Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

Diamond Drills/Bits will drill materials faster, produce smoothest surface finish quality, provide consistent performance, & yield (cost per part) possible.

Diamond drills are an excellent alternative to carbide, and other types of drills Unlike carbide, high speed steel, & other types of drills.

We have Thousands of Diamond Drills & Diamond Drill Bits are available from inventory in many different specifications, outside & inside diameters, drilling depths, bond types, diamond grit sizes, mountings, & tolerances & Custom Manufacturing to fit your particular requirements with 1 week or less lead time (non minimum order)

Diamond is the hardest material known to man kind. When used on diamond drills/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from hardness of 40 on Rockwell scale and up.

Diamond (diamond drills/bits) will machine hardest material, including those materials that other conventional types of abrasives, carbide and high speed steel will not

Diamond Drills last significantly longer then all other types of drills such as carbide, high speed steel, cobalt, etc. specially when drilling hard and abrasive materials. On most applications diamond drill last 10x to 30x times longer then High-Speed Steel (HSS) drills. And 2 to 5 times longer then carbide drills.

Diamond drills often produce smoother finishes and are less likely to cause chipping, especially in hard and brittle materials like glass, ceramics, stone, composites. Diamond drill works by grinding away material on micro (nano) level. Carbide and other types drills on the other hand cut material with a sharp cutting edge. The finish is often superior to what carbide or cobalt drills can produce in these materials.

Diamonds have excellent thermal conductivity, which equates to more affective heat dissipation. This reduces the possibility of excessive heat generation and overheating. Excessive overheating is the most frequent cause of diamond drill and material being drilled.

Diamond drills will drill most materials faster than any other types of drill types. This is due to the hardness of the diamond particles and their heat dissipation properties.

Diamond drills can be used on a wider variety of materials, from very hard ceramics and gemstones to softer materials such as glass and minerals. While specific materials and applications require proper and optimal diamond drill specifications designed and made for this purpose. Diamond are the most universal drills and tools available. In many cases one diamond drill specifications can be used in over a dozen of different materials and applications.

Diamond drills and bits is based on specification of the drill. It can be higher, same or lower price then other type of drills such as carbide. The price is based on diameter, bond type, diamond type, concentration, radius/angle, tolerances, mounting type and quantity. There is common misconception the diamond cost more then other type of drills such as carbide. This is not the reality and many cases.

For many metal-drilling applications, especially in softer metals, carbide or cobalt drills may be more effective and economical for this applications. However some diamond drills types such as chemical vapor deposition and PCD drills can be used for this purpose.

PCD drills are primarily used for non-ferrous materials such as aluminum, copper, and other non-metallic materials like wood, ceramics, rubber, and plastic. PCD offers excellent wear resistance, which means the drills can last longer without needing to be replaced or re-sharpened.

A core drill bit embedded with industrial diamonds. The diamonds are not used to drill but rather to grind away the material.Diamond drills work through a grinding process. The diamonds on the bit grind away the material as the drill rotates.

The tip of the diamond drill can be hollow (core drill), solid, non core formation have specific angle or radius depending on the application. diamond core drilling, most of the work is done by the diamonds located on the sides of the drill bit. The peripheral diamonds grind the material to create a hole, while the diamonds at the bottom face of the diamond drills to maintain a flat bottom in the hole.

drills work by cutting or chipping away at the material. Carbide, which is a very hard material, is often tipped or brazed onto the cutting edges of the drill bit. Carbide-tipped drills have a solid tip, which penetrates into the material. The geometry can vary depending on the specific application, such as twist drills, spade drills, or other specialized designs. carbide drills cut through the material, creating chips or fragments.

These drills have primary cutting edges at the tip and secondary cutting edges on the flutes. As the drill rotates, the primary cutting edges shear off the material, and the flutes help to guide and evacuate the chips away from the hole.

Diamond drills use either natural or synthetic diamond particles on their cutting edges. These diamonds can be bonded through various methods, including sintering, electroplating, or brazing.

They are typically used for hard, abrasive, and brittle materials. This includes ceramics, stone, glass, and composite materials. They’re a favorite in the gem and jewelry industry for gem cutting and shaping.

They are not ideal for drilling metals, as the carbon in the diamond can react with the metal, leading to reduced tool life.

Carbide is a composite material made from a combination of carbide particles (typically tungsten carbide) and a binder metal, usually cobalt. It’s harder than steel but not as hard as diamond. Various type of coatings to increase the life and hardness, as well as provide additional heat resistance, reduce friction, of these tools. Different types of coatings are available include Chemical Vapor Depositions, TiN (Titanium Nitride), TiCN (Titanium Carbonitride)

Tialn (Titanium Aluminum Nitride), Altin (Aluminum Titanium Nitride),

Zrn (Zirconium Nitride), Crn (Chromium Nitride) And Others

Carbide drills are frequently used for drilling metals, plastics, and other tough materials. They can retain their edge for a longer period compared to HSS (High-Speed Steel) bits and can operate at higher speeds.

They can be brittle. As such, they’re prone to chipping if mishandled or if the equipment isn’t stable. They also tend to be more expensive than traditional steel bits but are often justified by their longer life and performance.

These are not pure cobalt but are HSS drills with a certain percentage of cobalt added (usually 5-8%). The cobalt enhances the bit’s heat and wear resistance.

Ideal for drilling tough metals like stainless steel, which produce more heat when being drilled. They retain their hardness at high temperatures, making them effective for such applications.

They can be more expensive than standard HSS drills, but they’re typically less costly than carbide drills. Their main advantage is in heat resistance rather than hardness, so they might not outperform carbide drills in many applications.

While diamond drills are expensive, their cost can be justified when drilling hard, abrasive materials due to their long lifespan. Carbide drills, while also on the pricier side compared to HSS drills, provide better performance and longer life when drilling metals. Cobalt drills strike a middle ground in terms of cost and are specifically efficient for high-heat applications.

Both carbide and cobalt drills can handle heat well. Cobalt drills, in particular, are designed to resist the heat produced when drilling hard metals, which can cause other drill types to lose their temper and become dull.

Diamond is the undisputed champion in hardness, making diamond drills the best choice for very hard materials. Carbide also offers a high degree of hardness and wear resistance, making it suitable for many metals and tough materials.

In conclusion, the selection of a drill type should be based on the specific application, material, and the balance between performance needs and cost constraints. Each type has its niche where it shines the brightest.

Diamond drills are either made using diamond impregnated segments or with a diamond coating. The type and quality of diamonds, along with the concentration and matrix material, can vary based on the application.

Many diamond drilling applications require water or another coolant to prevent overheating and to wash away material debris, prolonging the drill bit life.

