How to Improve & Optimize Your Diamond Sawing Operation

-

Posted by

Alexander Schneider

Alexander Schneider

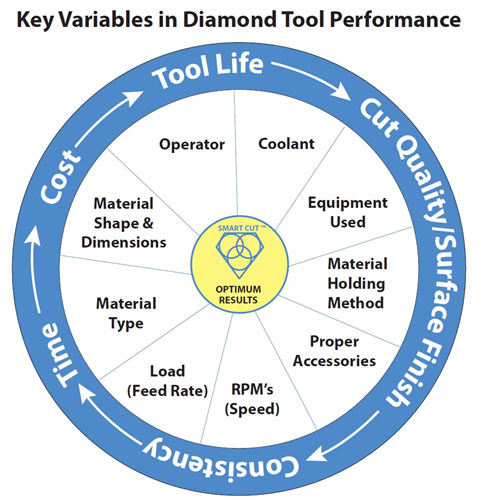

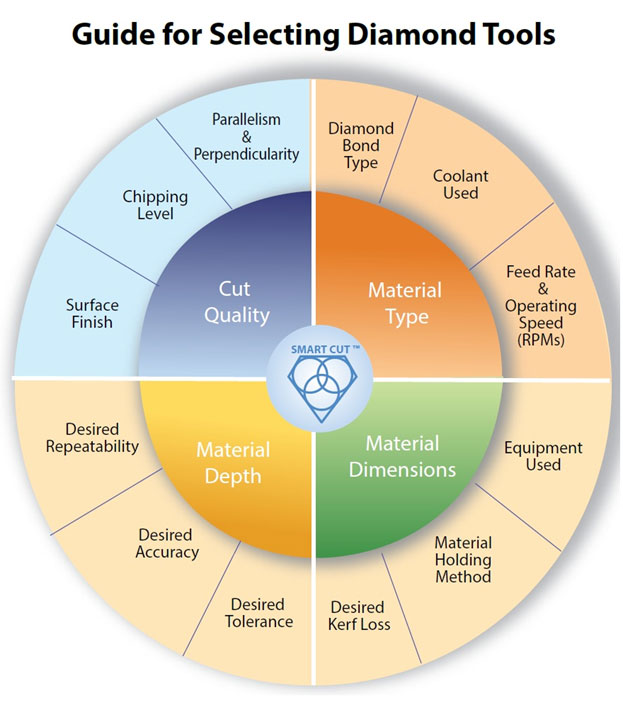

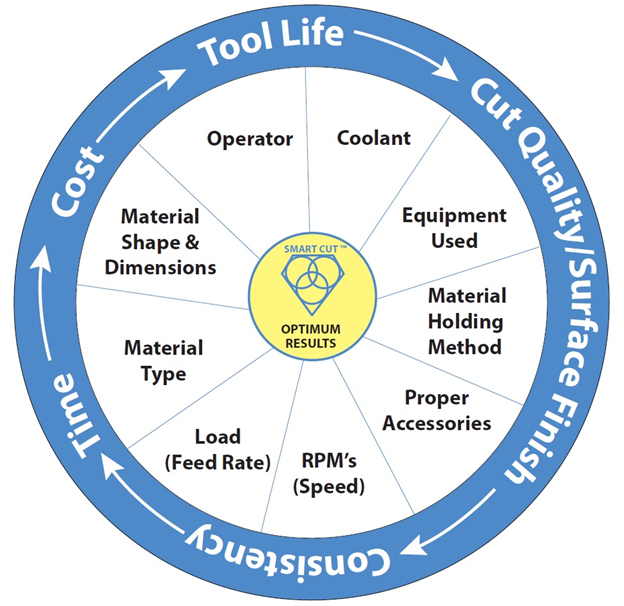

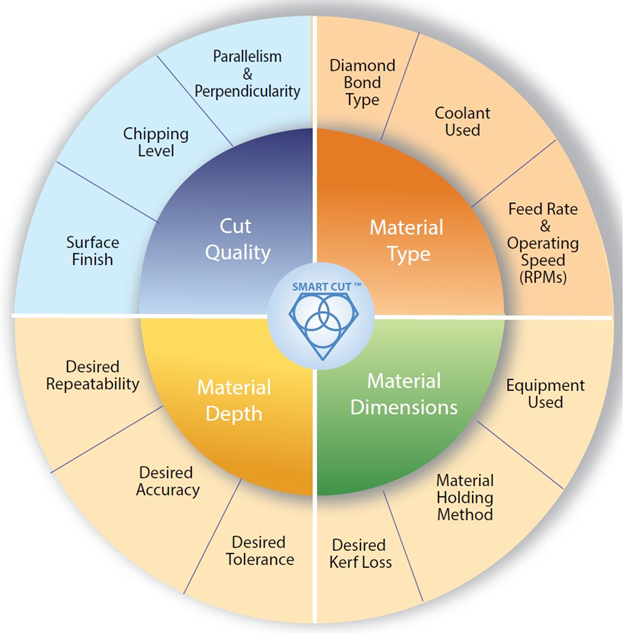

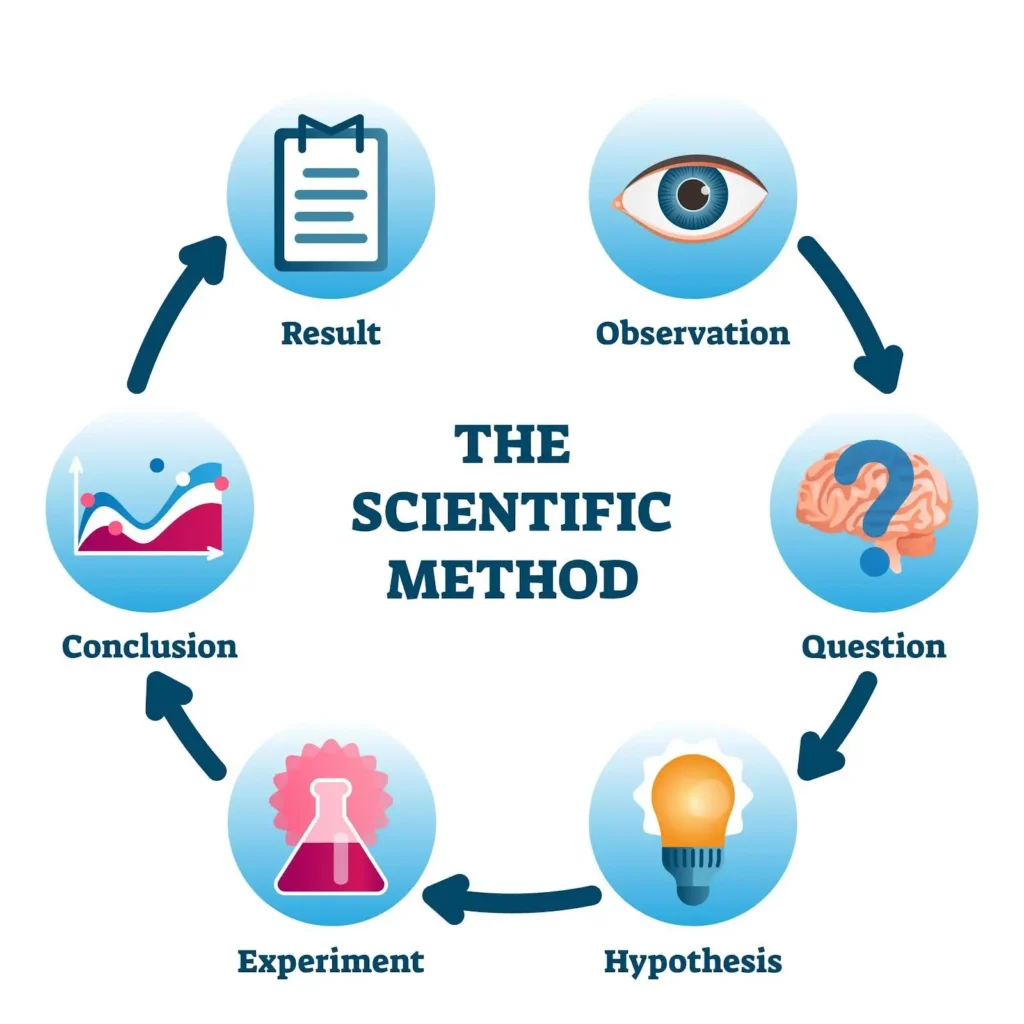

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations to achieve the highest level of efficiency. The objective of this article is to demonstrate that each variable in the diamond sawing process is just one component of a larger system. Altering one component or variable alone cannot create efficiency; it is only when all components of the system work together that the desired results can be achieved.

Similar to a mathematical equation, one incorrectly selected variable or component can negatively impact all other properly selected variables, rendering the entire diamond sawing system inefficient. Many end users approach their diamond sawing applications uninformed or misled, leading to errors during the setup phase and the skipping of critical steps. When problems arise, most rush to treat the symptoms rather than addressing the root cause. This frustration often leads them to incorrectly attribute their issues to the diamond cutting blade being used.

For example, what some customers consider a serious problem may be resolved by something as simple as adjusting the pressure or direction of the coolant flow. Solutions can also be as straightforward as changing the mounting method, RPMs, or educating the customer on the need to dress the blade. Selecting the right combination of variables for a specific material or application is both an art and a science, often taking years to master.

Share this Article with Friend or Colleague

Errors are made in the set up phase and critical steps are skipped. When problems do surface, most rush to treat a symptom rather than the cause. Frustration leads them attribute their problems to diamond cutting blade being used. What some customers refer to as serious problem for example, may be resolved by something as simple as changing pressure or direction of coolant flow. The solution can be as easy as changing mounting method, RPM’s, or educating customer about need to dress blade. Selecting the right combination of these variables for a specific material / application is both an art and science that often takes years to master. Information presented in this article is not based on R & D, but primarily on many years of process optimization experience.

DIAMOND BLADE SELECTION – (Selecting the Right Diamond Blade for your Application)

Each diamond blade application exhibits similar characteristics, whether its in specification or performance. Below is a list of the most important characteristics/parameters obtained from years of experience.

BASIC APPLICATION PARAMETERS

Diamond Blade Properties

1. Diamonds

-

Grit Size

Grit Size

-

Origin

Origin

-

Type

Type

-

Shape

Shape

-

Grade

Grade

-

Quality

Quality

-

Coating

Coating

-

Friability

Friability

-

Hardness

Hardness

2. Bond Type & Composition

-

Type

Type

-

Density

Density

-

Hardness

Hardness

-

Concentration

Concentration

-

Tensile Strength

Tensile Strength

-

Kerf Angle

Kerf Angle

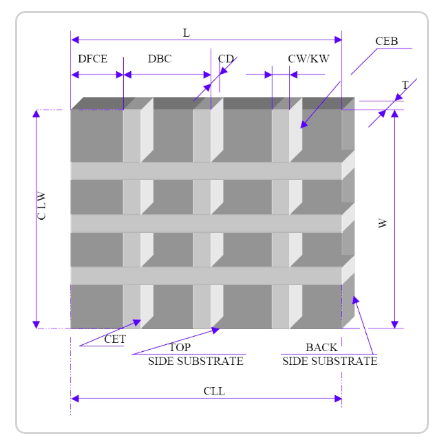

3. Metal Core

-

Thickness

Thickness

-

Tensioning

Tensioning

-

Gullet Design

Gullet Design

-

Grade

Grade

-

Hardness

Hardness

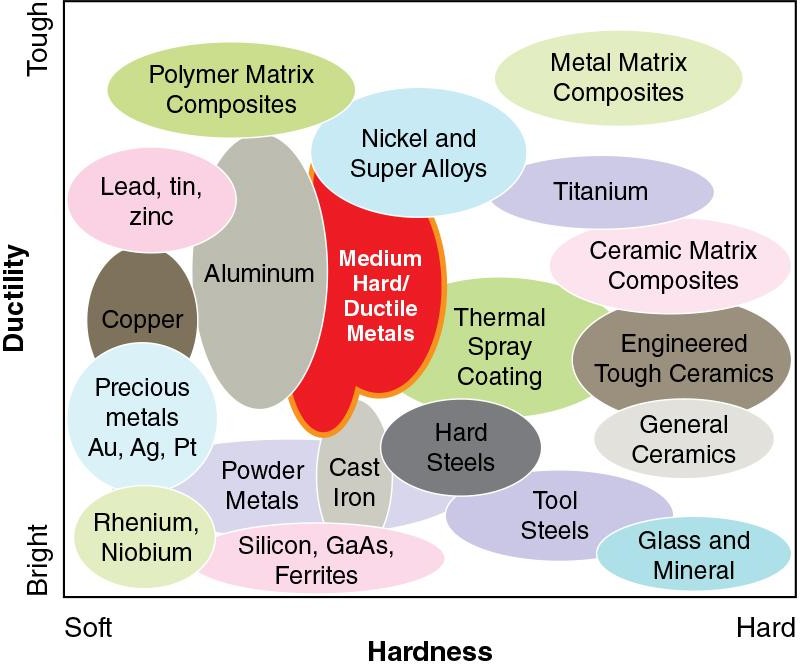

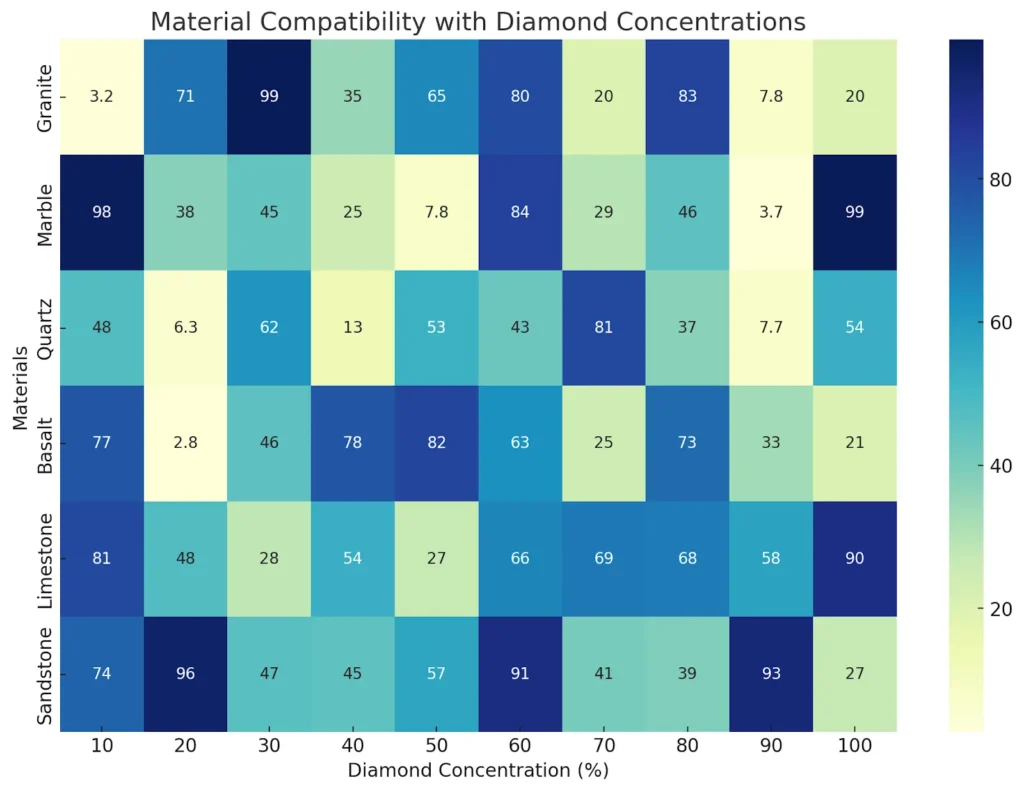

These parameters will play a major role in diamond blade performance. For the diamond blade manufacturer to recommend the right blade for your application. It is critical that the customer provide as much application information as possible. The first step in this process is to consider the properties of the material to be cut and to match diamond blade properties to this material. Table 2 shows a general matching of three basic blade properties to three basic material properties.

