-

0 items in quote

No products in the Quote Basket.

Solutions for Industry

UKAM Industires Superhard Tools

Diamond & CBN Tools, Consumables, & Equipment for INDUSTRY

We manufacture large variety of diamond & cbn tools, consumables & equipment for Industry Let us help you improve & optimize your diamond & cbn machining operationg to ultimate level of efficiency Consumables & Equipment at Affordable Price.

Our products Trusted by Customers from dozens of manufacturing fields ranging from Aerospace & Automotive to Mining, Semiconductor Microelectronics & Defense and many other fields. We are happy to work with companies of all sizes from Fortune 500 to startups. We support scientists and engineers around the world with high quality tools, consumables and equipment at an affordable price.

Why Choose Us?

Optimize Your Application To Ultimate Level Of Efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Industries Used In:

- Advanced Ceramics

- Automotive

- Ceramics/Porcelain

- Disc Drive

- Dental

- Engineering

- Electronics

- Glass

- Jewelry

- Medical Devices

- Metal

- Nano Technology

- Optics

- Photonics

- Photovaltaic

- Semiconductor

- Surface Preparation

- Tool & Die

Diamond & CBN Tool Bond Types

- Resin Bond

- Electroplated

- Braised Bond

- Hybrid Bond

- Vitrified Bond

- Sintered (metal bonded)

Other Types of Diamond Tools & Technologies

- Diamond Dressers

- Diamond Rotary Dressers

- SMART CUT technology

- PCD (polycrystalline diamond) Tools

- CVD (Chemical Vapor Deposition) Diamond Tools

Consumables, Equipment, & Accessories:

- Accessories

- Precision Abrasives

- Diamond Consumables

- Equipment for Cutting & Grinding/Polishing

- Abrasive Cut Off Blades for laboratory/abrasive cut off machines

Technology

SMART CUT® Technology

First company to develop SMART CUT® technology. ADVANCED Technology that redefines the standard in cutting and drilling. Diamonds are oriented inside matrix so that every diamond is better able to participate in cutting, drilling, or diamond machining action. Every diamonds works in the right place and at the right time, where you need it most Find out more

Application of SMART CUT® technology

Slicing, Dicing, Wafering, Cut-off, Singulation, Grooving, Slotting, Cross Sectioning, Gang Sawing, Slabbing, Rough Cutting, Drilling, Milling, Carving, grinding, polishing, chamfering, and many others

Electroplated

Diamond & CBN Tools

Electroplated Diamond Products from 0.5 microns to 20 grit (diamond mesh size) in Synthetic, Natural Diamond or CBN (cubic boron nitride). Electroplated DiamondProducts Manufactured by UKAM Industrial are Multi Layered. They have 3 layers of diamonds, not just 1 layer

of diamonds like conventional electroplated diamond tools. This provides longer drilling life, faster and freer machining action, & more consistent performance.

Application of Electroplated Diamond & CBN Tools

Electroplated Diamond Tools are used for cutting, slicing, dicing, drilling, milling, slotting, grinding and polishing of large range of materials. These Tools are used in semiconductor industry, composites, stone, glass, optics, plastics, & many others Sintered (Metal Bond) Diamond & CBN Tools Hybrid Bond™ Diamond & CBN Tools

Technology

Sintered (Metal Bond) Diamond & CBN

Sintered (metal bonded) diamond tools for a large variety of applications, materials, and industries. Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance Find out more

Application of Sintered (Metal Bond) Tools

Sintered (Metal bond) is the strongest of all the bond families. Offering the longest life, greatest variety of specifications and fields of use available. While its not the optimum solution for all applications, Its one of the most widely used bond across most industries today. All types and forms of diamond tools are available with this bond matrix. Such as diamond wheels used for grinding, diamond cut off wheels use for cutting, slotting, grooving, diamond core drills and bits used for drilling, reaming and milling. Diamond router bits, carving points and form tools used for shaping and forming. recommended for machining hard materials from 45 to 75 on Rockwell Scale

Diamond & CBN Tools

Hybrid Bond™

Between METAL BOND and RESIN BOND. Resin bond process with added nano fillers to increase bond hardness. Hybrid bond offers advantages of cutting speed and fine finish that you have come to expect in a resin bond, along with long life, consistency, aggressiveness, durability, and excellent performance typically available in sintered (metal bond)

Application of Hybrid Bond™ Tools

very hard and dense materials, tungsten carbide, metals, optical glass. Slicing, Dicing, & Grinding

Diamond & CBN Tools

Braised Bond

Brazed Bond Diamond Tools are produced inside vacuum oven at a high temperature, single layer of diamond crystal bonded to steel body with very high diamond exposure. Not only does it promote high diamond exposure, but it also eliminates the loss of diamond particles through pull-out. The diamond section will not strip or peel from the steel body.

