Precision Conventional Abrasives

UKAM Industrial Superhard Tools offers larger variety of precision abrasives for sample and surface preparation of larger variety of materials. We offer standard stock products available from stock or with short lead time and custom manufacturing to fit your specifications

Some of our standard products include:

- Abrasive Cut Off Blades

- Abrasive Discs

- Abrasive Rolls/Strips

- Abrasive Belts

- Abrasive Grinding Wheels

- Dressing Sticks

- Abrasive Film

- Abrasive Powders

- Abrasive Suspensions

Established in 1990

Ultra Thin Abrasive

Cut off Blades For Low & High Speed Wafering Saws

Used On: All Low & High Speed Wafering Saws, Sectioning Saws, Such as Buehler, Struers, Leco, & many others.

Available from stock from 4” (100mm) to 8” (200mm). Thicknesses range from .012” (0.3 mm) to .035” (0.8mm). Stadard arbor size is ½” (12.7mm). Our SMART CUT series Ultra Thin Abrasive Cutt off blades are Formulated for fast sectioning with minimum kerf loss. They Provide for cool cutting action & Minimize the structural damage to the sample/material. The silicon carbide wheels are formulated for non-ferrous and non-metallic materials. The aluminum oxide wheels are designed for ferrous materials.

Abrasive Cut off

Blades for Abrasive Cut off Saws

Used On: : All High Speed Wafering Saws, Sectioning Saws, Such as Buehler, Struers, Leco, & many others.

Choose from a large selection (57 different wheels) of application specific blades. The silicon carbide wheels are formulated for non-ferrous and non-metallic materials. The aluminum oxide wheels are designed for ferrous materials. Coarse grits will cut heavier sections faster and cooler. Fine grits produce better surfaces and less burning on delicate pieces. Soft wheels break down faster exposing new cutting surfaces more rapidly - preferred for hard materials. Hard wheels break down slower, wear longer and are recommended for softer materials

Silicon Carbide

Grinding Discs

Our high quality SiC Grinding Papers are Comparable to Buehler, Struers, Leco & many others. They are used for coarse and fine grinding of a wide variety of materials and metallurgical specimens (specially metals). The advantage of using SiC paper include: Easy to use, Repeatable - Relatively lower cost to other options. available in plain and Pressure Sensitive Adhesive (PSA) backing. Please note that other sizes, hole diameters, and grit sizes are available. The grit sizes listed are USA standards. Available in US ANSI grit sizes from F60 to F1200

Silicon Carbide

Grinding Paper

Abrasive Sheets are fabricated with high quality C weight paper used for coarse and fine Wet/Dry grinding of a wide variety of materials and metallurgical specimens. Our durable industry leading silicone carbide sheets are available in a standard size of 9”x 11” with plain and Pressure Sensitive Adhesive (PSA) backing. Please note that other sizes and grit sizes are available.

