Diamond Dicing Blades

Diamond & CBN Dicing Blades

SMART CUT® technology

SMART CUT® Diamond & CBN Dicing Blades help you improve cut quality, extend tool life, and keep your process stable. You see less chipping, more accurate kerf widths, and better dimensional control. The blades run with lower cutting forces and support faster, repeatable production. You reduce operating costs through fewer blade changes, less downtime, and longer blade life. This gives you stronger return on investment and the best cost of ownership

Best Return

on Investment

Attractive Cost of

Ownership

Thousands of Diamond & CBN Blades in stock

Custom Manufacturer with Fast Lead times

Unmatched

Prices in North America

Unmatched Experience & Technical Support

Dicing Blades from 0.5" (12.7mm) to 6" (154mm) in Diameter, starting from .001" (25 microns) Thick For all applications and all types of Dicing & Slicing machines

When it comes to dicing, there is only one company that stands out. UKAM Industrial Superhard Tools is a one of the leading precision U.S. diamond dicing blade & tool manufacturers. As the first company to develop SMART CUT® technology, UKAM Industrial is a Partner in Your Success. We have the Experience, Tradition, and the People to improve & optimize your dicing operation. Contact us for Free Quote & application recommendation today!

Metal Bond (Sintered) Dicing Blades

Excellent form holding & corner characteristics, provide very long life, high level of consistency. Recommended for users requiring very straight cuts and larger blade exposures.

Hybrid Bond™ Dicing Blades

You will find all the advantages of cutting speed and fine finish that you have come to expect in a resin bond, and long life, consistency, aggressiveness, durability, and excellent performance on you look for in a metal bond.

Nickel Bond (Hubless) Dicing Blades

Capable of maintaining excellent form & sharpness. Widely used for cutting wafers and thin substrates. Nickel Bond dicing blades provide minimum level of chipping on wide variety materials.

Resin Dicing Blades

More forgiving, self dressing, and freer cutting. Excellent choice for Ultra Hard & Brittle Materials. Recommended for applications where cut quality and surface finish is very important.

Nickel Bond (Hubbed) Dicing Blades

Typically used for dicing silicon and III-V materials. Creates very thin kerfs, 50 microns. Providing excellent cut quality with low wear rate

Carbide Dicing Blades

Slitting magnetic tape for computer backup applications, metal foils, P.E.T., polyester, sheet rubber, fine gauge steel, film, abrasive paper products, PC Board substrates, fiberglass, laminates, MLP/QFN

Dicing Equipment

Dicing

Table Top Slicing & Dicing Saw

Designed for Laboratory and R & D use. This machine can be used for slicing, dicing or cutting all kinds

Dicing

Accessories & Consumables

SMART CUT® Dicing Coolant (Water Soluble)

SMART CUT Synthetic Water Soluble coolant (fully contamination free) will reduce heat & friction between dicing blade and material. And improve

Dicing Service & Process Development

On all types of Metallic Materials, Ceramics, Optics, Substrates & Wafers. Typical Dimensions of material we work with: Maximum Size of

Dressing Sticks

We offer large range of dressing stick specifications in wide range of sizes and shapes for most dicing blade applications.

