-

0 items in quote

No products in the Quote Basket.

Diamond & Cbn

Wafering & Cut off Blades

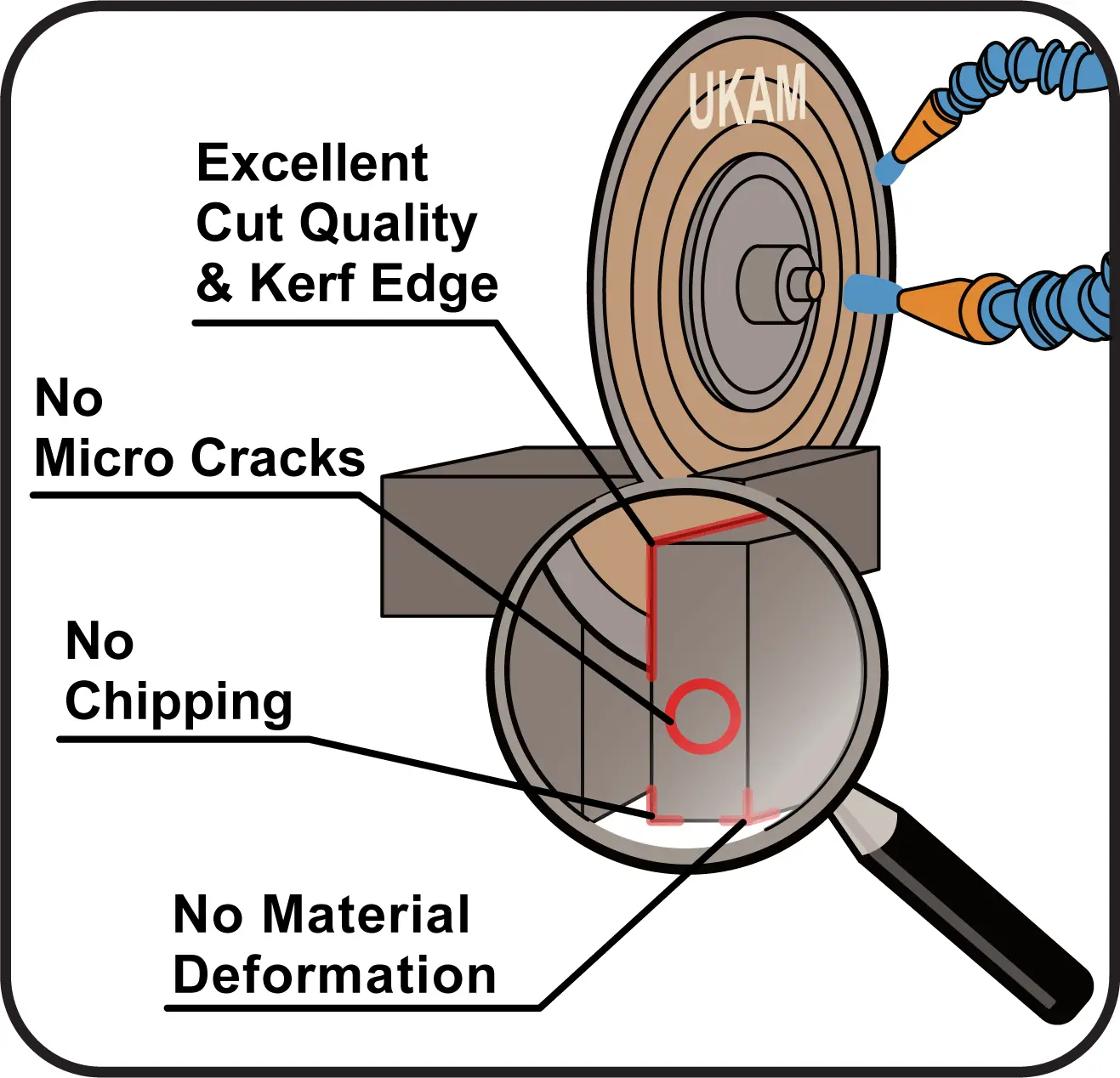

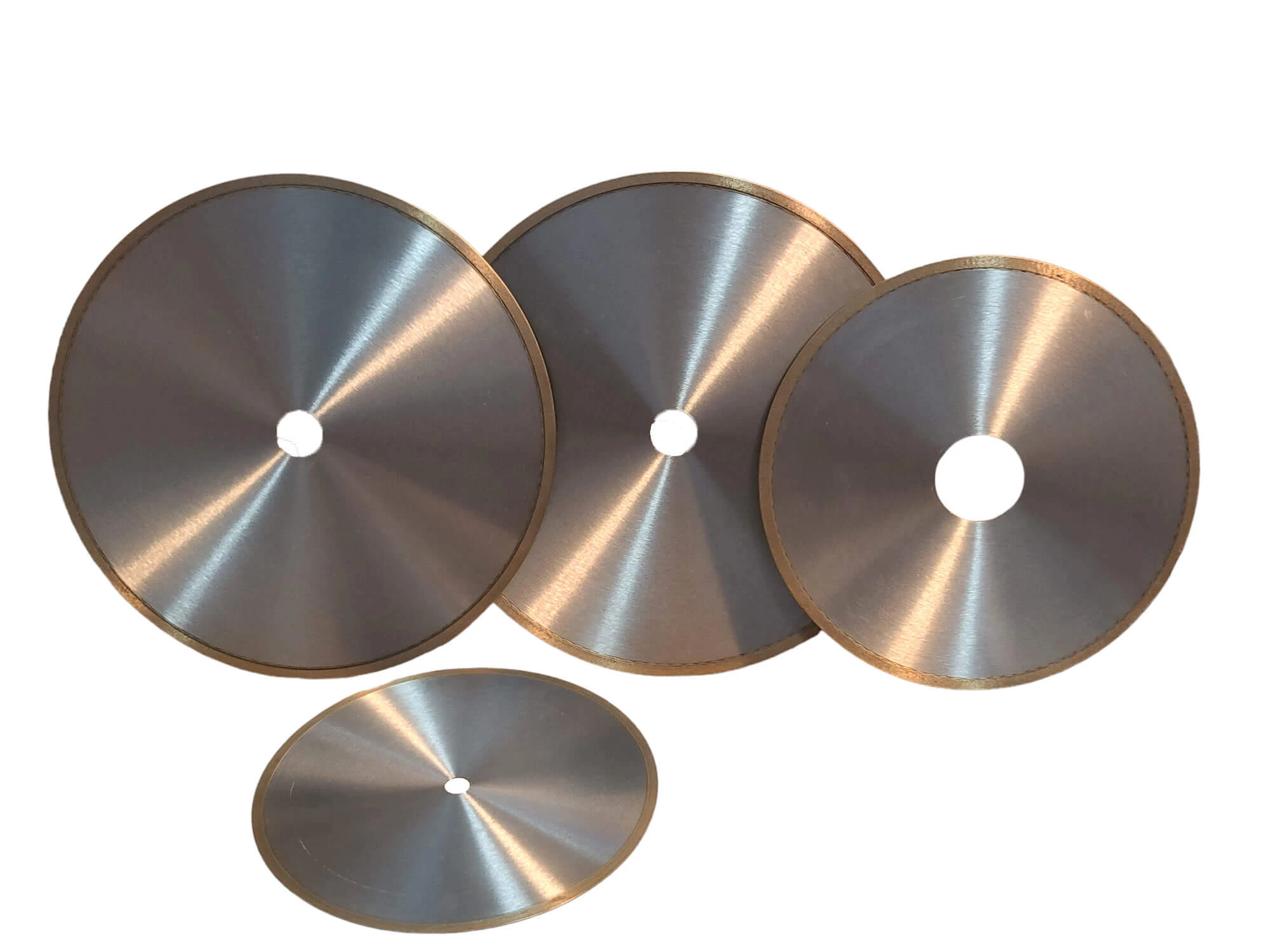

UKAM Industrial Superhard Tools is a Leading Manufacturer & Authority on Precision Diamond & CBN Wafering / Sectioning Blades, Wafering Saws. Used for just about any application. Our High Precision & Ultra Thin Diamond Wafering Blades will work on all popular low & high speed sectioning / wafering saws. Such as BUEHLER, STRUERS, LECO & many others. And larger machines such as precision cutting machines, abrasive cut off saws & other equipment.

DIAMOND & CBN

Wafering Blades for Low & High Speed Saws

For use on all popular low and high speed laboratory cutting saws. Available from stock in 3" (75mm) to 8" (200mm) Diameter with 1/2" (12.7mm) Inside diameter Inside diameter can be used to anything you want usually same day

Diamond & Wafering Blades, sintered (metal bond)

SMART CUT® Wafering Blades are available from inventory in many different diamond concentrations, mesh sizes, bond hardness, & inside diameters. Available from stock for any manufacturers low or high speed sectioning/wafering saw.

CBN Wafering Blades, sintered (metal bond)

SMART CUT CBN (Cubic Boron Nitride) Wafering Blades are provide faster & freer cutting speed for sectioning ferrous metals.

