-

0 items in quote

No products in the Quote Basket.

Diamond Wire

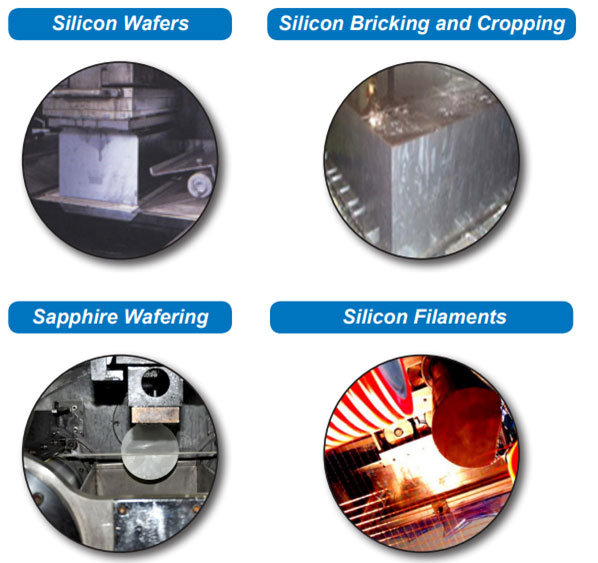

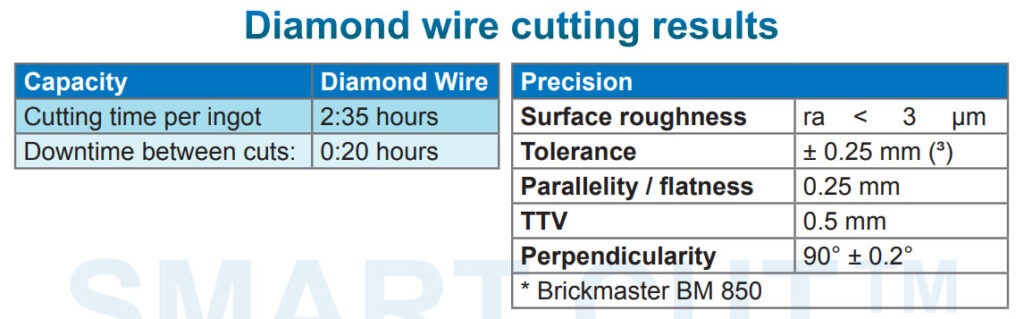

SMART CUT Diamond wire produces minimum kerf loss, less sub-surface damage, and contamination free coolant. Used for precision cutting of various types of artificial crystal, ceramic, quartz glass, monocrystalline silicon, polycrystalline silicon, sapphire and special metal materials. Diamond Wire cutting is an environmentally friendly cutting process as it eliminates slurry recycling and disposal issues.

It is widely used for slicing artificial crystals, ceramics, quartz glass, monocrystalline and polycrystalline silicon, sapphire, and specialty metals. The design provides high dimensional accuracy and smooth surfaces, often eliminating the need for extensive secondary processing.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

It is widely used for slicing artificial crystals, ceramics, quartz glass, monocrystalline and polycrystalline silicon, sapphire, and specialty metals. The design provides high dimensional accuracy and smooth surfaces, often eliminating the need for extensive secondary processing.

SMART CUT® Diamond wire cutting is also an environmentally responsible process, as it eliminates slurry recycling and disposal issues common in older abrasive methods. This makes it the preferred choice for laboratories and production environments that require consistent quality, process stability, and compliance with modern environmental standards.

SPECIFICATIONS

Tab Content

FREQUENTLY ASKED QUESTIONS

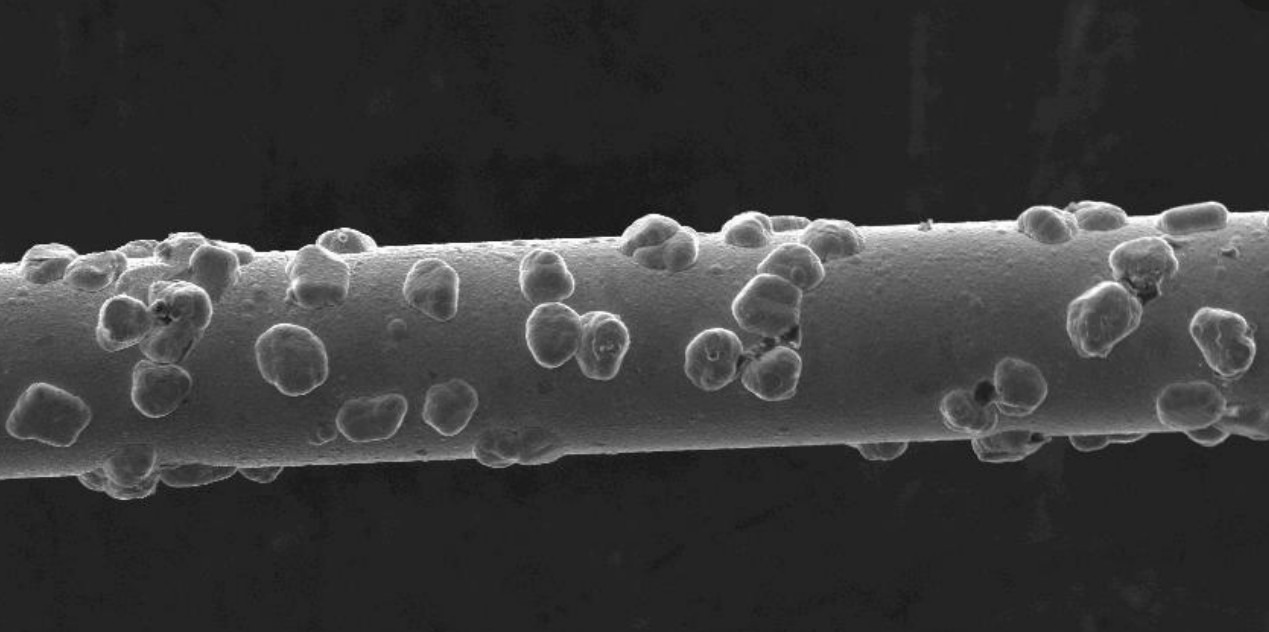

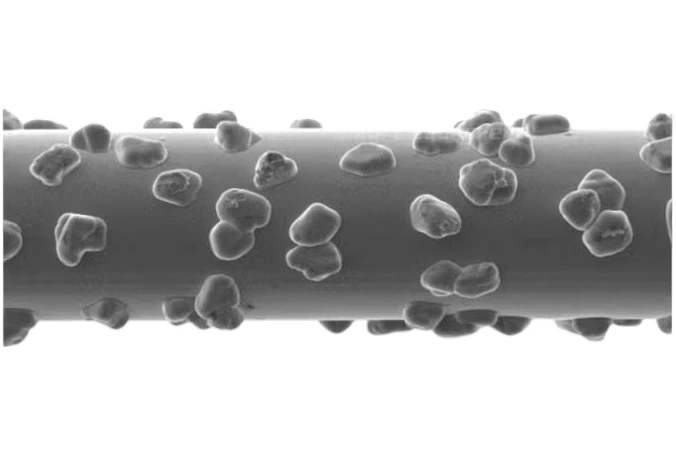

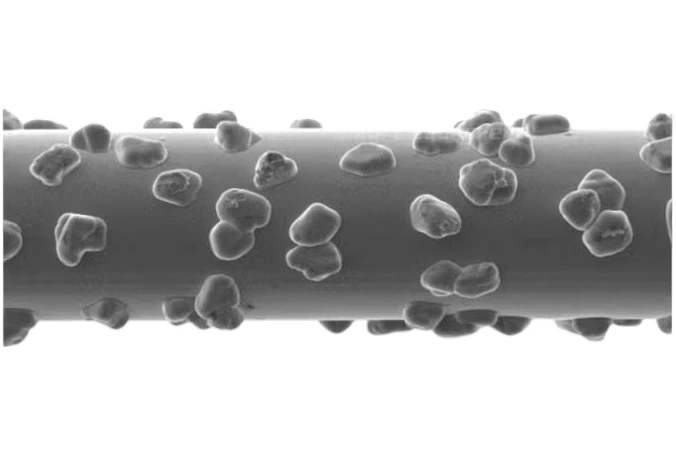

Diamond wire is a cutting technology that involves a multi-stranded cable impregnated with diamond grains. These diamonds, being the hardest material, allow the wire to cut through very hard materials like silicon, ceramics, sapphire, and various crystals with precision.