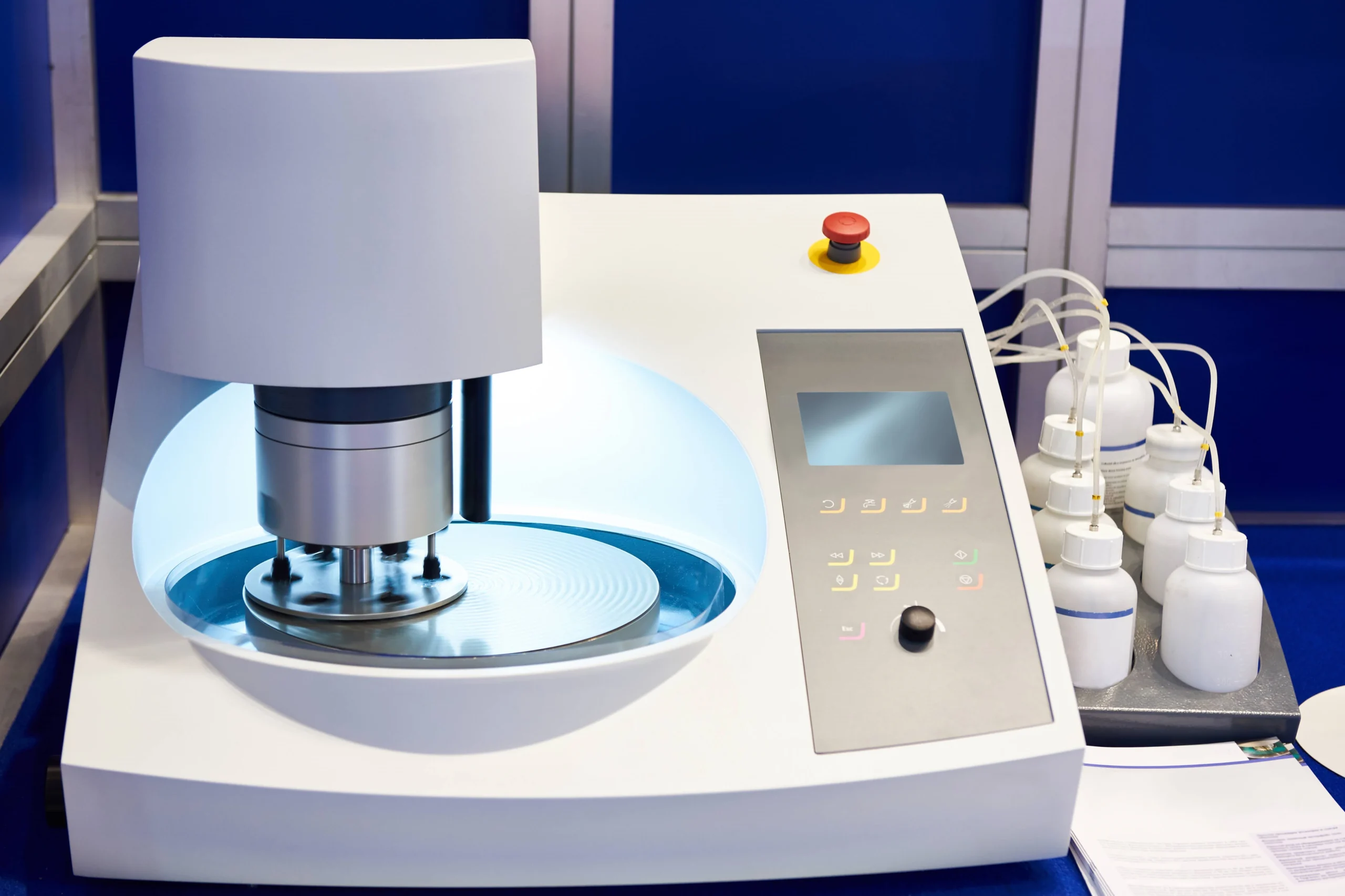

Metallographic

Polishing Pads

We offer large variety of polishig pads from 8” (200mm) to 12” (300mm) diameter with PSA ahesive or magnetic backing. Comparable to Buehler, Struers, Leco & many others. Polishing cloths are avaible with different fiber height (nap) and stiffness/resiliency of fiber. Lower nap (also non-woven) and stiffer fiber cloths are used for the rough polishing steps. These types of polishing cloths or pads are very effective in removing sectioning damage done by cutting and coarse grinding. Higher napped polishing cloths provide a more gentle abrasive interaction for the final polish.

Zirconia

Grinding Paper

For longer life, coarse grinding zirconia abrasive disks are especially useful. Zirconia abrasives are much more durable than either alumina or silicon carbide abrasives, however, to be effective higher applied grinding forces are required.

Diamond

Diamond & Abrasive Film

Lapping Films are ultra-fine, uniformly coated abrasive high performance films for use in lapping and polishing operations. Comparable to Buehler, Struers, Leco & many others. These are available from 8” (200mm) to 12” (300mm) with psa adhesive and no backing. Lapping films are available in silicon carbide, alumina and diamond abrasive . These are used for metal, ceramic, electronic, and lapidary fields. These films are ideally suited for use on flat lapping surfaces where slurries of fine abrasives are used. The coatings are extremely dense and may be used wet or dry.