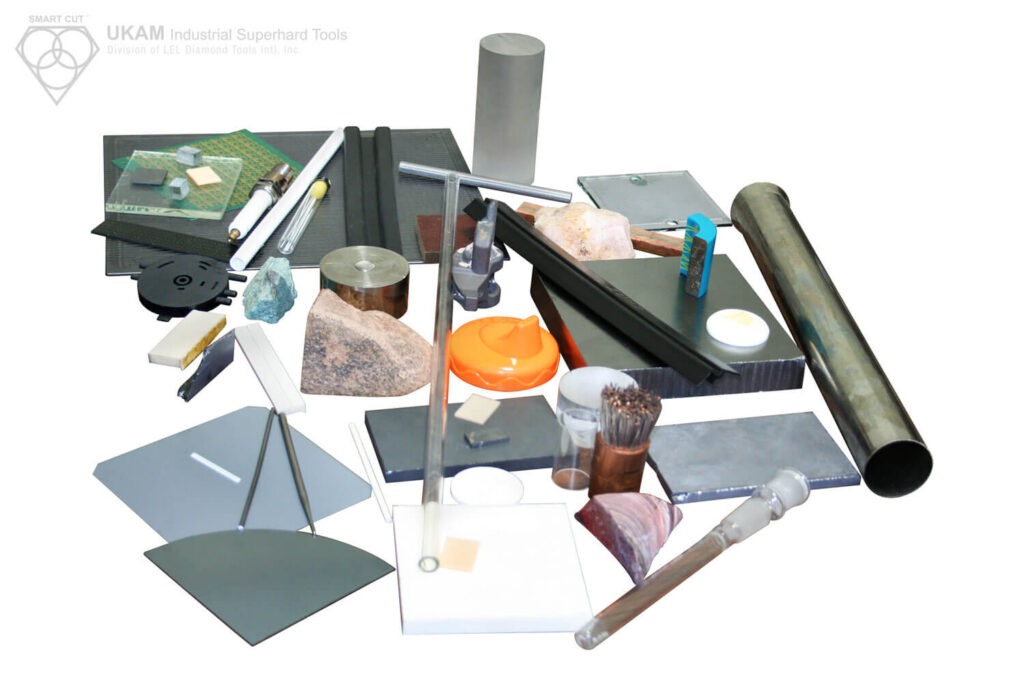

Common non metallic materials cut with diamond blades vary from hard, dense products like high alumina to loosely bonded, highly abrasive products like concrete block. No attempt is made to list specific diamond mesh sizes, concentrations or bond hardness to cut these materials. This information is to be used just as a guide in selecting diamond blade specifications.

Table 2 indicates that hard metal bonds are selected for highly abrasive material. Although physical prosperities are of primary importance in selecting blade properties, chemical properties can also play an important part. With refractory materials, for instance a high alumina content usually indicates that the material will be dense and hard requiring softer bond types and finder diamond mesh sizes.

Matching Basic Blade Properties to Material Properties

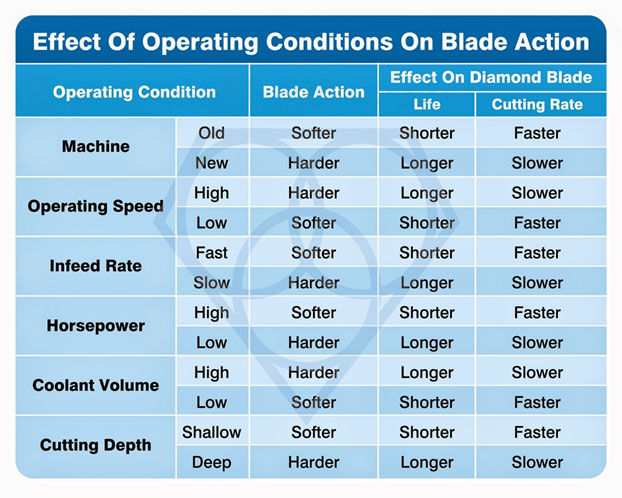

The second step in the blade selection process is to consider the effects of operating conditions on the diamond blade. Table 3 shows these anticipated effects.

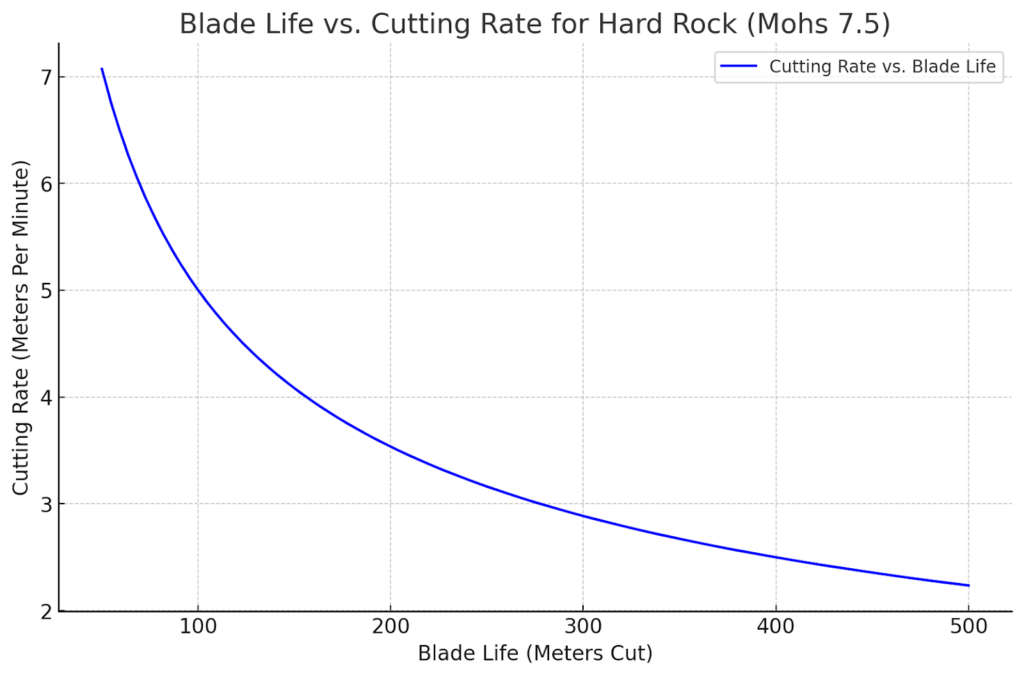

An operating condition which causes a diamond blade to have shorter life and a faster cutting rate is said to make the blade act softer.

A blade with longer life and slower cutting rate is harder acting blade (harder cutting action). Having tentatively selected a combination of blade materials from the material properties guidelines in Table 2 a change in diamond blade materials is made if there is a specific operation condition which will affect diamond blade hardness as shown on Table 3.

Effect of Operating Conditions on Blade Actions

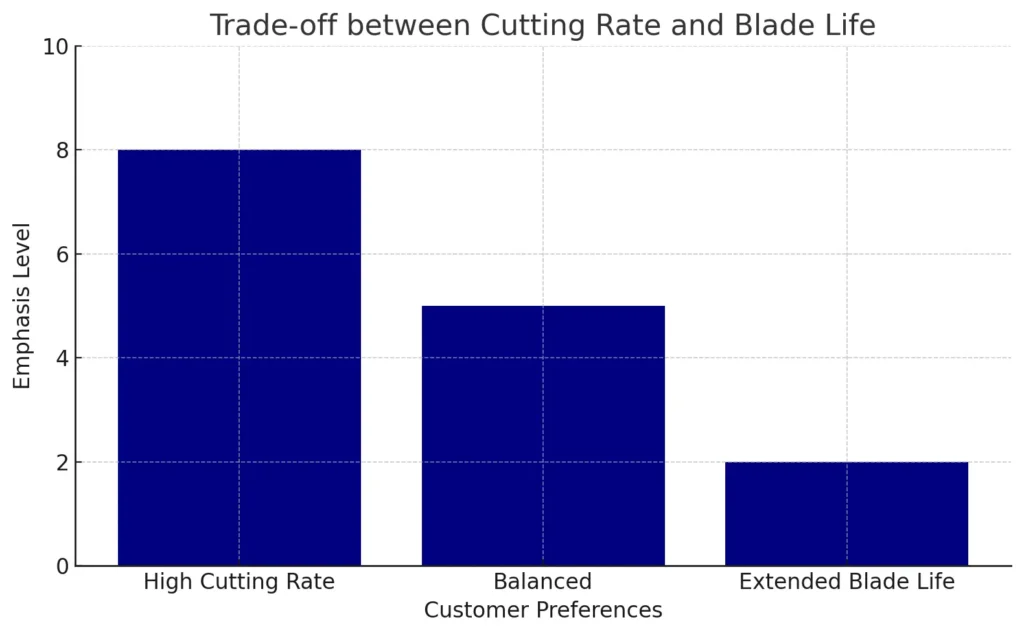

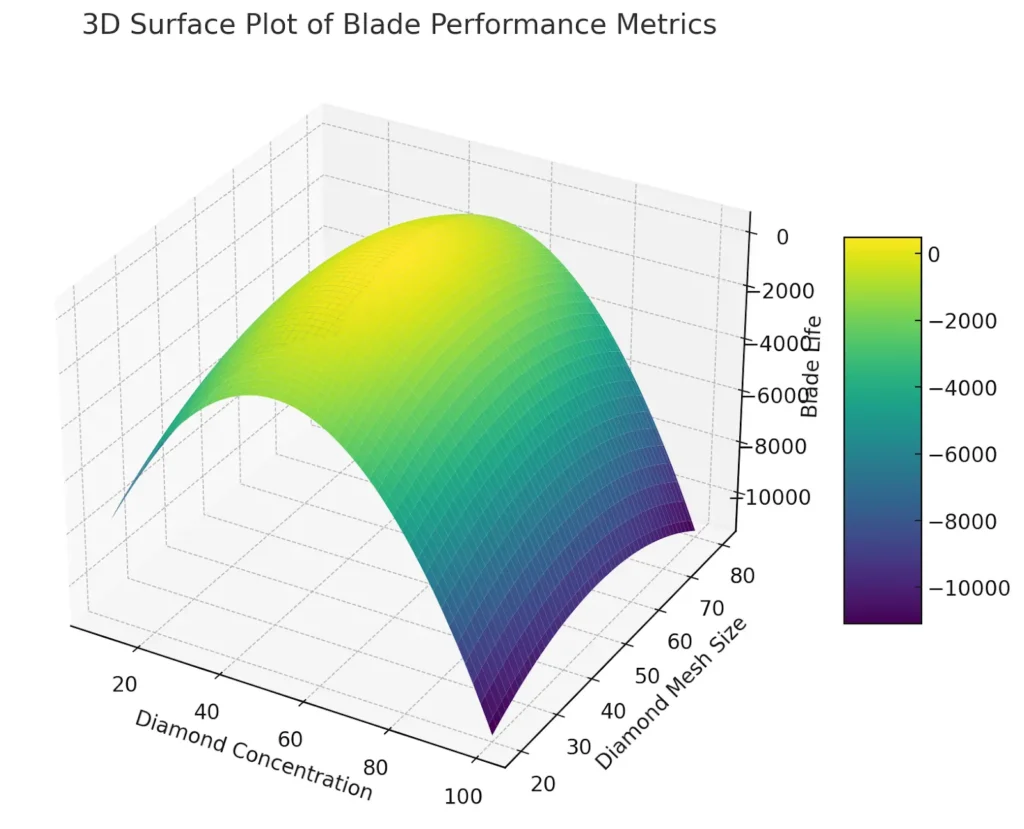

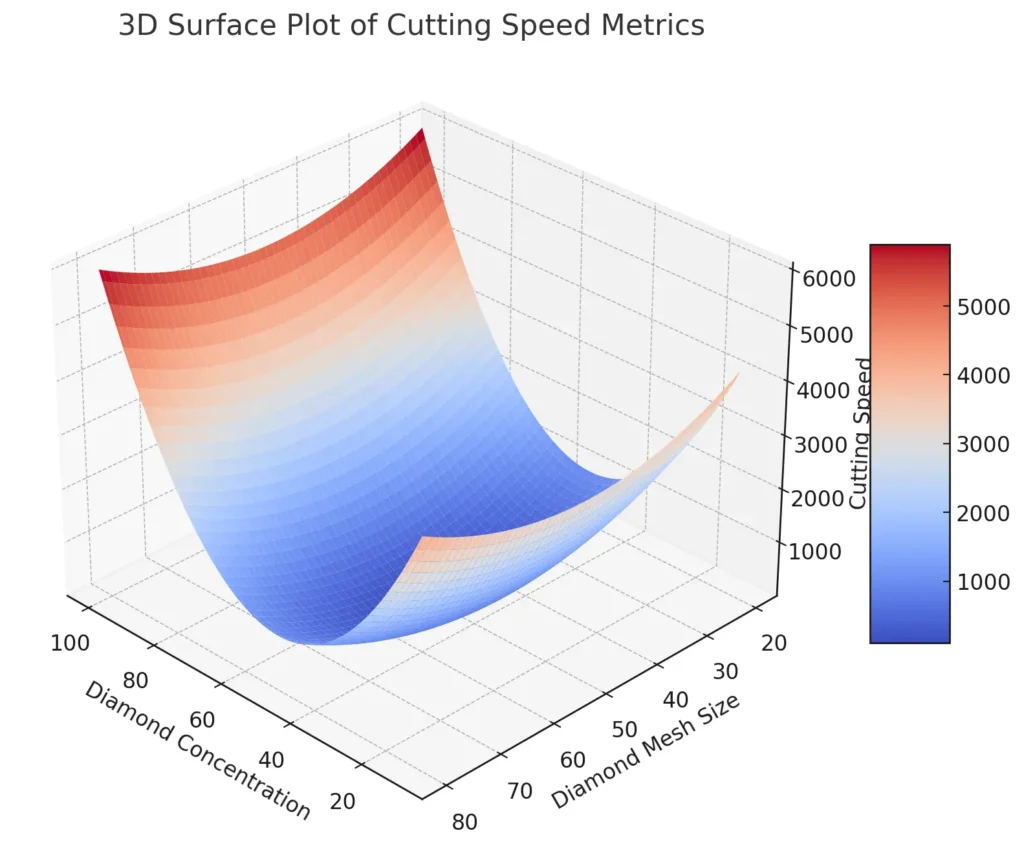

The third and final step in the blade selection process is the consideration of the customers stated blade preference, if any. Cutting rate (speed) and blade life are the primary measurements most customers are concerned with. Usually high cutting speeds reduce labor costs and high blade life reduces blade costs. There is an inverse relationship between blade life and cutting rate. as blade life increases, cutting rate deceases. The most common customer preference is for a diamond blade which will provide both longer life and a faster cutting speed. It is the job of the diamond

blade manufacturer to evaluate which is more important to the customer, blade life or cutting speed and then to adjust blade specification selection accordingly

If blade cost is the most important customer consideration

Initial cost of a diamond blade is primarily dependent on diamond content (concentration). A popular misconception among end users is that diamond content (concentration) and performance are directly proportional. However this is not the cause. In practice, there is an optimum number of diamond particles of a specific diamond mesh size in a specific bond which will produce optimum performance for a specific application. On many applications lower cutting costs are obtained user lower rather than higher diamond concentrations which, in some cases will not cut at all. For this purpose the customer should be concerned with performance, not diamonds.