Ultra-thin diamond drill bits are used in precision industries, like electronics, due to their ability to produce extremely fine holes without chipping the material.

Apart from the previously mentioned materials, diamond drills are used in the dental industry for tooth preparations and in the construction industry for creating openings in reinforced concrete.

Solid carbide drills are homogenous throughout. Still, there are also carbide-tipped drills where only the cutting edge is carbide, and the body is another material, often steel.

Many carbide drills feature coatings like Titanium Nitride (TiN) or Titanium Carbonitride (TiCN) to enhance hardness, reduce friction, and increase lifespan.

Different tip geometries can be crafted for specific materials. For example, a split-point tip design is effective in reducing ‘walking’ when starting a hole.

Carbide drills are popular in the aerospace and automotive industries, especially when drilling materials like titanium alloys or high-carbon steels.

As part of the High-Speed Steel (HSS) family, cobalt drills are steel alloys with varying percentages of cobalt, enhancing heat and wear resistance.

Cobalt drills are particularly suitable for applications where the drill speed is high, and the material—like stainless steel—generates a lot of heat.

Cobalt drills can be sharpened without losing their cobalt content, unlike coated drills which might lose their coating upon resharpening.

Apart from hard metals, cobalt drills are also suitable for drilling abrasive materials like fiberglass and hard plastics.

In environments where tool changes can be time-consuming or difficult, a longer-lasting tool like a diamond or carbide drill might justify the higher upfront cost.

Diamond and carbide drills, due to their high hardness, are more brittle compared to cobalt drills. This means in environments with potential lateral stresses or imperfect setups, a tougher drill like cobalt might be preferred to prevent breakage.

Diamonds can react with iron under high heat, forming iron carbide. This makes diamond drills unsuitable for many ferrous metal drilling applications.

In any drilling application, the choice of drill material and design is just one aspect. Other factors like drill speed, feed rate, coolant use, and workpiece clamping all play a role in successful, efficient, and precise drilling.

w is a comparative table highlighting key aspects of Diamond drills compared to other common drill types:

Hardness

Hardness

Very Hard

Harder than standard HSS

Standard

Material

Natural or synthetic diamonds (Mostly Synthetic)

Tungsten carbide composite

HSS alloyed with cobalt

High-speed steel

Heat Generation

Minimum due to diamond’s thermal conductivity

Good

Very Good due to cobalt content

Moderate

Cost

High to Medimum (depending on specification)

High to Medimum (depending on specification)

Medium to Low

Very Low

Recommended Application

Hard, abrasive, and brittle materials (e.g., glass, ceramics)

Metals, tough materials, plastics

Hard metals, especially those generating heat like stainless steel

General purpose for softer materials

Wear Resistance

Very High

High

High (especially against heat)

Moderate

Brittleness

High (can chip in unstable conditions)

High

Moderate

Low

Lifespan

Long (when used on suitable materials)

Long

Longer than HSS, but shorter than carbide

Shortest among the mentioned types

Thermal Reactivity

Can react with iron at high temperatures

Stable

Stable

Stable

Material Composition

Diamonds bonded to a substrate

Tungsten carbide

HSS with 5-8% cobalt

High-speed steel

Diamond particles sintered with tungsten carbide

Ceramic-based materials

Hardness

Extremely hard

Very Hard

Harder than standard HSS

Moderate

Extremely hard

Very hard

Heat Resistance

High

High

Very high

Moderate

Very high

Very high

Heat Resistance

Very high

High

High

Moderate

Superior wear resistance

High

Toughness/ Brittleness

Brittle

Brittle

Tough

Tough

Brittle

Brittle

Cost

Expensive

Expensive

Mid-range

Low

Very expensive

Expensive

Applications

Ceramics, stone, glass

Metals, hard materials

Hard metals, heat generating applications

General metals and woods

Non-ferrous metals, composites, ceramics

Aerospace, automotive (for hard materials)

Potential Issues

Not suitable for ferrous metals due to reactivity

Can chip if mishandled

None specific

Faster wear

Cost, not suitable for iron-containing materials

Chipping, especially with interrupted cuts

Coolant Requirement

Often requires water or coolants

Sometimes requires coolants

Depends on application

Often doesn’t require coolant

Often requires coolants

Often requires coolants

Lifespan

Long with suitable materials

Long

Longer than HSS

Short to moderate

Very long with suitable materials

Long with suitable materials, but can chip

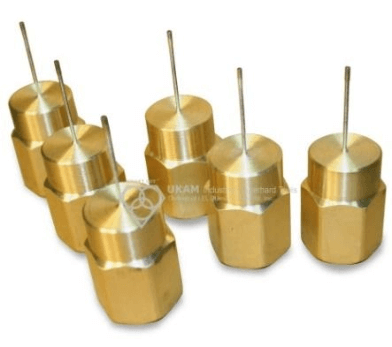

additional options: slots, radiuses, angles, etc.

Accessories & Related Products Available: water swivel adapters to run coolant through center, water soluble coolant, dressing sticks

Services: consulting, process development, drilling services of your material

Unmounted diamond core drills consists of steel tube and diamond section (not mounted) to any type of collet male, female or straight shank. These can be made in any bond type such as sintered (metal bond), nickel bond (electroplated) and braised bond. Most unmounted core drills tend to be smaller diameter, usually under ½” (12.7mm). As larger unmounted diamond core drills would be difficult to mount without shank or thread on your drilling machine chuck or collet.

Outside or Inside diameter, Diamond size, bond formulation, wall thickness, length, diamond section height, radius, slots in diamond section, windows in tube can be made to client requirements.

These are typically used for drilling very small holes in wide variety of materials. Coolant can be run through the center of the drill to push out the material swarf and core. This is important for deeper drilling of hard and fragile materials. As the coolant helps reduce amount of heat generated when drilling very small diameter holes in thicker material or more easily eject the core. Helping improve surface finish, reduce chipping, reduce amount of stress and heat generated while drilling and preserving material micro structure.

These core drills can be mounted to any type of female or male thread or straight shank per client specification. The drilling maximum drilling depth is usually in proportion to diameter of the drill. These an be made in either sintered (metal bond) or nickel bond (electroplated/galvanic) bond. Typical operating speeds range from 10,000 to 3,000 RPM. For optimal results using with our SMART CUT water soluble coolant to run the coolant through center of the drill and also submerge your material inside the coolant as well. If you need device for your existing drilling machine to run coolant through the center. We offer over dozen of standard water swivel adapters from stock and can also manufacture them to fit any drilling equipment, operating speeds and environment

diamond micro drills are used for drilling micro holes in large variety of hard and brittle materials such as sapphire, high density ceramics, micro-circuit substrates, glass, silicon, various wafers, substrates, tubes etc.

