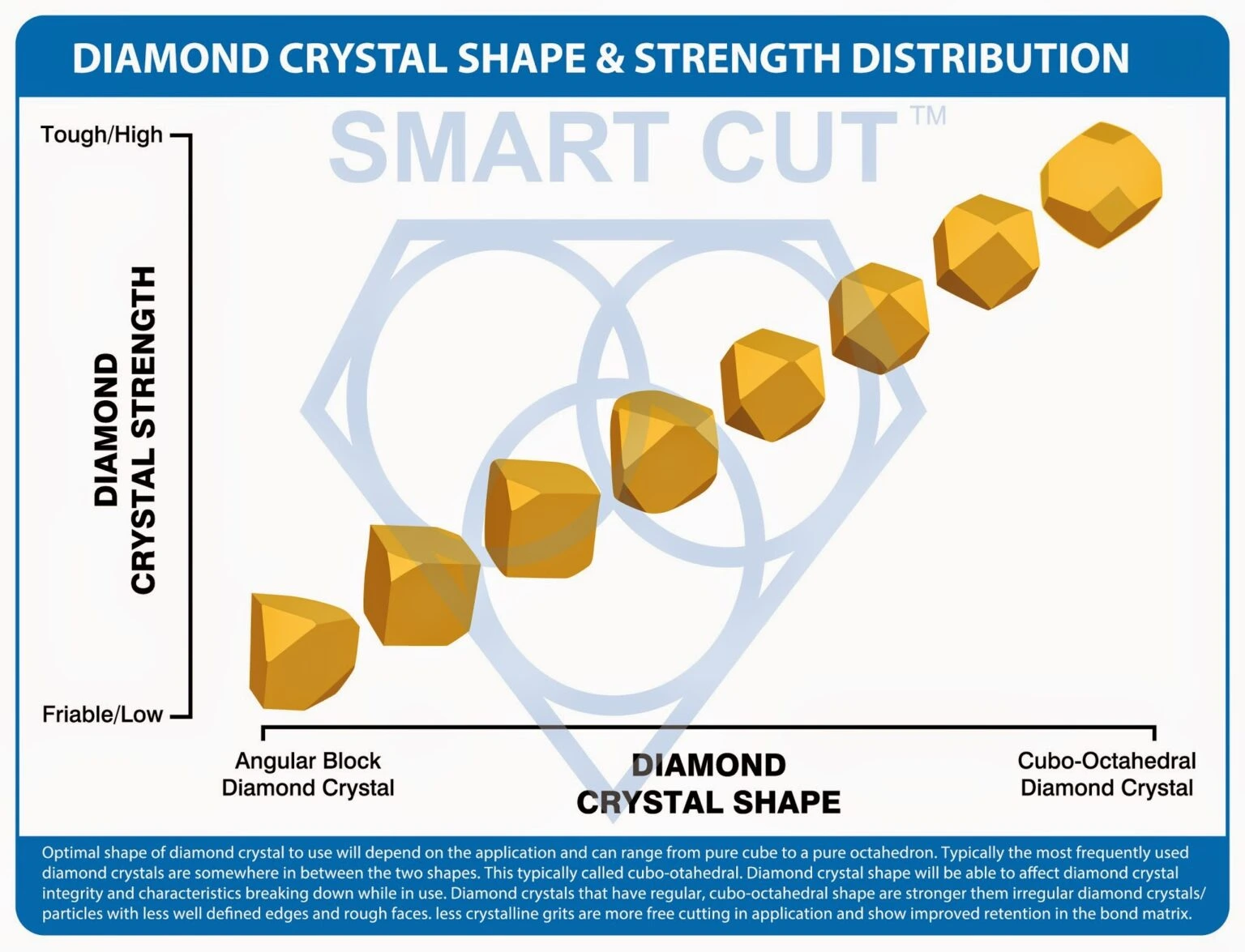

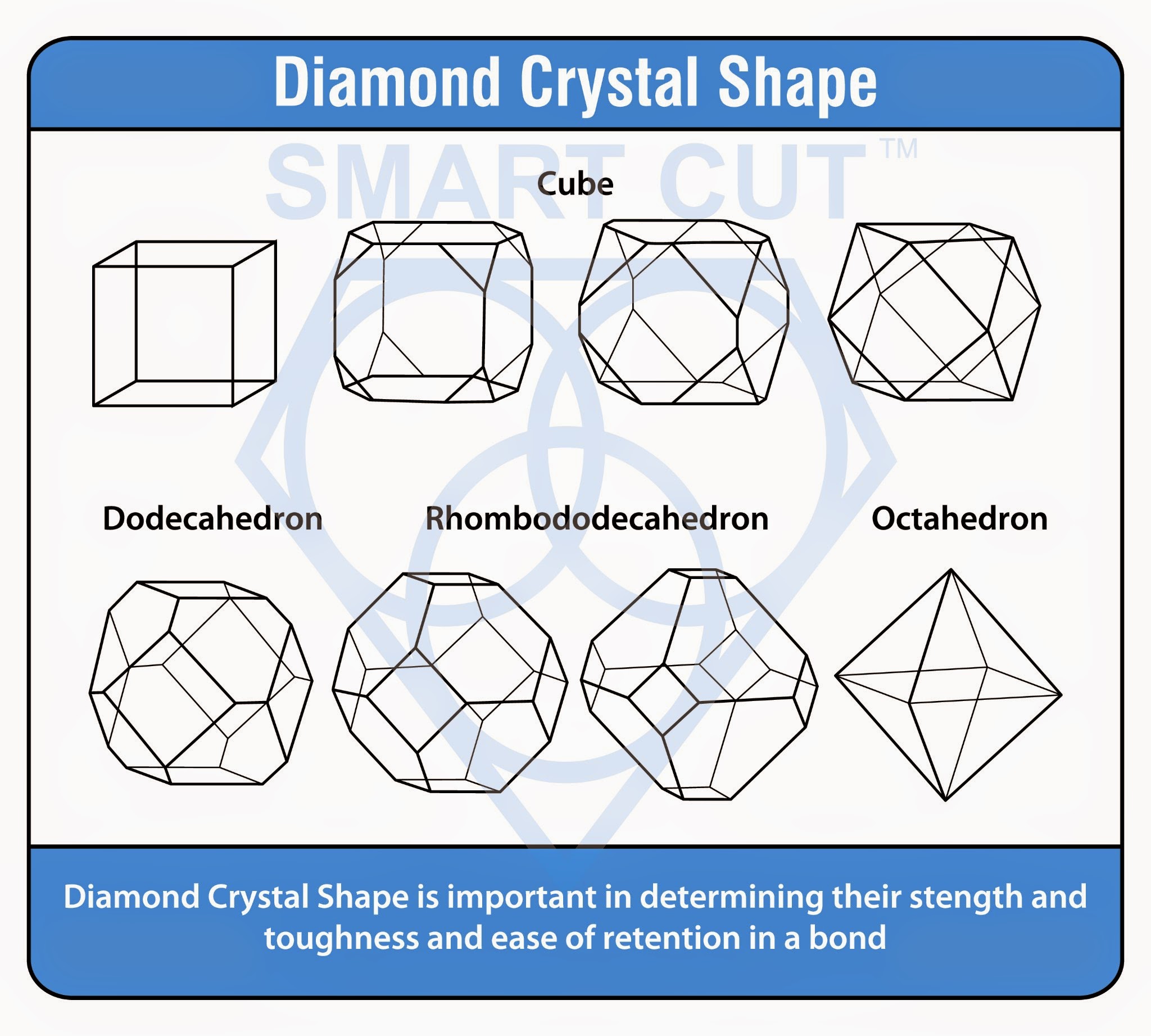

Diamond shape plays a significant role in the effectiveness of polishing solutions, affecting both the polishing rate and the quality of the final finish. Understanding the differences between monocrystalline and...

02

Jun

Diamond crystal quality – you get way you pay for

The diamonds impregnated inside the bond matrix of the diamond & tool, are what actually participate in cutting action. No matter what equipment and process you are using. You will not be able to obtain...