How To Select The Right Diamond Dicing Blade

For Your Application

|

Dicing Blade Bond Types |

Resin |

Sintered |

Hybrid |

Nickel Bond (Hubless) |

Nickel Bond (Hubbed) |

|---|---|---|---|---|---|

|

|

|||||

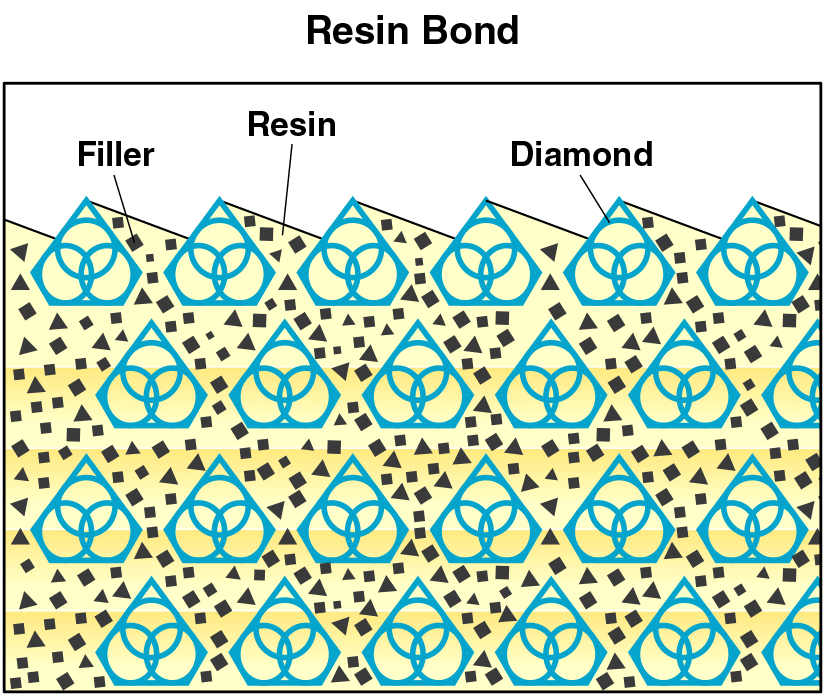

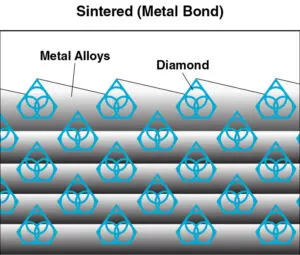

Bond Illustration |

|

|

|

|

|

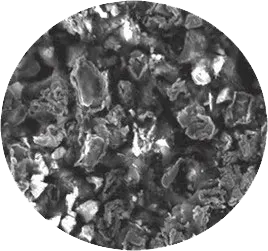

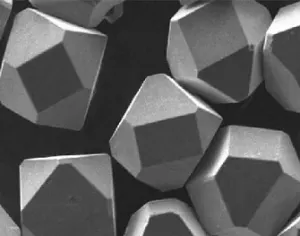

Sem Image |

|

|

|

|

|

Description: |

Organic bond matrix that is formed by high pressure and high temperature |

Metallurgical Bond with multiple layers of diamonds impregnated inside the metal matrix. |

Organic bond matrix that is formed by high pressure and high temperature |

Galvanic process, where diamond is deposited on steel body in chemical solution by time. |

Galvanic process, where diamond is deposited on steel body in chemical solution by time. |

Dicing Blade Applications |

|

|

|

|

|

Dicing Blade Characteristics |

Resin Bond dicing blade are typically more forgiving. self dressing, and freer cutting. Excellent choice for Ultra Hard & Brittle Materials. Recommended for applications where cut quality and surface finish is very important. |

Sintered (metal bond) Dicing blades have excellent form holding & corner characteristics, provide very long life, high level of consistency. Recommended for users requiring very straight cuts and larger blade |

You will find all the advantages of cutting speed and fine finish that you have come to expect in a resin bond, and long life, consistency, aggressiveness, durability, and excellent performance on you look for in a metal bond. |

Nickel Bond dicing blades are available with and without hubs. Capable of maintaining excellent form & sharpness. Widely used for cutting wafers and thin substrates. Nickel Bond dicing blades provide minimum level of chipping on wide variety materials. |

Nickel Bond Hubbed dicing blades are typically used for dicing silicon and III-V materials. Creates very thin kerfs, <50 microns. Providing excellent cut quality with low wear rate |