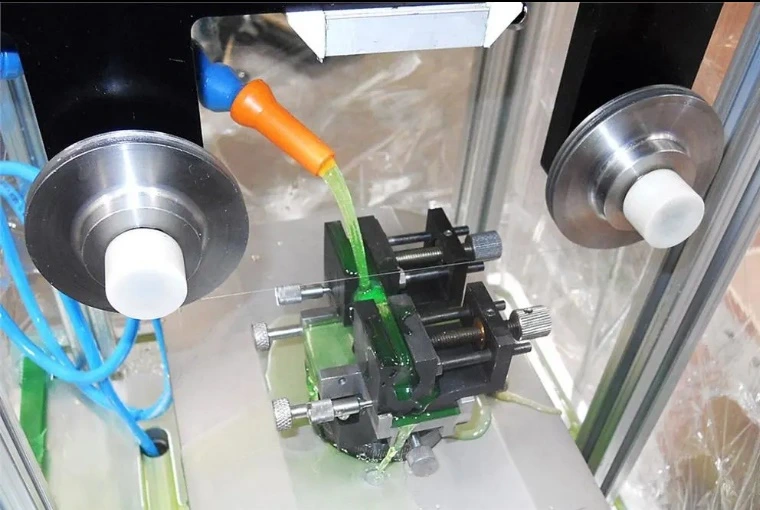

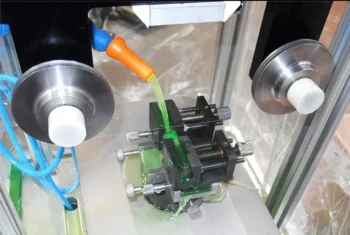

The process involves running the diamond-impregnated wire at high speed while it’s pulled through the material that needs cutting. The cutting action is a combination of sawing and grinding, where the diamonds abrade the material to create a cut or kerf.

Diamond wire provides a very precise cut with minimal damage to the material. It’s capable of slicing through hard, brittle materials that would be difficult or impossible to cut with other methods. It also allows for cutting complex shapes and maintaining tight tolerances.

Diamond wire can be reused to some extent; however, its lifespan depends on several factors such as the type of material being cut, the speed of the cutting, the wire tension, and the quality of the wire. Eventually, the diamonds wear down, and the wire needs to be replaced.

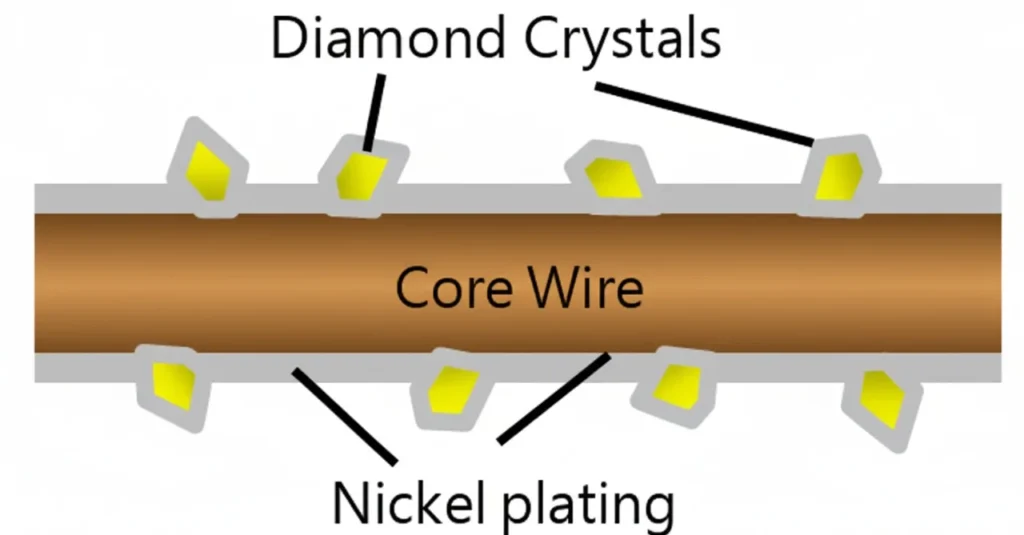

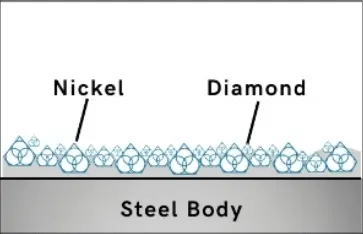

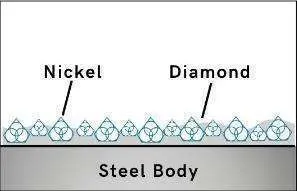

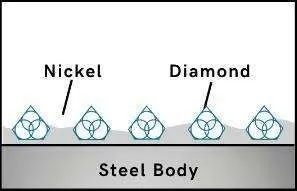

There are mainly two types of diamond wire: electroplated and sintered. Electroplated wires have diamonds bonded to the wire with a single layer of nickel or other metal, whereas sintered wires have diamonds that are embedded into a metal matrix that wears down over time, continuously exposing new diamond grains.

Diamond wire cutting can be hazardous if proper safety measures are not followed. The wire can break under high tension, potentially causing injury. Additionally, the process can produce silica dust, which is hazardous to inhale. Always wear appropriate personal protective equipment (PPE) and follow safety guidelines.

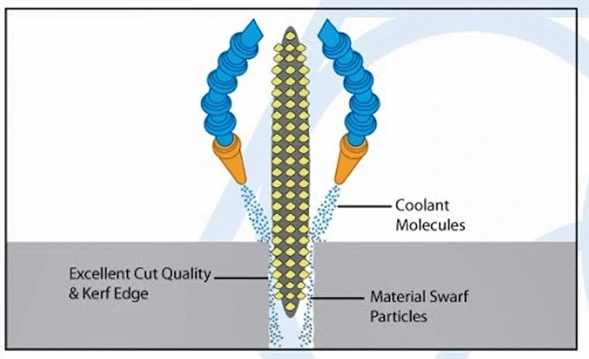

Yes, water is often used both as a coolant and to remove slurry and cut debris from the cutting area. It also helps to extend the life of the diamond wire by reducing frictional heat and wear.

The cutting speed can vary depending on the system and material, but typically diamond wire saws operate at speeds ranging from 10 to 40 meters per second.

The kerf of the cuts made by diamond wire is very thin, often just a few hundred micrometers, which minimizes material loss and can be important in industries where the material is expensive.

Yes, diamond wire cutting is often automated, which allows for consistent, precise cuts and increased safety. Automation can also lead to increased efficiency and throughput.

Diamond wire can be used to make straight cuts, contour cuts, and can also be shaped to cut complex three-dimensional geometries.

The choice of diamond wire depends on the material to be cut, the desired speed and precision of the cut, the equipment used, and the economics of the operation. Consulting with a diamond wire specialist can help in selecting the right type for your specific application.

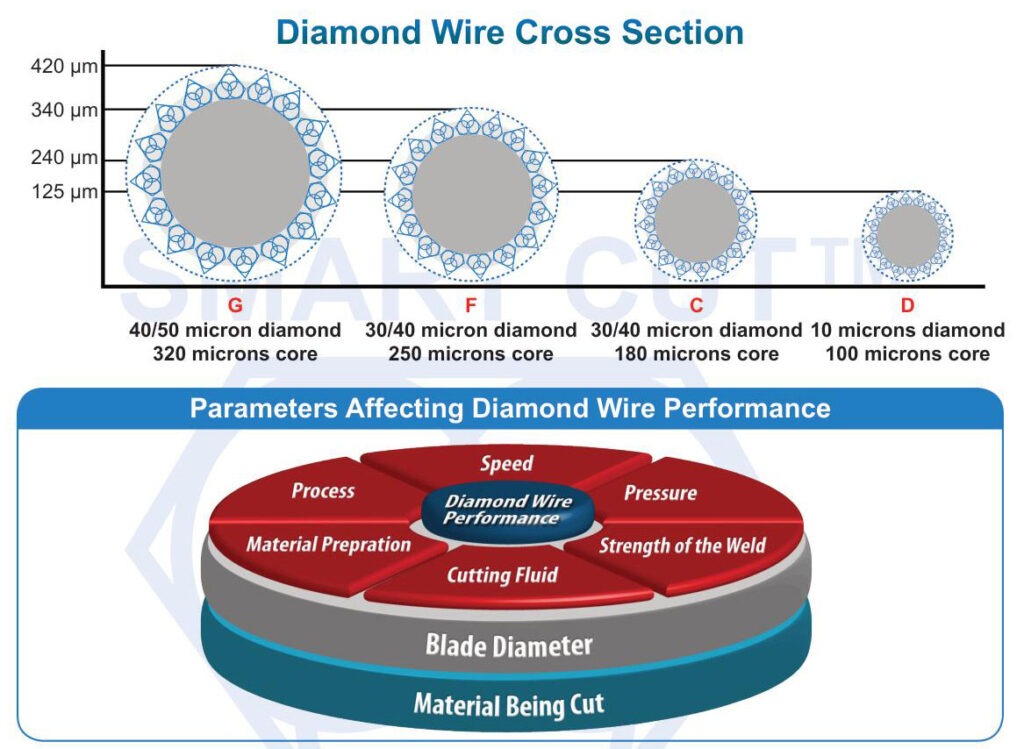

The specifications, such as the diamond size, wire diameter, and bond strength, are typically determined by the hardness and abrasiveness of the material being cut. Softer materials may require larger diamonds, while harder materials might need smaller, finer diamonds for a precise cut.

Wire tension is crucial for cutting accuracy. If the tension is too low, the wire may bow and lead to inaccurate cuts. If it’s too high, it could break the wire or cause premature wear. Tension must be carefully controlled and is often managed automatically by the cutting equipment.

Regular maintenance includes checking wire tension, inspecting the wire for wear or damage, ensuring that pulleys and guides are not worn out, and monitoring the water supply system for adequate flow and filtration. The machine itself may require lubrication and alignment checks.