Application of Brazed Bond (Metal Bond) Tools

Brazed Bond Diamond & CBN Tools are perfect for machining tough-to-cut materials where fast stock removal and deep cuts are required. Including applications such as: non-metallic materials such as graphite epoxy, FRP, graphite, fiberglass, friction material, honeycomb other composites, metals, marble & other soft materials.

Diamond & CBN Tools

Resin Bond

Organic bond matrix that is formed by high pressure and high temperature. Based on phenolic or polyimide resins mixed with fillers or abrasive grains. Recommended for applications where cut quality and surface finish is very important. Compared to their sintered (metal bond) counterparts. Used on wide range of applications due to their fast and cool cutting characteristics

Application of Resin Bond Tools

Recommended cutting, grinding and polishing hard, brittle or delicate materials including ceramics, glass tubing, optical glass, carbides, composites, silicon, magnetic materials, thermal spray alloys and exotic metals where low heat generation or improved surface finish is desired. Must be used at higher speeds. CBN, Resin bond Tools are recommended for cutting and grinding hard steels above Rc 60 at high speeds.

Diamond & CBN Tools

Vitrified Bond

Fired Ceramic Bond matrix, which is very brittle and porous. Also known as ceramic bond. Based on fusible glasses combined with fillers and abrasive grains. Offers durability of sintered (metal bond), along with free cutting action of resin bond. Vitrified bond has higher bonding strength then resin bond. Vitrified bond diamond tools are free cutting, produce good surface roughness, have good wear resistance and retain straightness and form very well.

Application of Vitrified Bond Tools

Automotive parts grinding, Paper Manufacturing Industry, Bearing Industry, Aerospace industry, Turbine Industry, Grinding of PCD and PCBN, Profile grinding of TC threading plates, OD grinding of Printing Rolls, Shafts and Rods, Flat grinding of Ceramic components, Flat, OD and ID grinding operations of various parts, Grinding of Camshafts and Crankshafts, Finishing of turbine parts.

PCD & PCBN

PCD & PCBN (polycrystalline diamond & CBN) Tools

PCD (polycrystalline diamond) is composed of diamond particles that are sintered with a metallic binder at extreme temperatures and pressures, creating the hardest and one of the most abrasion resistant materials used in cutting tools. These inserts are braised on to cutting tools and are used in machining applications in many applications where you find carbide tooling that includes sawing, routing, drilling and profiling to maximize tool life and reduce production cost.

Application of PCD Tools

PCD tools are used for processing aluminum and aluminum, aluminum alloys, copper, copper alloy, babbitt metal, wood, wood based fiber materials, aluminum oxide, reinforced floor boards, wear resistant plastic, Bakelite, graphite, stone materials, tungsten carbide, hard cartons. Epoxy resins, Fiberglass composites, Carbon-phenolic, Hard rubber, Plastics, Ceramics (unfired), Graphite

PCBN cutting tools are used for hardened steel, tool steel, mold steel, bearing steel, chilled cast iron, high chromium cast iron, nickel based high temperature alloy, gray cast iron, zinc alloys, sintered tungsten carbide & many other nonferrous materials that are difficult to machine.

Dressers

Diamond Dressers

Diamond dressing tools are made with natural diamond stones set in steel shanks of various shapes for straight or form dressing. For truing and dressing of conventional abrasive grinding wheels. Single point, multi point, chisel shape, straight, angle, and radius configurations.

Application of Diamond Dressers

Diamond dressers are used for truing and dressing conventional abrasive and super abrasive (diamond/cbn) wheels. Truing is to restore the wheels profile and dressing is opening the abrasive layers remove stock or closing to finish the face of the wheel.

Diamond

Diamond Rotary Dressers/Dressing Rollers

Diamond rollers are used to form grinding wheels for many different kinds of mass production. Shorter dressing time and long tool life leads to high productivity and consistent process conditions. Many kinds of conventional grinding wheels, and in special cases super-hard grinding wheels, can be dressed with this dressing method. Dressing rollers can be classified under Diamond profile dressing rollers and Diamond form dressing rollers. Diamond profile dressing rollers are used to share grinding wheels in shortest amount of time. Profile form dressing rollers are used to from simple and high complex profile contours.

Application of Diamond Rotary Dressers

Diamond rotary dressers are used for manufacture of components for automotive, aerospace, power generation, machine tool and precision engineering industries. Threads, Turbine Blades, Bearing Jornals, Bearings Races, Engine Valves, Fuel Injector Components, Shearing Blades, Gears, Engine Components, Transmission Components.