Advantages |

|

|

|

|

|

Dicing Blade Bonds |

|

|

|

|

|

Abrasive (Diamond/CBN) Sizes |

3 to 151 micron |

3 to 126 micron |

3 to 151 micron |

3 to 70 micron |

2 to 50 micron |

Abrasive (Diamond/CBN) Types |

Coated & Uncoated Synthetic Diamond or CBN |

Natural Diamond, Coated & |

Coated & Uncoated Synthetic Diamond or CBN |

Natural & Synthetic Diamond |

Natural & Synthetic Diamond |

Type of Diamond/CBN Used: |

High friability, excellent microfracturing |

Cubo-octahedral crystals, semi crystaline crystals |

High friability, excellent microfracturing |

Medium tough |

Medium tough |

Example of diamond Crystal Used: |

|

|

|

|

|

Abrasive Concentration |

25 to 200 con |

25 to 200 con |

25 to 200 con |

100 to 250 con |

100 to 250 con |

Minimum Dicing Blade Thickness |

.003" (.076mm) |

.004" (0.101mm) |

.004" (0.101mm) |

0003" (0.0076mm) |

.0003" (0.0076mm) |

SMART CUT® Precision Diamond Dicing Blades are designed and specially selected to provide maximum possible blade life, for your desired cut quality and speed

- Dicing blade OD : 0.5 in. to 8.0 in. (12 mm to 200 mm))

- Dicing blade thickness : As thin as 0.003 in. (0.076 mm)

- Diamond & CBN Abrasive Sizes : 3 to 151 micron

- Diamond/CBN Abrasive Concentration : 25 to 200 con

- Abrasive (Diamond/CBN) Types : Natural Diamond, Coated & Uncoated Synthetic Diamond or CBN

- Blade Types : 1A1, 1A8, 1A8S, 1E8, 1A1R & others

- Slots: we can grand any slot number depth and spacing

- Bond Hardness: Super Soft to Super Hard

- Accessories: coolants, dressing plates, and flanges

Equipment Used On:

- K & S (Micro-Swiss)

- Disco

- ADT

- Veeco

- MECO

- MTI

- ITI

- Meyer & Burger

- Surface Grinders

- Many Others

We Can Help You:

- Eliminate / Minimize Chipping

- Improve Surface Finish Quality

- Preserve True Material Microstructure

- Reduce & eliminate Material Deformation

- Increase Blade Life

- Improve dicing Process Consistency

- Improve Productivity

- Maintain Consistent Cutting Speed

- Reduce Blade Change & Mounting Cost

- Reduce Cost

- Reduce Chipping

- Reduce Blade Wear

- Increase Process Consistency

- Increase Production Rate

- Improve Part Geometry & Tolerances

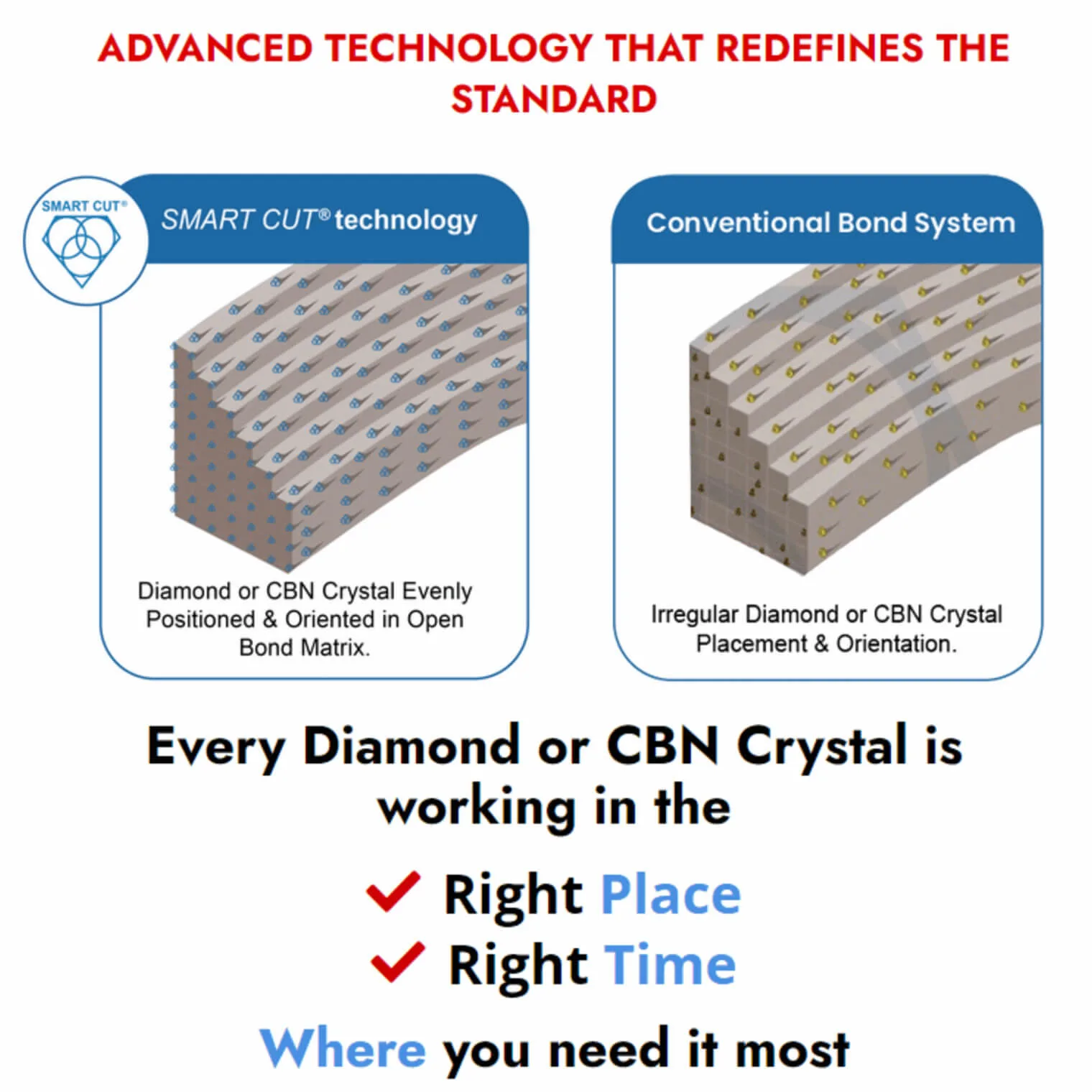

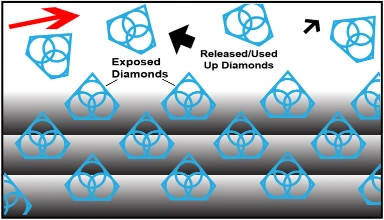

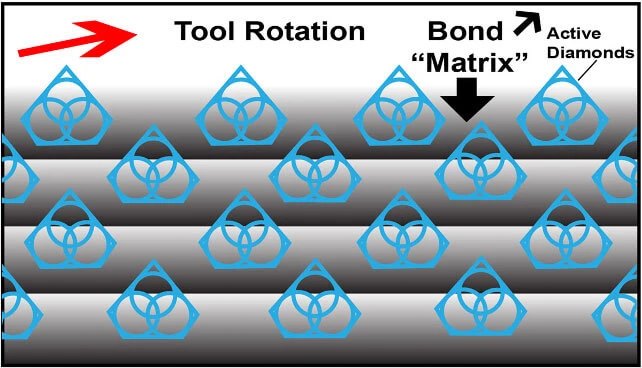

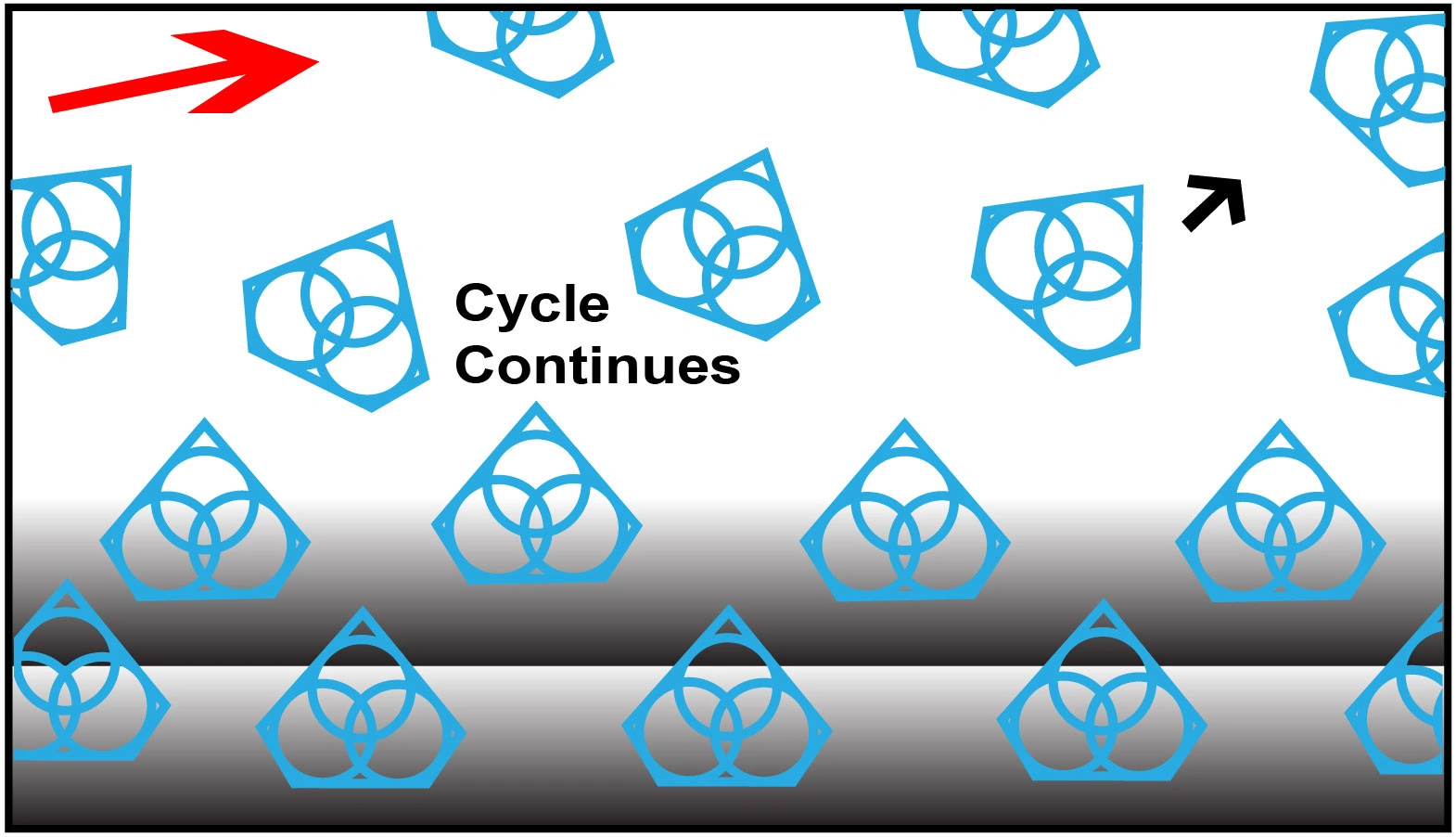

How SMART CUT® Bond Works?

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

ARE YOU USING RIGHT DIAMOND & CBN TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND & CBN TOOLS?