02

Jun

Diamond impact strength

Understanding the wear mechanisms of diamond crystals is essential for optimizing cutting performance in terms of both cutting ratio and speed. Diamond crystal loss, which primarily occurs through micro chipping rather than fracturing or pullout,...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

Diamond & CBN Bond Types

04

Aug

Resin Bond Tools

Learn everything you wanted to know about resin bond diamond tools. How they are made, what types are available and their application

Share this Article with Friend or Colleague

The resin bond...

04

Aug

SINTERED (METAL BOND) DIAMOND TOOLS

Sintered (Metal bonded) diamond tools have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or...

04

Aug

Electroplated Diamond Tools

Need Help Selecting the Right Diamond or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimalDiamond or CBN Tool specification/solution for your application

Request Applications Engineering...

04

Aug

What is Chemical Vapor Deposition and its application

CVD (Chemical Vapor Deposition) diamond coating is an advanced technique used to significantly enhance the performance of cutting tools. This process is conducted in a vacuum chamber, where tools, typically made from carbide,...

04

Aug

What is Polycrystalline Diamond and its application

PCD tools are used for processing aluminum and aluminum, aluminum alloys, copper, copper alloy, babbitt metal, wood, wood based fiber materials, aluminum oxide, reinforced floor boards, wear resistant plastic, Bakelite, graphite, stone materials,...

Diamond & CBN Usage Principals

29

Aug

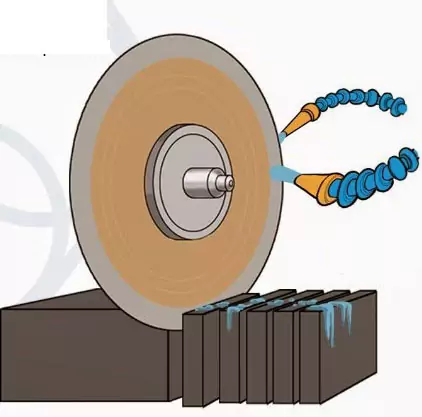

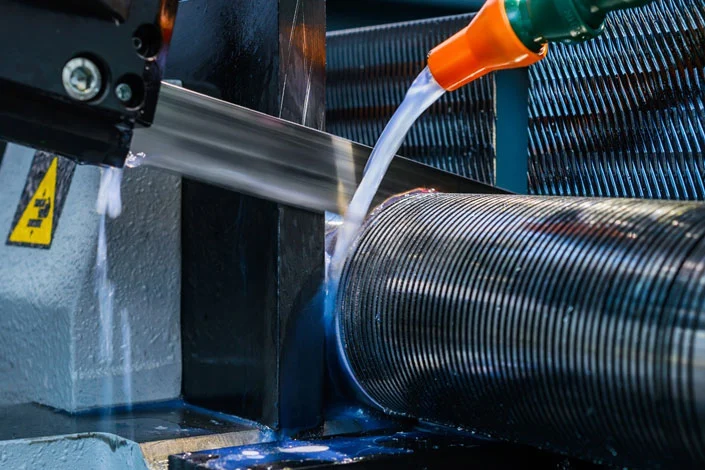

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

Dressing Diamond Tools Why, How, When & Where

Share this Article with Friend or Colleague

Dressing is the process of sharpening and exposing diamond particles within the bond matrix, allowing them to penetrate materials more effectively, minimize operational loads, and ensure high-quality cuts....

02

Jun

Material Holding Methods

Share this Article with Friend or Colleague

How to Select the Right Material Mounting or Fixturing Method for Your Application

Selecting the appropriate material mounting or fixturing method is essential for achieving precision, consistency, and efficiency...

02

Jun

RPM’s & Feed Rates

Selecting the right RPM (revolutions per minute) when using industrial diamond tools is a critical factor in achieving optimal results for a variety of applications. Whether you're slicing, dicing, drilling, grinding, or polishing, the RPM...

02

Jun

Material Guide

Learn everything you wanted to know about different materials and methods of working with them

Share this Article with Friend or Colleague

Understanding the material you will be working with, their unique...

02

Jun

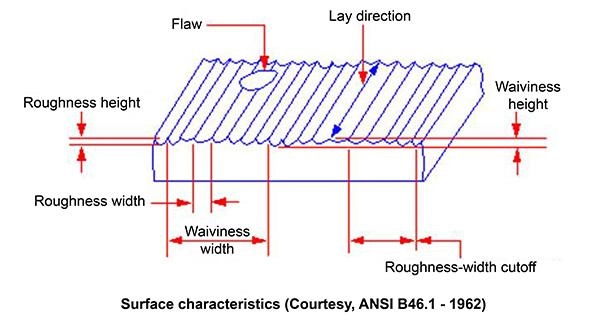

What is Surface Finish

Surface finish is typically measured in terms of roughness or smoothness. It influences the appearance, functionality, and performance of a product. A well-controlled surface finish can enhance the product's aesthetics, reduce friction, improve...

02

Jun

What are Tolerances, Accuracy, and repeatability

Tolerances, accuracy, and repeatability are essential concepts in the fields of engineering, manufacturing, and measurement. They all relate to the precision and consistency of a process, system, or measurement

Understanding Tolerances, Accuracy,...

02

Jun

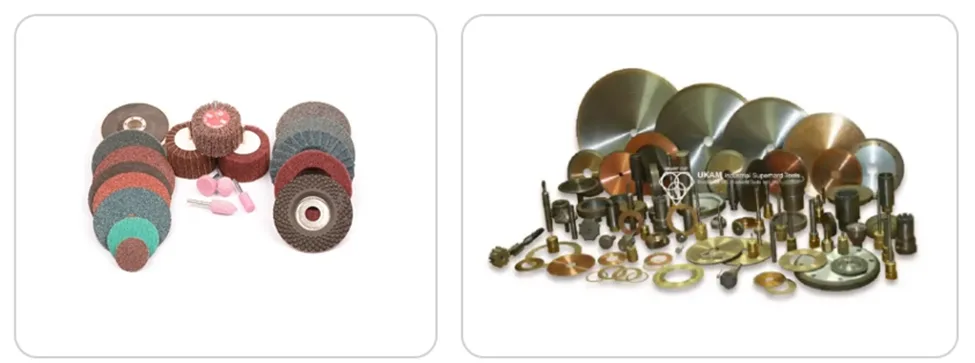

Diamond Tools compared with Abrasive Tools

Abrasive tools and diamond tools are two of the most widely used solutions for cutting, grinding, drilling, and polishing in manufacturing, research, and materials processing. While both serve the same purpose of removing material and...

04

Aug

Diamond vs. Laser and Water Jet

Machining with diamond tools and using diamond, laser, and water jet as cutting methods are all different processes with distinct advantages and applications

In selecting the most effective machining method...

12

Jan

Diamond Dressers: A Complete Guide to Types, Applications, and Best Practices in Grinding

Grinding is an important finishing and material-removal stage on components in manufacturing processes, which are secondary to precision, surface finish, and form errors of the workpieces. But wheels tend to lose their effectiveness through natural wear, loading,...

Coolant Articles

02

Nov

Diamond Tool Coolants Why, How, When & Where to Use

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

SMART CUT® Water Soluble Coolant Usage Recommendations

Mixing Ratios, Process, Best Practices, & Optimization

This usage guide will cover most aspects of coolant use, including mixing ratios, the mixing process, best practices, and optimization strategies. We will start by discussing the proper mixing...

08

Dec

Selecting the Right Dicing Surfactant / Fluid for Your Application

Selecting the correct dicing surfactant / fluid is essential for stable cutting, consistent kerf quality, and long blade life. Each operation places specific demands on lubrication, cooling, foaming control, and electrostatic behavior. You must choose...

09

Dec

How to Use SMART CUT XP Dicing Surfactants

SMART CUT® XP dicing surfactants should be introduced into the saw water supply in a controlled and consistent manner to ensure proper dilution, stable chemical performance, and uniform delivery to the cutting zone. Correct dosing equipment and proper...

09

Dec

Dicing Surfactants Guide

Dicing surfactants support stable and consistent wafer dicing. You use them as part of a complete dicing fluid designed to cool the blade, flush debris, and protect exposed device surfaces. Modern semiconductor wafers contain smaller...