Small diameter below .020” (0.5mm) are made using diamond plating (galvanic) method, where the diamond crystals are deposited evening on the tip evenly over time. The steel body using is usually high speed steel ranging in hardness from 40 to 50 Rockwell scale C. Precision tolerances are maintain on diameter. Diamond sizes used range form 6 microns to 120 microns. Head length made in proportion to diameter of the tool. Usually it cannot exceed 15 times the diameter of the tool. Diamond grit size used in in proportion to diameter of the drill tip and can range form 3 to 70 microns. shank size is usually 1/8” (3.2mm) or .040” (1mm).

Height of diamond coating can be adjusted to fit your particular requirements. Standard configuration of standard stock diamond micro tools is flat end cylinder but the angle and radius can also be customized if needed. diamond micro drills are used at high speeds ranging from 150,000 to 35,000 RPM’s. The smaller the diameter the tool the higher the recommended speed for optimal performance. The drills may work at lower rpm’s with significantly shorter drill life and possible drill breakage. We recommend using with our SMART CUT water soluble coolant for optimal results.

Electroplated & Metal Bond Diamond Solid Thin Drills are available from inventory in 0.75mm (.029″) to 6mm (.236″).

Multi Layered Electroplated solid drills are flat cylinder shape with transition angle. Head length and drill depth depends and is in proportion on diameter of the drill. Plated drills have multiple layers of diamond coating which provides best diamond adhesion in the bond matrix. This provides longer life span, compared to standard and comparable electroplated miniature drills. Higher level of consistency and better surface finish. The shank size varies depending on diameter of the drill. Our multi layered electroplated solid drills have a transition angle where the shank is larger then the head length. This provides more accurate drilling, and support. Hence these small plated miniature drills can withstand more pressure and force then typical music wire plated drills.

Typical applications include drilling precious and semi precious stones, beads, glass, crystals, ultra hard and brittle ceramic, composites, hard metals, and many other. Used on: Foredoom, Dremel Machines, High Speed Air Spindles, & other equipment running at 9,000+ RPM. Custom Manufacturing for Multi Layered Electroplated solid drills is available. The Height of diamond coating can be adjusted to fit your particular requirements. Standard configuration of standard stock diamond the miniature diamond drills is flat end cylinder but the angle and radius can also be customized if needed.

sintered (metal bond) diamond solid miniature/thin drills – have hundreds of layers of diamond impregnated inside metal matrix. These miniature drills will last significantly longer than electroplated diamond solid drills. Recommended for drilling Ultra Hard Materials (harder than 8 on mohes scale or 60 on Rockwell Scale and clients that need very long life span.

APPLICATION: drilling smooth and clean holes in a wide variety of:

many other materials

Nickel Bond (plated) Hollow minature core drills

electroplated minature hollow core drills consists of steel tube with diamond coating on the tip These are available in stock from 1mm to 3.5mm diameter. These must be used for drilling completey through the material. The hollow core shapeprovides extra stability for deep drilling applications and can also be used for extracting very small and thin diameter cores from materials such as rocks, ceramics, glass, composites, bone metals and many others. The shank diameter is slightly smallerthen Diamond Core Drill outside diameter. Custom manufacturing is available. We can produce the minature plated hollow core drills in any diameter, drill depth, wall thickness, diamond grit size to better fit your particular requirements

Nickel Bond (plated) Minature Diamond Twist Drills

Twisted diamond drills are available from stock in 1mm to 2mm diameter in 0.1mm increments. These are typically used for drilling pearls and enlarging/reaming holes in large variety of other materials. These drills provide faster drilling speeds, than most other type of diamond drills. And are frequently used together with diamond flat bottom cylinder diamond solid thin drills. Also very popular for drilling pearls. Customs specifications can be made upon request

Non Core Formation/Flat Bottom Tip Drill / Bottoming Drills / Disintegrating Diamond Core Drills / Diamond Offset Style Core Drills

Diamond Bottoming Drills/Tools, sintered (metal bond) are used for making Blind Holes in all types of material ranging in hardness from sapphire, to quartz and slate. A bottoming tool does not have a core, and essentially works as both a diamond drill and grinding disc. The bottoming tools works by grinding the bottom and inside of the hole to a flat surface. This tool is just about the only way you can drill larger than 3/8″ OD (outside diameter) blind holes. Coolant is supplied through center of the drill through slot on side od diamond section or through small hole in diamond section designed for this purpose.

Used for almost any application

Large diameter diamond core drills are usually 100mm to 70mm diameter. Drilling depths can be as short as 10mm to as long as 1000mm. These are used for drilling large variety of materials such as Quartz, Sapphire, Silicon, rocks, composites, concrete and construction materials. These can be used for drilling holes or extracting core samples. Continuous rim core drills are available up to 22” Diameter. Continuous rim core drills are usually preferred for hard and brittle materials, quartz, rocks and extracting core samples. As we can provide precision tolerances on outside and inside diameter of the diamond core drill diamond section (crown) and customize the wall thickness to fit your particular requirements. These type of core drills also have minimum amount of run out compared to standard segmented core drills designed for concrete and construction applications.

These have lighter weight, precision machines steel tubes that are specially made for each individual application and hence provide minimum run out and vibration compared to the mass produced concrete/construction core barrels, allowing them to be used on precision drilling, milling and cnc machines. Larger diameter are segmented. Spacing between the segments can be controlled depending on application. And if needed braised together so there is no spacing between the segments. Almost any type of mounting options are available such as female or male threads and straight shanks made to your specifications.

The wall thickness is in proportional to diameter of the drill. If the wall thickness is to thin and the diameter of the core drill is large and drilling depth is long, the core drill would be very fragile. Typically we recommend the wall (kerf) thickness for larger diameter core drills not be below 2mm for this reason. We can grind slots in the diamond section to make the core drill more freer cutting. This is specially helpful for really ultra hard and dense materials. The number, width and depth of slots can be varied. We can produce large diameter core drills with almost any type of mounting per client specification female or male thread or straight shank per client specification. Popular mounting type for large diameter core drills include following female thread sizes: 7/8-14,1-14,1-1/2-12, and 2-1/2-12”.

Diamond, CBN, PCD, and CVD Milling Tools, Diamond Chamfer Tools, Diamond Radius Tools, Diamond Profiling Tools, Diamond Ball Nose Tools, Diamond Full Ball Tools, Diamond Bottom Grinding Tools, Diamond Reamers, Diamond Threading tools, Diamond Engraving Tools, Diamond Radius Tools, Diamond Chamfer Tools, & many other custom tools made to your specifications

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms, milling, deburring, Thread grinding.