Diamond wire cutting is relatively environmentally friendly as it reduces material waste due to the thinness of the cut. However, the slurry produced must be properly disposed of or recycled, and measures must be taken to minimize water usage and prevent contamination.

Quality assurance for diamond wire typically involves testing for the uniformity of diamond distribution, the strength of the wire, and the bond durability. Manufacturers may also perform cutting tests to ensure that the wire performs as expected for its intended application.

Recent advancements include improved diamond bonding methods, increased wire lifespan, and developments in wire saw machine technology that allow for better control and higher cutting speeds.

Yes, each material may require different cutting techniques. For instance, silicon might be cut at different speeds or tension settings than sapphire due to differences in material properties. Manufacturers often provide recommended parameters for various materials.

Disposal regulations may vary depending on the location and the materials involved. Generally, used diamond wire should be considered industrial waste and disposed of according to local environmental regulations. Some components of the wire may be recyclable.

Yes, the diameter of the wire affects both the cutting process and the material’s surface finish. Thinner wires can make more precise cuts but may also break more easily and may not be suitable for all materials.

While diamond wire may have a higher upfront cost than other cutting methods, its efficiency, precision, and reduced material waste can result in a lower overall cost per cut, especially for expensive and hard-to-cut materials.

Optimal performance can be ensured by selecting the correct wire type and specifications for the material, maintaining the wire saw equipment, using the correct cutting parameters (speed, tension, and coolant flow), and by implementing a regular maintenance and inspection schedule.

Yes, diamond wire cutting can be used for both applications. Surface slicing is common in semiconductor wafer production, while deep cutting may be required for segmenting bulk materials like large sapphires or ceramics.

Continuous cutting involves a wire that is continuously moved through the material, while oscillating cutting involves a wire that moves back and forth in a reciprocating manner. The choice depends on the material and the desired finish.

Wire speed can impact the surface finish and the rate of wire wear. A higher speed may lead to a faster cut but can also cause increased wire wear and a rougher surface finish. Conversely, a slower speed may improve the surface finish and extend wire life but will reduce cutting efficiency.

The bonding matrix holds the diamonds in place on the wire. Its wear rate determines how quickly new diamonds are exposed during the cutting process. A good balance between diamond exposure and matrix wear is crucial for optimal cutting performance.

Unlike traditional blades, diamond wires cannot be sharpened once they become dull. The wire must be replaced when the cutting performance declines to an unacceptable level.

Harder and more abrasive materials will wear down the diamond wire more quickly than softer materials. The cutting parameters and the efficiency of the coolant system also play a significant role in the wire’s lifetime.

Yes, controls such as proper ventilation, dust collection systems, and waste management protocols are necessary to comply with health, safety, and environmental regulations.

Some advanced cutting systems include monitoring technologies that can detect wire wear or breakage, ensuring that maintenance or replacement can be carried out before a failure occurs.

Poor cutting performance can be due to several factors including incorrect tension, excessive wire speed, worn wire, misaligned pulleys, or inadequate cooling. Checking and adjusting these parameters can help to troubleshoot cutting issues.

The cooling system is very important. It not only prevents overheating, which can lead to wire breakage and material damage, but also ensures that debris from the cutting process is cleared from the cut path, allowing for smoother operation and longer wire life.

Cutting complex geometries can introduce challenges such as maintaining wire tension, managing wire wear, and controlling the cutting path. Advanced wire saw systems with computer controls are often required for such tasks.

The grit size of the diamonds affects the cut rate and finish. Coarser grits remove material more quickly but can leave a rougher finish, while finer grits produce a smoother finish but may cut more slowly.

Yes, diamond wire can cut a range of composite materials. It’s effective for composites with hard phases, such as ceramic matrix composites or metal matrix composites with carbide or ceramic phases. The wear on the wire might be higher due to the abrasive nature of these materials.

The concentration of diamonds in the wire affects the cutting efficiency and wire longevity. Higher diamond concentration can increase the cutting rate and extend the wire’s life by reducing the wear on individual diamonds, but it can also make the wire more expensive.

The crystallographic orientation can significantly affect the cutting process. Some crystal planes are harder to cut than others due to differences in bond strength between atoms in the crystal lattice.

Recent advancements include improved wire tension control systems, more precise wire feeding mechanisms, enhanced cooling and debris removal systems, and integration with CNC technology for automated and intricate cutting patterns.

Automated systems typically use sensors to detect changes in wire tension, speed, or vibration that indicate breakage. Some systems may also monitor electrical conductivity or use machine vision systems to detect wire integrity.

Lubrication reduces friction between the wire and the material, which can decrease wire wear and extend its life. It can also improve the surface finish of the cut and help with the removal of cut debris.

While diamond wire cutting is generally precise and causes minimal subsurface damage, improper cutting parameters or a worn wire can result in microcracks, particularly in brittle materials like sapphire or ceramics.

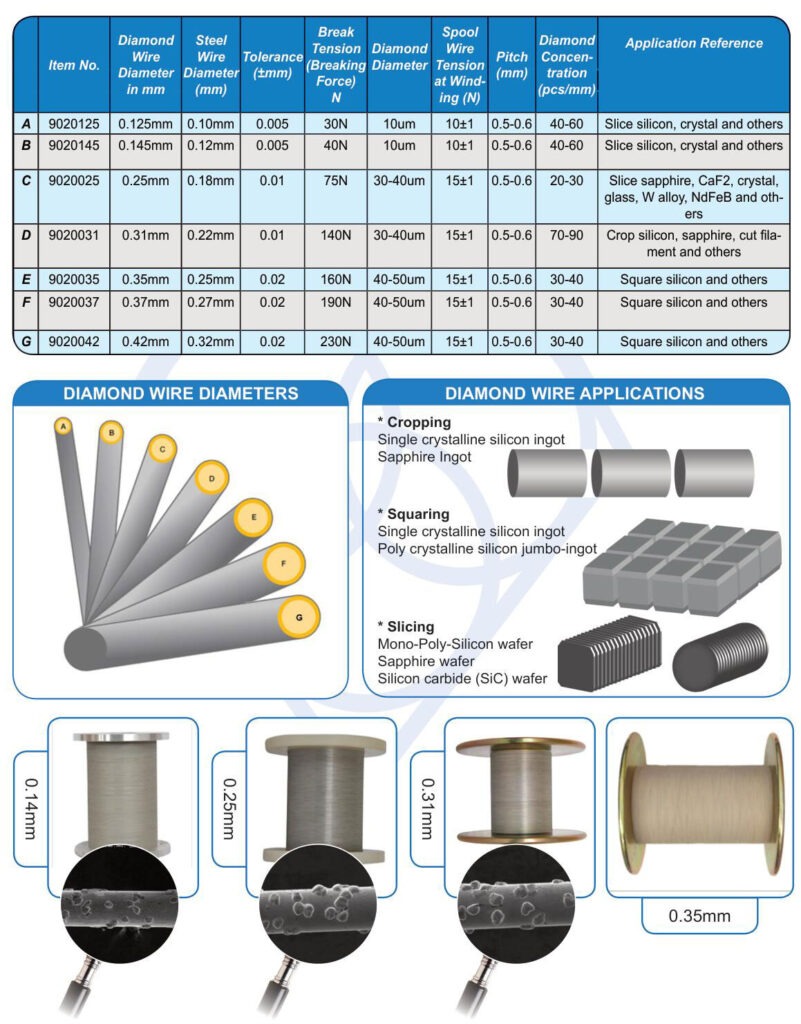

Diamond wires come in various diameters, typically ranging from 0.10 mm to 0.60 mm, though the specific range available can vary depending on the intended application.

The optimal speed for cutting is calculated based on the material’s hardness, abrasiveness, and the desired cut quality. Optimal speeds can also be determined through trial and error or by conducting a series of test cuts.

Diamond wire cutting machines vary from small, benchtop setups for precision work to large industrial machines capable of cutting through large volumes of material. There are also CNC machines that can manipulate the wire in three dimensions for complex shapes and patterns.

To minimize waste, use the thinnest wire that is practical for your application and ensure that cutting parameters are optimized for material conservation. Additionally, computer-aided cutting paths can maximize material usage.

Diamond wire should be stored in a clean, dry environment to prevent corrosion or degradation of the wire or the diamonds. It should also be kept coiled or on a spool to avoid kinks and tension that could lead to breakage.

Material preparation might include cleaning the surface, marking the cutting line, and securing the material to prevent movement during cutting. For some materials, pre-cutting treatments like annealing may be required to reduce internal stresses.

The cross-section can influence the cutting behavior. Round wires are the most common and offer flexibility and uniform wear. Shaped wires can have advantages in certain applications, such as increased cutting speed or a modified kerf profile.

While less common, there are hand-held cutting devices that can use diamond wire for small-scale or precise cutting tasks. These require careful handling to maintain effective tension and avoid wire breakage.

Alternatives include laser cutting, water jet cutting, and traditional blade saws with diamond edges. Each method has its own set of advantages and limitations depending on the specific application requirements. For any cutting operation, especially with materials as diverse as silicon, ceramic, sapphire, and various crystals, it is important to match the cutting technology and parameters to the specific characteristics of the material to achieve the best results.