Knowledge Center

Select right Diamond Dicing Blade for your application

Dicing Blade Operations Recommendations

Optimizing your Diamond Dicing Performance

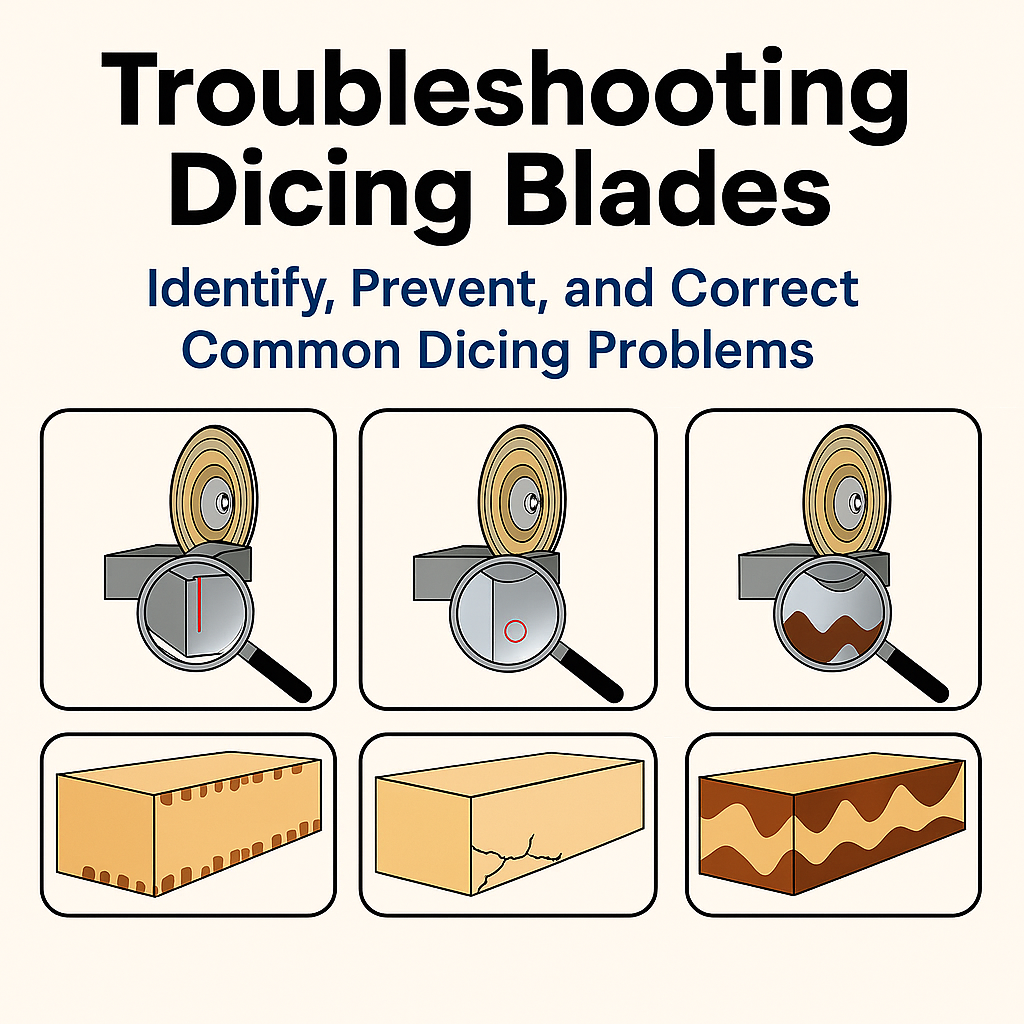

Trouble Shooting Dicing Problems