These tools are used on large variety of ultra hard, dense, and brittle materials, such as advanced ceramics (alumina, silicon carbide, boron nitride, boron carbide, pzt, sapphire, silicon, yag, quartz. Glass, crystals, large variety of natural and semi precious stones, composite materials, ferrous and non ferrous metals, carbide, ceramics, ferrites tough alloys and cements, and many others.These tools are used on large variety of routers, jig grinding machines, hand pieces, milling machines, etc. Operating speeds : 15,000 to 35,00 rpm’s range. These are available in 4 bond types.

Used for almost any application

Dual Core Drills are used when drilling parts that require a specific ID and OD dimension at the same time. Saves time be drilling out the required core and hole in material at the same time. These are made to each individual client requirements. We can make almost any outside and inside diameter, wall thickness, drill depth and mounting type standard tolerances depend on diameter but they usually range + / – 100 microns. with special tolerances of up to 25 microns are also available. Most diameters can be made from really small to much larger diameters. standard lead time is 2 to 3 weeks. Expedited lead time of 1 week is also available at additional charge. Usually dual core drills are sintered (metal bond).

diamond &cbn countersinks used to create conical holes, expanding existing holes,breaking corners and chamfering holes and polishing existing holes in large variety of materials. Available from stock in many specifications and we can also manufacture almost any diameters, angles, radiuses, diamond bond types, diamond grit sizes, lengths, shanks sizes are available to fit your particular application. Standard lead time is usually 2 to 3 weeks and expedited lead time of 1 week is also available at additional charge if needed. diamond &cbn countersinks can be mounted on any type of mounting such as female or male collet (thread) or straight shank per your specification. Diamond countersinks can be solid to use submerged in coolant or with coolant slot in diamond section, where the coolant can pass through center of the tool this is specially recommended for ultra hard and dense material applications. Diamond Countersinks are available in many different bond types.

Nickel bond (plated) and braised diamond countersinks are recommended for softer materials such as composites, glass, marble. Sintered (metal bond) are recommended for more harder and dense material such as ceramics.

heavy wall core drills are typically used when using hand held machines, drilling abrasive material or by less experiences users. Most standard diamond core drills/bits designed for stone fabrication/installation and core bits for concrete/construction are heavy wall. There are number of specialized application of drilling other materials where heavy wall can be advantageous. We can produce core drills with almost any wall thickness you require

primarily to create a beveled edge at the intersection of two surfaces

To create beveled edges on countertops, tiles, and monuments. This provides a smoother transition between surfaces and can be particularly useful for aesthetic reasons or to prevent chipping on the edges.

For smoothing and bevelling edges of glass sheets, especially those that will be exposed in the finished product.

In industries where precision is crucial, diamond chamfer tools can be used to create bevels on metal parts, especially when working with hard alloys.

For bevelling and refining the edges of various components, including ceramic substrates.

For bevelling edges, especially in decorative concrete applications or when creating joints.

Diamond radius tools are specialized tools designed to create a rounded edge or profile on various materials.

Used to give a rounded finish on countertops, tiles, and stone monuments. A rounded edge can be more resistant to chipping compared to a sharp edge.

Employed to create rounded edges on glass pieces for both aesthetic and safety reasons.

For refining and finishing edges, especially for decorative pieces.

While diamond isn’t typically the first choice for metals, it can be used for hard alloys or metals that are abrasive when machined.

Used to shape and finish edges, especially when working with hard composite materials.

Diamond profile tools are specialized tools used for creating specific shapes, contours, and profiles on hard materials.

For shaping and profiling countertops, edges, and stone details.

Used to create intricate designs, edges, and finishes on ceramic pieces.

For detailing and shaping glass items.

In decorative concrete applications or for specialized masonry detailing.

Produces a fully rounded edge on the material.

Creates a semi-circular profile.

A classic “S” shape often used in countertop edges.

A straight incline, typically at a 45-degree angle.

A straight drop transitioning into a rounded or curved profile.

Diamond engraving tools are specialized cutting instruments that utilize diamond tips or edges to inscribe, etch, or carve intricate designs on various materials. When CNC (Computer Numerical Control) technology is integrated, the precision and repeatability of the engraving process significantly increase, making it suitable for intricate designs and high-volume production.

Materials: Diamonds, due to their unparalleled hardness, can engrave a wide range of materials, from metals (like aluminum and copper) to hard ceramics, glass, gemstones, and even some hard plastics.

Drag (or non-rotating) engravers: The diamond tip does not rotate but is dragged across the material to scribe or scratch a line.

Rotating engravers: The diamond tip rotates, allowing for deeper and broader engraving, similar to traditional drill bits but designed for detailing.

Nameplate engraving, jewelry design, creating intricate designs on glassware, etching barcodes or QR codes on industrial components, and decorative engraving on stone or tiles.

CNC technology ensures each engraving is consistent and precise, especially critical for intricate designs and logos.

Users can program designs into the CNC system, which then guides the diamond engraving tool with high accuracy.

Suitable for high-volume production runs, as the same design can be engraved repeatedly with minimal manual intervention.

CNC systems can work with various diamond engraving tools, enabling a wide range of engraving depths, styles, and finishes.

High-volume jewelry production, engraving serial numbers on industrial components, intricate designs on electronics housings (like phone and laptop exteriors), and detailed artwork on glass or ceramics.

The shape and geometry of the diamond tip play a crucial role in determining the engraving style. Points, conical shapes, and pyramidal tips are common.

Depending on the CNC machine or engraving setup, various shank configurations may be used, like straight shanks or threaded designs.

Especially when engraving metals, coolants or lubricants can prevent overheating and extend tool life.

It’s essential to match the diamond engraving tool with the material. Some tools might be optimized for softer metals, while others are designed for hard ceramics or glass.

The desired depth will influence the choice of tool and CNC settings. Deep engravings might require multiple passes or specialized diamond tips.

Regular inspection of the diamond tip is necessary to ensure it remains sharp and free from damage.

In summary, diamond engraving tools, especially when paired with CNC technology, offer industries an advanced method for inscribing intricate designs on a wide range of materials. Whether for artistry, identification, or functionality, these tools are invaluable for precision engraving tasks.

Diamond cone grinding tools are specialized grinding tools that have a cone shape and are embedded with diamond particles. The conical shape allows these tools to grind, shape, or debur in areas that might be difficult to reach with other types of grinding tools.

Used for deburring, chamfering, and finishing of intricate metal parts, especially after machining or casting.

These tools are used for detailed work on stone, especially in sculpting, to create fine details or to smooth hard-to-reach areas.