Diamond Wire & Band Saw Blades

02

Nov

Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

07

Oct

Selecting the Right Diamond Band Saw blade for your Application

Selecting the right diamond band saw blade is important for getting the best results in your cutting process. The right blade can help you achieve clean cuts, reduce material waste, and make your blades last...

17

Sep

Diamond Band Saw Blades Usage Recommendations & Best Practices

Diamond band saw blades are used for cutting large variety of materials from ultra hard ceramics to glass and composite materials. This article covers all critical usage recommendations and best practices for diamond band saw...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

Before purchasing, avoid these common errors:

Silicon Manufacturing

02

Jun

Silicon Fabrication Guide

Share this Article with Friend or Colleague

Cutting silicon wafers is a critical process in the manufacturing of semiconductor devices, where precision and control are paramount to the success of the final products. Silicon, a...

08

Jul

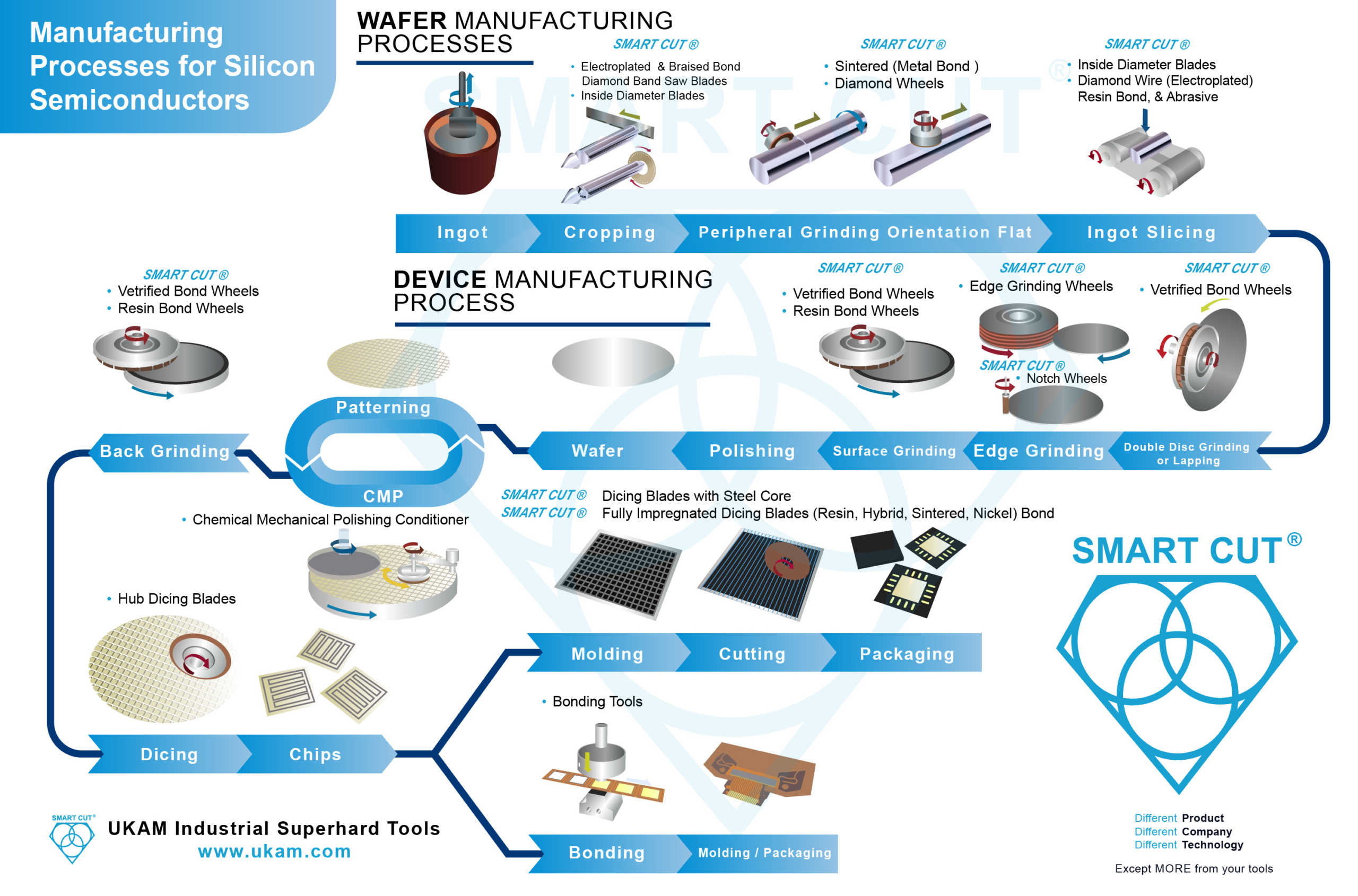

Manufacturing Processes for Silicon Semiconductors From Ingot to Integrated Circuit

Share this Article with Friend or Colleague

1. Ingot Production

The journey begins with the creation of silicon ingots, which are pure silicon cylinders produced through methods like the Czochralski process. Once formed, these ingots undergo a...

08

Jul

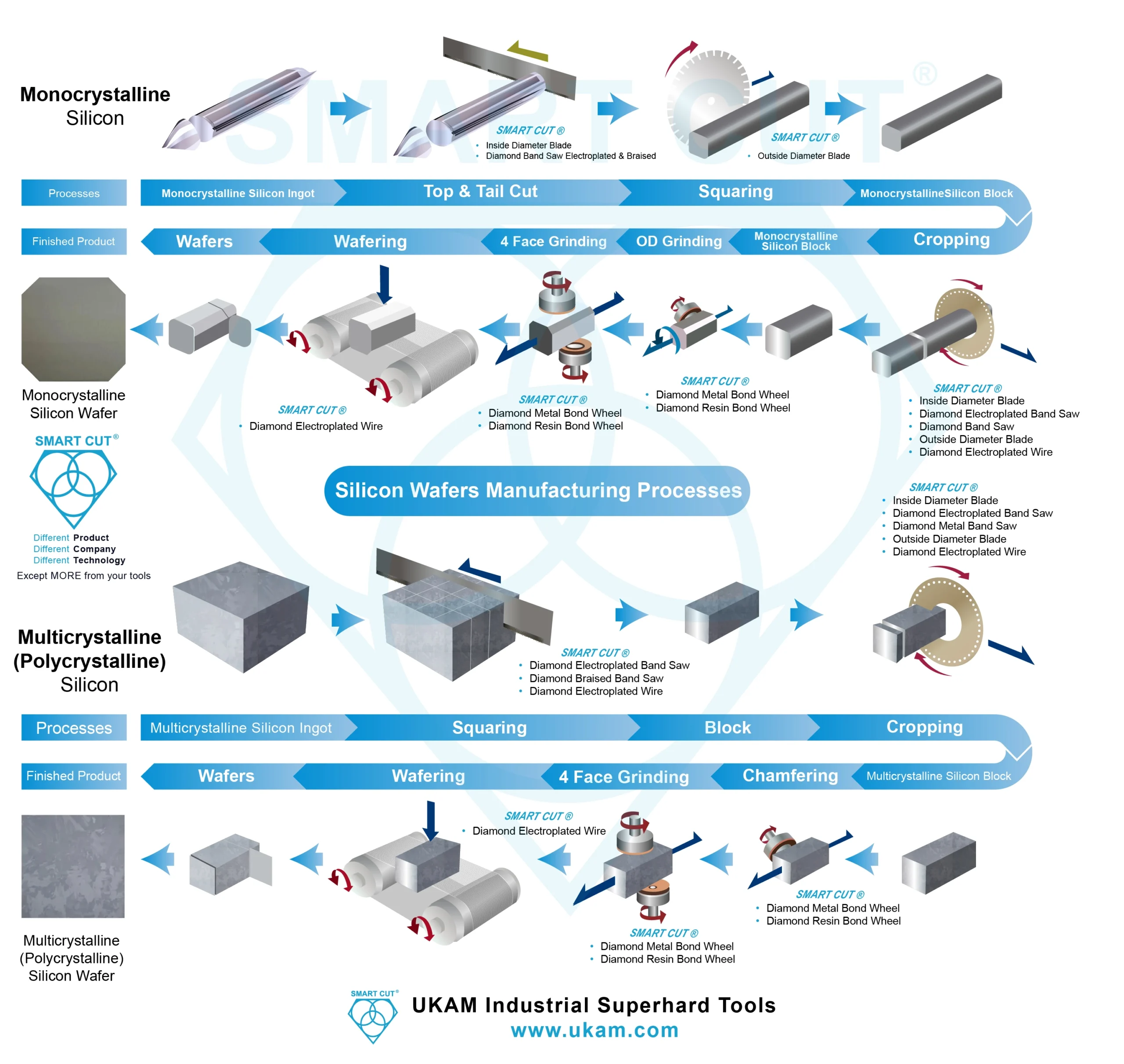

The Comprehensive Guide to the Processes of Silicon Wafers Production

Share this Article with Friend or Colleague

The production of silicon wafers, an essential component in semiconductor manufacturing, involves several intricate steps to ensure precision and quality. This article explores the detailed processes depicted in...