Safety considerations include wearing appropriate personal protective equipment (PPE), such as gloves, eyewear, and hearing protection. The work area should be well-ventilated, and operators should be trained to handle wire breakage and to avoid being caught in the moving wire.

Factors that can affect accuracy include wire tension, machine calibration, material holding stability, wire wear, and the presence of vibrations during cutting. Consistent monitoring and maintenance can help to mitigate these issues.

Longer wires can dissipate heat more effectively, which can be beneficial when cutting for extended periods. However, longer wires may also be more prone to vibration and require better tension control systems to maintain accuracy.

Diamond wire is generally not repairable. If it is damaged, it is usually discarded because repairing it might compromise its strength and cutting precision.

Wear can be measured by examining the decrease in wire diameter or by using a microscope to assess diamond protrusion and bond wear. Some high-end wire saws have automated systems that monitor wear and performance.

Yes, diamond wire cutting is very suitable for mass production due to its precision and efficiency. It is widely used in industries like semiconductor manufacturing, where wafers need to be sliced from silicon ingots.

Life expectancy varies widely depending on the material being cut, the cutting parameters, and the quality of the wire. Actual life can only be determined based on specific cutting conditions.

Yes, the methods for anchoring the wire can vary between machines. Some use mechanical clamping, others use adhesives, and some might weld the wire to a leader or a connector.

The wire guide system helps maintain the wire alignment and tension. A precise guide system can significantly improve cutting accuracy and help prevent wire breakage.

While the wire itself might not be recyclable due to the small size and dispersion of diamonds, some components of the cutting system or the wire may be made from recyclable materials.

The kerf refers to the width of the cut made by the wire. A smaller kerf means less material is wasted, which is particularly significant when cutting expensive materials like sapphire or certain ceramics.

If the cutting speed drops, check for wire wear, machine alignment, tension settings, and whether the coolant/lubricant system is functioning properly. Adjusting these parameters can restore cutting speed.

High temperatures can degrade the diamond wire more quickly and affect its cutting ability. Proper cooling is essential to maintain optimal temperature and cutting performance.

With the proper equipment, diamond wire can be used to make angled cuts. CNC-controlled wire saws can manipulate the wire to cut complex shapes and angles.

Diamond wire cutting generally offers faster cutting speeds and is more cost-effective for slicing hard materials like silicon, sapphire, and ceramics compared to EDM. However, EDM can produce more intricate cuts and complex geometries without introducing mechanical stress to the material.

While a single wire can cut various materials, it’s not optimal. Different materials can require different diamond sizes, bond types, and wire tensions for efficient cutting. Using a wire optimized for a specific material can extend wire life and improve cut quality.

High humidity can lead to corrosion of the wire, while excessive dust can clog the wire guides and cooling system. Consistent, controlled environmental conditions are preferable for optimal cutting performance and equipment longevity.

Cutting without a coolant is not recommended, as it can lead to overheating, rapid wear of the diamond wire, and possible thermal damage to the material being cut. Coolant serves to lubricate, cool, and remove debris from the cutting area.

Wire tension affects the straightness of the cut and the life of the wire. Too much tension can lead to wire breakage, while insufficient tension can cause the wire to bow or deviate, resulting in inaccurate cuts.

Yes, manufacturers can produce custom wires tailored to specific cutting requirements, such as varying the diamond size, concentration, or bond material based on the customer’s material and process.

The primary hazards include the potential for wire breakage, which could lead to injury, and exposure to fine particulate matter from the cutting process. Proper PPE and a well-designed ventilation system are necessary to mitigate these risks.

Yes, diamond wire can be used in artistic applications to create sculptures or intricate designs, particularly with materials like stone or thick ceramics, where precision and minimal material stress are desired.

The machine feed rate controls how quickly the wire cuts through the material. An optimal feed rate minimizes wire wear while maximizing cutting speed without compromising the quality of the cut.

Preventive maintenance should include regular inspections of the wire tension, wire condition, pulleys, guides, and coolant systems, along with timely replacement of worn components to prevent machine downtime and ensure consistent cutting performance.

Yes, there are CAD/CAM software solutions that can program and optimize cutting paths for wire saws, especially those integrated with CNC systems for precise and intricate cutting applications.

Lifespan can be increased by maintaining optimal cutting parameters, ensuring proper machine alignment and tension control, using the correct wire type for the material, and keeping the wire and machine clean and well-maintained.

The quality of the diamonds can greatly affect the cutting efficiency and finish. Higher quality diamonds will cut more consistently and have a longer life, resulting in fewer wire changes and better cut quality.

The diamond size affects the aggressiveness of the cut and the finish quality of the material surface. Larger diamonds may cut faster but could leave a rougher surface, while smaller diamonds create a finer finish but may cut more slowly.

The bond hardness determines how quickly diamonds are exposed as the wire cuts. A harder bond holds diamonds longer, which is beneficial for cutting softer materials, while a softer bond exposes fresh diamonds more quickly, which is necessary for cutting harder materials.

Yes, diamond wire saws can cut through reinforced concrete and other materials with metal inclusions. The diamond impregnation is effective at cutting through both the concrete matrix and the reinforcing steel.

Poor cutting performance can be addressed by checking for worn or misaligned wire, incorrect tension, inadequate cooling or lubrication, material holding issues, or the need for machine calibration.

The environmental impacts include the disposal of spent wires and cutting slurry. The process itself is relatively clean, especially when compared to more traditional cutting methods that generate significant waste and emissions.

Vibration can lead to uneven cutting and reduced precision. It can also increase wear on the wire and reduce its lifespan. Good machine design and proper tensioning can minimize vibration.

Continuous diamond wire cutting involves a wire that moves in a single direction, while oscillating cutting involves back-and-forth movement. Oscillation can help improve the cutting speed and wire life for certain materials.

The cooling system is crucial. It prevents overheating of the wire and the material, reduces dust and debris, and helps to achieve a cleaner cut. A good cooling system can also extend the life of the wire.

Uniform wear along the wire is normal, while localized wear or “flat spots” can indicate improper tension or alignment. Excessive wear on one side might suggest an issue with the wire guides or pulleys.

Diamond wires cannot be sharpened; they are replaced when the cutting efficiency decreases beyond an acceptable level due to wear or diamond loss.

Limitations include the initial cost of equipment, the need for regular maintenance, the inability to cut extremely tough materials as efficiently as some other methods, and the potential for wire breakage.

Research is focusing on developing new diamond impregnation methods, improved wire materials for increased durability, advanced bond matrices, and optimizing wire saw machine technology for better performance and reduced environmental impact.

Higher wire speeds can lead to a rougher surface finish due to the increased friction and potential for chipping. Slower speeds generally produce a smoother finish but can decrease cutting efficiency.

Longer wires can dissipate heat over a greater area but may require more precise tension control. Shorter wires offer more rigidity and can be easier to manage but may heat up more quickly.

Training should cover safe operation practices, understanding of cutting parameters, maintenance procedures, emergency response for wire breakages, and knowledge of material-specific cutting techniques.

The future may include automated process control, advanced real-time monitoring systems, more durable wire constructions, and integration with Industry 4.0 technologies for improved efficiency and data analytics.

Yes, diamond wire cutting can be scaled down for precision cutting in micro-material processing. Advances in wire technology have enabled the production of ultra-thin diamond wires that are suitable for microelectronic manufacturing and other applications requiring fine detail.

A thinner wire can provide a finer cut with less material loss (narrower kerf), but may be less durable and more prone to breaking. A thicker wire may be more durable and have a longer life, but it also removes more material and can be less precise.

The wire’s core material affects its strength, flexibility, and heat dissipation characteristics. Common materials include steel and other metal alloys, with varying properties to suit different cutting conditions and materials.

To minimize breakage, maintain proper tension, ensure correct alignment and pulley operation, use the correct speed and feed rates, and replace the wire before it becomes too worn.

Multi-wire cutting machines can significantly increase productivity by slicing multiple wafers or pieces simultaneously. They also offer better material utilization and can lower the production cost per unit.

Wire feed is typically controlled through a combination of motorized pulleys and tensioning systems that adjust the wire speed and tension in response to cutting conditions and operator settings.

Yes, it can be used in combination with other techniques, such as pre-scribing with a laser, to improve efficiency or tackle complex cutting tasks.

Signs include a significant decrease in cutting speed, frequent wire breakages, uneven wear patterns, and visual inspection revealing a loss of diamond grit or wire diameter reduction.

Wire geometry influences the cutting action and debris removal. For example, a helical wire can enhance the clearing of material from the cut, potentially reducing wire wear and improving cut quality.

Yes, specialized wires are developed for specific industries such as semiconductor, photovoltaic, and aerospace, where the materials and precision requirements can vary greatly.

Electrical conductivity is less of a concern for diamond wire cutting, which is a mechanical process, as opposed to methods like EDM where electrical conductivity is a critical factor.

Yes, many modern wire cutting machines are fully automated and can be integrated with computerized control systems for precision and repeatability.

Operator skill can greatly impact the precision, efficiency, and safety of the cutting process. Skilled operators are better at setting up the machine, responding to cutting issues, and maintaining the equipment, which can lead to better cut quality and longer wire life.

Diamond wire cutting is typically not affected by extreme temperatures because the process does not generate significant heat in the wire itself when proper cooling is applied. However, extreme ambient temperatures could affect the machine’s mechanical components and cooling fluids.