For detailed shaping or finishing of glass pieces

Refining, shaping, and deburring ceramic pieces, especially in complex or detailed parts.

Grinding and shaping advanced materials and composite structures.

Diamond hole or bore finishing tools are designed to achieve precision internal surface finishes in bores or holes. The use of diamond as the abrasive ensures longevity and a high-quality finish, especially for hard and abrasive materials.

These are used to improve the geometric form of a surface and the surface texture. Honing tools usually consist of one or more honing stones with diamond abrasives that are held against the bore as the tool rotates and reciprocates inside the hole.

These are rotary cutting tools that are used to accurately finish a previously drilled or bored hole. Diamond reamers ensure a high level of precision and surface finish.

Lapping processes use a lapping paste which contains diamond particles. The tool is moved back and forth inside the bore or hole with the abrasive paste in between, providing a fine finish.

For finishing cylinder bores in engines to ensure smooth piston movement.

For achieving precision bore geometries and surface finishes in components.

For honing hydraulic cylinder bores.

In any sector where high-precision bores are essential, such as in molds, spindles, or certain instrumentation.

Ultra-thin wall diamond core drills with kerf thicknesses ranging from .010” (0.254mm) to .020” (0.5mm) are specially designed tools that prioritize precision and minimal material loss. Their narrow kerf is ideal for tasks where material conservation and precision are essential.

For ultra-thin wall core drills, typical diameter ranges can be from as small as 0.5mm up to larger diameters (such as 50mm or more). However, as the diameter increases, maintaining such a thin wall can be challenging. For very large diameters, there might be additional considerations for structural integrity and tool rigidity.

Very thin wall diamond core drills with kerf thicknesses ranging from .021” (0.5334mm) to .040” (1.016mm) are specialized tools used in industries where there’s a balance between precision, material conservation, and tool strength.

The diameter range for very thin wall core drills can vary widely, from small diameters (like 1mm or even smaller) up to larger sizes (such as 50mm or more). The specific diameter selection typically depends on the application and material being drilled.

Thin wall diamond core drills with kerf thicknesses ranging from .041” (1.0414mm) to .060” (1.524mm) are versatile tools that strike a balance between robustness and precise cutting, making them suitable for various applications across several industries.

The diameter for thin wall core drills can be as small as a couple of millimeters to larger sizes, possibly exceeding 100mm. Their broad diameter range makes them suitable for diverse applications and tasks.

Standard wall diamond core drills with kerf thicknesses ranging from .061” (1.5494mm) to .100” (2.54mm) are among the most commonly used in various industries due to their general-purpose nature. They offer a good balance between tool durability and precision cutting.

These drills can have diameters ranging from just a few millimeters to over 150mm. They are ideal for situations where the precision of a thinner wall drill isn’t crucial, but the strength and durability of the tool

Heavy wall diamond core drills, with kerf thicknesses of .100” (2.54mm) and above, are constructed for demanding drilling tasks where the tool’s strength, durability, and wear resistance are of paramount importance.

These can span from smaller diameters (10mm or even less in some cases) to much larger sizes, potentially exceeding several inches (or even feet for specific industrial applications).

made for tough jobs where the tool’s strength and longevity are key. They are used in various demanding industries, from mining to large-scale construction, to handle tasks that thinner drills might not withstand.

Hollow diamond drills and non-core (or solid) diamond drills serve different purposes, have distinct designs, and are used in various applications. Here’s a breakdown of the differences and their applications:

These drills are hollow in the center. The drilling action creates a cylindrical core as the hole is drilled.

Removes a cylinder of material (the core) instead of grinding away the entire hole’s volume, which can be more efficient.

The extracted core can be analyzed or used for other purposes in certain applications.

Used to extract samples of rock, soil, or sediment for analysis.

Drilling holes in granite, marble, and tiles without removing all the material.

Drilling holes in concrete or masonry, especially when you want to avoid excess dust or want a clean hole.

For drilling precise holes in glass panels or products without cracking or chipping.

These drills are solid and don’t produce a cylindrical core when drilling. Instead, they grind away the material throughout the drilling process.

Can be more durable since there’s more material supporting the diamond abrasive edge.

Often produces a smoother wall finish because it’s grinding away the entire hole’s material.

Drilling hard metals or materials where you don’t need or want a core.

Where a smooth finish on the hole is required.

Drilling very small, precise holes in hard materials.

Drilling holes where the finish is more critical than material removal efficiency.

While both types of drills use diamond abrasives to cut through hard materials, the choice between them often boils down to the specific application and the desired outcome. Hollow drills (core drills) are preferable when you want to remove a core or avoid grinding away all the material, while solid diamond drills are chosen for their durability and finish quality.

Both female thread collet and straight shank mounting are methods to attach diamond core drills to their respective driving mechanisms. Each method offers its own advantages based on the application and the type of equipment being used. Let’s dive into the differences:

This refers to a collet (or sometimes the tool itself) that has an internal threading. The driving mechanism or the spindle will have a male thread that matches this internal thread to ensure a secure connection.

Quick tool changes due to threaded connection.

Can offer a secure hold, especially for tools that might experience lateral stress.

May provide better centering or alignment, especially if the threads and collet are precision-made.

Thread wear can result in reduced holding capability over time.

Specific thread types might be limited to certain equipment or manufacturers, reducing interchangeability.

Often used in applications that require quick tool changes or when the tool might need to resist forces from multiple directions.

In this method, the diamond core drill has a straight cylindrical shank without any threading. The shank is held by friction inside a chuck or collet. The diameter of the shank is consistent along its length, although some might have slight grooves or flats to improve grip.

Universal compatibility: Straight shanks can be used with a variety of chucks as long as the diameter matches.

Less wear and tear on the connection point because there are no threads to degrade.

Can be secured very tightly, especially with high-quality chucks.

Tool changes might be slower compared to threaded connections, depending on the type of chuck.

If not secured properly, the tool might slip, especially under heavy load.

Commonly used in many drilling applications, especially when a secure hold is paramount and the user is less concerned about rapid tool changes.

In choosing between these two mounting methods, one should consider the specific needs of the application, the equipment being used

thread has an outer diameter of 1 inch with 14 threads per inch. This type of mounting is used on larger diameter inside diameter and outside diamond core drills usually for larger diameter sizes. This is frequently used in geology, optics and ceramic industries

1/2″ Gas Male Connection,” commonly known as the “1/2″ Gas Thread” or “Belgium Mount,” is a standardized thread type frequently used in the glass, and stone for diamond core drills, milling tools, and many other types of tooling. This is most popular type of mounting for cnc machines designed for these types of applications. For this reason you can find lot of diamond tools and drill specifications from stock with this type of mounting.