Diamond & CBN Wheels

02

Jun

CBN (Cubic Boron Nitride) Grinding Wheels – Everything you wanted to know

Share this Article with Friend or Colleague

Why Use Cubic Boron Nitride (CBN) Wheels?

Cubic boron nitride (CBN) grinding wheels are gaining recognition as superior tools for machining difficult metals. Initially used in toolrooms and cutter-grinding...

02

Jun

Diamond & CBN Wheel Troubleshooting Guide

Our illustrated troubleshooting guide was designed to help you optimize your grinding operations. It assists in diagnosing most possible issues that may arise when using diamond & CBN WHEELS. This guide highlights the signs to watch out for, their...

23

Dec

SMART CUT® Cut‑Off Wheels Designed for High‑Performance Cutting Applications

Abrasive cut‑off wheels are a necessary tool within industrial manufacturing and metal fabrication operations. Critical is the accuracy, performance, and safety in the workplace. Whether you need to cut iron, steel, or stainless steel rod or tubing,...

20

Feb

Diamond Backgrinding Wheels: An In-Depth Guide to Wafer Thinning and Precision Grinding

With the further shrinking of semiconductor devices and ramping up of performance, wafer processing has become increasingly stringent. Perhaps one of the most important steps, and yet often underemphasized, is backgrinding. Key to this is diamond backgrinding...

Diamond Core Bit Articles

02

Jun

Diamond Core Bit Ultimate Guide

Diamond Core Bits for Concrete & Construction are available in countless of specifications. Diamond core bits, known for their unmatched durability and cutting ability, are a necessity for professionals needing to drill through reinforced concrete,...

02

Jun

Concrete Drilling Metrics – Optimizing your Diamond Core Bit

Recommendations on speeds, feed rates and equipment to use to obtain best return on investment for using diamond core bits for drilling concrete and related materials

Share this Article with Friend or...

02

Jun

Optimal Drilling Performance – How to Properly Use Diamond Core Bits

To achieve the best drilling results, it's important to know the right techniques and tips for using diamond core bits. Whether you're experienced or new to construction and drilling, using these bits properly can make...

Metallography / Sample Preparation

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Selecting the correct diamond suspension, whether monocrystalline or polycrystalline, has a significant impact on the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can...

17

Jun

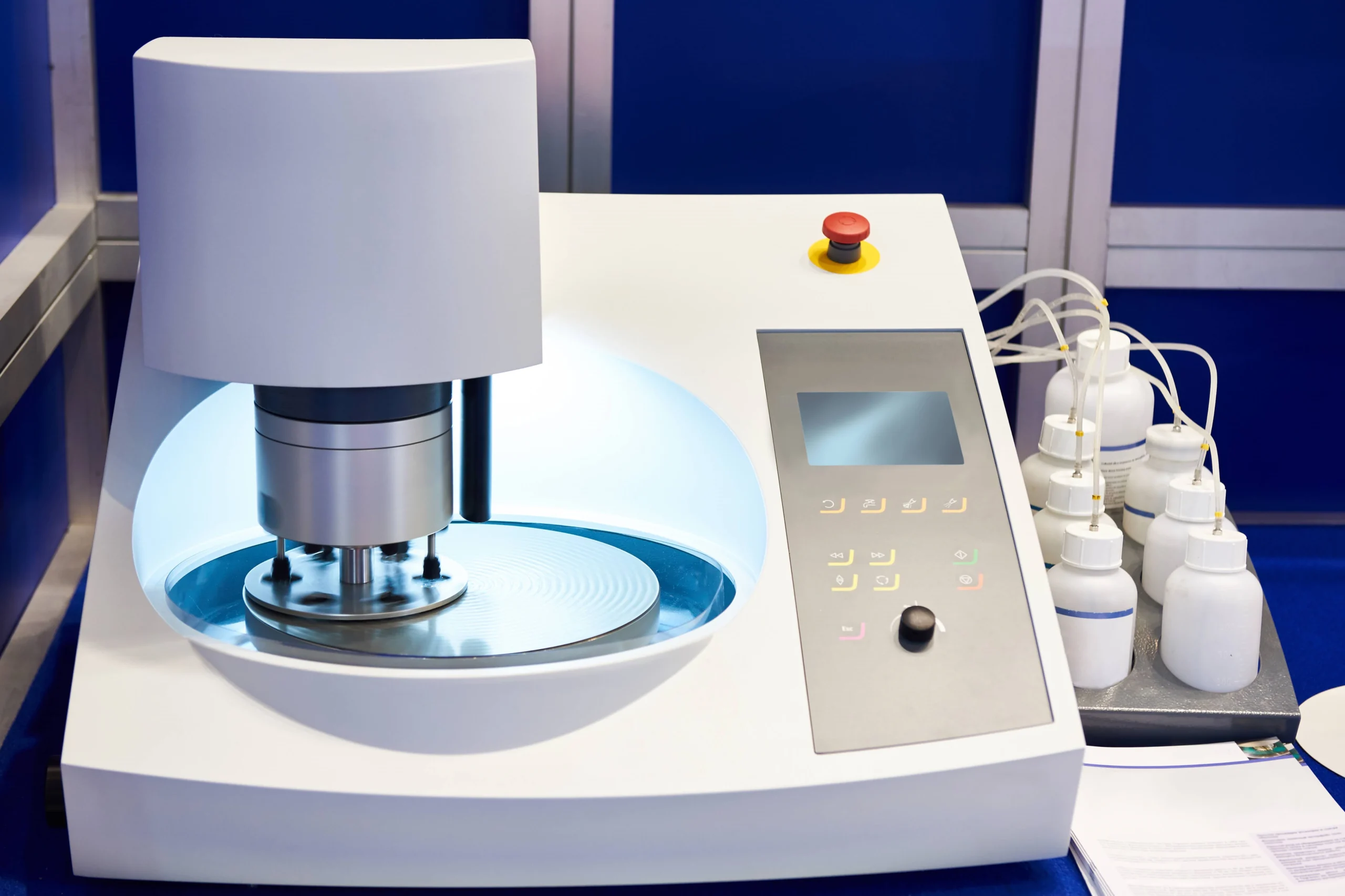

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...

29

Jan

Guide to Selecting the Right SMART CUT® Metallographic / Metallurgical Polishing Cloth & Pads for Your Application

Proper selection of SMART CUT® Metallographic / Metallurgical Polishing Cloths and Pads is important to achieving best results in metallography and sample preparation. These products are specially designed for precision, durability, and compatibility with various...

30

Jan

Select the Right Silicon Carbide Paper Discs for Metallography Sample Preparation

Selecting the right silicon carbide paper for metallographic sample preparation is important for achieving accurate and reliable results in material analysis. The grinding and polishing process plays a fundamental role in preparing specimens for microscopic...

30

Jan

Upgrading Metallography Grinding with Silicon Carbide Paper

This guide covers the best practices for using silicon carbide paper in metallography. It includes tips on proper grit progression, optimizing pressure and speed settings, preventing common issues, and extending the life of the abrasive....

19

Feb

Sample Preparation Consumables for Metallography: Selection, Function, and Best Practices

Careful sample preparation is the key to good metallographic analysis. Although equipment features and process conditions are significant factors, the impact of sample preparation consumables is equally crucial for surface quality, reproducibility, and trustworthiness in microstructural...