Tension sensors monitor and adjust the wire tension in real-time to ensure optimal cutting performance and to prevent wire breakage. They are critical for maintaining the quality and consistency of the cut.

Optimization can be achieved through the careful selection of wire specifications, precise machine calibration, and real-time monitoring and adjustment of cutting parameters.

Generally, increasing cutting speed can lead to reduced accuracy due to higher vibration and wire deflection. A balance must be found where the desired speed does not negatively impact the precision requirements of the operation.

Performance can be measured by the speed of the cut, the quality and consistency of the surface finish, the amount of material wasted (kerf), the uniformity of the cut, and the wear rate of the wire.

While diamond is the hardest material and thus ideal for cutting, research is ongoing into other superhard materials such as cubic boron nitride (CBN), although these are generally less effective than diamond.

hazardous when inhaled. Proper machine guarding, the use of personal protective equipment (PPE), and adequate ventilation are essential to address these risks.

Temperature variations can affect the cutting process by altering the wire’s tension and potentially affecting the hardness and brittleness of the material being cut. Machines often have temperature compensation features to mitigate these effects.

Limitations include the initial cost of equipment, the need for regular wire replacement, difficulty in cutting very thick or very hard materials, and the potential for wire deflection which can affect cut straightness and accuracy.

Diamond wires tend to have a higher wear rate compared to other cutting methods such as waterjet or laser cutting. However, they are more efficient for certain applications, particularly where the hardness of the material makes other methods impractical.

While diamond wire is typically used for cutting very hard materials, it can be used for metals when precision is more critical than speed. However, other methods might be more cost-effective for bulk metal processing.

Wire speed affects the rate of material removal, the heat generated during cutting, and the overall finish quality. Too fast may lead to a rough cut or wire breakage, while too slow can reduce efficiency and productivity.

Predictive maintenance technologies, such as monitoring vibration and acoustic emissions, can help predict wire failure by detecting changes in cutting behavior indicative of wire wear or damage.

Used diamond wires must be disposed of in accordance with local regulations. Some components of the wire may be recyclable, but the disposal of the diamond grit requires special consideration due to its abrasive nature.

Regular maintenance is vital to ensure the cutting machine operates at peak efficiency, to extend the life of the diamond wire, and to prevent unexpected downtime and potential safety issues.

The concentration of diamonds in the wire determines its cutting aggressiveness and life. Higher diamond concentration can provide a longer-lasting wire with a steadier cutting rate, while lower concentrations may cut faster initially but wear out more quickly.

Yes, diamond wire cutting can be integrated into robotic systems for automated, precise cutting tasks, particularly in complex or hazardous environments where precision and flexibility are required.

Common methods include visual inspections, measuring the diameter of the wire over time, monitoring cutting forces and wire tension, and using acoustic or vibration sensors to detect changes in the cutting process that indicate wear.

The cross-sectional shape of the wire can influence the contact area between the wire and the material, the distribution of the diamond grit, and how debris is cleared from the cut, affecting both cutting speed and the quality of the cut.

Yes, coolants used for diamond wire cutting are typically formulated to optimize heat dissipation, lubricity, and debris removal. They can be oil-based, water-based, or gels specifically designed for the material being cut and the cutting conditions.

Pulley size can affect the tension and flexibility of the wire, as well as the precision of the cut. Larger pulleys can provide smoother wire movement and less wire fatigue, while smaller pulleys may allow for tighter turning radii but can increase wire stress.

Yes, diamond wire cutting can be used for decorative cutting of stone, glass, and ceramics, allowing for intricate patterns and details that are difficult to achieve with other cutting methods.

Signs include inconsistent diamond grit size and distribution, weak wire bonding, irregular wire diameter, and poor cutting performance such as slow cutting speeds or uneven cuts.

Wire vibration can lead to irregular cuts, striation patterns on the cut surface, and potential wire breakage. It can also reduce the precision of the cut and increase wear on the wire.

Installation and tensioning of diamond wires on cutting machines are typically done by threading the wire through a series of guides and pulleys, then applying tension using a mechanical or hydraulic system to achieve the desired rigidity and performance.

The doping of materials such as silicon can affect their electrical and physical properties, potentially altering the wire cutting process. Heavily doped materials may be more abrasive or conductive, which can influence the wear on the wire and the cutting speed.

Coarser diamond grit is typically used for softer materials to maximize cutting speed, while finer grit may be needed for harder materials to improve cut quality and precision. The choice of grit size also affects the surface finish and the amount of material removed (kerf).

Economic benefits include faster cutting times, the ability to cut harder materials, reduced waste due to thinner kerf, and often a better surface finish, which can reduce or eliminate post-processing steps.

Worn pulleys can cause wire misalignment, increased wire wear, and potential breakage, as well as inconsistencies in the cutting process, resulting in reduced precision and quality of the cut.

For cutting hard crystals like sapphire, optimization can involve using finer-grit diamond wire at appropriate tension, slow cutting speeds to minimize wire and material stress, and the use of high-performance coolants to prevent overheating.

INDUSTRIES USED IN

Tab Content

ACCESSORIES

USAGE RECOMMENDATION

Tab Content

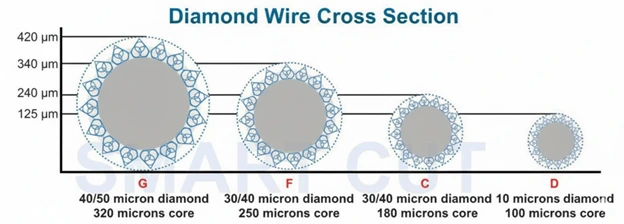

Diamond Wire Diameters:

- Fine Wire (75–180 µm, grit 10–30 µm): Semiconductor wafers, sapphire, optics

- Medium Wire (240–340 µm, grit 30–40 µm): Solar wafers, glass, ceramics

- Large Wire (340–420 µm, grit 40–50 µm): Stone, composites, silicon ingots

Diamond Wire Core Materials:

- High-Tensile Steel: Strong, cost-effective, widely used

- Stainless Steel: Corrosion-resistant, good for wet environments

- Tungsten: High strength, heat resistant, used for ceramics and sapphire

- Molybdenum: Strong, corrosion-resistant, stable for fine wires

- Specialty Alloys (NiTi, composites): Ultra-flexible, fatigue-resistant, used in advanced semiconductor cutting

Features

- Ultra-Precise Kerf Control: Experience minimal kerf loss with SMART CUT™, delivering precise material cuts and significantly reducing waste.

- Reduced Sub-Surface Damage: Our diamond wire is engineered to cut delicately, preserving the integrity of the material's surface for high-quality post-process results.

- Clean Cutting Operation: Designed to be used with contamination-free coolants, ensuring that your material remains pure and unblemished.

- Broad Material Compatibility: From monocrystalline silicon to exotic metal materials, SMART CUT™ is versatile enough to handle a diverse range of cutting challenges.

- Environmentally Friendly Process: Eliminate the need for slurry disposal with a diamond wire sawing process that's cleaner for your workspace and the planet.

- Optimal Material Preservation: Superior cutting action translates to less material deformation, chipping, and loss, conserving your valuable resources.

- Preferred by Experts: A trusted tool amongst professionals in solar energy, advanced materials manufacturing, and crystal growth industries.

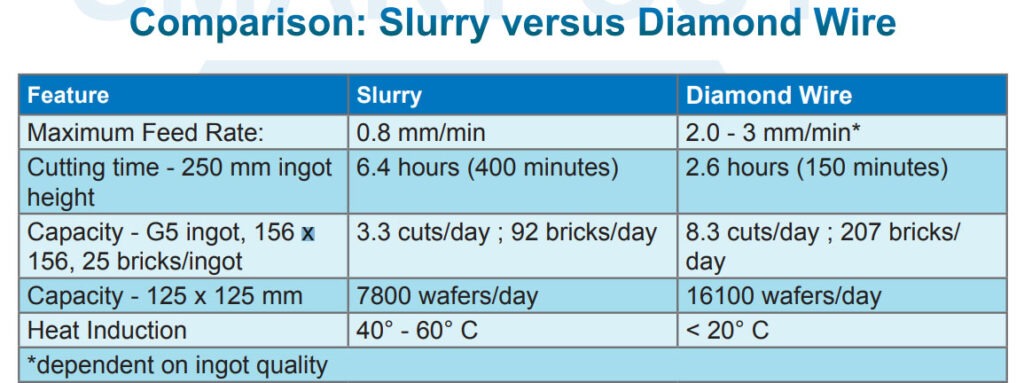

Advantages

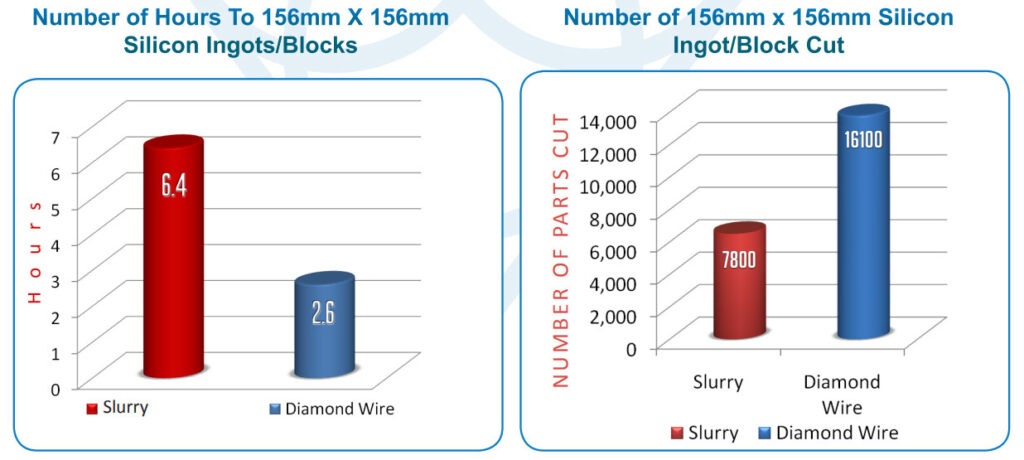

- High cutting feed & capacity

- Increase Cutting Speed & Productivity - 3 to 5 times cutting rate of abrasive slurry