Thread Diameter:As indicated, the diameter is approximately 5/8″.

Threads per Inch: The “11” in the 5/8-11″ specification indicates there are 11 threads per inch.

Thread Profile: It’s a coarse thread, which allows for quicker attachment and detachment compared to fine threads and offers better resistance to accidental detachment, especially in applications with significant vibration.

This is one of the most popular mounting types used for large variety of diamond core drill and tool specification across many industries and applications. From precision to do it your self applications. Large variety of stock diamond drills and tools is usually available from stock in this mounting type.

This is used in stone, construction, tile/porcelain glass industries. Also can be used for more precision

Straight shank diamond core drills are widely used across many industries due to their simplicity and adaptability. The straight shank simply fits into a chuck, collet, or similar holding mechanism. While the exact specifications can vary depending on the manufacturer and intended application, there are some common dimensions that are prevalent in the industry:

Standard sizes often include: 3mm, 6mm, 8mm, 10mm, and 12mm.

However, many manufacturers offer a wide range of diameters, from as small as 1mm to as large as 25mm or even more, to fit various collets and chucks.

Common lengths for straight shanks range from 30mm to 60mm. However, specific lengths can vary based on the drill’s overall size and intended application. Longer shanks can be useful when trying to reach deeper areas or when additional clearance is required.

For diamond core drills that are intended for wet drilling (to reduce heat and increase tool life), the shank might have a hole to allow for water or coolant passage. The diameter of this hole can vary, but it’s typically in the range of 1mm to 3mm. The exact size often depends on the overall size of the drill and the amount of coolant flow required for efficient cooling.

If you’re drilling only partially through a material and not all the way through, a hollow diamond core drill is typically not the best choice. This is because the core (the cylinder of material that gets removed during drilling) might become trapped inside the hollow drill bit if you don’t drill all the way through. Removing a trapped core can be challenging and might even damage the drill bit.

In such situations, a non-core formation diamond drill (solid drill) is generally preferable. Here are the reasons:

Since it grinds away the entire hole’s volume without producing a cylindrical core, there’s no concern about material getting trapped inside the drill.

With a solid drill, you have more control over the depth you’re drilling, especially when paired with a drill press or other machinery that allows depth stops or measurements.

Solid drills often produce a smoother finish in the hole, which might be desirable if the partial hole will be exposed or used in a precision application.

However, if you have a specific need to extract a partial core from a material, then you’d use a hollow core drill, but you’d have to have a method to remove the core from the bit afterward. This is a rarer scenario, but there are applications, especially in research or specialized material analysis, where this might be necessary.

In such situations, a non-core formation diamond drill (solid drill) is generally preferable. Here are the reasons:

Grinding a radius on the diamond edge tip of core drills (or any drill) refers to modifying the cutting or leading edge to have a rounded or curved profile instead of a straight or pointed profile. Here are the purposes and advantages of such a design:

A radius on the diamond tip can offer a smoother start when drilling. Instead of a sharp, abrupt entry, the rounded edge provides a gentler engagement with the material, reducing the chance of chipping, especially in brittle materials like glass or certain ceramics.

A radius can distribute the stress over a larger area, which might prevent premature wear or fracturing of the diamond edge.

A rounded tip can help maintain stability during drilling, especially if there’s any lateral movement. This can lead to straighter holes.

The increased surface area from a radius can help in better heat dissipation, reducing the chances of the diamond tip overheating.

With a rounded tip, there’s a bit more forgiveness when the drill isn’t perfectly perpendicular to the material. This is especially beneficial in hand-held drilling operations.

As the radius might distribute the wear more uniformly across the tip, the drill can maintain its performance for a longer duration before requiring re-sharpening or replacement.

In certain materials, a rounded edge can produce a smoother sidewall finish in the drilled hole.

Diamond core drills are often made by attaching diamond segments (which do the cutting) to a steel core or body. How these segments are attached to the body can significantly influence the performance, durability, and applications of the drill. Here are the primary methods used:

Brazing involves the use of a filler metal (braze alloy) to join the diamond segment to the steel core. The filler metal is heated until it’s molten and then allowed to cool, bonding the diamond segment to the drill body.

Strong bond, especially when done correctly.

Cost-effective and widely used.

The high temperatures involved in brazing can potentially damage the diamonds, reducing their efficiency.

Not suitable for high-demand applications, as the bond might wear out faster.

This method uses a laser to fuse the diamond segment and the steel core together. The laser creates a high-energy beam that melts a small portion of both the segment and the core, creating a solid bond.

Extremely strong bond, suitable for demanding applications

No filler metal is used, so there’s a direct bond between the diamond segment and the drill body.

Lower risk of diamond damage since the heat is localized.

More expensive due to the equipment and expertise required.

Not as widespread as brazing, so might not be available for all drill types or sizes.

Runout is a critical specification for drills, as it directly impacts the quality of the hole being drilled and the longevity of the tool. The term “runout” refers to the extent to which the tool (or the workpiece) doesn’t rotate perfectly on its central axis. High runout can cause uneven wear on the tool, reduced hole quality, and increased heat generation.

For diamond drills, which are often used for precision applications and hard, brittle materials like glass, ceramics, and certain stones, minimizing runout is especially crucial.

For general-purpose drilling where absolute precision might not be necessary, a typical runout could range from 0.0005 inches (0.013mm) to 0.002 inches (0.05mm). However, it’s essential to note that “standard” can vary based on the manufacturer and the specific application.

Precision diamond drills are crafted with higher manufacturing standards and stricter tolerances. For these tools, a runout of less than 0.0002 inches (0.005mm) might be expected. Some ultra-precision drills might even have tighter runout specifications.

Even a precision drill can have increased runout if it’s not held correctly. High-quality collets and toolholders are essential for minimizing runout.

The spindle’s precision and condition of the machine also impact the runout.

How the drill is mounted can influence runout. For example, a drill with a shank that’s not perfectly cylindrical can introduce more runout.

Over time, as tools and machines wear down, runout can increase. Regular maintenance and tool replacement are essential to maintain low runout.

Runout in diamond drills can be influenced by the drill diameter, wall thickness, and mounting type, among other factors. Here’s how these parameters can affect runout:

These might inherently have more potential for runout, especially if the spindle or tool holder is not up to par. This is because small misalignments or imperfections can translate into more significant discrepancies over the longer circumference of larger diameter drills.

While they may have less inherent runout due to diameter, they might be more sensitive to even minor runout because the tolerance and clearance in the workpiece are often less.