What application parameters are the most significant in making application decisions? In general, the most important factor is the type of material being cut. Manufacturers recommended stock specifications have been developed to cut specific materials under average operating conditions where no specific customer preference has been expressed.

For example soft diamond bond, with coarse diamond size and high diamond grade has been found to provide optimum performance on most alumina cutting applications.

This specification was developed as a result of many laboratory and field tests of various diamond blade specifications cutting same material. However when this specification does not provide optimum performance, specifications changes are made following the general guidelines presented in Table 2 and Table 3.

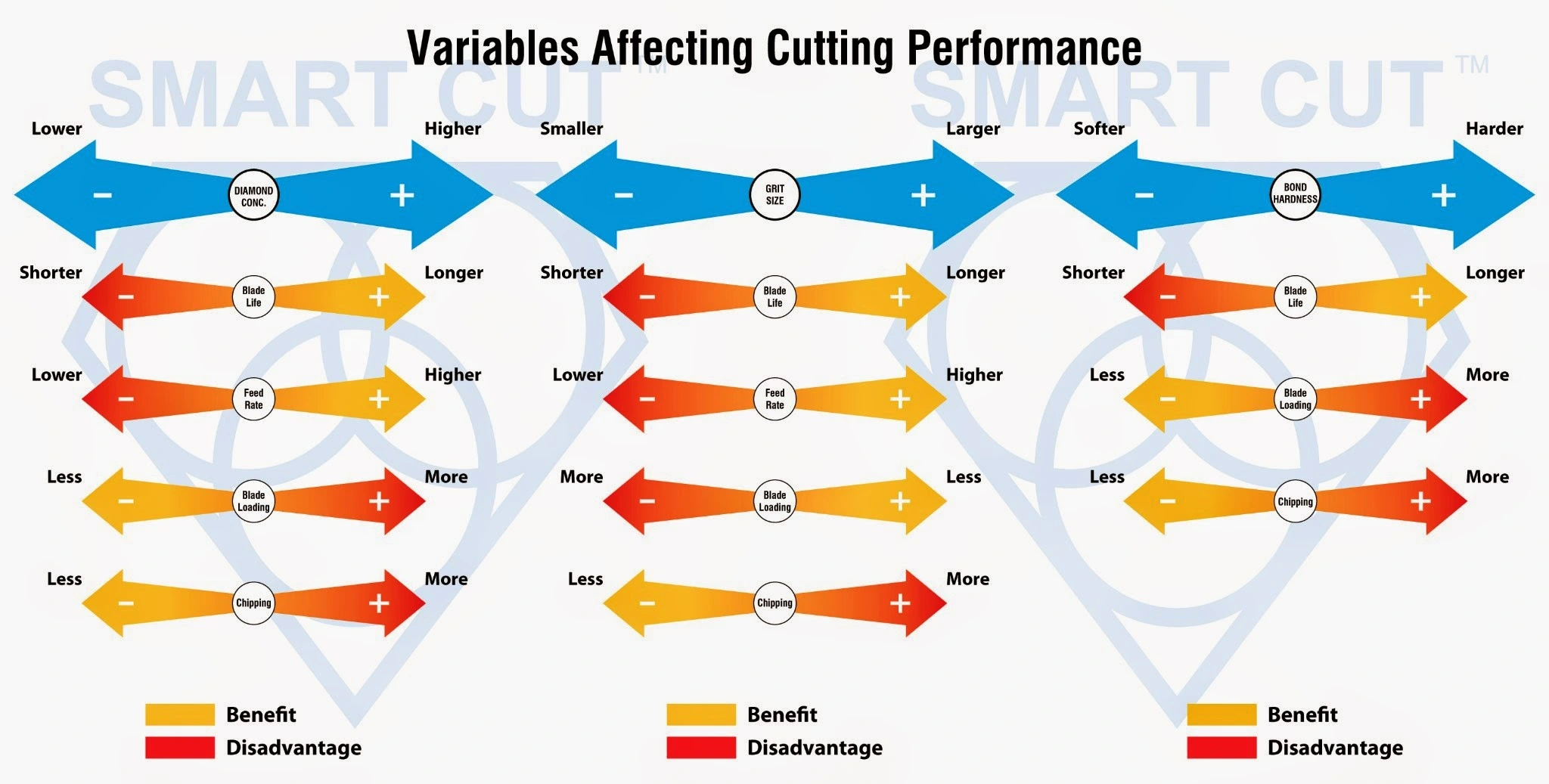

OPTIMIZING BLADE PERFORMANCE

For a any set of application conditions there is a combination of diamonds and bond which will produce optimum diamond blade performance. Finding that combinations depends on

- the customers knowledge and ability to communicate initial application conditions, blade performance results and operating conditions changes

- application engineers knowledge and ability to interpret those results and take appropriate action.

Except on most common applications, a successful initial blade tests is rare. In many cases it may take several attempts and adjustments on both part of customer and diamond blade manufacturer to come to optimum solution.

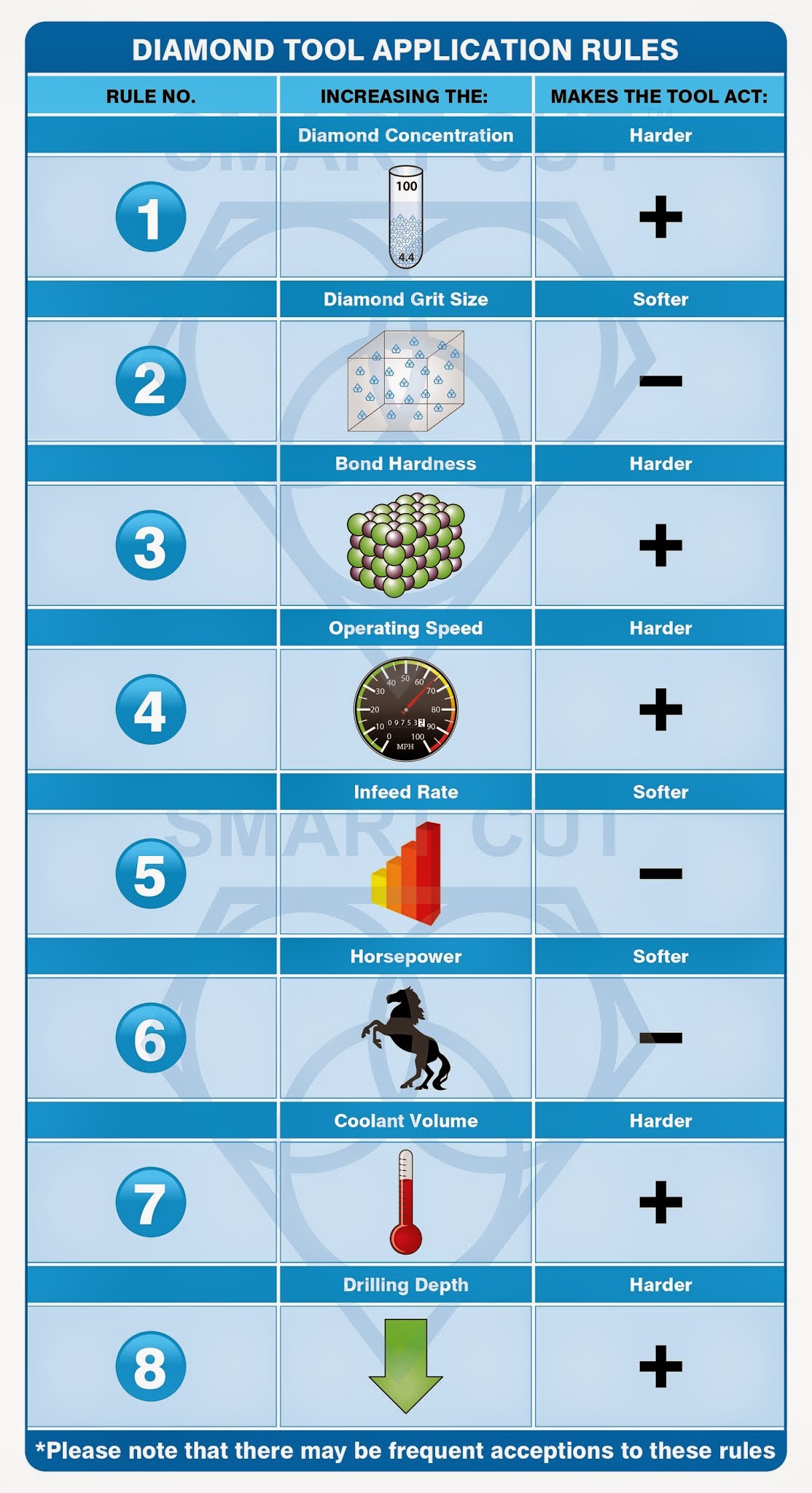

APPLICATION RULES

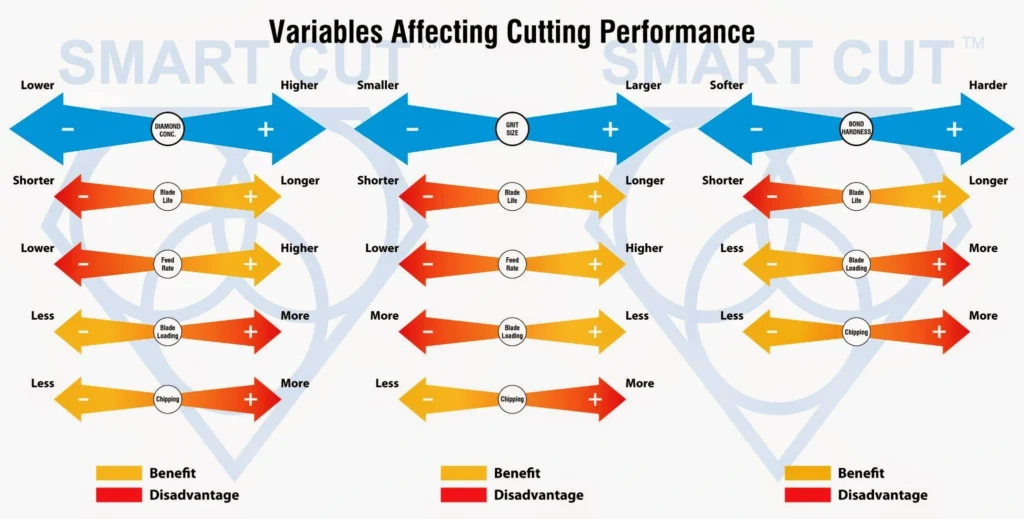

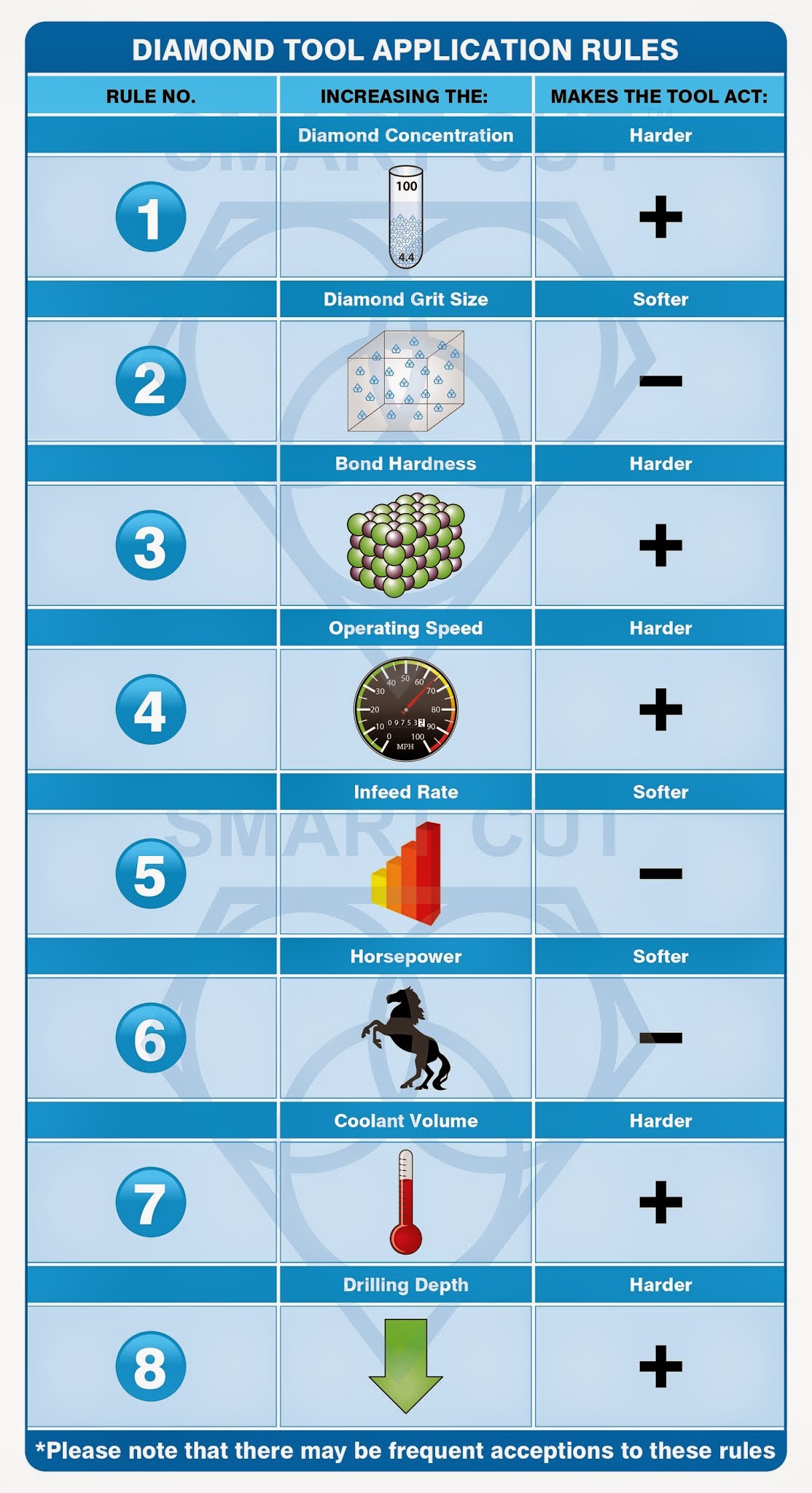

Blade performance is adjusted by changing blade materials, but it can also be adjusted by changing operating conditions. Information presented in Table 2 and Table 3 implies certain application rules. Table 4 summarizes these rules showing the effect of changing either blade materials or operating conditions, holding all other variable constant.