- Improve Return on Investment - less initial capital required

- Reduce Costs from reduced TCO, less utility costs, & reduced secondary operations

- Excellent cutting accuracy

- High Level of Consistency & Process Stability

- Very low kerf loss - 0.12mm to 0.42mm

- Improve TTV

- Lower cost of ownership than comparable slurry-based systems

- Environment Friendly - No need for slurry recycling and disposal

- Can be implemented in almost any environment to replace slurry wire saws

- Possibility of silicon kerf recycling

Materials Used On

- Sapphire

- Silicon

- SiC

- Glass

- GaAs

- Ge

- CaF2

- Crystal

- Magnetic materials

- W alloy

- Other hard brittle materials

Advanced Applications

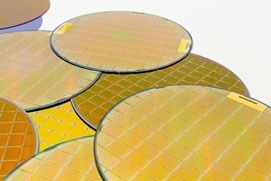

- Microelectronics and semiconductors: Achieve unparalleled precision in wafer production and chip manufacturing.

- Photonics and crystal fabrication: Cut crystals with exacting standards required for high-tech optical applications.

- Specialized ceramics: Shape ceramics for use in advanced biomedical implants and aerospace components.

- Sapphire processing: Deliver precise dimensions for high-end sapphire windows and luxury watch components.

How Diamond Wire Works

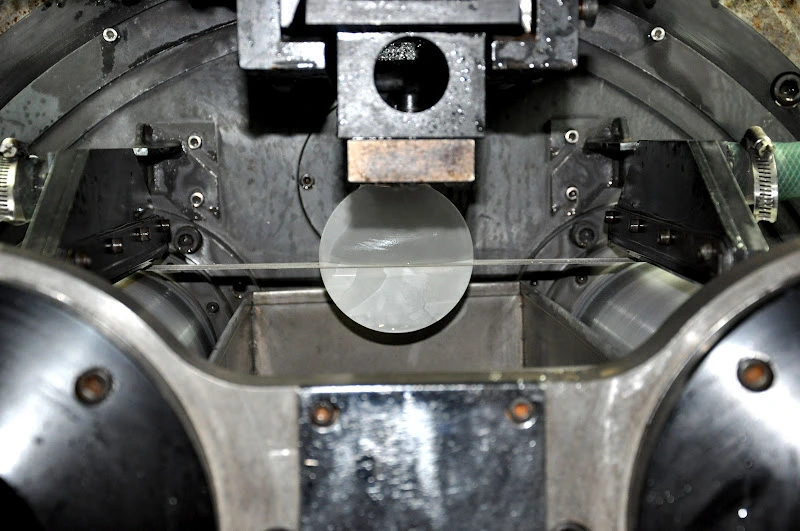

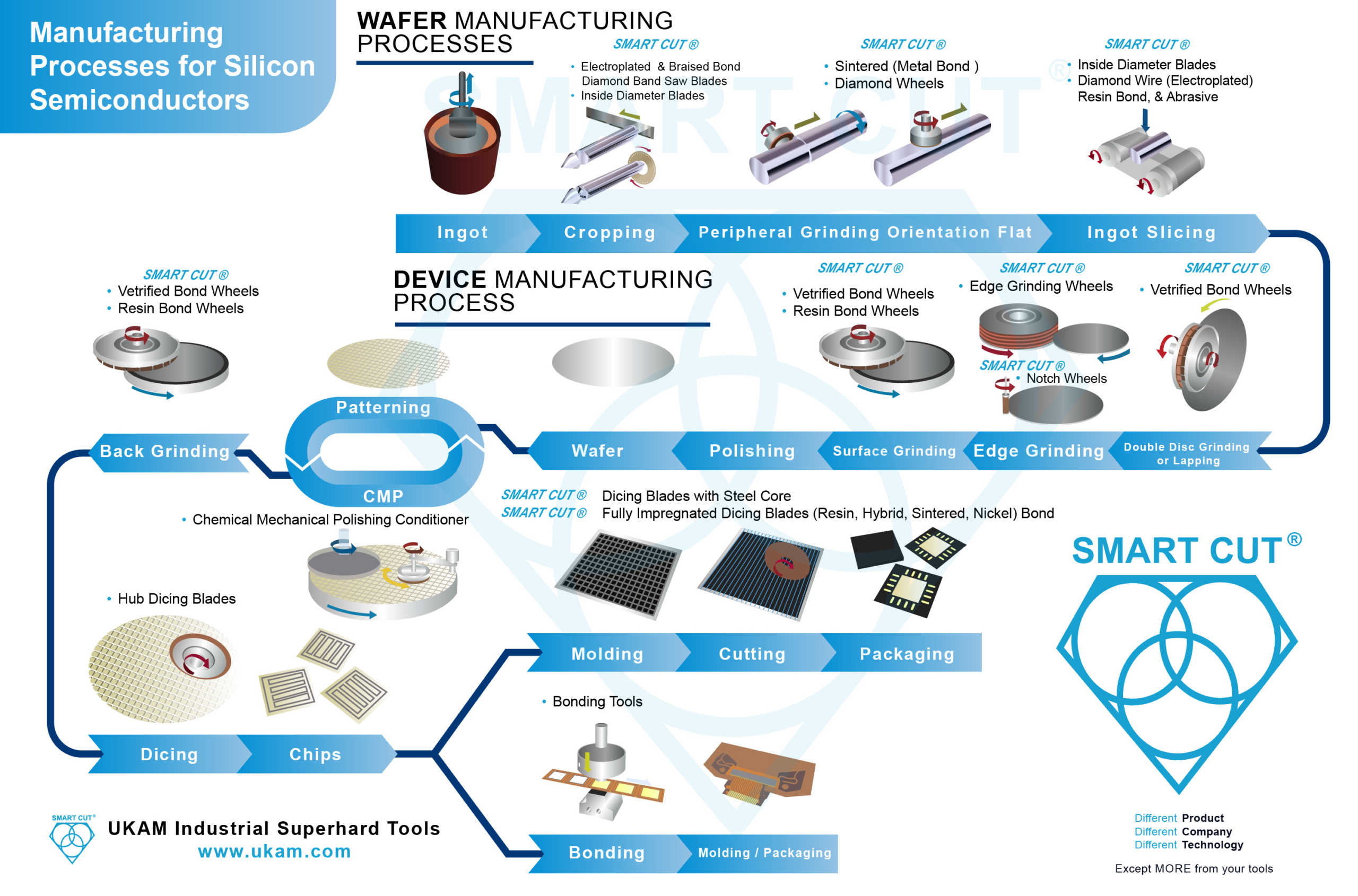

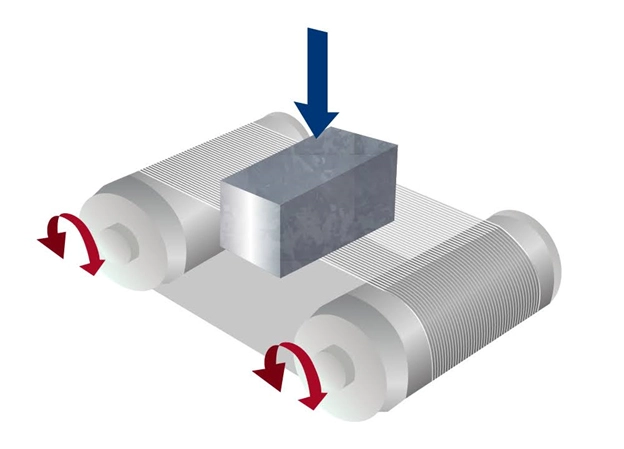

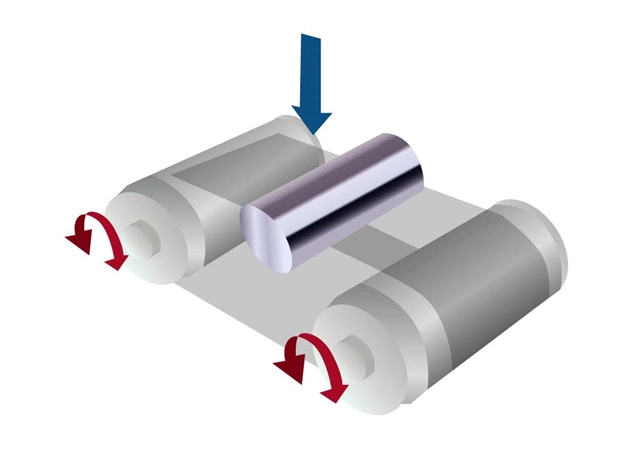

Diamond Wire saws provide the most accurate cutting with the least amount of material deformation and chipping of material. Today diamond wire sawing is preferred by majority of solar silicon manufacturers, crystal growers, advanced ceramic manufacturers over other technologies/ cutting methods. diamond Wire saw operates similarly to horizontal hack saw, where head containing a pack of blades lengths of plain edge stainless or spring steel mounted parallel to head travel oscillates back and forth over the work piece or pieces which are mounted on a bed.