These are more fragile and can be more prone to deflection, which might increase perceived runout. They might also be more susceptible to damage from runout because uneven wear can quickly erode the thin wall.

They offer more rigidity and can be more forgiving to minor runout. However, a significant runout can still cause uneven wear and reduced drilling quality.

This is a common type of mount. The quality of the fit between the shank and the toolholder or collet is crucial. If the shank isn’t perfectly cylindrical or if the toolholder is worn, runout can be significant.

Such as a 5/8″-11 thread, for instance, relies on the quality of the thread engagement. If threads are damaged or dirty, or if there’s play between the male and female threads, runout can increase.

This type often provides a more stable and accurate mounting, reducing the chance of runout, especially in larger diameter drills.

Such as Morse tapers, can provide excellent alignment and minimal runout if the taper is clean, undamaged, and fits well within its corresponding socket.

In addition to these factors, the overall quality of the diamond drill manufacturing process, including the concentricity of the diamond layer, the quality of the bonding material (like braze or laser welds), and the straightness of the drill body, will all influence runout.

The diamond depth (or height) for diamond core drills refers to the height of the diamond segment or layer that’s bonded to the core drill’s body. This diamond segment is where the actual cutting action takes place. The height of this segment is crucial because it indicates the usable life of the drill before it needs to be replaced or refurbished.

Here are some considerations regarding the diamond depth or height for diamond core drills:

Diamond segment heights can vary, but common heights for many commercially available core drills are in the range of 5mm to 10mm. Some specialized drills might have shorter or taller segments based on the specific application.

The diamond segment height essentially dictates how much material can be drilled before the diamond wears away, and the drill becomes ineffective. A greater diamond height generally indicates a longer life, but the actual life also depends on the hardness and abrasiveness of the material being drilled, the drilling speed, and the cooling/lubrication methods used.

Drills with a greater diamond segment height might be more expensive initially due to the added diamond and bonding material. However, the longer life could offer cost savings in the long run, especially in high-volume applications.

The type of bonding matrix (metal bond, resin bond, etc.) can influence the wear rate. Some bonds are designed to wear faster to expose new diamond grit continuously, ensuring sharpness. The segment height needs to be paired with an appropriate bond for the material to ensure optimal life and performance.

For very hard materials, a taller diamond segment might be preferable, as these materials can cause more rapid wear. For softer materials or materials that can be abrasive (like some types of concrete), the bonding matrix’s composition might be more critical than the segment height.

The height of the diamond segment can influence the drill’s stability and heat dissipation characteristics. Taller segments might offer better heat dissipation due to increased surface area, but if not properly balanced, they might also introduce more vibration or instability.

When selecting a diamond core drill, it’s essential to consider the diamond segment height along with other factors like the diamond grit size, bonding matrix, and drill geometry. The optimal segment height will often depend on the specific application, drilling equipment, and project requirements.

The depth of a diamond drill bit, often referred to as the drilling depth, working length, or drilling length, is the maximum depth to which the drill can penetrate the workpiece. This should not be confused with the diamond segment height (often referred to as diamond depth or diamond height), which determines the longevity of the drill.

The drilling depth of a diamond drill bit can affect performance and other variables in the following ways:

Tends to dissipate heat more efficiently since there’s less frictional surface and more opportunities for cooling fluid to reach the drilling interface.

Can generate more heat due to increased friction. Proper cooling and lubrication become even more critical in deep drilling to prevent overheating.

Typically has more efficient chip removal because chips have a shorter distance to travel.

Can face challenges in chip evacuation, especially if the flute design isn’t optimized for deep drilling. Accumulated chips can cause binding or excessive heat.

Offers more stability and is less prone to deflection.

Can lead to more potential deflection or wobbling, especially if there’s excessive runout or if the drill is not adequately supported.

Often allows for faster drilling speeds due to better heat dissipation and chip removal.

Might require slower speeds to ensure efficient chip evacuation and to prevent overheating.

Tends to have more consistent wear across the diamond segment.

Can experience uneven wear, especially if cooling isn’t uniform throughout the depth, leading to potential premature failure or reduced hole quality.

Easier to ensure adequate lubrication and cooling.

Requires more deliberate cooling strategies, such as pressure-assisted coolant delivery, to ensure the drill bit remains cool and lubricated.

Easier to maintain hole straightness and accuracy.

Increases the risk of hole deviation, especially if the drill bit encounters varying material hardness or if there’s any misalignment.

In general, as drilling depth increases, challenges related to heat, chip evacuation, stability, and hole accuracy become more prominent. Proper tool selection, machine setup, and drilling parameters are essential to overcome these challenges. For very deep drilling applications, specialized drills with specific flute designs, enhanced cooling mechanisms, and optimized diamond segments might be required.

The pilot, which is essentially a smaller bit at the tip of the core drill, aids in guiding the core drill accurately into the workpiece. This ensures that the drill starts at the precise desired location without wandering or skating across the material’s surface.

Provides a precise start for the hole.

Minimizes chances of bit wandering or misalignment.

Results in a cleaner hole entry.

Useful in materials where precision is essential, like certain ceramics or delicate composite structures.

These segments feature a pointed or peak-like design on the top.

The rooftop design assists in starting the drilling process, allowing for quicker penetration into hard materials. The design also facilitates better debris removal and cooling.

Fast drilling in concrete, granite, and other hard materials.

The edge of the segment is serrated or notched.

These segments offer good speed and longevity. The gaps in the serrations allow for better heat dissipation and debris removal.

General-purpose drilling in a variety of materials, especially concrete.

These segments have a T-shape, which provides a wider cutting surface.

Offers smoother drilling and is less likely to cause chipping on the material.

Stones like marble and granite where a smooth finish is required.

The bit contains a continuous ring of diamond segments.

Allows for very fast and smooth drilling.

Materials where fast, continuous cutting is required.

Segments are placed in a cross or X pattern.

Provides increased stability and more uniform wear.

Balanced cutting in medium to hard materials.

Segments are shaped like a star.

Allows for faster starting and good debris removal.

Versatile and can be used on various materials.

A smaller segment at the tip of the core bit, followed by regular segments.

Assists in guiding the drill bit accurately into the material for a precise start.

Delicate materials or when precision is essential.

Instead of having defined segments, these bits have diamond particles impregnated throughout the matrix material.

Offers consistent performance and wear as diamonds are uniformly distributed

Drilling in very abrasive materials.

The specific segment design chosen depends on the material being drilled, the type of equipment used, the desired speed and finish, and other factors. For example, while drilling very hard concrete, a segmented design may be preferred for its aggressive cutting ability. In contrast, for more delicate stones like marble, a T-segmented or ring-segmented design may be chosen to prevent chipping and achieve a smoother finish.