- Increasing diamond concentration causes a blade to act harder because there are more diamond particles in contact with the material which reduces the unit pressure per diamond particle and the grain penetration depth.

- Increase diamond mesh size cause softer blade action because the fewer diamond particles are subjected to higher unit pressures.

- Increased bond hardness’s make a blade act harder because of increased diamond holding capacity and abrasion resistance.

- Increase machine operating speeds (RPM’S) make a blade act harder because each diamond particle is in contact with the material being cut for a shorter time period reducing grain penetration and removing less material per diamond particle per blade revolution.

- Increased infeed rates cause a blade to act softer because the increased unit pressure causes each diamond particle to do more work per blade revolution. Some diamond particles may be prematurely pulled out of the blade because of increased pressure.

- Increased horsepower causes a blade to break down faster because of premature pull out of diamond particles caused by higher cutting pressures. Stated another way, higher horsepower applications allow the use of harder bonds with hold the diamond particles longer because dull diamond particles cut better at highrather than at low horsepower ratings.

- An increased coolant volume aids cutting swarf removal which reduces the amount of wear on the bond making the blade act harder

- Increased blade cutting depths cause a blade to act harder because the increased contact area reduces the pressure per unit particle and the grain penetration depth

These are the few important rules which guide the diamond blade manufacturer and customer in changing blade elements or operating conditions to optimize blade performance

APPLICATION RULES

Nevertheless there are frequently exceptions. For example beyond optimum point O, blade life decreases with increased concentration. This may occur because the harder acting blades require dressing to maintain a satisfactory cutting action, or increased infeed pressures may have to be used to maintain satisfactory cutting rates.

Increased diamond size beyond optimum point O cause a blade to act harder because the coarser particles do not penetrate a very hard material. There is a complex relationship between the number of diamond particles in a blade and the contact area of a single diamond particle. For example a change from 20/30 mesh diamond to 30/40 mesh diamond at the same concentration level provides approximately three times as many diamond particles but reduces the individual particle contact area by approximately one third. It is common to expect harder bonds to produce longer blade life.

One theory that supports the contradiction beyond optimum point O is that harder bonds are more brittle and start to break away rather than wear away, This causes shorter blade life

Other changes in diamond blade materials or operating conditions which make a blade act harder will produce similar effects. Contradictions beyond optimum hardness’s can be explained with similar theories. The accuracy of these theories is not important when considering the blade selection process.

VARIATION

Variation is a critical factor which further complicates the blade selection process. Some degree of variation is fairly common and is to be expected involving most aspects of diamond blade usage, raw material composition, operating conditions and etc.

Some sources of variation diamond blade applications:

1. Diamond Blade

Diamonds

-

Origin

Origin

-

Friability

Friability

-

Hardness

Hardness

-

Internal Structure

Internal Structure

-

Processing

Processing

-

Sizing

Sizing

-

Ovalizing

Ovalizing

-

Tabling

Tabling

-

Sorting

Sorting

-

Grinding

Grinding

Powdered Metal

-

Particle Sizes

Particle Sizes

-

Particle Size Distribution

Particle Size Distribution

-

Physical Properties

Physical Properties

-

Chemical Properties

Chemical Properties

-

Flow Rate

Flow Rate

Processing

-

Weighing

Weighing

-

Mixing

Mixing

-

Pressing Pressure

Pressing Pressure

-

Processing Temperatures

Processing Temperatures

-

Finished Dimensions

Finished Dimensions

-

Tensioning

Tensioning

-

Core Quality

Core Quality

-

Hardness

Hardness

1. Machine Operating Condition

Machine

-

Speed

Speed

-

Feed

Feed

-

Horsepower

Horsepower

-

Type

Type

-

Power Source

Power Source

-

Condition

Condition

-

Coolant Volume

Coolant Volume

Operator

-

Skill

Skill

-

Temperament

Temperament

-

Objectivity

Objectivity

Purchaser

-

Flexibility

Flexibility

-

Communicativeness

Communicativeness

2. Material Being Cut (Raw Materials)

-

Particle Sizes

Particle Sizes

-

Particle Size Distribution

Particle Size Distribution

-

Grog Size & Type

Grog Size & Type

-

Chemical Composition

Chemical Composition

Processing

-

Weighing

Weighing

-

Pressing

Pressing

-

Firing

Firing

-

Kiln Location

Kiln Location

Final Product

-

Tensile Strength

Tensile Strength

-

Chemical Composition

Chemical Composition

-

Refractoriness

Refractoriness

-

Abrasiveness

Abrasiveness

-

Hardness

Hardness

-

Density

Density

-

Permeability

Permeability

Many factors can affect each of the variables listed above and methods used to control and minimize these variations. Manufacturer of diamond blades goes to great length to control the quality of the diamonds and powders used and to control the processing conditions which affect the performance of the finished product.

By the same taken raw material manufacturers that supply material that is cut by diamond blades also have formable quality control standards to minimize process and manufacturing variation. Unfortunately the cut ability of these materials is seldom taken into consideration in initial raw material design and process control when designing original product. Refractory products for example are closely controlled for properties such as thermal conductivity, spalling and refractoriness, but cut ability (hardness and abrasiveness) is not specifically controlled. Operating conditions are typically under poorer control than either material properties or diamond blade properties. For instance, the objectivity of the saw operator and the communicativeness of the purchaser are major sources of variations that have important effect on blade performance.

Typically the diamond blade manufacturing processes are in far better control than other factors of the application environment in which those diamond blades perform.

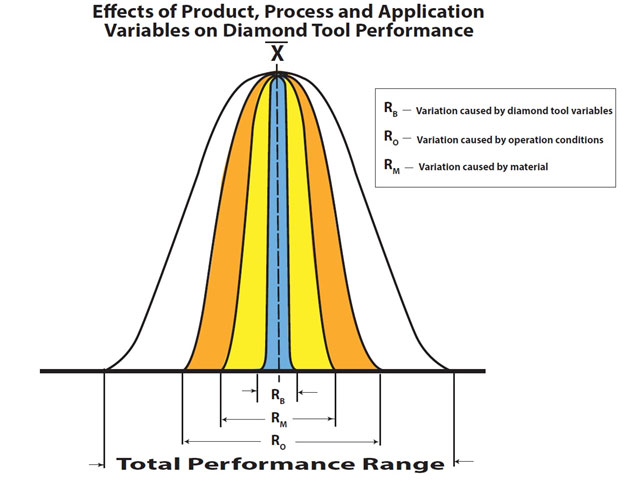

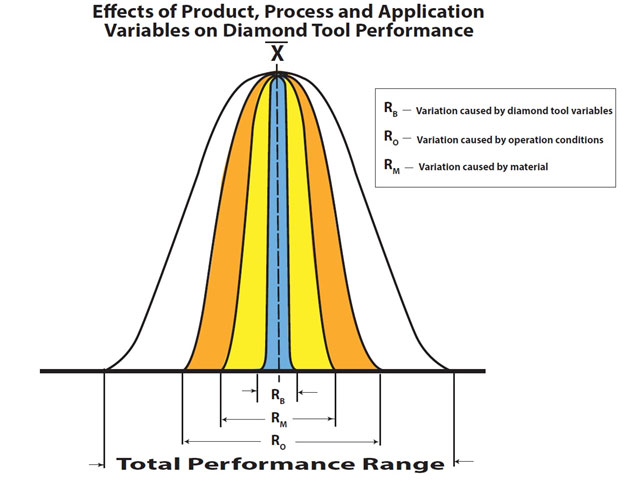

AFFECTS OF PRODUCT, PROCESS AND APPLICATION VARIABLES ON DIAMOND BLADE PERFORMANCE

This normal variation curve represents a hypothetical population of blade performance results on the a specific application. The curve represented by range Rb depicts the relative amount of variation caused by diamond product variables. Curve represented by range RM accounts for the amount of variation cause by variables in the material being cut.

The range Ro represents the variation in performance results due to variations in operation conditions. The goal in this case is not to relieve the blade manufacturer of the all responsibility of application variations, but it does express the experience of diamond blade manufacturers.

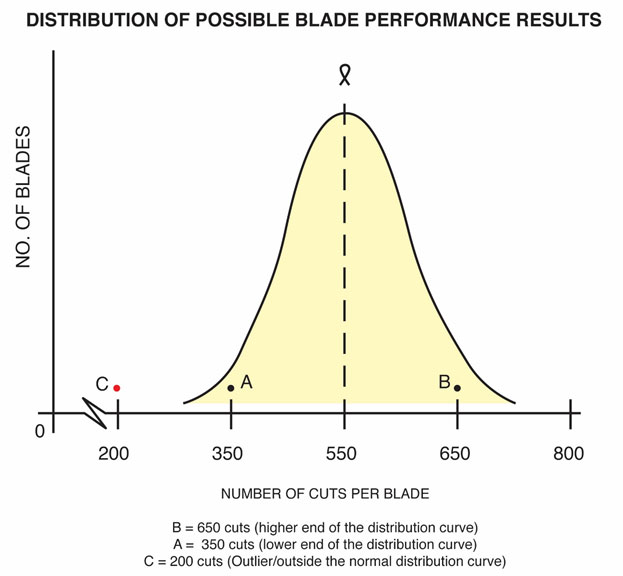

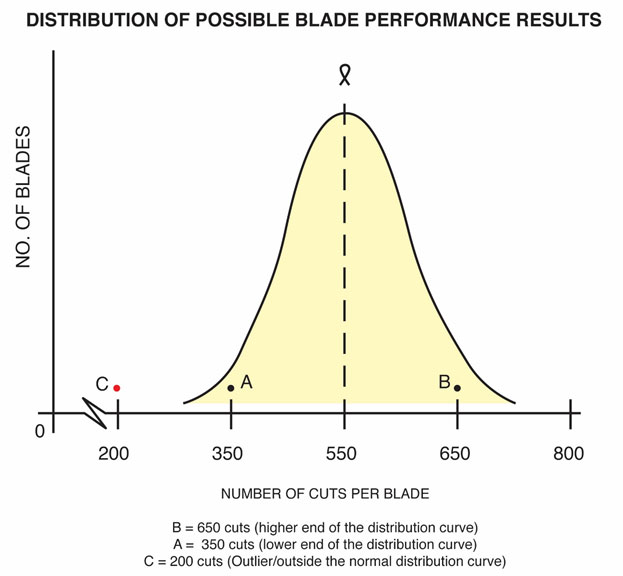

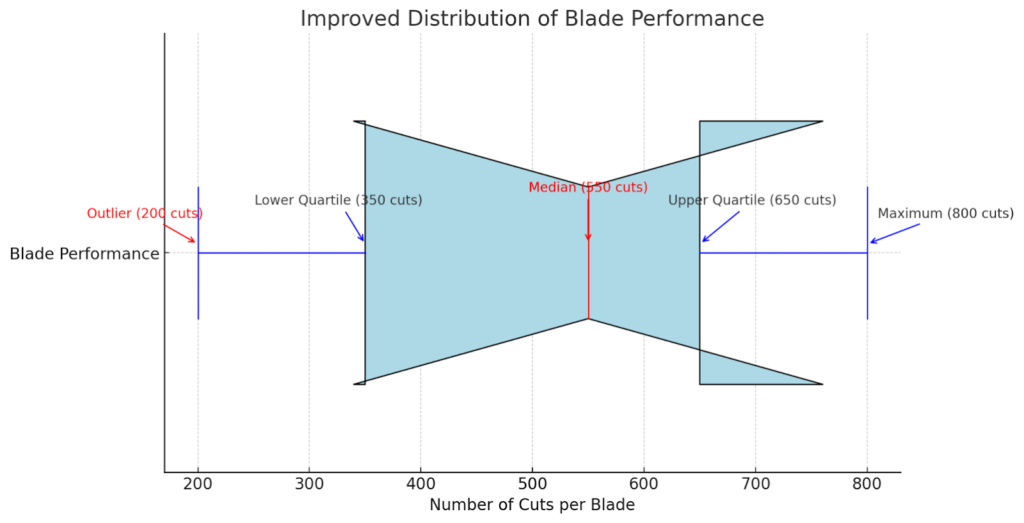

One of the most difficult tasks an application engineer faces is solving application problems that are cause by variation. For example, in cutting one material typical blade life is average of 500 cuts per blade is considered normal.

Figure 1 presents another frequency distribution curve showing the average and range of performance on this specific hypothetical application

Blade represented by point A performed 350 cuts. The user of this blade is not happy and may request a credit. However what the end user should realize is that blade life they have experienced is not out of the ordinary and still falls within the normal distribution curve. When using this particular diamond blade the user was affected by all variables discussed above. Therefore, credit is not really warranted (despite what the customer may feel).

This problem occurs frequently and it is the diamond blade manufacturers application engineers task to explain to the disappointed end user that the 350 cut performance level, although low is normal. In these situations, note that blade performance represented by point B is rarely mentioned.

On other hand if a blade provided only 200 cuts as shown in point C, this would be outside the normal distribution curve. There could be more than one explanation to attribute to this poor blade performance. In statistics this performance would be attributed to assignable cause. Finding and assigning cause and correcting the problem behind this poor performance is a challenging task. Most customers logically conclude that there is something wrong with this diamond blade. However, this is not always the case.

In this situation it is very important of the customer (end user) and blade manufacturer (supplier) to face these circumstances with an open mind in order to resolve the problem. Both blade manufacturer and user can dramatically benefit by working together to resolve problem, instead of approaching it as advisories.

The end users lack of cooperation with blade manufacturer or supplier will be costly to the end user. Important information will be lost unless the end user communicates complete blade application information to manufacturer.

The manufacturer can assist the end user by providing important recommendations in changing operation conditions or usage parameters. And in some cases provide different blade specification that will more closely and better match customers application parameters.

It’s important for the customer to understand that manufacturers do not rule out diamond blade variability as cause of poor diamond blade performance. Its just very rare. Most diamond blade manufacturers maintain elaborate records documenting diamond blade manufacturing and quality control process at every stage.

Each batch and blade produced is frequently assigned as serial number. Every processes underwent in diamond blade manufacturing process can be reexamined and traced to each individual blade.

This information is frequently inspected when looking into validity of customer poor blade performance claims.

Most customers when experiencing poor blade performance or variation frequently assume the tool used (diamond blade) is at fault. Rarely do these users consider material variations or changes in operating conditions as a factor behind these problems.