Abrasive Powders

(Silicon Carbide & Alumina Oxide)

We offer large range of Alumina and Silicon Carbide Powders for polishing samples. These can be mixed with distilled water to create various consistencies, based on your desired mix ratios. Alumina powders are used for final polishing of metallographic specimens. Accurately controlled purity levels and particle size distribution assure optimum polishing results. Mix with DI water to produce a liquid slurry. Silicon carbide powders are used for grinding petrographic thin sections and for flat lapping of hard metal plates.

Abrasive Suspensions

(Alumina & Cerium Oxide)

Used for final polishing, colloidal and alumina suspensions are mixtures of abrasive particles dispersed throughout a chemically aggressive liquid carrier. This combination provides a chemical-mechanical polishing action, resulting in deformation-free surfaces. Our Abrasive Suspensions allow for versatility of application by automatic, manual or gravity fed systems. Our liquid carrier permits the particles to remain totally suspended, thus avoiding agglomerates and sedimenting. Sizes Available: 0.5 µm, to 5µ

Lubricants

Lubricants

Lubricants are used to enhance the polishing performance of diamond suspensions, compounds, sprays and films. They reduce friction and increase the life of polishing cloths. All 16 and 32 oz. bottles include trigger sprayer and flip-top for dispensing. Apply manually or with automatic dispensing systems. Our Lubricants have been specially designed to allow for versatility of application by automatic, manual or gravity fed systems. Our liquid carriers permits the particles to remain totally suspended, thus avoiding agglomerates and sedimenting. Available in 16 oz (480 ml), 32 oz (950 ml), 128 oz (3.8 L) & 640 oz (19 L) containers

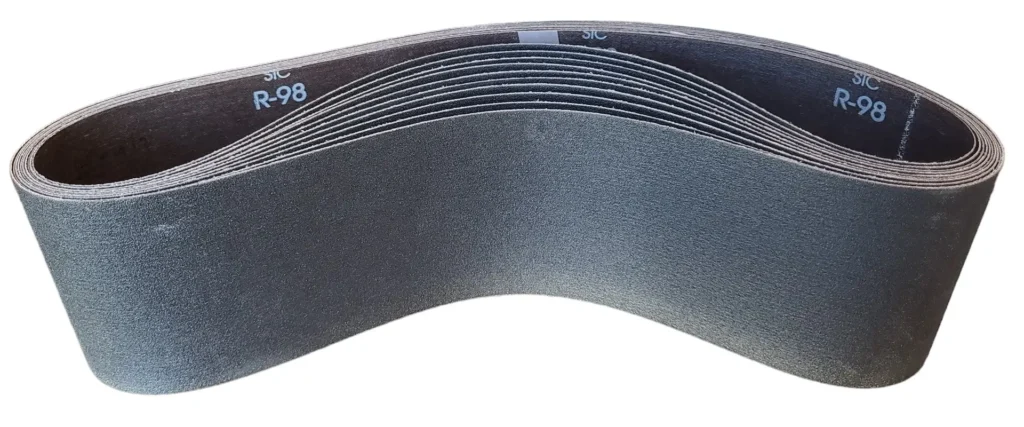

Abrasive Belts

(Silicon Carbid, Zirconia, & Alumina)

Abrasive Belts are offered in aluminum oxide, silicon carbide and zirconia alumina. Comparable to Buehler, Struers, Leco & many others. Our belts are resin bond for both wet and dry use. Please note that other sizes and grit sizes are available. Grit sizes from 40 to 400 mesh. Dimensions: 4” x 36” to fit most abrasive grinding machines

Silicon Carbide

Grinding Rolles

Abrasive Rolls are fabricated with high quality C weight paper used for coarse and fine Wet/Dry grinding of a wide variety of materials and metallurgical specimens. Our durable industry leading silicone carbide rolls are available in plain backing. All rolls are wrapped around 1/2” paper cores, except 4” rolls which are wrapped around 3-3/8” diameter plastic spools with 1” center holes. Please note that other sizes and grit sizes are available.

Contact Us for FREE Quote & Recommendation

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

WE ARE A PARTNER IN YOUR SUCCESS

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

AMERICAN MANUFACTURER

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Save Money Save up to 650%

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

Advanced Technology

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years Let Us Help You