Diamond Blade Articles

02

Jun

How to Properly Use Precision Diamond & CBN Blades

The diamond blade itself is only a small factor in your cutting operation. Successful diamond sawing is both an art & science. Requiring proper use and understanding of the right: RPM's, Coolants, Equipment, Dressing Devices, Accessories...

02

Jun

Precision & Ultra Thin Diamond Blade Guide

Diamond and CBN blades are available in an extensive array of varieties, each differing in bond types, manufacturing methods, and design specifics. Ultra Thin & High Precision Diamond Blades are particularly versatile, applicable...

02

Jun

Troubleshooting Diamond Sawing Problems

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

05

Aug

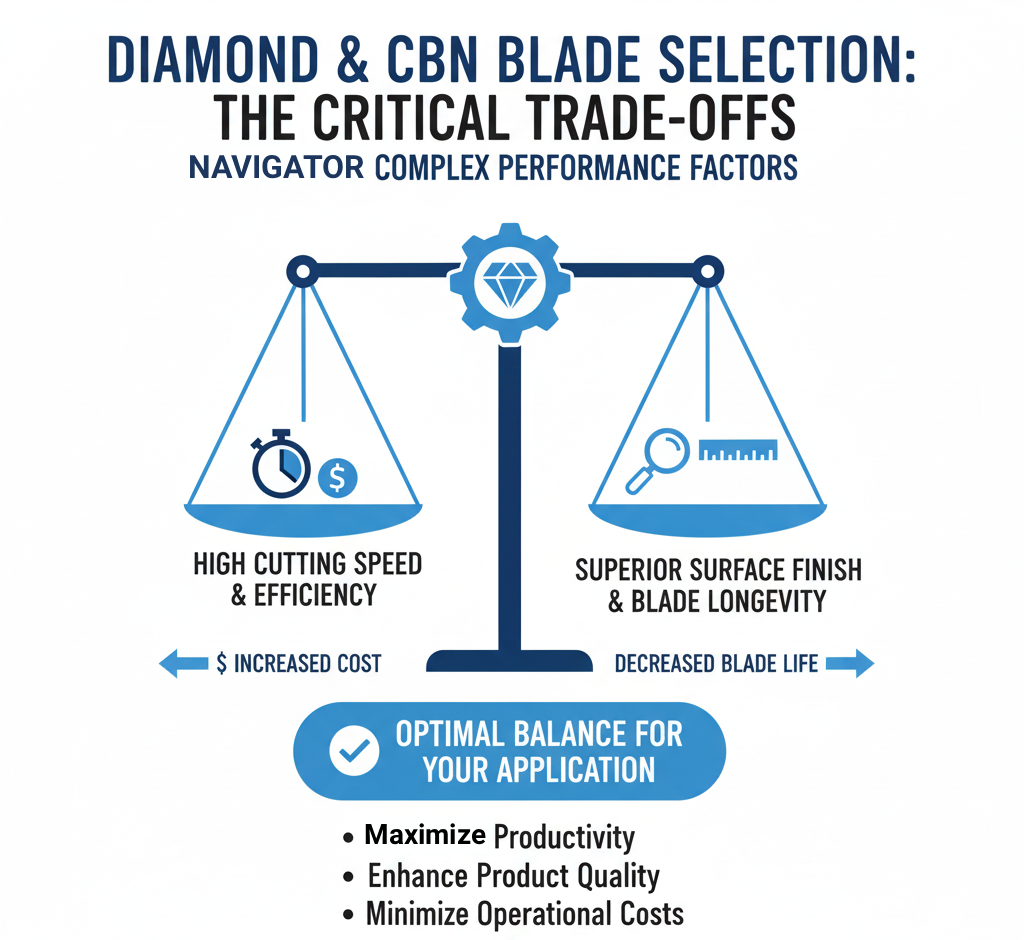

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

10

Oct

Everything You Wanted to Know About Cutting Glass with Diamond Blades

Cutting glass is a delicate process that requires the right set up, technique and process to avoid cracks, chips, or fractures. The inherent brittleness and hardness of glass make it challenging to work...

26

Dec

Select right Diamond Blade for your application

Selecting the right parameters for your Precision & Ultra Thin Diamond Blade can be a very time consuming, trial & error frustrating process. The guide below has been designed to help you better understand the most...

19

Jan

Diamond Blades for Glass: The Complete Guide to Cutting Glass Safely, Cleanly, and Precisely

Glass is one of the hardest materials to cut. It is a tough, brittle material that is extremely heat and vibration resistant. Kegs: Small cutting errors can result in chipping, cracking or catastrophic failure of the work piece....

Diamond Lapidary Blade Articles

08

Apr

Mastering the Art of Lapidary cutting

Mastering the Art of Lapidary, Gemstone, Cabochon, & Slab Cutting: A Comprehensive Guide to Slab and Trim Sawing Techniques

The process of transforming rough lapidary rocks & gemstones into beautiful, polished pieces is both an art...

10

Apr

What Makes a Great Diamond Lapidary Blade

Cutting is a foundational step in the lapidary process, and the choice of diamond Lapidary blade significantly influences subsequent stages. While the market offers a plethora of blades for lapidary work, their performance and quality...

10

Apr

Signs of a High Quality Diamond Lapidary Blade

Getting the best results when using lapidary blades is not only skill but also about using the right blade for the application. When we talk about a good blade for lapidary application, we are really...

12

Apr

How to Properly Use Diamond Lapidary Blades

Share this Article with Friend or Colleague

(Guide on getting the most from your blade)

Welcome to the User Guide on How to Properly Use Diamond Lapidary Blades. This guide is designed to provide detailed insights...

Diamond Hole Saws / Composites Articles

12

Sep

Drilling Composite Materials Using Diamond Drills & Hole Saws

Drilling composite materials presents a unique set of challenges due to their heterogeneous nature, which combines different materials with varying properties. To achieve precision and maintain the integrity of both the tool and the workpiece,...

12

Sep

Selecting Right Diamond Drills & Tools for Drilling Composites

Drilling composite materials, such as Carbon Fiber Reinforced Polymer (CFRP), Glass Fiber Reinforced Polymer (GFRP), Kevlar, and hybrid laminates, presents unique challenges due to their abrasive nature, heterogeneous structure, and susceptibility to issues like delamination,...

Dicing Blade Articles

01

Jun

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Share this Article with Friend or Colleague

Dicing QFN packages presents several challenges due to the composition of materials and the precision required for clean, defect-free cuts. These challenges arise from the multi-layered structure of...

01

Jun

Select right Diamond Dicing Blade for your application

Selecting the right dicing blade for your application requires careful consideration of several key variables that influence both performance and cost. The type of material being cut, the depth of the required cuts, the level...

02

Jun

Dicing Blade Operations Recommendations

Share this Article with Friend or Colleague

Selecting the right dicing blade parameters often involves a trial and error process, many aspects of which can be mitigated through experience and a deep understanding of how to...

02

Jun

Optimizing your Diamond Dicing Performance

Share this Article with Friend or Colleague

The performance of diamond dicing blades is influenced by a wide range of interdependent variables, and understanding these factors is essential for selecting the correct blade specifications and...