DESIGNING BLADE TESTS

Rarely does the first blade specification recommended by diamond blade manufacturer provide optimized level of performance desired by customer. Even if by chance the first blade specification tested hits the target, subsequent blades would not perform to most optimized level of performance. This is why results of one blade test are not particularly valid. It is recommended that several blades of same specification by used to establish a average and a range of performance results before adjusting a specification of optimum results.

It is therefore in customers best interest to sample as many blade specifications and their variations as possible to establish a precedent (performance benchmark) from which they can measure all other blades.

In constructing field tests, the end user should attempt to control operating conditions and material specifications as much as possible to minimize diamond blade performance variation. For this reason laboratory tests utilize statistical methods such as random or multiple blade deigns to minimize the affects all variables that may cause variation, except for those being specifically evaluated.

Here are some of the methods used to control and minimize variation in laboratory testing environment

-

when possible, use automatic cutting equipment which operates at a constant surface speed, infeed pressure and power consumption. If using a human operation becomes necessary, specific amperage levels should be selected and operators cutting technique closely monitored to make sure physical movements are as consistent as possible.

when possible, use automatic cutting equipment which operates at a constant surface speed, infeed pressure and power consumption. If using a human operation becomes necessary, specific amperage levels should be selected and operators cutting technique closely monitored to make sure physical movements are as consistent as possible.

-

material being cut is consistent and carefully controlled. We recommend purchasing large lot of material to represent a total range of variation in cutting properties of that specific material. Doing so will minimize effect of piece to piece variation, when selecting individual pieces at random. In order to minimize material hardness variation, we recommend selecting different places of material and cutting at each different location.

material being cut is consistent and carefully controlled. We recommend purchasing large lot of material to represent a total range of variation in cutting properties of that specific material. Doing so will minimize effect of piece to piece variation, when selecting individual pieces at random. In order to minimize material hardness variation, we recommend selecting different places of material and cutting at each different location.

-

when evaluation one or several variables such as diamond mesh size, bond hardness, concentration, andetc in same test, select specific blade specification combination at random. By selecting random sequent in which only a few cuts are made with each combination of variables and then another random sequence selected. This is important to minimize variation cause by factors such as operator fatigue, weather conditions, power sources variations and machine condition changes.

when evaluation one or several variables such as diamond mesh size, bond hardness, concentration, andetc in same test, select specific blade specification combination at random. By selecting random sequent in which only a few cuts are made with each combination of variables and then another random sequence selected. This is important to minimize variation cause by factors such as operator fatigue, weather conditions, power sources variations and machine condition changes.

PREDICTING DIAMOND BLADE PERFORMANCE RESULTS

Frequently customers ask the manufacturer to make certain predictions about diamond blade performance.

Questions such as “How many cuts will this blade make?” are frequently asked. Unfortunately, there is not real answer to this question. Because it takes a considerable amount of time and patience to explain all of possible variations behind diamond blade performance.

Why can performance results be more accurately predicted?

One customer may achieve certain blade life or chipping level on specific application. While another customer may experience longer or shorter life on exact same material and application. Even though operating condition and materials appear to be relative same. Any estimate from blade manufacturer may be interpreted by customer as a commitment or statement of performance guarantee. This is unrealistic and discourages for objective testing, the results of which will benefit both customer and manufacturer. Find out more: Evaluating & Comparing Diamond Blades >>>

The information presented in this article is based not on research and development alone, but primarily on many years of process optimization experience. By understanding and optimizing each variable, end users can achieve superior performance and efficiency in their diamond sawing operations.

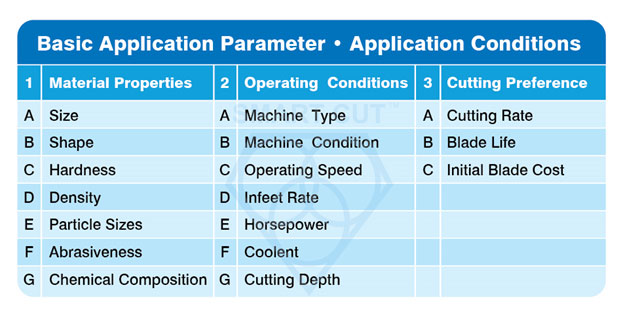

To optimize your diamond sawing operation, it is essential to understand and consider various application parameters and conditions. The table below outlines the key factors to take into account:

Basic Application Parameters and Conditions

|

Material Properties |

Operating Conditions |

Cutting Preferences |

|---|---|---|

|

1. Size |

1. Machine Type |

1. Cutting Rate |

|

2. Shape |

2. Machine Condition |

2. Blade Life |

|

3. Hardness |

3. Operating Speed |

3. Initial Blade Cost |

|

4. Density |

4. Infeed Rate |

4. Surface Finish Quality |

|

5. Particle Sizes |

5. Horsepower |

5. Tolerances and Precision |

|

6. Abrasiveness |

6. Coolant |

6. Cutting Noise Levels |

|

7. Chemical Composition |

7. Cutting Depth |

7. Environmental Impact |

|

8. Thermal Conductivity |

8. Vibration Control |

8. Operator Safety |

|

9. Brittleness |

9. Blade Mounting Method |

9. Material Waste Minimization |

|

10. Electrical Conductivity |

10. Cutting Environment (Wet/Dry) |

10. Ease of Blade Maintenance |

|

11. Toughness |

11. Material Clamping Method |

11. Cycle Time |

|

12. Heat Generation and Management |

||

|

13. Flexibility and Versatility |

||

|

14. Automation and Integration |

||

|

15. Cost per Cut |

Material Properties:

1 Size: The dimensions of the material being cut, including length, width, and thickness.

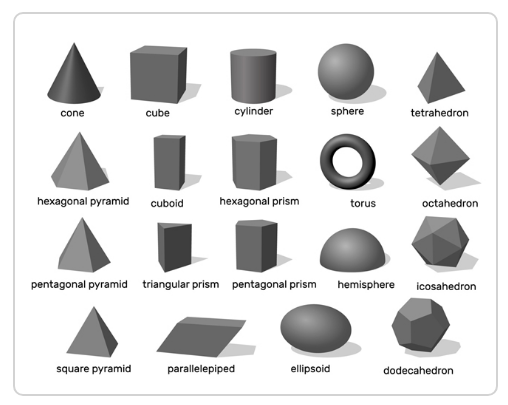

2 Shape: The geometric shape of the material, whether it is a flat sheet, cylinder, or complex shape.

3 Hardness: The resistance of the material to deformation or scratching, often measured on the Mohs scale.

4 Density: The mass per unit volume of the material, which affects cutting resistance and blade wear.

5 Particle Sizes: The size distribution of particles within the material, relevant for composite or granular materials.

6 Abrasiveness: The tendency of the material to wear down the cutting blade through friction.

7 Chemical Composition: The elemental makeup of the material, which can influence the choice of blade and cutting conditions.

8 Thermal Conductivity: The material’s ability to conduct heat, which affects cooling requirements.

9 Brittleness: The material’s tendency to fracture or break under stress, influencing cutting speed and blade choice.

10 lectrical Conductivity: The material’s ability to conduct electricity, which may affect certain cutting methods.

11 Toughness: The material's ability to absorb energy and plastically deform without fracturing, impacting the cutting strategy.

Operating Conditions:

-

Machine Type: The specific type of cutting machine being used, such as a precision saw, high-speed saw, or manual saw.

-

Machine Condition: The maintenance and operational status of the machine, ensuring it is in good working order.

-

Operating Speed: The rotational speed of the blade, measured in RPM (revolutions per minute).

-

Infeed Rate: The speed at which the material is fed into the blade, affecting the cutting rate and quality.

-

Horsepower: The power output of the machine's motor, which influences cutting efficiency and capability.

-

Coolant: The type and flow rate of coolant used to reduce heat and remove debris from the cutting area.

-

Cutting Depth: The depth to which the blade penetrates the material in a single pass.

-

Vibration Control: Measures to minimize vibrations during cutting to ensure precision and blade longevity.

-

Blade Mounting Method: The technique used to secure the blade in the machine, impacting stability and cut quality.

-

Cutting Environment (Wet/Dry): Whether the cutting process is performed wet (with coolant) or dry, which affects heat generation and debris management.

Material Clamping Method: How the material is held in place during cutting to ensure stability and accuracy.

Cutting Preferences:

-

Cutting Rate: The desired speed at which the material is cut, balancing between efficiency and quality.

-

Blade Life: The expected durability of the blade before it needs replacement, influencing overall cost and downtime.

-

Initial Blade Cost: The upfront cost of purchasing the blade, which needs to be balanced with performance and longevity.

-

Surface Finish Quality: The desired smoothness or roughness of the cut surface, which affects the need for additional finishing processes.

-

Tolerances and Precision: The acceptable level of dimensional accuracy and precision in the cuts, crucial for applications requiring tight tolerances.

-

Cutting Noise Levels: Acceptable noise levels during cutting operations, important for maintaining a comfortable and safe working environment, especially in noise-sensitive areas.

-

Environmental Impact: Consideration of the ecological footprint of the cutting process, including the disposal of coolants and other waste products, as well as energy consumption.

-

Operator Safety: Measures to ensure the safety of the operator, such as the use of blade guards, proper training, and adherence to safety protocols.

-

Material Waste Minimization: Strategies to reduce the amount of material waste generated during the cutting process, which can help in cost savings and environmental sustainability.

-

Ease of Blade Maintenance: The ease with which the blade can be maintained, cleaned, and dressed, impacting downtime and operational efficiency.

-

Cycle Time: The total time required to complete a cutting cycle, including both setup and actual cutting time, which affects overall productivity.

-

Heat Generation and Management: The amount of heat generated during cutting and methods to manage it to prevent damage to both the blade and the material.

-

Flexibility and Versatility: The ability of the blade to handle a variety of materials and cutting conditions, providing operational flexibility.

-

Automation and Integration: Compatibility with automated systems and the ability to integrate the cutting process into existing production workflows for enhanced efficiency.

Cost per Cut: The overall cost efficiency measured as the cost incurred per cut, taking into account the blade life, cutting rate, and other operational costs.

Assess Material Properties

Understanding the material you will be cutting is the foundational step in optimizing your diamond sawing operation. The properties of the material directly influence the choice of diamond & cbn blade specifications, cutting parameters, and overall process efficiency. Below are the key material properties to assess:

A. Material Size

The size of the material refers to its overall dimensions, including length, width, and thickness. Accurate measurements of these dimensions are crucial as they determine the type and size of the blade needed for effective cutting. For larger materials, blades with a greater diameter and cutting depth capacity are often required. These high-durability blades ensure that the material can be cut efficiently and effectively without compromising on the quality of the cut. Conversely, smaller materials necessitate the use of precision blades that offer fine control and accuracy. These blades are designed to handle intricate cuts with high precision, ensuring that the smaller dimensions of the material are not damaged or inaccurately cut.

In addition to the general considerations for size, it's important to understand the specific requirements of different sizes of materials. For example, large materials might not only need larger blades but also robust machines with higher horsepower to manage the increased load. The cutting speed and feed rate must also be adjusted accordingly to handle the larger size without causing undue stress on the blade or the material. On the other hand, smaller materials, while requiring precision blades, also benefit from higher RPMs and more controlled infeed rates to achieve the delicate and accurate cuts needed for small dimensions.

Understanding the implications of material size also involves considering the setup and support for the material during the cutting process. Larger materials may require additional supports and clamping methods to ensure stability during cutting, preventing vibrations and movement that could affect the cut quality. Smaller materials, while easier to handle, require precise clamping methods that do not damage the material but provide sufficient stability for accurate cutting.

For large materials, selecting high-durability blades with larger diameters ensures the blade can withstand the increased load and provide effective cutting depth. For small materials, using precision blades that offer fine control and accuracy is essential for achieving intricate cuts with high precision. The machine setup, including horsepower, RPM, and infeed rates, must be tailored to accommodate the specific size of the material, ensuring stability and cut quality.

B. Material Shape

The shape of the material is a critical factor in the diamond sawing process, as it can range from simple geometric forms to complex and irregular profiles. Understanding the shape of the material is essential for selecting the appropriate blade that can navigate through the material effectively without causing damage or inaccuracies.

For simple shapes, such as straight lines, squares, or circles, standard blades are typically sufficient. These blades are designed to handle straightforward cuts with ease, providing consistent performance and good cut quality. The simplicity of the shape allows for a more predictable and manageable cutting process, reducing the likelihood of errors and ensuring efficient material removal.

In contrast, complex or irregular shapes present unique challenges that require specialized solutions. Materials with intricate designs, curves, or non-uniform profiles may necessitate custom blade profiles or specialized blades specifically designed for intricate cuts. These blades are engineered to handle the nuances of complex shapes, ensuring precision and minimizing the risk of damaging the material. Custom blades can be tailored to the specific requirements of the shape, providing the necessary control and accuracy for high-quality cuts.

When dealing with complex shapes, it is also important to consider the cutting strategy and machine settings. Precision cutting machines with advanced control systems can significantly improve the accuracy and quality of cuts for irregular shapes. Features such as CNC (Computer Numerical Control) technology allow for precise movement and positioning of the blade, ensuring that even the most intricate shapes can be cut accurately.

Additionally, the material's shape can impact the setup and clamping methods used during the cutting process. Simple shapes often require minimal setup and standard clamping techniques to hold the material securely in place. However, complex shapes may need specialized fixtures or supports to ensure stability during cutting. Proper clamping is crucial to prevent movement or vibrations that could compromise the cut quality and lead to material damage.

For simple shapes, standard blades are generally sufficient, handling straightforward cuts with ease and ensuring consistent performance. For complex or irregular shapes, custom blade profiles or specialized blades designed for intricate cuts are necessary to achieve precise and high-quality results. The cutting strategy, machine settings, and clamping methods must be carefully considered to accommodate the specific requirements of the shape, ensuring effective and accurate cutting without damaging the material.

C. Material Hardness

Material hardness is a critical factor in blade selection and plays a significant role in determining the appropriate blade specifications. Hardness is typically measured using the Mohs scale or more precise methods such as Vickers or Knoop hardness tests. These measurements provide insight into the material’s resistance to deformation or scratching, which directly influences the type of blade needed for effective cutting.

Understanding Hardness Measurements:

-

Mohs Scale: This scale ranks materials based on their ability to scratch or be scratched by other substances. It ranges from 1 (talc) to 10 (diamond), with higher numbers indicating harder materials.

Mohs Scale: This scale ranks materials based on their ability to scratch or be scratched by other substances. It ranges from 1 (talc) to 10 (diamond), with higher numbers indicating harder materials.

-

Vickers/Knoop Hardness Tests: These tests provide more detailed measurements of a material's hardness by assessing the size of an indentation left by a specific force applied through a diamond indenter. The results are expressed in terms of hardness numbers, which are used to determine the material's resistance to deformation.

Vickers/Knoop Hardness Tests: These tests provide more detailed measurements of a material's hardness by assessing the size of an indentation left by a specific force applied through a diamond indenter. The results are expressed in terms of hardness numbers, which are used to determine the material's resistance to deformation.