Diamond Tools

CVD (Chemical Vapor Deposition)

CVD diamond coating takes place in a vacuum chamber using a hot-filament, chemical vapor deposition (CVD) process. Carbon gases are introduced into the vacuum chamber where high temperatures cause carbon atoms to re-bond into a 100% pure crystalline diamond structure. The crystalline diamond slowly grows on the surface of cutting tools (usually made from carbide) forming a continuous coating of up to 20 microns in thickness. Standard carbide tooling with this type of coating depending on application will last 10 to 50 times longer.

Diamond dressing tools are made with natural diamond stones set in steel shanks of various shapes for straight or form dressing. For truing and dressing of conventional abrasive grinding wheels. Single point, multi point, chisel shape, straight, angle, and radius configurations.

Application of CVD Dressers

Used on softer and gummy materials where usually tungsten carbide tooling is used by wears out or has to be reshaped quickly. Applications such as machining graphite, hard carbon, green ceramic, carbon fiber, reinforced polymers, fiberglass, plastics, wood laminates, non ferrous metals.

for Industry, R & D

Precision Abrasives

Abrasive Cut Off Wheels, Abrasive Discs, Abrasive Rolls/Strips, Abrasive Belts, Silicon Carbide (SIC), Zirconia Alumina (ZA), Aluminum Oxide (ALOX), Grinding Wheels - (Aluminum Oxide and Silicon Carbide), Lapping Films (Plain Backed & PSA Backed, Felt Polishing Pads.

Application of Precision Abrasives

We provide large variety of precision graded abrasives for large variety of applications. Including optics, semiconductor, advanced ceramics, photovoltaic, sample preparation, materials research, and glass industries. Applications include cutting, grinding, and polishing.

Diamond

Consumables

- Diamond Suspensions - Polycrystalline, Monocrystalline, & Natural

- Diamond paste - Polycrystalline, Monocrystalline, & Natural

- Diamond micro powder - Polycrystalline, Monocrystalline, & Natural

- Diamond Spray - Polycrystalline, Monocrystalline, & Natural

Application of Diamond Consumables

Used for polishing and lapping fine ceramics, integrated chips, micro electronic packages, magnetic heads, quartz, cemented carbide, optical lenses, copper, ultra hard & brittle materials and many other materials.

Tools

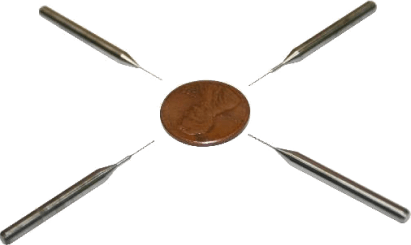

Ultra Thin, High Precision & Micro Carbide Tools

- Ultra Thin & High Precision Carbide Blades for Slicing, Dicing, Slotting, & Grooving - available as thin as .004" and diameters from 50mm to 500mm

- Micro Carbide Drills & Tooling - available from small as 20 microns

- Specialized Coatings such as Diamond Like Carbon are available to extend the life of these tools

Application of Ultra Thin, High Precision, & Micro Carbide Tools

Used for large variety of softer and gummy materials where diamond is not usually used such as: graphite, copper alloys, CFRP, Plastic, Thermoset Plastic, High Density Plastic, Nickel/Cobalt, Titanium Alloy, steel, magnetic tape, metal foils, P.E.T., polyester, sheet rubber, fine gauge steel, film, abrasive, paper products, green ceramics, PC Board substrates, fiberglass, laminates, MLP/QFN

Equipment for Industry and Research & Development

for Industry and Research & Development

Precision Cutting Machines

Complete range of diamond saws, equipment and accessories for cutting (sawing) advanced materials. Such as: ceramics, glass, plastics, quartz, metals, and graphite. From high capacity cutting of very large work pieces to precision cutting of even the most delicate samples. Our diamond saws are widely used in Research and Development, Quality Control, Failure Analysis, as well as Industry.

Application of Precision Cut Machines

Diamond Sectioning Saws, Slicing Saws, Dicing Saws, Rough Cutting Saws, Slab Saws, Band Saws, Gang Saws, and other sawing equipment. In additional to their industrial and R & D application, our saws have been successfully used in fields such as: geology, archeology, paleontology, criminology, forensics, biology, pathology, histology, anatomy, and dentistry.

for Industry and R & D

Grinding/Polishing Equipment

6" to 24" (150mm to 609mm) diamond grinding, polishing, & lapping machines for Industry and R & D. Designed coarse & fine grinding and polishing of Advanced, Ultra Hard & Brittle Materials, Optical Materials, Composites. High hardness materials including

Application of Cutting & Grinding/Polishing Equipment

Metals, ceramics, refractories, cement, and petrographic thin sections. As well as full range of optical materials, such as: Bk7, Fused Silica, Zeroder, Quartz, Soda Lime Glass, Yag, Sapphire, and Many Other Materials.

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Share this Article...

02

Jun

Why use diamond

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...