02

Jun

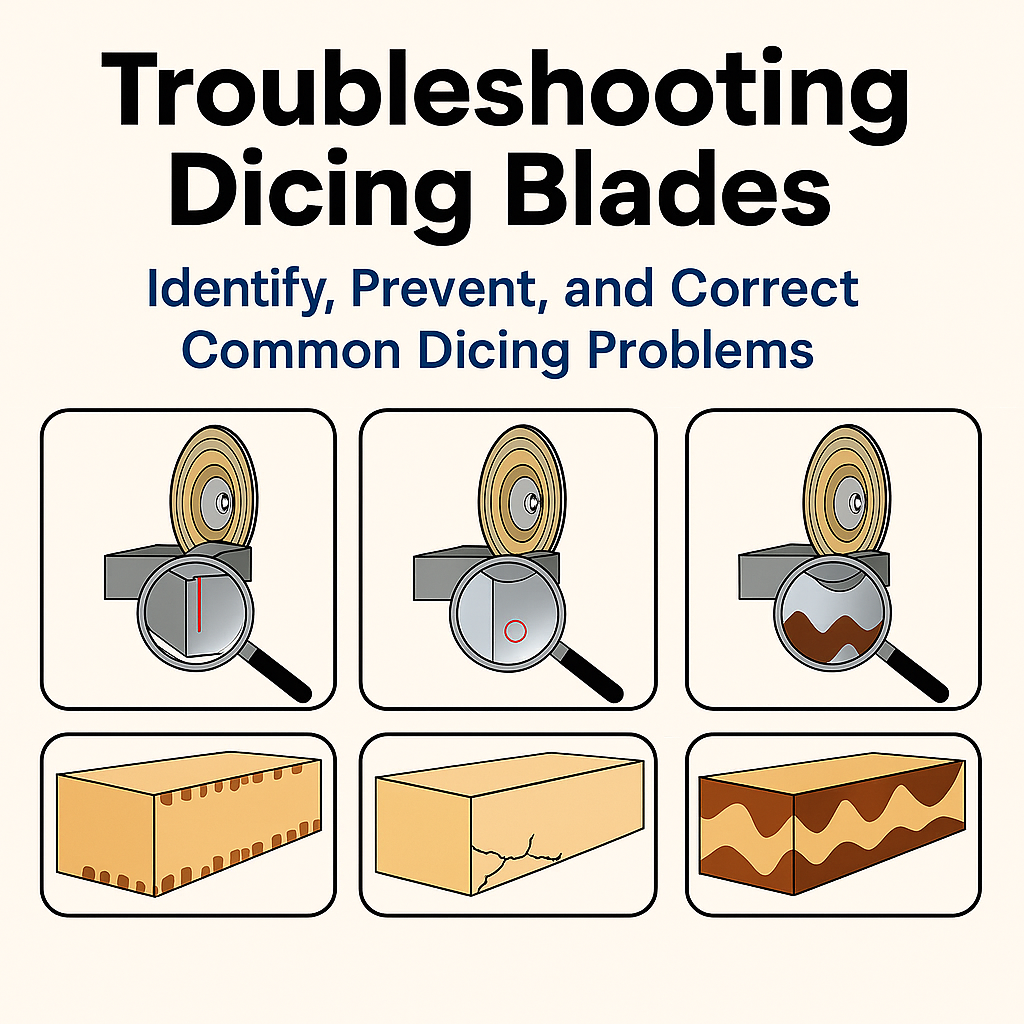

Trouble Shooting Dicing Problems

Guide on most common dicing problems and how to resolve them

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP YOU

CONTACT US

HAVING ISSUES WITH

YOUR...

02

Jun

Application Recommendations

This article provides important guidelines for optimizing the dicing process in semiconductor packaging, focusing on package singulation for various technologies such as BGA, QFN, LED, CMOS, and wafer substrates. It covers key variables such as...

02

Jun

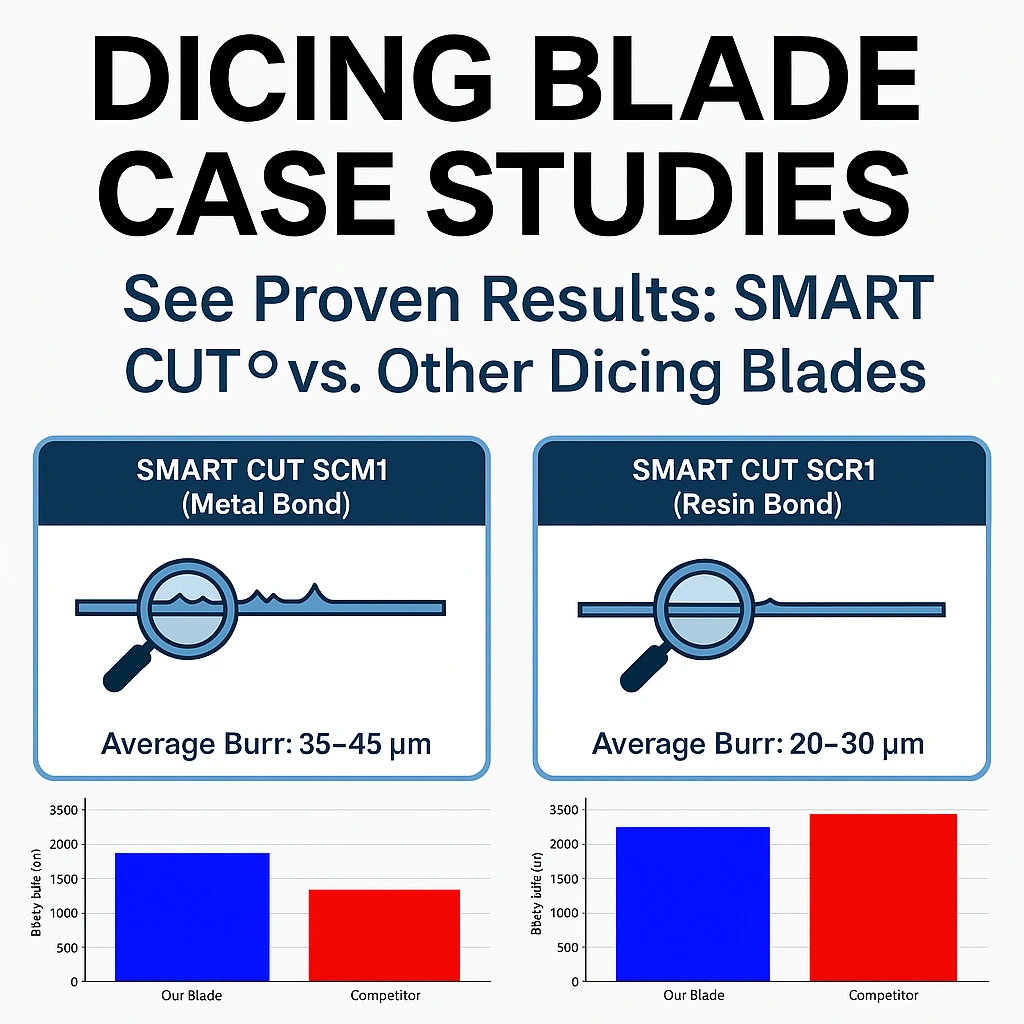

Dicing Blade Case Studies

Selecting the right dicing blade is important to achieving high yields, superior edge quality, and consistent reliability in microelectronics and optics manufacturing. Across industries such as semiconductors, electronics packaging, photonics, and precision optics, even small...

27

Aug

Selecting the Right Wafer Dicing Saw Practical Guide

Selecting the proper wafer dicing saw is a important decision for manufacturers, researchers, and engineers working with large variety of materials. Whether processing silicon wafers in microelectronics, ceramics in materials science, or glass substrates in...

17

Sep

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

Many companies still judge diamond dicing blades by purchase price alone. At first, the cheapest blade may appear to be the best choice. However, price does not equal cost. The real economics of diamond dicing...