Application Recommendations

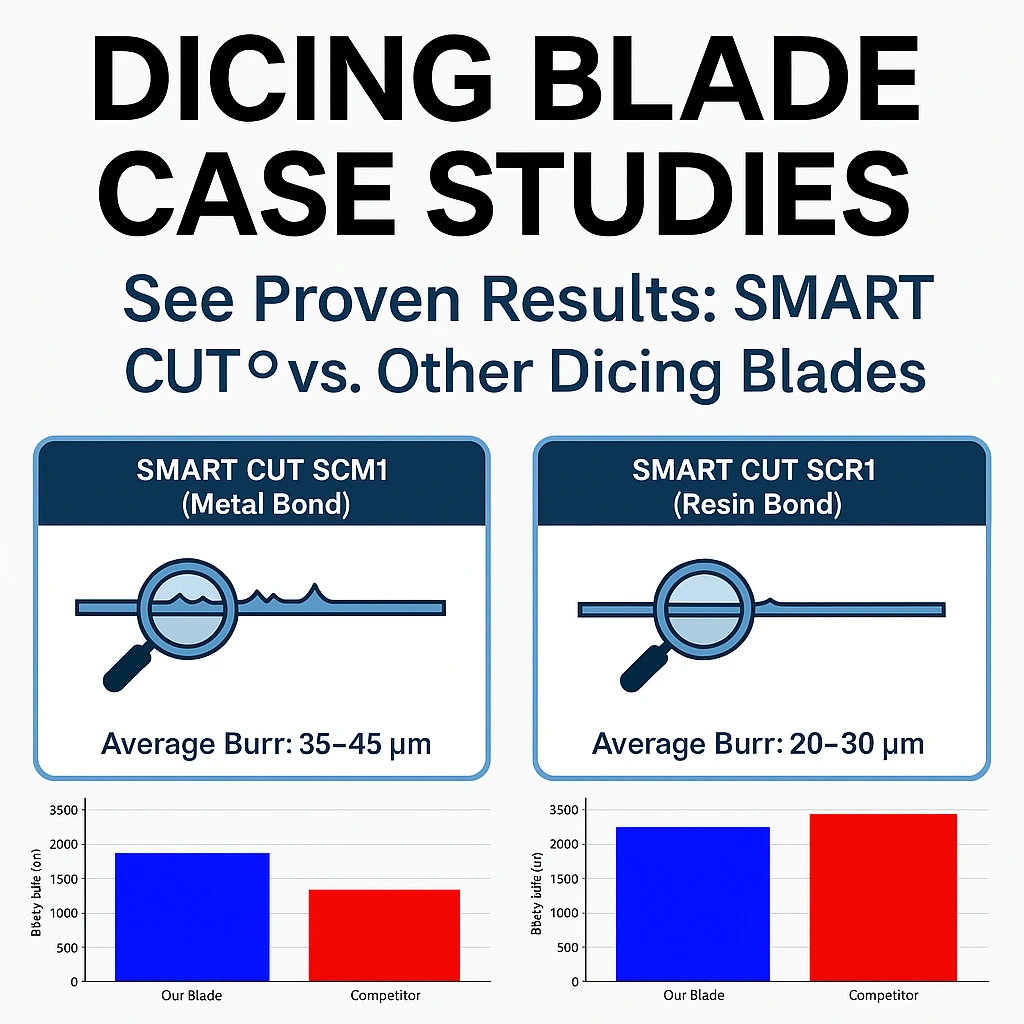

Dicing Blade Case Studies

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Selecting the Right Wafer Dicing Saw Practical Guide