Hard Materials: Hard materials such as ceramics, metals, and gemstones present significant cutting challenges due to their high resistance to abrasion and deformation. To effectively cut these materials, blades with a high diamond concentration are required. Diamonds are the hardest known material and can efficiently cut through hard substances. Additionally, the bonding matrix that holds the diamonds in place must be exceptionally durable to withstand the increased cutting resistance and prevent premature wear of the blade.

For instance, when cutting ceramics or hard metals, the blade must maintain sharpness and integrity over extended periods. Therefore, a tough bonding matrix, such as a metal bond, is often used to ensure that the diamonds remain securely embedded and continue to cut effectively. These blades are designed to handle the high stress and heat generated during the cutting process, ensuring precise and efficient material removal.

Soft Materials: In contrast, soft materials such as plastics, rubber, and softer metals do not require the same level of cutting intensity. Blades with a lower diamond concentration are often sufficient for these materials. The reduced hardness of the material means that the cutting force required is significantly lower, and the blade does not need to be as robust.

For soft materials, a softer bonding matrix can be used. This type of bond allows for a quicker exposure of new diamonds as the old ones wear down, maintaining the blade’s cutting efficiency without excessive wear. Resin bonds are commonly used for softer materials, providing the necessary flexibility and wear rate to handle the material without causing damage or excessive blade wear.

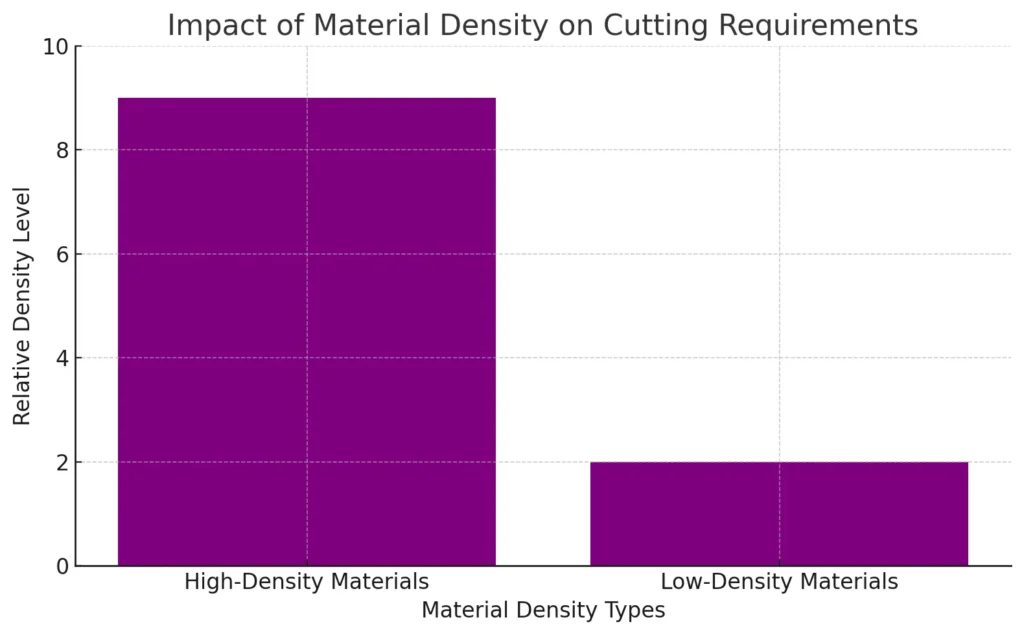

D. Material Density

The density of a material is a crucial factor in the cutting process as it significantly affects the rate of material removal and the stress exerted on the blade. Density, typically measured in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³), represents the mass per unit volume of the material. This property influences how the material interacts with the blade during cutting, impacting both the efficiency of the cut and the wear on the blade.

High-Density Materials: High-density materials, such as certain metals, ceramics, and composite materials, pose a greater challenge during the cutting process due to their substantial mass and compact structure. These materials require robust, high-performance blades capable of handling the increased load and resistance. The blades must be designed to withstand the higher forces involved in cutting dense materials without deforming or wearing out prematurely.

To effectively cut high-density materials, blades with a higher concentration of diamonds and a durable bonding matrix are essential. The increased diamond concentration provides the necessary cutting power, while the tough bond, often a metal or hybrid bond, ensures that the diamonds remain securely in place and resist the stresses encountered during cutting. Additionally, these blades must be able to dissipate heat effectively to prevent overheating, which can lead to blade failure and poor cut quality.

Low-Density Materials: Low-density materials, such as plastics, foams, and some softer metals, are easier to cut due to their lower mass and less compact structure. These materials do not require the same level of cutting force, allowing standard blades to be used effectively. The focus when cutting low-density materials is often on speed and efficiency rather than the robustness of the blade.

Standard blades with a lower diamond concentration and a softer bond, such as a resin bond, are suitable for cutting low-density materials. These blades can achieve high cutting speeds and remove material quickly without excessive wear. The softer bond allows for rapid exposure of new diamonds, maintaining the blade's cutting efficiency over time.

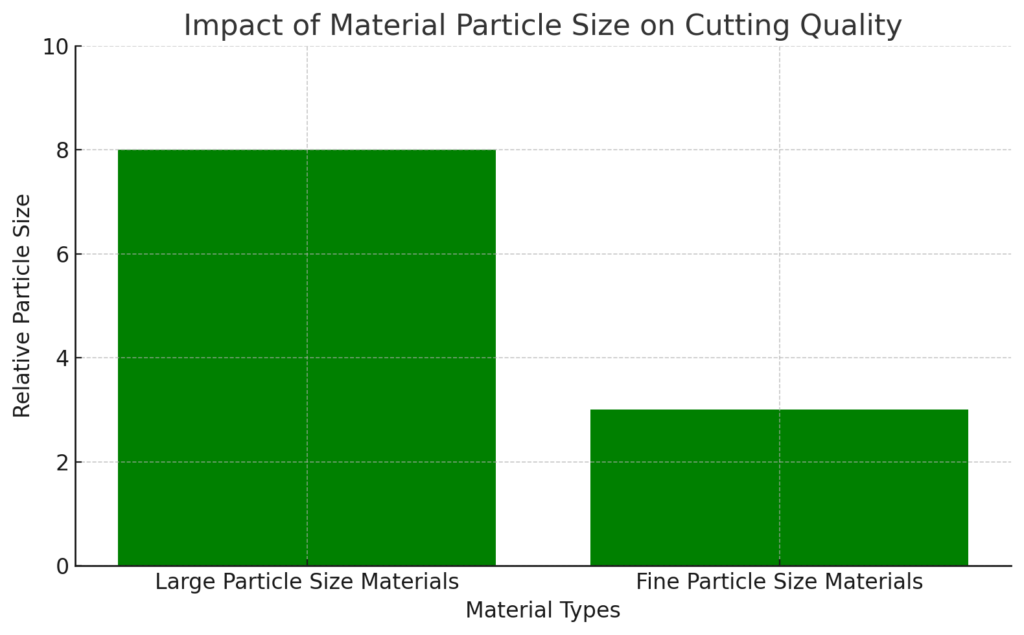

E. Material Particle Sizes

The size of the particles within a material is a critical factor that influences both the surface finish and the overall cutting quality. Particle size refers to the dimensions of the individual grains or components that make up the material. These sizes can vary significantly and are typically measured in micrometers (µm). The particle size affects how the material interacts with the cutting blade and can dictate the type of blade needed to achieve the desired cut quality and surface finish.

Materials with larger particle sizes can result in a rougher cut surface. This is because the larger particles create more significant disruptions along the cutting path, leading to an uneven finish. To effectively cut materials with large particle sizes, blades need to be designed to manage these particles, which often involves using blades with larger diamond grits. The larger grits can better handle the roughness and irregularities caused by big particles, ensuring the blade can cut through efficiently without being prematurely worn down.

Conversely, materials with fine particle sizes typically produce smoother cut surfaces. The smaller particles create fewer disruptions along the cutting path, allowing for a finer finish. Precision blades with finer diamond grits are essential for cutting materials with fine particle sizes. These blades can make cleaner cuts and provide high-quality surface finishes, which are often required in applications where precision and aesthetics are crucial.

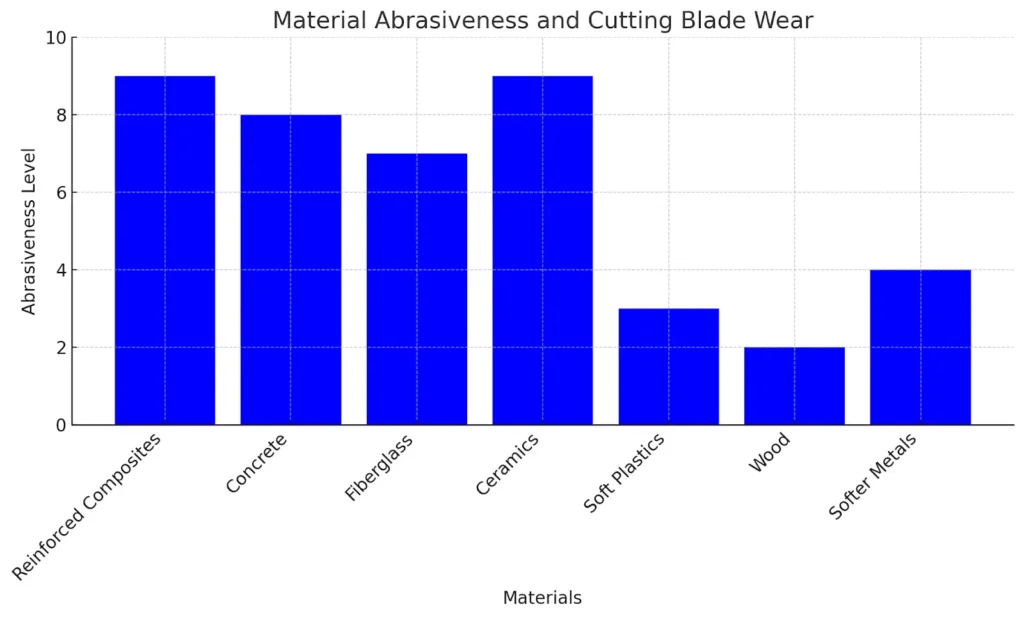

F. Material Abrasiveness

The abrasiveness of a material is a critical factor that affects the longevity and performance of cutting blades. Abrasiveness refers to the material's tendency to wear down or erode the cutting edge of the blade through friction and mechanical interaction. Materials that are highly abrasive can cause rapid blade wear, leading to frequent blade replacements and increased operational costs if the wrong type of blade is selected. Therefore, understanding the abrasiveness of the material and choosing blades with appropriate wear-resistant properties is essential for efficient and cost-effective cutting operations.

High Abrasiveness: Materials such as reinforced composites, concrete, fiberglass, and certain ceramics are considered highly abrasive. These materials contain hard, gritty particles that can quickly wear down the blade's cutting edge. To effectively cut highly abrasive materials, blades with advanced wear-resistant properties are required.

Blades for highly abrasive materials often incorporate a metal bond, which is tougher and more durable compared to other bond types. The high diamond concentration and the use of superior quality diamonds ensure that the blade maintains its sharpness and cutting efficiency over an extended period, even when subjected to the abrasive nature of the material. Additionally, the design of these blades may include features such as segmented rims or specific gullet configurations to improve debris removal and cooling, further enhancing their wear resistance.

Low Abrasiveness: Materials such as soft plastics, wood, and some softer metals exhibit low abrasiveness. These materials are less likely to cause significant wear on the cutting blade, allowing for the use of standard blades with moderate wear resistance. Blades for low abrasive materials typically have a lower diamond concentration and use softer bonding matrices, such as resin bonds, which provide sufficient durability for the task while being cost-effective.

Standard blades for low abrasive materials focus on maintaining a balance between cutting efficiency and blade longevity. Since these materials do not exert as much wear on the blade, there is less need for the advanced wear-resistant properties required for highly abrasive materials. This allows for faster cutting speeds and higher productivity, as the blade can maintain its performance over longer cutting cycles without the need for frequent maintenance or replacement.

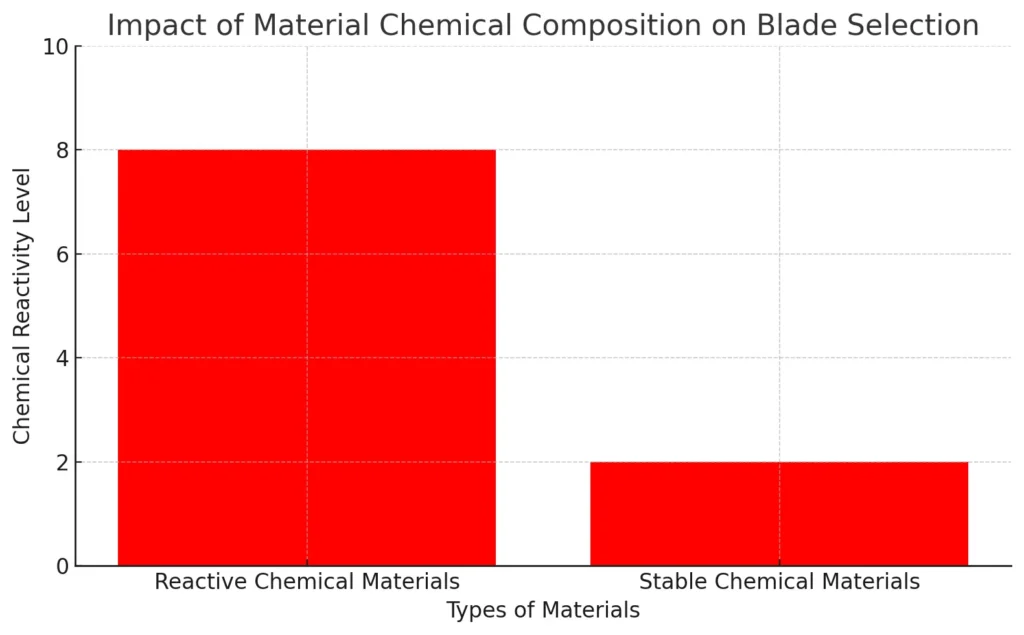

G. Material Chemical Composition

The chemical composition of the material is a crucial factor that can significantly affect the interaction between the cutting blade and the material being cut. The presence of certain chemicals in the material can lead to reactions with the blade's bond, potentially causing degradation, corrosion, or reduced performance. Understanding the chemical makeup of the material is essential for selecting blades with bond materials that are compatible and resistant to any adverse chemical reactions.

Materials with reactive chemicals can interact negatively with the bonding matrix of the blade. These interactions can weaken the bond, causing the diamonds to dislodge prematurely and reducing the overall efficiency and lifespan of the blade. For instance, materials containing acids, alkalis, or other corrosive substances can corrode metal bonds, while certain polymers or composites might react with resin bonds, leading to bond breakdown and compromised cutting performance.

To mitigate these issues, it is important to select blades with chemically resistant bonds when working with reactive chemicals. Chemically resistant bonds are designed to withstand corrosive environments and prevent degradation. These bonds may include specialized coatings or formulations that protect the bond from chemical attack, ensuring the blade maintains its integrity and cutting performance over time.