18

Sep

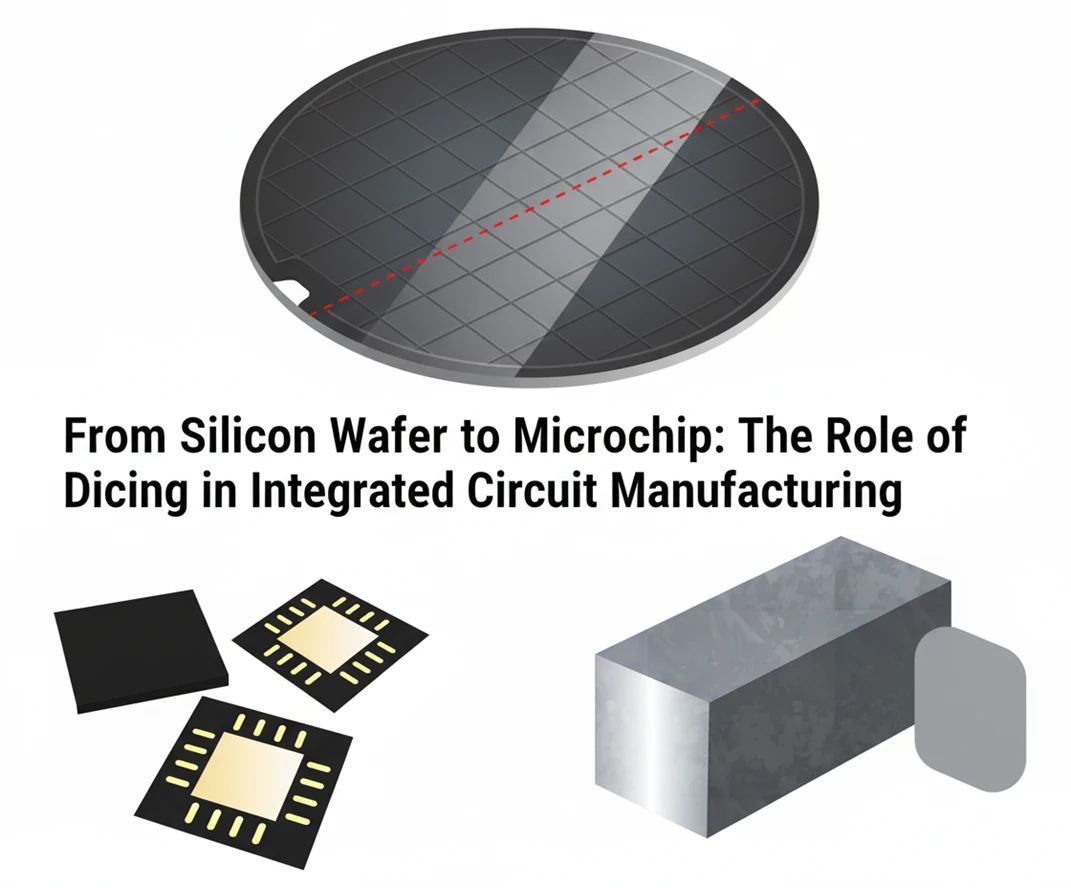

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

The making of the integrated circuit is a long and complex process that involves many critical steps. In most cases, the wafer travels to multiple facilities before it is completed and turned into the final...

19

Sep

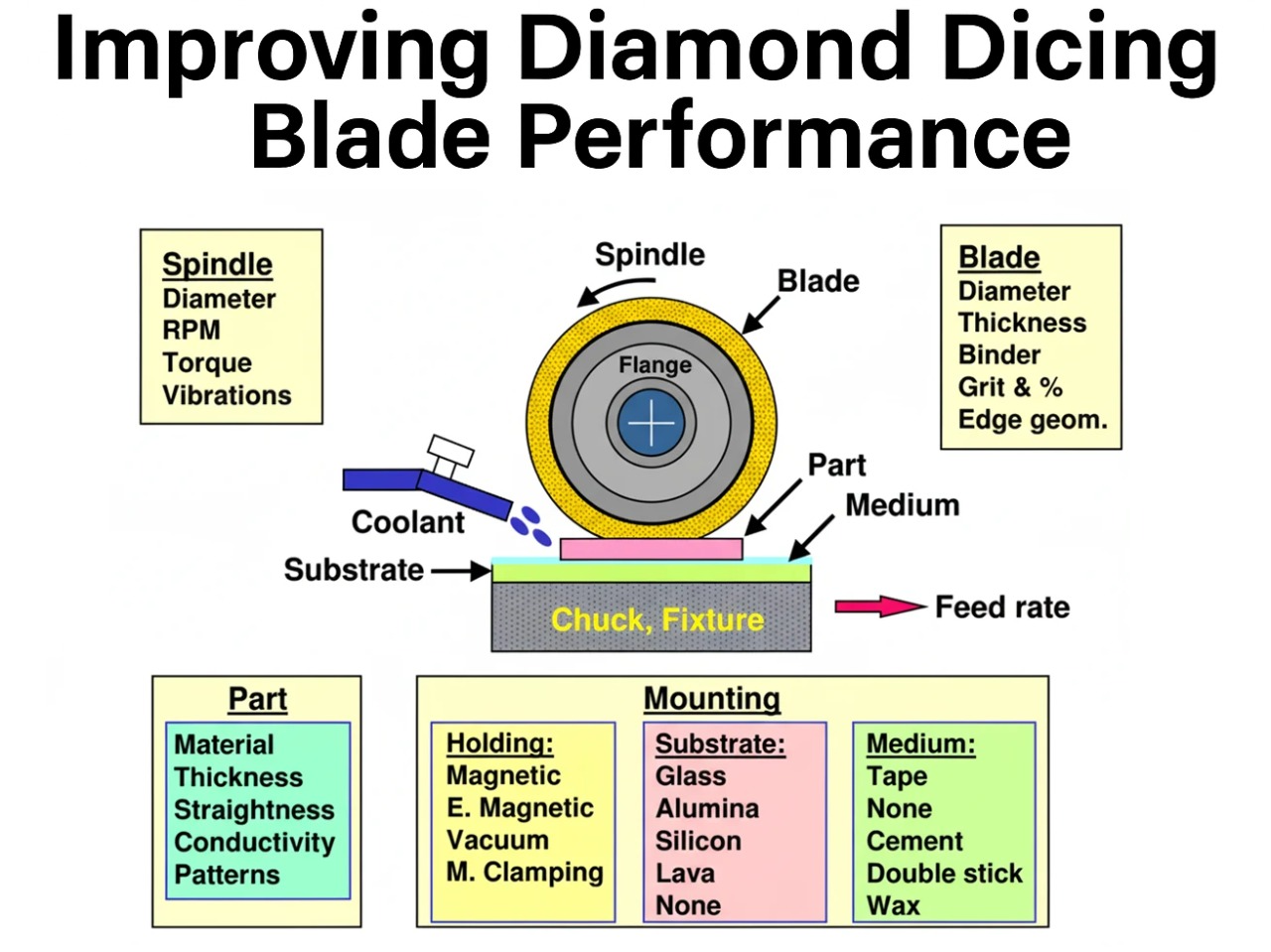

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

Diamond dicing is one of the most important step in semiconductor & microelectronics manufacturing package. Although the process itself does not add direct value to the finished device, it has a decisive impact on yield,...