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

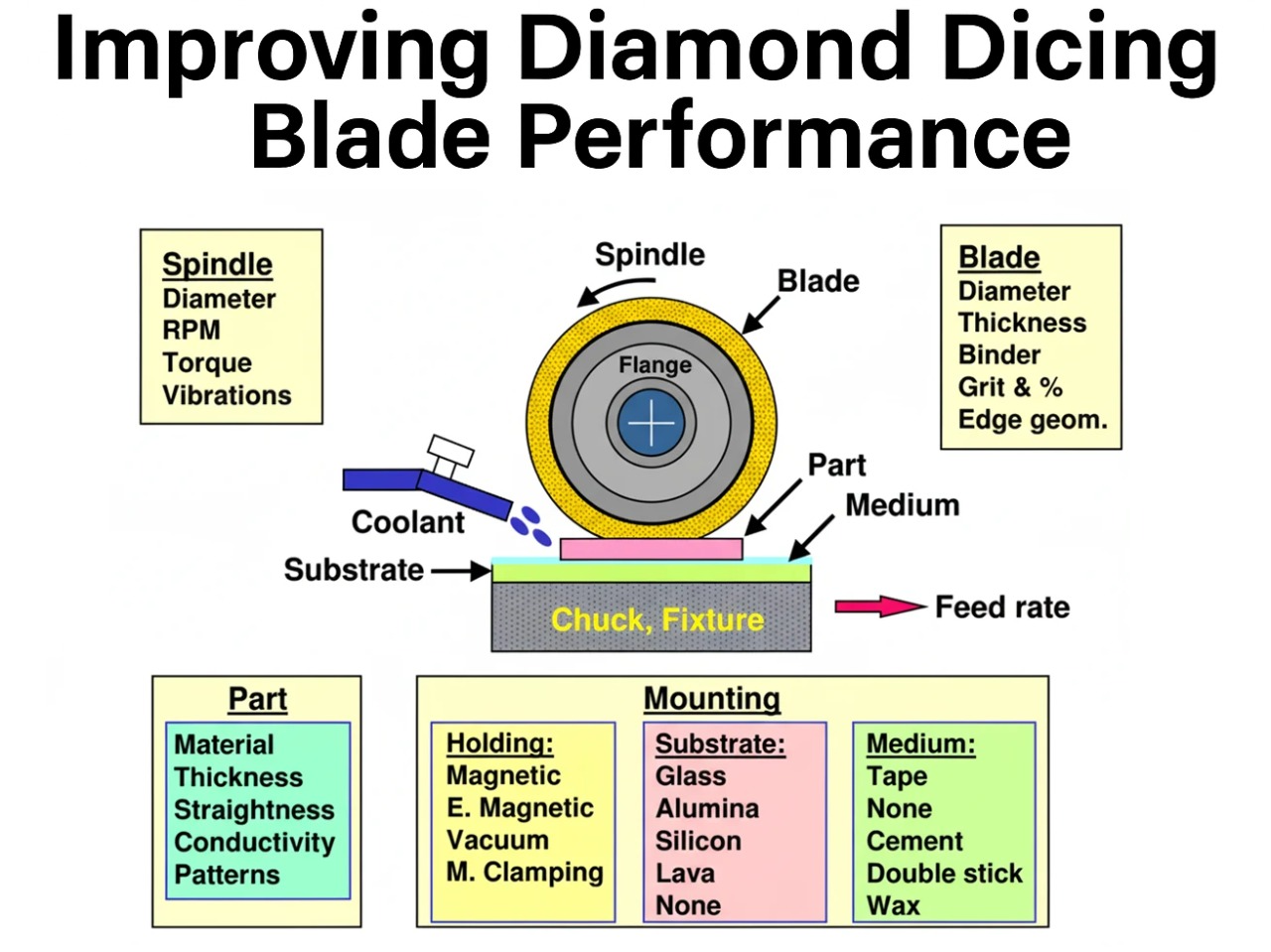

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

Selecting the Right Dicing Surfactant / Fluid for Your Application

How to Use SMART CUT XP Dicing Surfactants

Dicing Surfactants Guide

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

Diamond Tool Coolants Why, How, When & Where to Use

Diamond vs CBN (cubic boron nitride) Tools

Choosing The Correct Diamond Bond Type

Selecting the Right Coolant Method for your Diamond & CBN Tools

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

Excellent form holding & corner characteristics, provide very long life, high level of consistency. Recommended for users requiring very straight...

You will find all the advantages of cutting speed and fine finish that you have come to expect in a resin bond, and long life, consistency...

Capable of maintaining excellent form & sharpness. Widely used for cutting wafers and thin substrates. Nickel Bond dicing blades....

More forgiving, self dressing, and freer cutting. Excellent choice for Ultra Hard & Brittle Materials. Recommended for applications..

Typically used for dicing silicon and III-V materials. Creates very thin kerfs, 50 microns. Providing excellent cut quality with low wear...

Slitting magnetic tape for computer backup applications, metal foils, P.E.T., polyester, sheet rubber, fine gauge steel, film, abrasive paper...

Designed for Laboratory and R & D use. This machine can be used for slicing, dicing or cutting all kinds..

Selecting the right diamond dicing blade & parameters for your material/application can be a very time con...

Share this Article with Friend or Colleague Selecting the right dicing blade parameters often involve...

There are many variables that affect dicing blade performance. Each variable of the dici...

Guide on most common dicing problems and how to resolve them...