In contrast, materials with stable chemicals do not pose the same risk of adverse reactions with the blade's bond. Standard blade bonds, whether metal or resin, are typically sufficient for cutting non-reactive materials. These bonds provide reliable performance without the need for additional chemical resistance, allowing for efficient cutting and long blade life.

2. Evaluate Operating Conditions

Evaluating and optimizing the operating conditions of your diamond sawing operation is crucial for achieving the desired cutting performance and efficiency. By examining the machine type, condition, and specific operating parameters, you can ensure that the cutting process is both effective and reliable. Here are the key factors to consider:

A. Machine Type

The type of machine used in the cutting operation plays a significant role in determining the appropriate blade and cutting parameters. Different machines are designed for specific types of cuts and materials.

-

Precision Saws: Ideal for intricate cuts and high-precision applications.

Precision Saws: Ideal for intricate cuts and high-precision applications.

-

High-Speed Saws: Suitable for rapid cutting of hard materials.

High-Speed Saws: Suitable for rapid cutting of hard materials.

-

Manual Saws:Used for smaller, less complex cuts.

Manual Saws:Used for smaller, less complex cuts.

-

Automatic Saws: Provide consistent and repeatable cuts for high-volume production.

Automatic Saws: Provide consistent and repeatable cuts for high-volume production.

B. Machine Condition

The condition of the machine directly impacts the cutting performance. Regular maintenance and inspection are essential to ensure the machine operates efficiently.

-

Maintenance:Regularly check for wear and tear, and replace worn-out parts.

Maintenance:Regularly check for wear and tear, and replace worn-out parts.

-

Alignment Ensure the machine is properly aligned to avoid inaccurate cuts.

Alignment Ensure the machine is properly aligned to avoid inaccurate cuts.

-

VibrationMinimize machine vibration to prevent blade damage and ensure smooth cutting.

VibrationMinimize machine vibration to prevent blade damage and ensure smooth cutting.

C. Operating Speed

Operating speed, measured in revolutions per minute (RPM), is a critical factor that affects the cutting efficiency and blade life. The optimal speed varies based on the material and blade type.

-

High-Speed Operation:Regularly check for wear and tear, and replace worn-out parts.

High-Speed Operation:Regularly check for wear and tear, and replace worn-out parts.

-

Low-Speed Operation: Better for softer materials and precision cuts, extending blade life.

Low-Speed Operation: Better for softer materials and precision cuts, extending blade life.

D. Infeed Rate

The infeed rate, or the speed at which the material is fed into the blade, needs to be carefully controlled to achieve the desired cut quality and prevent blade damage.

-

High Infeed Rate:Increases cutting speed but can lead to poor cut quality and higher blade wear.

High Infeed Rate:Increases cutting speed but can lead to poor cut quality and higher blade wear.

-

Low Infeed Rate:Provides better cut quality and reduces blade wear, suitable for precision applications.

Low Infeed Rate:Provides better cut quality and reduces blade wear, suitable for precision applications.

E. Cutting Depth

Adjusting the cutting depth according to the material properties ensures efficient material removal and prolongs blade life.

-

Deep Cuts:Require blades with greater durability and robust bond systems.

Deep Cuts:Require blades with greater durability and robust bond systems.

-

Shallow Cuts: Suitable for thin or delicate materials, reducing the risk of damage.

Shallow Cuts: Suitable for thin or delicate materials, reducing the risk of damage.

F. Horsepower

The machine's horsepower must be adequate to handle the material and blade type. Insufficient power can lead to stalling and poor cut quality.

-

High Horsepower:Necessary for cutting hard or dense materials.

High Horsepower:Necessary for cutting hard or dense materials.

-

Low Horsepower: Sufficient for softer materials and small-scale operations.

Low Horsepower: Sufficient for softer materials and small-scale operations.

Determine Cutting Preferences

Determining your cutting preferences is a crucial step in optimizing your diamond sawing operation. By clearly defining your cutting goals, you can select the most appropriate blade and set the optimal cutting parameters to achieve the desired results. Here are some additional articles that can help with this

Here are the primary factors to consider:

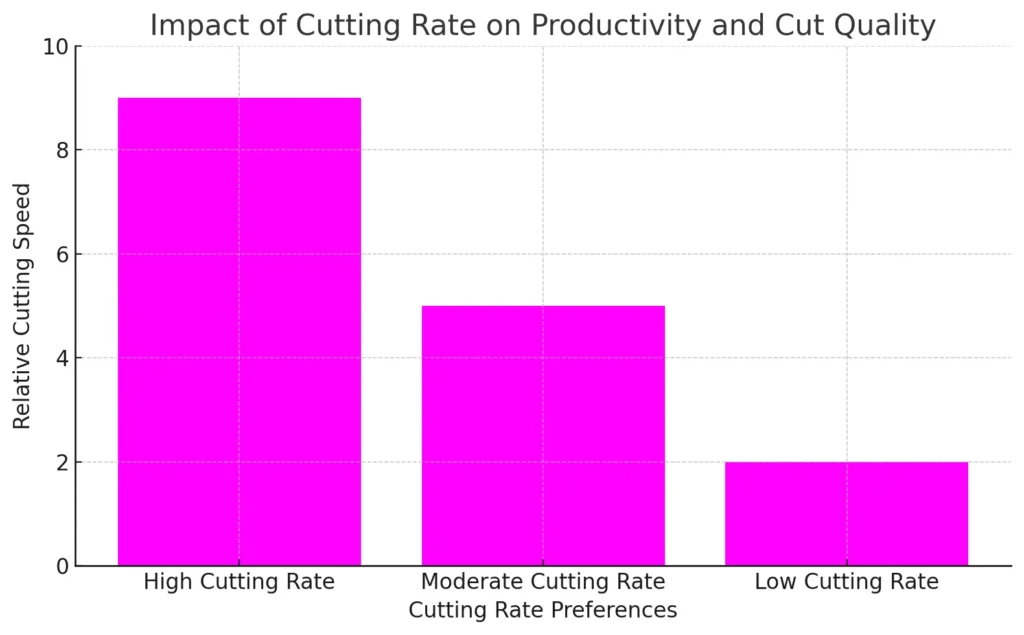

A. Cutting Rate

The cutting rate, or speed at which the material is cut, is a key performance metric that impacts productivity and efficiency. Determining the ideal cutting rate involves balancing the need for speed with the quality of the cut and the longevity of the blade.

-

High Cutting Rate:Prioritizing a high cutting rate is suitable for applications where productivity is paramount. This often involves using blades with aggressive cutting action but may lead to increased blade wear and reduced cut quality.

High Cutting Rate:Prioritizing a high cutting rate is suitable for applications where productivity is paramount. This often involves using blades with aggressive cutting action but may lead to increased blade wear and reduced cut quality.

-

Moderate Cutting Rate: Balancing speed and quality is essential for many applications. This approach ensures reasonable productivity while maintaining acceptable cut quality and blade life.

Moderate Cutting Rate: Balancing speed and quality is essential for many applications. This approach ensures reasonable productivity while maintaining acceptable cut quality and blade life.

-

Low Cutting Rate:A slower cutting rate is often necessary for precision applications where cut quality and surface finish are critical. This reduces blade wear and ensures high-quality cuts but may decrease overall productivity.

Low Cutting Rate:A slower cutting rate is often necessary for precision applications where cut quality and surface finish are critical. This reduces blade wear and ensures high-quality cuts but may decrease overall productivity.

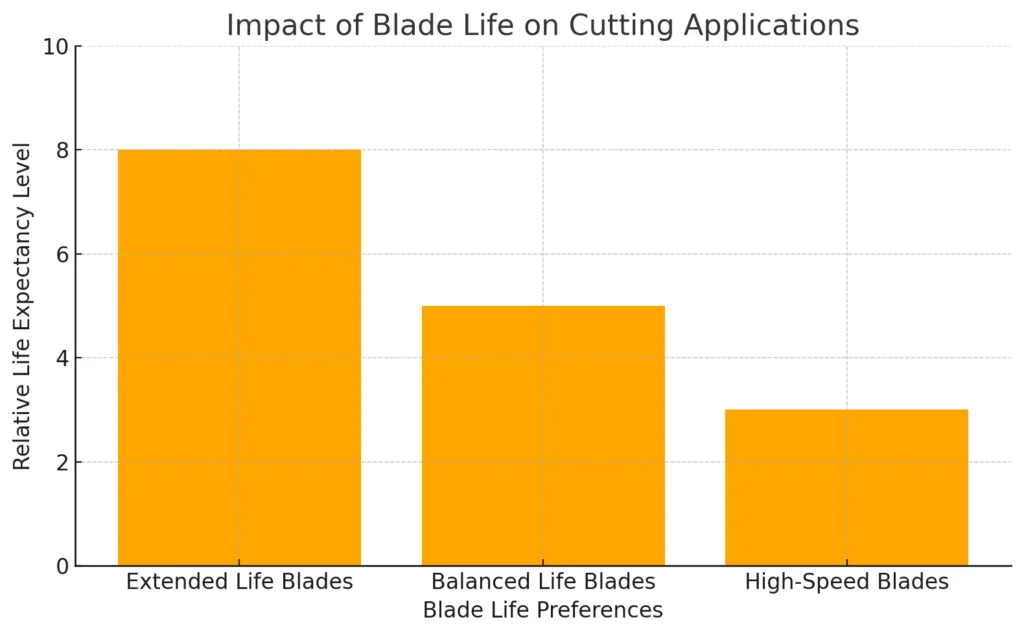

B. Blade Life

Diamond & CBN Blade life, or the durability of the blade, is another crucial factor that impacts the cost-effectiveness and consistency of the cutting process. Longer blade life reduces downtime and blade replacement costs but may require a trade-off with cutting speed. Blades designed for extended life are ideal for applications where minimizing downtime and replacement costs is essential.

These blades may have a slower cutting rate but provide consistent performance over a longer period. A balanced approach, where blade life is sufficient for regular use without compromising too much on cutting speed, is suitable for most general-purpose cutting applications. In scenarios where maximum cutting speed is required, blades may wear out more quickly. This is acceptable for short-term projects or when cutting soft materials where blade replacement costs are lower.

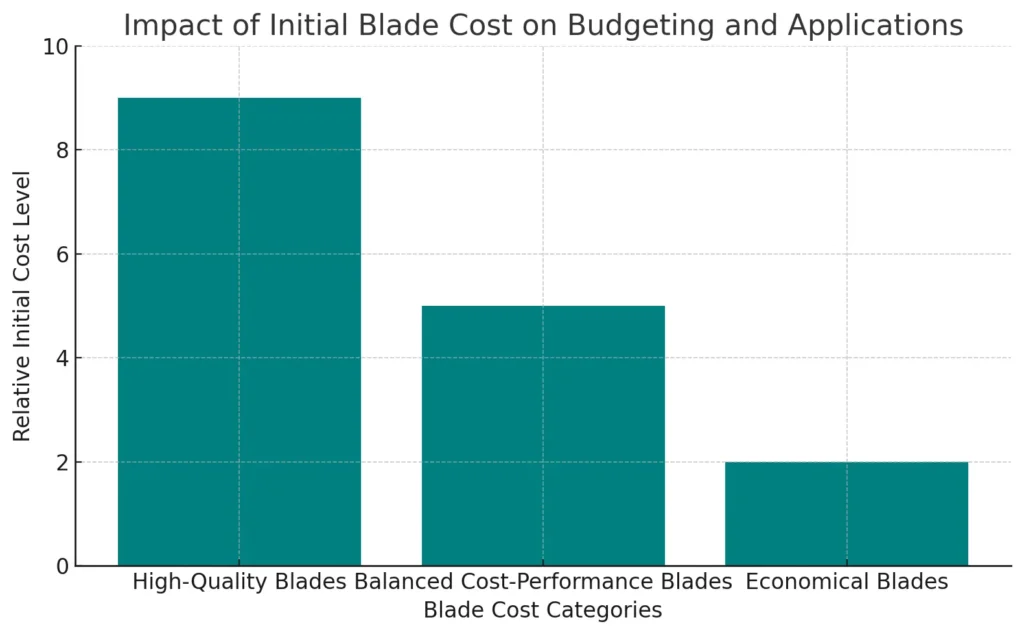

C. Initial Blade Cost

The initial cost of the blade is an important consideration, especially when working within budget constraints. Balancing initial cost with performance and longevity ensures cost-effective operations. High-quality blades with superior performance and longevity often come with a higher initial cost.

These are suitable for critical applications where precision and durability are essential. Diamond & CBN Blades that offer a good balance between cost and performance are ideal for many standard applications, providing reliable performance without excessive upfront investment. Economical blades are suitable for short-term projects or less demanding applications. While they may have a shorter lifespan and reduced performance, they help keep initial expenses low. Find out more: Diamond & CBN Blade Total Cost of Ownership >>>

Diamond and CBN Blade Properties

|

Category |

Property |

Description |

|---|---|---|

|

1. Diamonds and CBN |

Grit Size |

Size of the diamond or CBN particles used in the blade |

|

Origin |

Source of the particles (natural or synthetic) |

|

|

Type |

Monocrystalline, polycrystalline, cubic boron nitride (CBN) |

|

|

Shape |

Cubic, irregular, etc. |

|

|

Grade |

Overall quality and purity of the particles |

|

|

Quality |

Level of defects and inclusions |

|

|

Coating |

Surface treatment (e.g., nickel or titanium coating) |

|

|

Friability |

Tendency of the particles to fracture |

|

|

Hardness |

Hardness of the particles (Mohs scale or Vickers/Knoop) |

|

|

Thermal Stability |

Ability to withstand high temperatures |

|

|

Toughness |

Resistance to impact and chipping |

|

|

2. Bond Type & Composition |

Type |

Metal, resin, hybrid, etc. |

|

Density |

Density of the bonding material |

|

|

Hardness |

Hardness of the bonding material |

|

|

Concentration |

Amount of diamonds or CBN within the bond |

|

|

Tensile Strength |

Strength of the bond to withstand cutting stresses |

|

|

Kerf Angle |

Angle of the cut created by the blade |

|

|

Wear Resistance |

Ability to withstand wear and maintain cutting edge |

|

|

Chemical Resistance |

Resistance to degradation by chemicals |

|

|

Thermal Conductivity |

Ability to dissipate heat generated during cutting |

|

|

Flexibility |

Ability to absorb stress and maintain structural integrity |

|

|

3. Metal Core |

Thickness |

Thickness of the metal core |

|

Tensioning |

Method of tensioning to ensure stability |

|

|

Gullet Design |

Design of the spaces between segments for debris removal |

|

|

Grade |

Quality of the metal used in the core |

|

|

Hardness |

Hardness of the metal core |

|

|

Thermal Stability |

Ability to withstand high temperatures |

|

|

Vibration Dampening |

Ability to reduce vibrations during cutting |

|

|

Corrosion Resistance |

Resistance to rust and corrosion | |

|

Flexibility |

Ability to absorb stress and maintain structural integrity |

1. Diamonds or CBN Particles

A. Grit Size

The grit size of the diamond or cbn particles, determines the surface finish and cutting efficiency. Finer grits produce smoother finishes, while coarser grits are used for faster cutting of harder materials.