The bed can be fed up into the blades at selected pressures. The diamond wire provides cutting or lapping action between the blades and material. The wire saw allows slicing of hundreds of wafers simultaneously with the same continuous wire.

In the past abrasives slurry wire saws were the main method used for cutting these ultra hard and brittle materials. Copper plated piano wires was used to trap abrasive particles (such as alumina or SiC) suspended in mechanical oil or water based coolant. To provide the cutting action and lubrication of the moving wire. The wire diameter used was smaller than 0.15mm and cutting kerf is about 0.19mm and 0.15mm and smaller.

Abrasive slurry grit ranged from 1000 to 250 grit. Viscosity and continuous mixing of the slurry must be maintained in order to produces consistent results. The improvement in diamond wire manufacturing technology and reduction in cost has made diamond wire cutting and industry standard. Diamond wire bonded with diamond offers many advantages in terms of faster cutting speed (frequently triple the speed) and improved surface finish quality (less secondary operations such as polishing). Using Diamond Wire is much cleaner and faster process Today most Diamond Wire is wound around 2, 3,or 4 grooved mandrels in order to allow multiple loops for simultaneous slicing of the same ingot. When the looped wire is running across the ingot, the diamond particles on the surface of the wire will slowly lap/ grind off silicon on micro level (bit by bit). The cutting action is done by reciprocating motion. The wire is used once, and replaced with a new roll.

Typically this type of wire saw can travel at surface speed of 6 mm/sec. The wire moves forward for abut 300mm and this is retraced for abut 200mm. Net advance of the new wire is at an average speed of 2 m/sec with about 100 m new wire passed through each cycle. The wire can run continuously for more than 300 km long. More than 500 slices can be sawn simultaneously. In a production environment 8” (200mm) silicon boul can be cut in less than 8 hours and 12” (300mm) boul in less than 12 hours.

Diamond Wire Loops

Closed-loop wires are mounted on pulleys and designed for precision cutting of wafers, optics, and crystals. They maintain stable tension and ensure repeatable performance.

Applications: Semiconductor wafers, sapphire, quartz, advanced optics, R&D.

Specifications

- Wire Diameter: 80–350 µm

- Core Material: High-tensile steel, tungsten, molybdenum, NiTi alloys

- Diamond Grit Size: 5–50 µm

- Bond Type: Electroplated (nickel), resin bond, multi-layer

- Loop Length: 600–1500 mm (larger available for production)

- Tensile Strength: 2000–4000 MPa

- Wire Speed Range: 0.5–20 m/s

Advantages

- Long service life due to even wear

- Capable of ultra-thin kerf widths (10–25 µm)

- High stability, minimal vibration

- Preferred in laboratory and production environments requiring repeatability

Continuous Diamond Wire

- Fully coated with diamonds for uniform cutting

- Produces smooth surfaces and narrow kerfs

- Ideal for semiconductors, optics, ceramics

Segmented Diamond Wire

- Diamond-coated intervals with gaps for chip clearance

- Lower cutting temperature, prevents clogging

- Suitable for silicon ingots, ceramics, composites

Multi-Layer / Spiral-Coated Diamond Wire

- Several abrasive layers or spiral coatings

- Balances speed, finish, and tool life

- Common in photovoltaics, ceramics, specialty glass

Diamond Wire Spools (Bobbin-Based)

Spool wires are wound onto reels and continuously fed through the workpiece. They are designed for long cuts and large material blocks.

Applications: Stone slabs, photovoltaic silicon blocks, ceramics, composites, industrial-scale production.

Specifications

- Wire Outer Diameter: 50–520 µm

- Core Material: 40–400 µm

- Diamond Grit Size: 5–50 µm

- Tensile Strength: : 6–320 N

- Spool Lengths: 30–1000 m (custom lengths available)

- Minimum Pulley Diameter: 40–250 mm

Advantages

- Suitable for cutting large blocks of stone, silicon ingots, and ceramics

- Flexible for many industries including solar and composites

- Lower machine cost (though higher wire consumption)

Types of Diamond Wire by Bond

Electroplated Diamond Wire

Electroplated diamond wire is made with a single layer of diamond particles bonded with nickel plating, providing very sharp cutting edges, aggressive performance, and high throughput. It is widely used for semiconductor wafers, sapphire, optical crystals, and glass substrates, where speed and precision are essential. The design ensures consistent sharpness and fast material removal

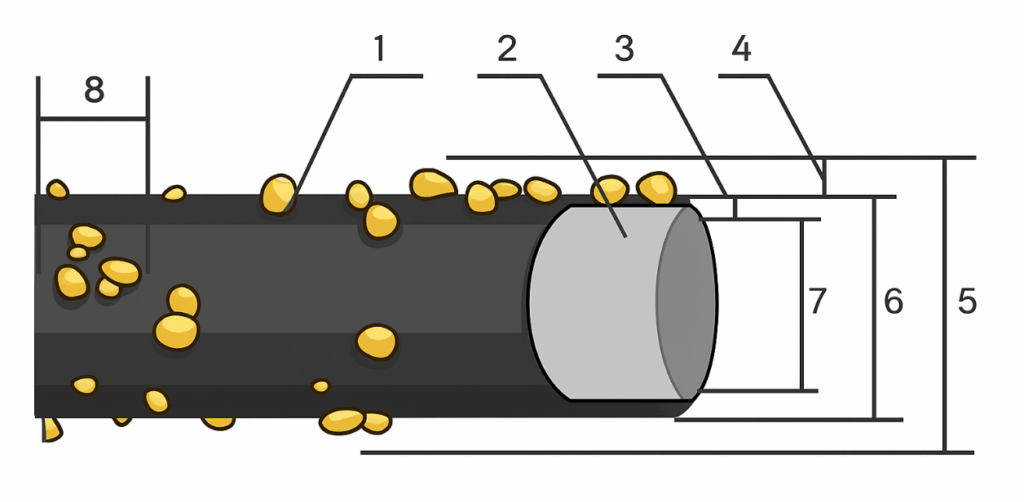

Diamond Wire Saw Structure

1. Wire saw products

2. Wire saw matrix (bare wire)

3. Coating layer thickness

4. Abrasive cutting layer height

5. Envelope diameter of the wire saw (including abrasive layer)

6. Total wire saw diameter

7. Core wire (bare wire) diameter

8. Diameter of accumulated abrasive particles

Advantages

- Provides the fastest cutting speeds

- Consistent sharpness throughout its short life cycle

- Ideal for high-volume wafer slicing and precision industries

- Excellent for materials that require aggressive, efficient cutting

Resin Bond Diamond Wire

Resin bond diamond wire is produced by embedding diamond particles in a resin matrix, which gradually wears away during cutting to expose fresh, sharp diamonds. This creates a self-renewing cutting surface that ensures consistent performance, smoother cuts, and reduced chipping compared to electroplated wire. Because of its controlled cutting action, it generates lower cutting forces and less heat, making it ideal for delicate or brittle materials such as advanced ceramics, thin glass, composites, and optical substrates.

Advantages

- Self-renewing cutting surface

- Smoother surface finishes

- Lower cutting forces

- Minimal heat generation

- Extended tool life

- Greater process reliability

Why Use Diamond Wire

Diamond wire is used because it offers a highly controlled and efficient method of cutting hard and brittle materials while maintaining accuracy and surface integrity. Unlike traditional cutting tools, diamond wire distributes force evenly along its length, which reduces stress, vibration, and heat on the material.

This makes it possible to achieve thin kerf widths, often less than 25 microns, and produce smooth surfaces with minimal chipping or microcracking. The process generates very little heat, typically less than a 10°F rise, which prevents thermal damage, warping, or subsurface fractures in sensitive materials such as semiconductors, sapphire, quartz, and ceramics. Diamond wire is also versatile, capable of cutting both delicate samples and large blocks, depending on the wire type and machine configuration.

It reduces material waste, often eliminates the need for secondary finishing, and offers longer tool life with the proper bond selection, making it a cost-effective and reliable choice for industries that demand precision, repeatability, and clean cutting results.