The spacing between the segments and the number of segments on a diamond core bit are determined by several factors, including the bit’s diameter, the material being drilled, and the specific drilling requirements. Here’s a general overview of how these design aspects are considered:

The gaps or spaces between the segments allow for better heat dissipation and facilitate the removal of debris or slurry from the drilling process.

For harder materials like granite or reinforced concrete, wider spacing can assist in removing larger amounts of dust and debris. For softer, more abrasive materials like limestone or some sands, closer spacing can ensure consistent wear and more even cutting.

Larger diameter bits will naturally have more segments than smaller diameter bits.

Example: A 1-inch diameter core bit might have 4 segments, while a 4-inch diameter bit might have 12 or more.

Harder materials might benefit from more segments as this can spread out the work and heat, leading to longer segment life. Softer materials, on the other hand, might work better with fewer segments to prevent bit overcrowding and to ensure effective debris removal.

Narrower segments might be used in higher quantities than wider segments. The width is another variable to consider in conjunction with the number and spacing.

More segments generally mean more cutting edges engaging the material at one time, which can lead to faster drilling. However, this also means increased friction and heat.

Core bits used with water or other cooling mechanisms might have different segment configurations compared to those intended for dry drilling.

More segments can distribute the wear more evenly across the bit, potentially increasing its lifespan. However, the material and the drilling conditions play significant roles in determining actual wear rates.

The thickness of the segments on a diamond core bit can vary depending on the design and intended application of the bit. Generally speaking, the segment thickness is determined by factors such as the material to be drilled, the type of equipment used, the desired speed and longevity of the bit, and the overall design of the bit.

Typically, segment thickness for diamond core bits can range from:

These thinner segments are generally used for more delicate operations, such as drilling softer materials or when a precise and fine finish is required, like in the case of tiles or some stones. They’re also more prone to wear out faster due to the thinner profile.

These are common thicknesses for general-purpose diamond core bits. They provide a good balance between cutting performance and longevity. Such segments are used for materials like concrete, masonry, and various stones.

Thicker segments are designed for heavy-duty operations, usually in professional, industrial, or construction settings. They’re suitable for hard and abrasive materials, providing longer service life. These are commonly found in larger core bits designed for tough applications such as reinforced concrete or certain hard stones.

The segment’s thickness directly affects the bit’s lifespan. Thicker segments contain more diamond and metal bond material, which means they can undergo more wear before becoming unusable. However, thicker segments might also result in slower drilling speeds, as there’s more material to cut through and more friction generated.

radius or angle of the segments on a diamond core bit refers to the profile or geometry of the segment’s cutting edge. These profiles are engineered for specific applications, drilling conditions, and materials. Here’s a breakdown of some of the common shapes and their functions:

General-purpose drilling in a variety of materials.

Widely used for drilling concrete, masonry, and stone. Provides consistent cutting performance.

Fast drilling and quick starting in hard materials. The pointed design allows for quicker penetration.

Often used for hard materials like granite or reinforced concrete.

Smooth drilling with minimal chipping. The curved profile allows for a softer engagement with the material.

Ideal for more delicate materials like marble or some ceramics where chipping can be a concern.

To remove larger amounts of material and to avoid core jamming. The U-shape facilitates efficient debris removal.

Often used for larger diameter bits or in situations where core removal is crucial.

Designed to offer a compromise between fast cutting and longevity. The tapered profile engages the material aggressively at the tip but offers a wider base for heat dispersion.

Varied, but often found in mid to hard materials like certain stones or harder concretes.

Some bits feature segments with a combination of profiles, intending to offer the advantages of different shapes.

Specific to the challenges of a particular drilling situation.

The exact radius or angle of a segment will vary based on manufacturer specifications, tool design, and intended application. For example, a roof top segment for one manufacturer might have a steeper or more pronounced point than another, based on their proprietary design and testing.

The geometry of the segment can influence drilling speed, finish quality, heat generation, and overall bit lifespan.

tolerance range for diamond core drills varies based on numerous factors such as the drill’s diameter, wall thickness, bond type, and the specific application for which the drill is intended. Here’s a general overview:

Typically ±0.02 to ±0.05 mm.

Typically ±0.05 to ±0.15 mm.

Typically ±0.1 to ±0.5 mm.

tolerances for the inside diameter (ID) of diamond core drills depend on several factors, including the drill’s intended application, size, bond type, and manufacturing quality. Here’s a general breakdown based on the drill’s diameter:

Typically ±0.01 to ±0.03 mm.

Typically ±0.02 to ±0.05 mm.

Typically ±0.05 to ±0.15 mm.

Typically ±0.1 to ±0.5 mm.

The inside diameter of the core drill is often formed using precision grinding machines that can remove material with an accuracy of micrometers. These machines are often CNC-controlled for added precision.

For certain high-precision applications, EDM can be used to form the desired shape with very tight tolerances. This process uses electrical discharges to erode material and achieve the desired dimensions.

After initial machining, the inside diameter can be fine-tuned using lapping processes. This involves using a lapping compound (usually a very fine abrasive) and a lapping tool to polish and refine the internal diameter.

This method involves a collet or a piece of steel that’s brazed onto a tube or shaft to create the core drill body.

Modularity: If the design requires different components or sections (like adaptors for mounting or specific fluting), braising allows for combining these distinct parts efficiently.

Potential Cost Savings: Depending on the design complexity, brazing might offer a more cost-effective method of manufacturing.

Joint Weakness: The brazed joint can introduce a potential weak point, which might become a problem under high mechanical stresses.

Consistency: Repetitive brazing might introduce some variation between individual drills, affecting consistency in large batches.

The entire body of the core drill is machined from a single steel piece using CNC equipment.

Strength: Without any joints, the tool body possesses inherent mechanical strength.

Precision & Consistency: CNC machining ensures each drill body adheres to precise specifications, ensuring consistency across batches.

Customization: Modern CNC machines can produce complex geometries and features tailored to specific applications.

Cost: Depending on the intricacy of the design, CNC machining might incur higher production costs compared to brazing, especially when considering material wastage.

Production Time: For specific designs, CNC machining might be more time-consuming than a brazing process.

Purpose: The pilot, which is essentially a smaller bit at the tip of the core drill, aids in guiding the core drill accurately into the workpiece. This ensures that the drill starts at the precise desired location without wandering or skating across the material’s surface.

Accuracy: Provides a precise start for the hole.

Reduced Risk: Minimizes chances of bit wandering or misalignment.

Better Finish: Results in a cleaner hole entry.

Applications: Useful in materials where precision is essential, like certain ceramics or delicate composite structures.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales