-

0 items in quote

No products in the Quote Basket.

Diamond Tools For Contractor Applications

UKAM Industires Superhard Tools

Diamond Tools for Contractors

UKAM Industrial Superhard Tools specializes in manufacturing and offering a wide range of high-quality standard and custom tools for contractors. Our produced offers superior level of performance compared to what is typically available in the market. While standard tools for concrete and construction may be sufficient in many cases, they often fall short when dealing with tougher materials and challenging applications. That's where we excel. When your standard tools fail to meet the cutting requirements, we have the solution you need. As a small American diamond tool manufacturer, we distinguish ourselves through our commitment to quality, high-performance capabilities, excellent value, and the ability to deliver unique and customized solutions.

Let our experience work for you!

We manufacture tools in-house while also collaborating with renowned manufacturers in Europe and Asia who produce tools according to our specifications. Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards

With a team of highly knowledgeable and experienced engineers, we possess a deep understanding of the challenges you encounter when cutting, drilling, grinding, and polishing concrete and construction materials. This expertise is gained from decades of experience manufacturing sophisticated and high precision tools and equipment for advanced industries and complex applications. Unlike other companies that exclusively focus on tools for the concrete and construction industries, we offer unique solutions that surpass their capabilities and expertise. As pioneers in new product development, we continuously raise standards for the whole industry.

Solutions For

Cutting Concrete & Construction Materials

We have Diamond Blades available from 0.5” to 48” OD, Used for cutting large variety of concrete and construction. We have large variety of blades in stock and can custom manufacture almost any specification. We machine custom arbor sizes, pin holes and even restore and retip blades if needed in our machine shop. Contact us for volume pricing

Solutions For

Drilling Concrete & Construction Materials

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond cup wheels, polishing discs and accessories for grinding and polishing all types of lapidary materials.. Below you will find information, specifications & prices on all diamond cup wheels and polishing discs for this application. Contact us for volume pricing. We can also produce any custom diamond tool per your specification.

Solutions For

Grinding Concrete & Construction Materials

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond cup wheels, polishing discs and accessories for grinding and polishing all types of lapidary materials.. Below you will find information, specifications & prices on all diamond cup wheels and polishing discs for this application. Contact us for volume pricing. We can also produce any custom diamond tool per your specification.

Diamond Routers , Diamond Points, Profile Tools, & Milling Tools

Large variety of diamond & cbn tools from stock and made to your specifiction using all bond types. Products include:

- Carving Points

- Mounted Points

- Diamond Counter Tools

- Grinding Pins

- Routers

- ID Grinding Points

- Jig Grinding Mandrels

- Countersinks

- Counter Bores

- Milling Tools

- Generating Tools

- Face Grinding Tools

- Chamfer Tools

- Radius Tools

- Profiling Tools

- Ball Nose Tools

- Ball Nose Tools

- Bottom Grinding Tools

- Reamers

- Honing Tools

- Honing Tools

- Endmills

- Threading Tools

Contact Us For free Quote & Recommendation

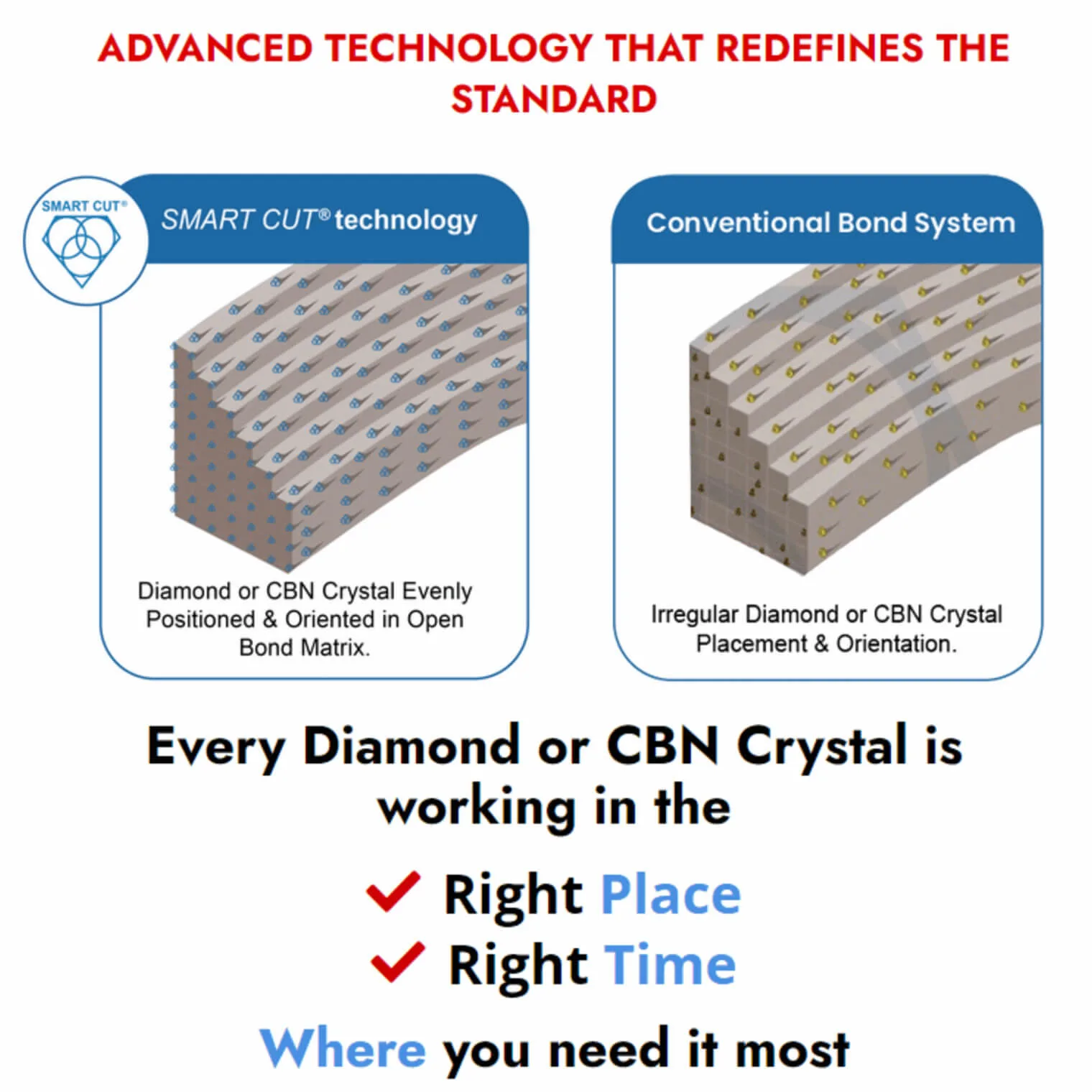

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

SMART CUT® technology

How SMART CUT ® Bond Works?

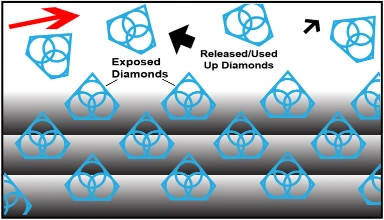

Step 1

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

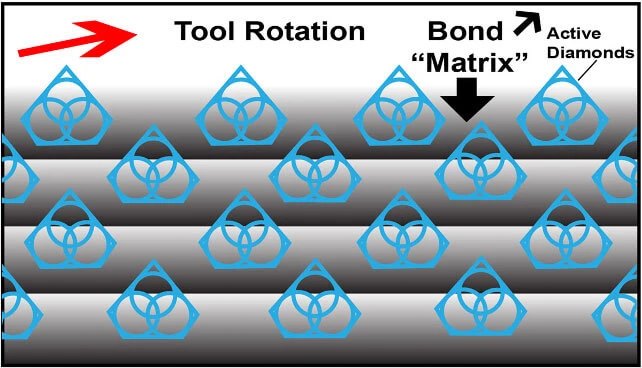

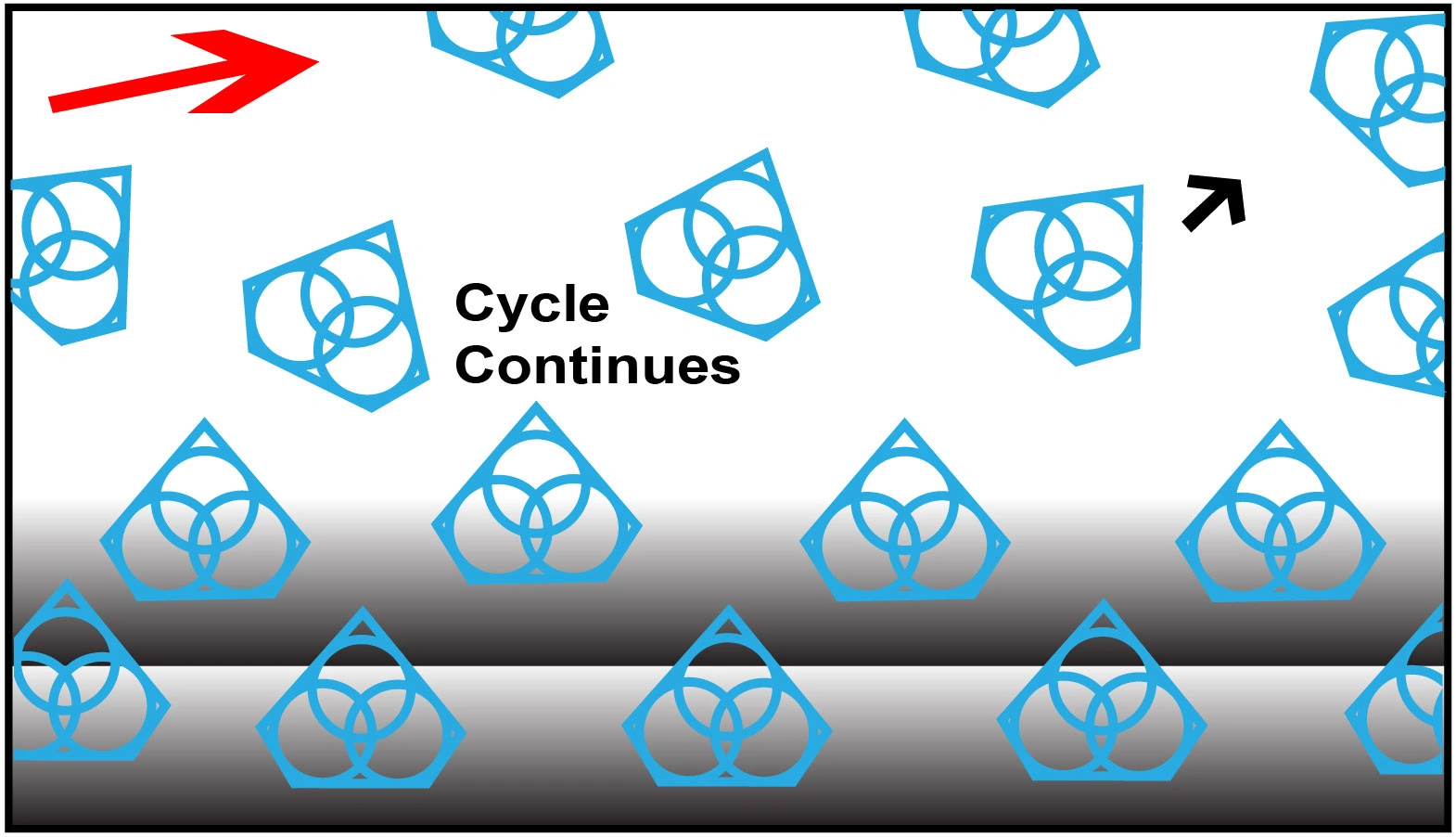

Step 2

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Why Work With Us?

Comprehensive Source Of Information On Diamond Tools

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting, drilling, grinding and polishing on the web. Find everything you ever wanted to know about diamond tools.

Large Inventory & Custom Manufacturing

We have the largest variety of diamond tools available in stock. we regularly produce custom diamond tools to better fit customers specific needs & specifications. Just about any diamond tool can be designed and manufactured per customer drawing or specifications.

Umatched Technical Support

WE ARE A PARTNER IN YOUR SUCCESS

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality & Consistency

Different Product

Different Company

Different Technology

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

EXPECT MORE FROM YOUR TOOLS

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

With a team of highly knowledgeable and experienced engineers, we possess a deep understanding of the challenges you encounter when cutting, drilling, grinding and polishing. This expertise is gained from decades of experience manufacturing sophisticated and high precision tools and equipment for advanced industries and complex applications. Unlike other companies that exclusively focus on tools for the stone and construction industries, we offer unique solutions that surpass their capabilities and expertise.

Best Value For The Money

We are always looking for partners to work with in expanding the market reach. We produce and offer highest quality products at very attractive pricing. While we may not be the lowest cost solution provider. Our products offer one of the best Return on Investment available & quality, that you cant find anywhere. We offer amazing discounts based on quantity. Lets us develop a win, win relationship.

Unmatched Performance & Quality

Our standard and custom products offer the best performance and value for your money.

count on us to provide higher level of performance compared to what is typically available in the market. While standard tools for stone may be sufficient in many cases, they often fall short when dealing with tougher materials and challenging applications.

Don't struggle with inferior tools - DEMAND THE BEST!

Time, Money, & Material - you will save will more than pay for these TOOLS in short period of time

Let Us Help You:

- Improve Tool Life

- Save Time & Money

- Obtain More Consistent Results

- Improve Surface Finish

- Preserve True Material Microstructure

- Reduce & eliminate Material Deformation

- Improve Tool Lite & Overall Performance

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...