Fully Sintered (Metal Bond) Diamond & CBN, Wafering Blades

Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. The diamond edge is all the way through the blade

Diamond & CBN Wafering Blades, Resin Bond

SMART CUT® Series 400 are Designed for Precision, Chip Free cutting of wide variety of materials These are very thin kerf blades and are very delicate. Diamond Size is Medium providing faster cutting speed, while still providing surface quality unmatched by 95% of other blades.

Diamond & CBN Wafering Blades, Nickel Bond

SMART CUT® Series 105N more freer cutting & aggressive than continuous rim nickel bond wafering blades. Best Suited for cutting larger variety of micro-electronics packages, pcb boards, plastics, composites, soft and precious metals, fish and human bones, graphite, GRP, FR4.

Diamond Wafering Blades Nickel Bond Continous Rim

SMART CUT® Series 100N will provide finer cut quality than interrupted rim nickel bond wafering blades. Best suited for cutting soft and fragile crystals, silicon wafers & substrates, fiberglass, glass fibers.

Ultra Thin Abrasive Cut off Blades For Low & High Speed..

SMART CUT® Series Ultra Thin Abrasive Blades are designed to provide high quality sectioning results with no burning and minimal surface deformation. This can reduce the amount of grinding & polishing required later in the preparation process.

SMART CUT® Abrasive Cut Off Blades For Metallography & Sample Preparation

These blades are specifically formulated to achieve the optimal surface finish required for metallographic preparations. Available in diameters ranging from 250mm to 400mm, and inside diameters of 1.25” and 32mm.

Ultra Thin & High Precision Carbide Blades

Used in slow speed cutting machine. Applications include green ceramics, PC Board substrates, fiberglass, laminates, MLP/QFN, and similar materials.

DIAMOND & CBN

Cut off Blades for High Speed & Metallographic Saws

For use on large precision laboratory, metallographic abrasive saws, and other equipment. These are available from stock in 8" (200mm) to 24" (500mm) diameters, with 1.25" or 32mm inside diameter. Inside Diameter can be changed to any nything you want usually same day

CBN, Resin Bond Cut Off Blades

SMART CUT® Series 600 RCBN - CBN, Cut Off blades are designed for cutting of extremely hard ferrous metals (HV 500-1400) used on large variety of high speed & abrasive cut off saws.

Diamond, Nickel Bond Cut Off Blades for Laboratory & Abrasive Cut Off Saws

SMART CUT Nickel Bond Diamond Cut off blades Blades are Recommended for cutting softer and more gummy materials, where sintered (metal bond) diamond wafering blades load up or glaze over frequently.