-

Fine Grit:deal for precision cutting and smooth surface finishes.

Fine Grit:deal for precision cutting and smooth surface finishes.

-

Coarse Grit:Suitable for rapid material removal and cutting harder materials.

Coarse Grit:Suitable for rapid material removal and cutting harder materials.

B. Origin

The origin of the diamonds (natural vs. synthetic) can influence their properties.

-

Natural Diamonds:Generally harder but more variable in quality.

Natural Diamonds:Generally harder but more variable in quality.

-

Synthetic Diamonds: More consistent in quality and tailored for specific applications.

Synthetic Diamonds: More consistent in quality and tailored for specific applications.

C. Type

Different types of diamonds are used depending on the application.

-

Monocrystalline Diamonds:Single crystal structure, offering durability and consistency.

Monocrystalline Diamonds:Single crystal structure, offering durability and consistency.

-

Polycrystalline Diamonds: Multiple crystal structures, providing high wear resistance and toughness.

Polycrystalline Diamonds: Multiple crystal structures, providing high wear resistance and toughness.

D. Shape

The shape of the diamond particles affects cutting efficiency and blade life.

-

Cubic:Provides sharp cutting edges and efficient material removal.

Cubic:Provides sharp cutting edges and efficient material removal.

-

Irregular Offers multiple cutting points, enhancing cutting efficiency.

Irregular Offers multiple cutting points, enhancing cutting efficiency.

E. Grade

The grade of the diamonds refers to their overall quality, including purity and defect levels.

-

High-Grade:Few impurities and defects, ensuring superior cutting performance.

High-Grade:Few impurities and defects, ensuring superior cutting performance.

-

Low-Grade: More impurities and defects, suitable for less demanding applications.

Low-Grade: More impurities and defects, suitable for less demanding applications.

F. Quality

The overall quality of the diamonds used in the blade impacts its performance and lifespan.

-

Premium Quality:Long-lasting and high-performance, suitable for critical applications.

Premium Quality:Long-lasting and high-performance, suitable for critical applications.

-

Standard Quality: Adequate for general-purpose cutting tasks.

Standard Quality: Adequate for general-purpose cutting tasks.

G. Coating

Diamonds can be coated to enhance their properties, such as bonding strength and thermal stability.

-

Nickel Coating:Improves diamond retention in the bond.

Nickel Coating:Improves diamond retention in the bond.

-

Titanium Coating: Enhances thermal stability and wear resistance.

Titanium Coating: Enhances thermal stability and wear resistance.

H. Friability

Friability refers to the diamond’s tendency to fracture. Controlled friability ensures self-sharpening of the blade.

-

High Friability:Self-sharpens but wears out faster.

High Friability:Self-sharpens but wears out faster.

-

Low Friability: Lasts longer but may require frequent dressing.

Low Friability: Lasts longer but may require frequent dressing.

I. Hardness

The hardness of the diamonds determines their ability to cut through materials.

-

Higher Hardness: Suitable for cutting hard materials.

Higher Hardness: Suitable for cutting hard materials.

-

Lower Hardness: Used for softer materials.

Lower Hardness: Used for softer materials.

2. Bond Type & Composition

The bond holds the diamond or cbn particles in place and wears away to expose new diamond cutting edges. Its properties are critical to blade performance.

A. Type

The bond type varies depending on the application and material.

- Metal Bond (Sintered): Durable and wear-resistant, suitable for hard materials.

- Resin Bond: Provides a smoother finish, ideal for delicate materials.

- Hybrid Bond: Combines properties of metal and resin bonds for versatile performance.

- Nickel Bond - A medium hardness bond that offers a balance between durability and flexibility

- Braised Bond - strong, durable bond that holds abrasive grains securely, ideal for aggressive cutting and rapid stock removal

B. Density

The density of the bond affects the blade’s cutting ability and wear rate.

-

High Density:Provides greater support for diamonds, extending blade life.

High Density:Provides greater support for diamonds, extending blade life.

-

Low Density: Wears away quickly, exposing new diamonds faster.

Low Density: Wears away quickly, exposing new diamonds faster.

C. Hardness

The bond’s hardness must match the material being cut.

-

Hard Bond:Used for soft, abrasive materials to minimize bond wear.

Hard Bond:Used for soft, abrasive materials to minimize bond wear.

-

Soft Bond:Suitable for hard materials to ensure efficient diamond exposure.

Soft Bond:Suitable for hard materials to ensure efficient diamond exposure.

D. Concentration

The concentration of diamonds or cbn particles within the bond impacts cutting efficiency.

-

High Concentration: Increases cutting speed and longevity.

High Concentration: Increases cutting speed and longevity.

-

Low Concentration: Reduces cost but may wear out faster.

Low Concentration: Reduces cost but may wear out faster.

E. Tensile Strength

The bond’s tensile strength ensures it can withstand cutting stresses without breaking.

-

High Tensile Strength: Suitable for high-stress applications.

High Tensile Strength: Suitable for high-stress applications.

-

Moderate Tensile Strength: Adequate for general-purpose cutting.

Moderate Tensile Strength: Adequate for general-purpose cutting.

F. Kerf Angle

The angle of the kerf (cut created by the blade) affects the quality and efficiency of the cut.

-

Narrow Kerf:Reduces material waste and requires less power.

Narrow Kerf:Reduces material waste and requires less power.

-

Wide Kerf: Suitable for thicker materials but increases material waste.

Wide Kerf: Suitable for thicker materials but increases material waste.

3. Metal Core

The metal core provides the structural backbone of the blade, affecting its stability and performance.

A. Thickness

The thickness of the core influences the blade’s stability and cutting performance.

-

Thicker Core:Provides stability and reduces blade flexing.

Thicker Core:Provides stability and reduces blade flexing.

-

Thinner Core: Allows for finer cuts and is less resistant to flexing.

Thinner Core: Allows for finer cuts and is less resistant to flexing.

B. Tensioning

Tensioning ensures the blade runs true and reduces wobbling.

-

Proper Tensioning:Essential for maintaining blade stability and cut quality.

Proper Tensioning:Essential for maintaining blade stability and cut quality.

-

Improper Tensioning: Leads to blade wobble and poor cutting performance.

Improper Tensioning: Leads to blade wobble and poor cutting performance.

C. Gullet Design

The gullets (spaces between the segments) are designed to remove debris and reduce heat.

-

Large Gullets:Improve debris removal and cooling but may reduce blade stability.

Large Gullets:Improve debris removal and cooling but may reduce blade stability.

-

Small Gullets: Increase stability but may require more frequent cleaning.

Small Gullets: Increase stability but may require more frequent cleaning.

D. Grade

The grade of the metal core affects its durability and performance.

-

High-Grade Steel:Offers superior strength and longevity.

High-Grade Steel:Offers superior strength and longevity.

-

Standard-Grade Steel: Suitable for less demanding applications.

Standard-Grade Steel: Suitable for less demanding applications.

E. Hardness

The hardness of the metal core ensures it can withstand the rigors of cutting.

-

High Hardness:Provides better stability and longer life.

High Hardness:Provides better stability and longer life.

-

Moderate Hardness: Adequate for general-purpose cutting.

Moderate Hardness: Adequate for general-purpose cutting.

Understanding and Selecting Diamond Blade Specifications

The parameters outlined will play a major role in determining diamond blade performance. For a diamond blade manufacturer to recommend the right blade for your application, it is critical that the customer provides as much application information as possible. The first step in this process is to consider the properties of the material to be cut and to match the diamond blade properties to this material. The table below illustrates a general matching of three basic blade properties to three basic material properties.

Common non-metallic materials cut with diamond blades vary widely, from hard, dense products like high alumina to loosely bonded, highly abrasive products like concrete blocks. While this guide does not list specific diamond mesh sizes, concentrations, or bond hardness required to cut these materials, it serves as a general framework for selecting Diamond & CBN blade specifications.

For instance, Table 2 indicates that hard metal bonds are selected for highly abrasive materials. Although physical properties are of primary importance in selecting blade properties, chemical properties can also play an important part. With refractory materials, for example, a high alumina content usually indicates that the material will be dense and hard, necessitating the use of softer bond types and finer diamond mesh sizes.

|

Material Properties |

Blade Properties |

|---|---|

|

High Abrasiveness |

Hard metal bonds |

|

High Density and Hardness |

Softer bonds and finer diamond mesh sizes |

|

Low Density and Softness |

Standard bonds and coarser diamond mesh sizes |

This information should be used as a guide to help in selecting the appropriate diamond blade specifications for various materials. By providing detailed application information, you can ensure that the diamond blade manufacturer can recommend the most suitable blade for your specific needs.

Matching Basic Blade Properties to Material Properties

The second step in the blade selection process is to consider the effects of operating conditions on the diamond or cbn blade. The table below shows these anticipated effects.

An operating condition that causes a diamond or cbn blade to have a shorter life and a faster cutting rate is said to make the blade act softer. Conversely, a blade with a longer life and a slower cutting rate is considered to have a harder cutting action.

After tentatively selecting a combination of blade materials based on the material properties guidelines in Table 2, adjustments to the diamond blade materials can be made if specific operating conditions affect the blade's hardness.

Material Properties Affect on Diamond & CBN Blade Speciation

|

Material Properties |

Basic Blade Properties |

Diamond Size |

Concentration |

Hardness |

|---|---|---|---|---|

|

Hardness |

Hard |

Fine |

Low |

Soft |

|

Soft |

Coarse |

High |

Hard |

|

|

Density |

High |

Fine |

Low |

Soft |

|

Low |

Coarse |

High |

Hard |

|

|

Abrasiveness |

Low |

Fine |

Low |

Soft |

|

High |

Coarse |

High |

Hard |

Effects of Operating Conditions on Diamond Blade

|

Operating Condition |

Effect on Blade Life |

Effect on Cutting Rate |

Blade Action |

|---|---|---|---|

|

High Speed |

Shorter |

Faster |

Softer |

|

Low Speed |

Longer |

Slower |

Harder |

|

High Feed Rate |

Shorter |

Faster |

Softer |

|

Low Feed Rate |

Longer |

Slower |

Harder |

|

Inadequate Coolant Flow |

Shorter |

Faster |

Softer |

|

Adequate Coolant Flow |

Longer |

Slower |

Harder |

|

High Pressure |

Shorter |

Faster |

Softer |

|

Low Pressure |

Longer |

Slower |

Harder |

When specific operating conditions are known to impact blade hardness, adjustments should be made accordingly. This ensures optimal performance and efficiency of the diamond or cbn blade in your specific application. By understanding and incorporating both material properties and operating conditions, users can achieve superior cutting results and extend the life of their diamond or cbn blades.

Effects of Various Operating Conditions on Blade Action

|

Operating Condition |

Blade Action |

Effect on Diamond Blade Life |

Cutting Rate |

|---|---|---|---|

|

Machine |

|||

|

Old |

Softer |

Shorter |

Faster |

|

New |

Harder |

Longer |

Slower |

|

Operating Speed |

|||

|

High |

Harder |

Longer |

Slower |

|

Low |

Softer |

Shorter |

Faster |

|

Infeed Rate |

|||

|

Fast |

Softer |

Shorter |

Faster |

|

Slow |

Harder |

Longer |

Slower |

|

Horsepower |

|||

|

High |

Harder |

Longer |

Slower |

|

Low |

Softer |

Shorter |

Faster |

|

Coolant Volume |

|||

|

High |

Harder |

Longer |

Slower |

|

Low |

Softer |

Shorter |

Faster |

|

Cutting Depth |

|||

|

Shallow |

Softer |

Shorter |

Faster |

|

Deep |

Harder |

Longer |

Slower |

Machine Age:

-

Old Machines:Tend to produce a softer blade action, leading to a shorter blade life but a faster cutting rate. This might be due to wear and tear reducing the machine’s efficiency in maintaining optimal blade stability.

Old Machines:Tend to produce a softer blade action, leading to a shorter blade life but a faster cutting rate. This might be due to wear and tear reducing the machine’s efficiency in maintaining optimal blade stability.

-

New Machines: Generally offer harder blade action, promoting longer blade life but at a slower cutting rate. This can be attributed to better precision and stability in newer machines.

New Machines: Generally offer harder blade action, promoting longer blade life but at a slower cutting rate. This can be attributed to better precision and stability in newer machines.

Operating Speed:

-

High Speed:Results in harder blade action which extends the life of the blade but decreases the cutting rate due to the increased heat and potential for blade wear.

High Speed:Results in harder blade action which extends the life of the blade but decreases the cutting rate due to the increased heat and potential for blade wear.

-

Low Speed: Causes softer blade action, reducing blade life but increasing the cutting rate because of the reduced heat generation and mechanical stress.

Low Speed: Causes softer blade action, reducing blade life but increasing the cutting rate because of the reduced heat generation and mechanical stress.

Infeed Rate:

-

Fast:Softens the blade action, shortens the life but increases the cutting rate. This could be due to the increased mechanical load causing quicker wear.

Fast:Softens the blade action, shortens the life but increases the cutting rate. This could be due to the increased mechanical load causing quicker wear.

-

Slow: Hardens the blade action, which prolongs the life of the blade and decreases the cutting rate, likely due to less stress on the blade per unit of time.

Slow: Hardens the blade action, which prolongs the life of the blade and decreases the cutting rate, likely due to less stress on the blade per unit of time.

Horsepower:

-

High: Provides a harder blade action, lengthening blade life and reducing the cutting rate. Higher horsepower might stabilize the blade and reduce the blade’s exposure to mechanical stresses per cut.

High: Provides a harder blade action, lengthening blade life and reducing the cutting rate. Higher horsepower might stabilize the blade and reduce the blade’s exposure to mechanical stresses per cut.

-

Low: Leads to softer blade action, shorter blade life, and a faster cutting rate, likely because the blade isn’t driven as forcefully.

Low: Leads to softer blade action, shorter blade life, and a faster cutting rate, likely because the blade isn’t driven as forcefully.

Coolant Volume:

-

High:Harder blade action, longer blade life, and slower cutting rates. This may be because ample coolant reduces overheating and wear.

High:Harder blade action, longer blade life, and slower cutting rates. This may be because ample coolant reduces overheating and wear.

-

Low: Softer blade action, shorter blade life, and faster cutting rates, possibly due to less effective cooling and lubrication.

Low: Softer blade action, shorter blade life, and faster cutting rates, possibly due to less effective cooling and lubrication.

Cutting Depth:

-

Shallow: Results in softer blade action, shorter blade life, and faster cutting rates. Shallow cuts reduce mechanical stress per cut.

Shallow: Results in softer blade action, shorter blade life, and faster cutting rates. Shallow cuts reduce mechanical stress per cut.

-

Deep Causes harder blade action, which extends blade life and reduces cutting rates, likely due to increased stability and effective use of the blade's cutting edge.

Deep Causes harder blade action, which extends blade life and reduces cutting rates, likely due to increased stability and effective use of the blade's cutting edge.