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

How SMART CUT ® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Step 2

Diamonds or CBN Crystals

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Diamond Wire Blade Case Studies

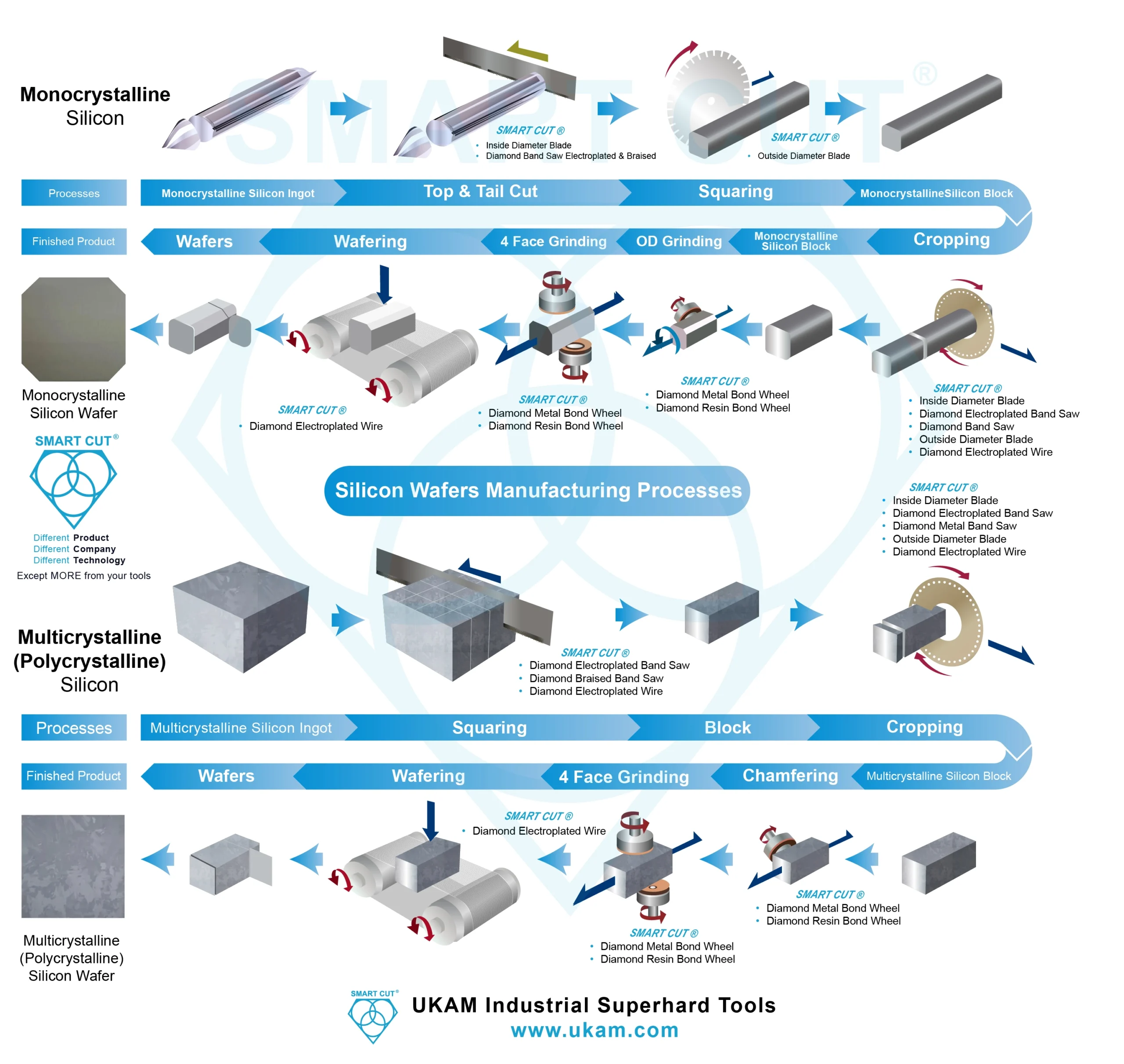

Diamond Wire for Wafering of Monocrystalline & Polycrystalline Silicon

Wafering monocrystalline and polycrystalline silicon using diamond wire, despite its efficiency and precision, involves several challenges that can complicate the manufacturing process and affect output quality.

Firstly, achieving consistent quality in diamond wire itself is a significant challenge. Variations in the diamond coating, such as inconsistency in grain size or density, can lead to uneven wear and tear during cutting, affecting the quality of the wafers. Manufacturers must ensure that the diamond wire used is of high quality and consistently manufactured to avoid these issues.

Another major challenge is optimizing the cutting parameters, including wire speed, tension, and the volume and type of coolant used. These parameters must be precisely controlled to maximize cutting efficiency and minimize damage to the wafers. Incorrect settings can lead to wire breakage, excessive material loss, or suboptimal wafer surface quality, necessitating costly post-processing.

Wire breakage is a frequent issue and can cause significant disruptions in production. It often results from mechanical stress or from the wire becoming worn out. Regular monitoring and replacing of the wire is required to prevent unexpected downtime, which can be costly both in terms of production delays and material wastage.

Cooling and debris removal also pose challenges. The cutting process generates heat and silicon debris, which must be effectively managed with appropriate coolant systems. If cooling is insufficient, it can lead to overheating, which affects the structural integrity of the silicon wafers. Moreover, the spent coolant and debris need to be handled and disposed of in compliance with environmental standards, adding to the operational complexities.

SMART CUT® HD-2B

Synthetic Low IFT Coolant / Lubricant for Wire Saws

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

SMART CUT® HD-2B Coolant enhances cutting performance by providing exceptional cooling and lubrication. The coolant's molecules interact with the cutting area, efficiently absorbing heat to prevent overheating.

While SMART CUT® HD-2B is not specifically designed to be mixed with water, its advanced formula works effectively in "once-through" systems, where it helps maintain optimal cutting conditions by reducing friction. This results in improved tool life, superior material quality, and smoother cuts. By dissipating heat effectively, SMART CUT® HD-2B minimizes tool wear, improves cut quality, and enables faster, more efficient cutting, all while ensuring a cleaner, more environmentally friendly process.

SMART CUT® HD-2B 2B acts as both a coolant and lubricant, effectively reducing heat generated by friction and minimizing surface tension. As a lubricant, it enhances the dispersion of material swarf, ensuring that swarf particles are effectively moved away from the diamond tool and cutting zone, preventing buildup within the kerf. The coolant's advanced formula works by bonding with the cutting area, helping to penetrate the kerf and flush out material debris, preventing chipping and internal cracking. Additionally, because SMART CUT® HD-2B keeps the cutting area clean and free from debris, it minimizes the need for secondary material processing and cleaning operations, enhancing overall efficiency and reducing maintenance requirements.

Related Products

SMART CUT® Diamond Cylindrical Grinding Wheels

SMART CUT® Diamond Cylindrical Grinding Wheels are engineered for the precise peripheral grinding of silicon ingots, making them an ideal choice for industries such as semiconductors, electronics, automotive, and photovoltaics. These high-performance grinding wheels are designed to process the outer surfaces of silicon ingots, ensuring accurate orientation flats are created, which are essential for subsequent processing steps. The addition of the orientation flat, a marked edge indicating the crystallographic plane of the wafer, is crucial for the wafer's alignment in future manufacturing processes.

During the post-slicing phase, wafers undergo shaping and smoothing through peripheral grinding.

SMART CUT® Diamond Notch

SMART CUT® Diamond Notch Grinding Wheels in Single & Multi Layered electroplated nickel bond & sintered (metal bond) are construction are developed for high precision notch formation on semiconductor wafers. These wheels support performance requirements for Silicon, Silicon Carbide, Gallium Arsenide, and Sapphire. The electroplated structure holds diamond particles firmly on the surface, producing accurate geometry, clean edges, and stable performance during continuous wafer processing. You receive predictable grinding behavior, long wheel life, and consistent notch dimensions under demanding production conditions.

SMART CUT® Diamond Edge Grinding Wheels (Electroplated)

SMART CUT® Diamond Edge Grinding Wheels are engineered to deliver exceptional performance for precision grinding applications, providing superior results in both rough and fine grinding. These wheels are ideal for use in industries that require highly accurate EDM processing and consistent wafer-to-wafer results. Manufactured with synthetic diamond grit, SMART CUT® wheels offer improved surface roughness and extended tool life due to their tightly controlled diamond distribution and uniform bond structure.

Electroplated (Nickel Bond) Diamond Band Saw Blades

SMART CUT® Braised Bond Diamond Band Saw Blades

ID blades

SMART CUT® HD Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing Silicon

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

DIAMOND BACKGRINDING WHEELS

SMART CUT® Diamond Backgrinding Wheels are designed for precision thinning and flattening of silicon wafers, glass, and ceramic substrates. These high-performance wheels are used on backgrinding machines, including models from Disco, Okamoto, Strasbaugh, and other leading manufacturers. Available in sizes ranging from 8” to 14” O.D., they are engineered to handle a wide range of materials and applications, from semiconductor wafers to microelectronic packages.

Recently Viewed Products

ARE YOU USING DIAMOND WIRE

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR DIAMOND WIRE?

Knowledge Center

08

Jul

Share this Article with Friend or Colleague

1. Ingot Production

The journey begins with the creation of silicon ingots, which are pure silicon cylinders produced through methods like the Czochralski process. Once formed, these ingots undergo a...

08

Jul

The Comprehensive Guide to the Processes of Silicon Wafers Production

Share this Article with Friend or Colleague

The production of silicon wafers, an essential component in semiconductor manufacturing, involves several intricate steps to ensure precision and quality. This article explores the detailed processes depicted in...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

02

Nov

Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...