Diamond, Sintered (Metal Bond) Cut Off Blades for Advanced Ceramics & Ultra Hard/Dense Materials

SMART CUT 205M Diamond Sintered Metal Bond Cut Off Blades are designed for ultra hard and brittle materials. Such as sapphire, silicon carbide, boron nitride, alumina oxide, yag and other materials are very hard to cut

Petrographic Diamond Blades

SMART CUT Diamond, Sintered (Metal Bond) Cut Off Blades for Petrographic Samples Specifically Designed for Petrographic Samples & Thin Sections

SMART CUT® 435BS

Braised Bond is a Slotted diamond cut off wheel that replaces general purpose abrasive cut off wheels/blades. Fast & efficient cutting without use of coolant, this blade can be used on any simple hand held machine or abrasive cut off saw.

DIAMOND & CBN

Cut off Blades for Tile & Other Cutting Machines

Resin Bond Diamond Cut off blades (Medium Size Diamond)

SMART CUTTM Series 2000 is the most commonly used Resin Bond Diamond Cut off Blades. Perfect for cutting soda lime and borosilicate glass tubing, ceramic tubing (al203, silicon carbide, sapphire, tungsten carbide, metals, alloys, etc.

Resin Bond Diamond Cut off blades (Fine Size Diamond) for use on manual tile saws

SMART CUT™ Series 3000R Resin Bond Diamond Cut Off Blades are Finer Diamond Grit Size, and Slightly Higher Diamond Content then the SMART CUT Series 3000 blades. They are used for cutting very thin wall tubing, more fragile material, that need best surface finish possible to achieve. Cutting speed would be slower then the 3000 series.

Diamond Cut Off Blade for Glass, Optical Glass, & Ceramic

SMART CUT 455M designed for glass cutting where minimizing chipping and excellent surface finish is important. Produced with high diamond concentration of high quality and fine, evenly spaced diamonds and radius on diamond edge to minimize chipping.

Accessories

Dressing Sticks

Dressing Sticks are available from stock to fit all types of diamond, cbn, abrasive wafering & cut off blades and sectiong saws. Such as Buehler.

Blade Stiffeners

Wheel Stiffeners provide stability, rigidity & additional support for your blades. They help in prventing the blade from loosing wobbling

Precision Arbors

Precision arbors ½” (12.7mm) and 5/8” (15.75mm) diameter to fit many different type of cutting machines and cutting blades. Use in conjunction...

Precision Cutting Service & Process Development

We offer large variety of of services including: Dicing, Slicing, Sectioning, Drilling, Coring, Micro Drilling, Grinding, Polishing, & Machining

Why Work With Us?

Read More

Save Money Save up to 650%

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

Umatched Technical Support

WE ARE A PARTNER IN YOUR SUCCESS

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

Advanced Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Let Us Help You

- Obtain More Consistent Results

- Save Time & Money

- improve Surface Finish

- Preserve True Material Microstructure

- Improve Consumable Life & Overall Performance

- Reduce & eliminate Material Deformation

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Related Products

SMART CUT® SM Polishing and Grinding Head

SMART CUT® AMF Water Soluble Coolant

Advanced Materials Formula

Super Premium water soluble synthetic coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

SMART CUT® Water Soluble Coolant – Advanced Materials Formula is a high-performance, fully synthetic, aqueous-based coolant specifically engineered for precision machining in the most demanding applications. Designed to excel in the cutting and grinding of advanced materials such as ceramics, composites, optics and ultra-hard, brittle materials. This premium coolant/lubricant optimizes removal rates while delivering superior surface finishes.SMART CUT VP – Vibratory Polisher

Precision Arbors

Recently Viewed Products

ARE YOU USING RIGHT WAFERING BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT WAFERING BLADES?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools help with detailed tasks like engraving and finishing, providing good control and helping you work efficiently....

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin, high precision cutting blades, precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use