26

Nov

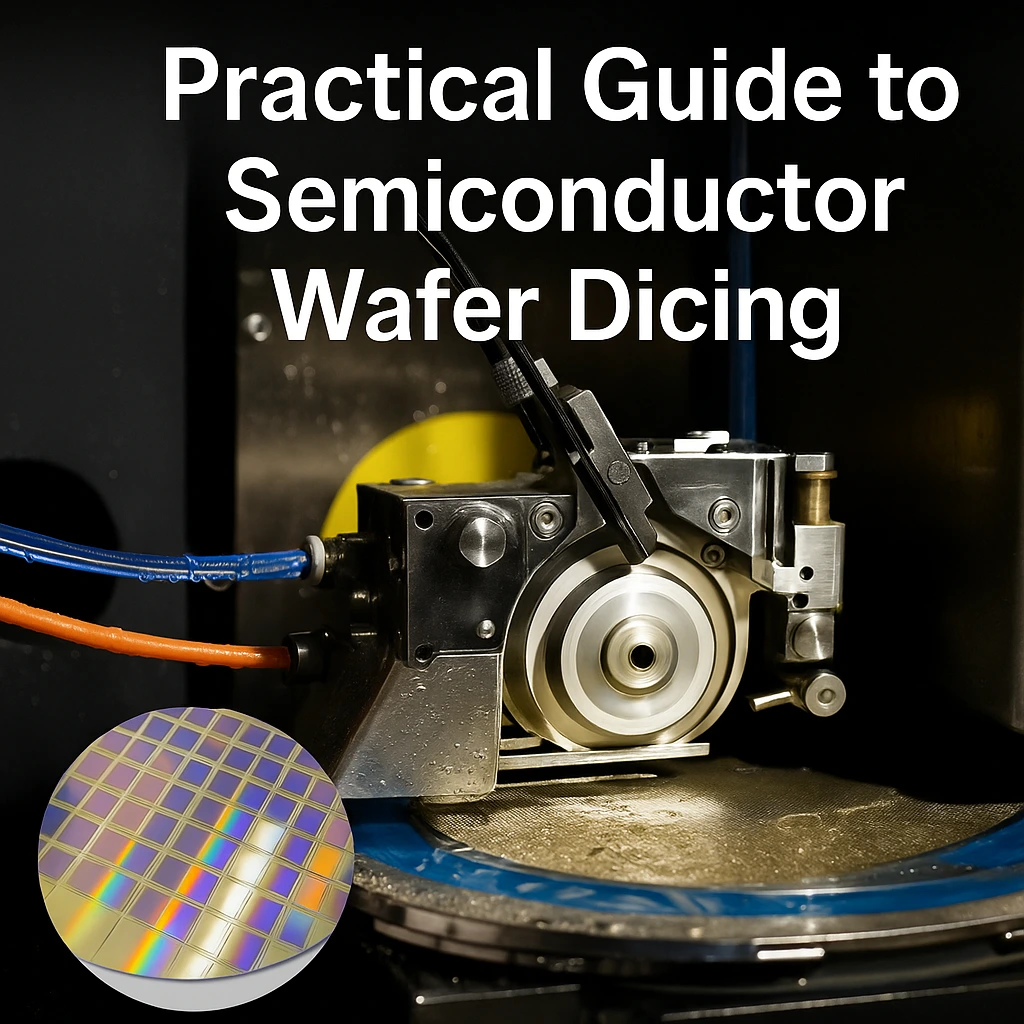

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

Semiconductor wafers are the foundation of nearly all modern electronics, from integrated circuits and photonic devices to advanced power components. As device geometries shrink and packaging density increases, the requirements placed on wafer dicing processes...

Diamond Drill Articles

02

Jun

Select Right Diamond Drill for your Application

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will...

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind...

02

Jun

Diamond Tools Guide – Selecting Right Drills & Tools for your application

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms,...

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency....

02

Jun

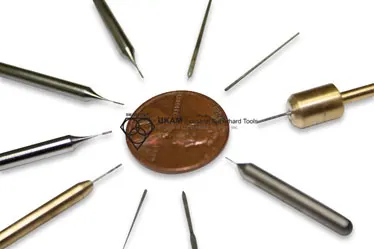

Micro Drilling Guide

Share this Article with Friend or Colleague

In order for you to get the most out of your diamond micro drill or carbide / high speed steel micro drill, we strongly urge you to read...

02

Jun

Selecting Right Drilling Equipment for your Application. What you features & functionality you should look for?

Share this Article with Friend or Colleague

There are hundreds or even thousands of different drilling equipment options. Selecting the right equipment for a specific application involves carefully considering several variables and attributes of the...

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

https://ukam.com/wp-content/uploads/2024/07/diamond-drill-troublehsooting-guide.mp4

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide...

09

Sep

Understanding & Calculating Return on Investment for Diamond Core Drills & Other Tools

The term "ROI" (Return On Investment) is widely used across industries, often interpreted differently depending on the context. However, few truly understand what ROI represents and its specific implications, particularly in the context of diamond...

09

Sep

Understanding Tradeoffs – Searching for Perfect Diamond Drill & Tool

Choosing the right diamond drill or tool can significantly impact efficiency, cost, and quality. However, this is not a simple and clear-cut process. Selecting the optimal drill or tool involves navigating a complex landscape of...

19

Sep

Why Use Diamond Drills?

Diamond, known as the hardest material on Earth, enables diamond drills and tools to grind away material at a micro (nano) scale. This extreme hardness allows diamond tools to effectively work on materials with a...

20

Sep

Diamond Drill Terminology Guide – Key Terms Explained for Precision Drilling

How to fine tune each of these variables to improve and optimize your drilling operation in the success of your diamond drilling operation

Share this Article with Friend or Colleague

DIAMOND DRILL...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools facilitate detailed tasks such as engraving and finishing, offering precise control and enabling you to work...

Diamond & CBN Wafering Blade Articles

02

Jun

Selecting Right Wafering Blade for your application

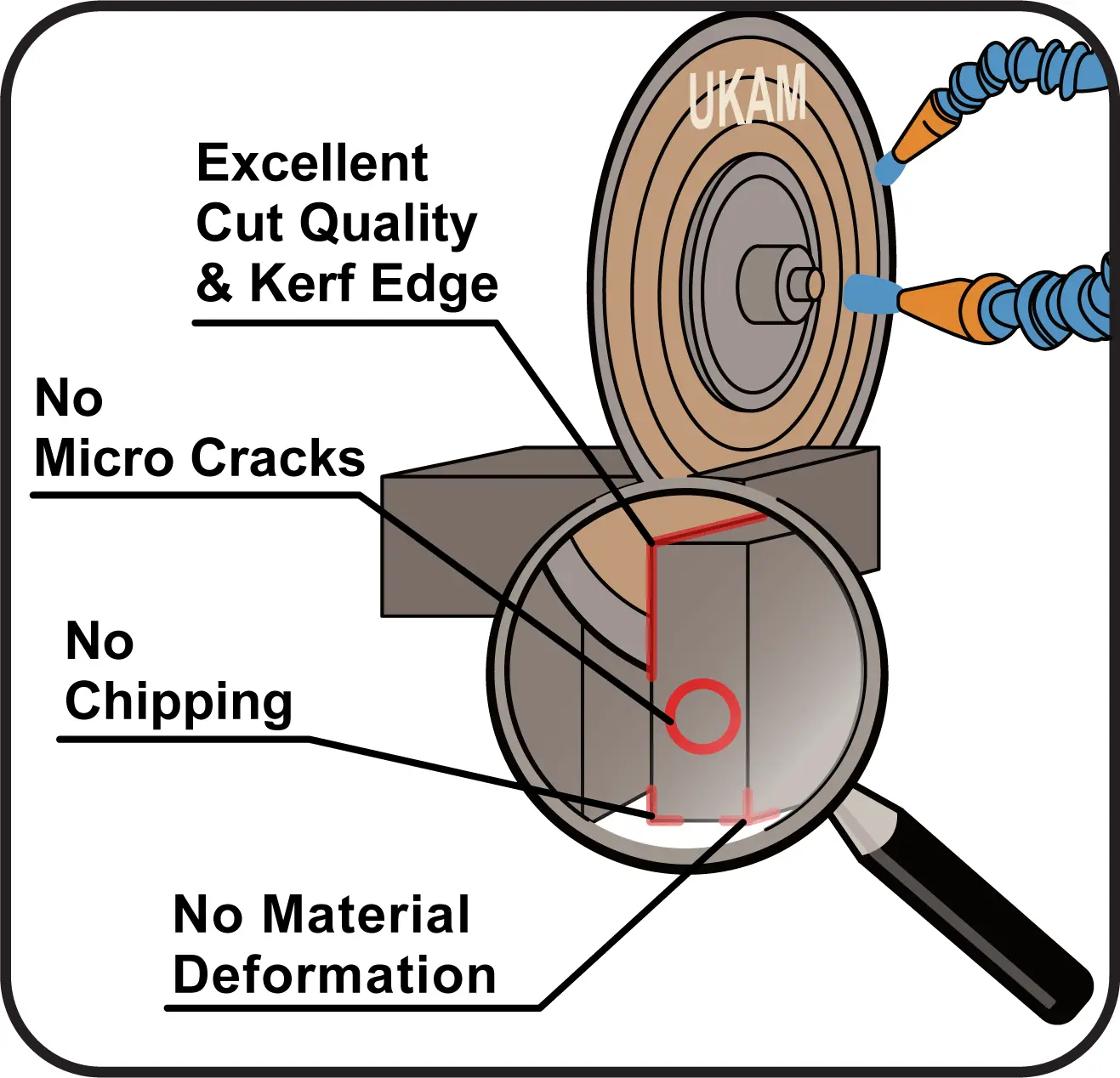

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Diamond & CBN Wafering Blade Case Studies

This study evaluates the cutting performance of SMART CUT® Diamond & CBN Wafering Blades compared to Conventional Wafering Blades under identical test conditions. The objective was to measure differences...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Let us Help you Improve & Optimize your Diamond Machining Operation to Ultimate Level of Efficency

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your slicing, dicing, and drilling operation to ultimate efficiency.

- Eliminate / Minimize Chipping

- Improve Surface Finish Quality

- Increase Tool Life

- Increase Process Consistency

- Preserve True Material Microstructure

- Reduce & Eliminate Material Deformation

- Improve Productivity Reduce Cost