-

0 items in quote

No products in the Quote Basket.

Diamond Wheel Stiffeners

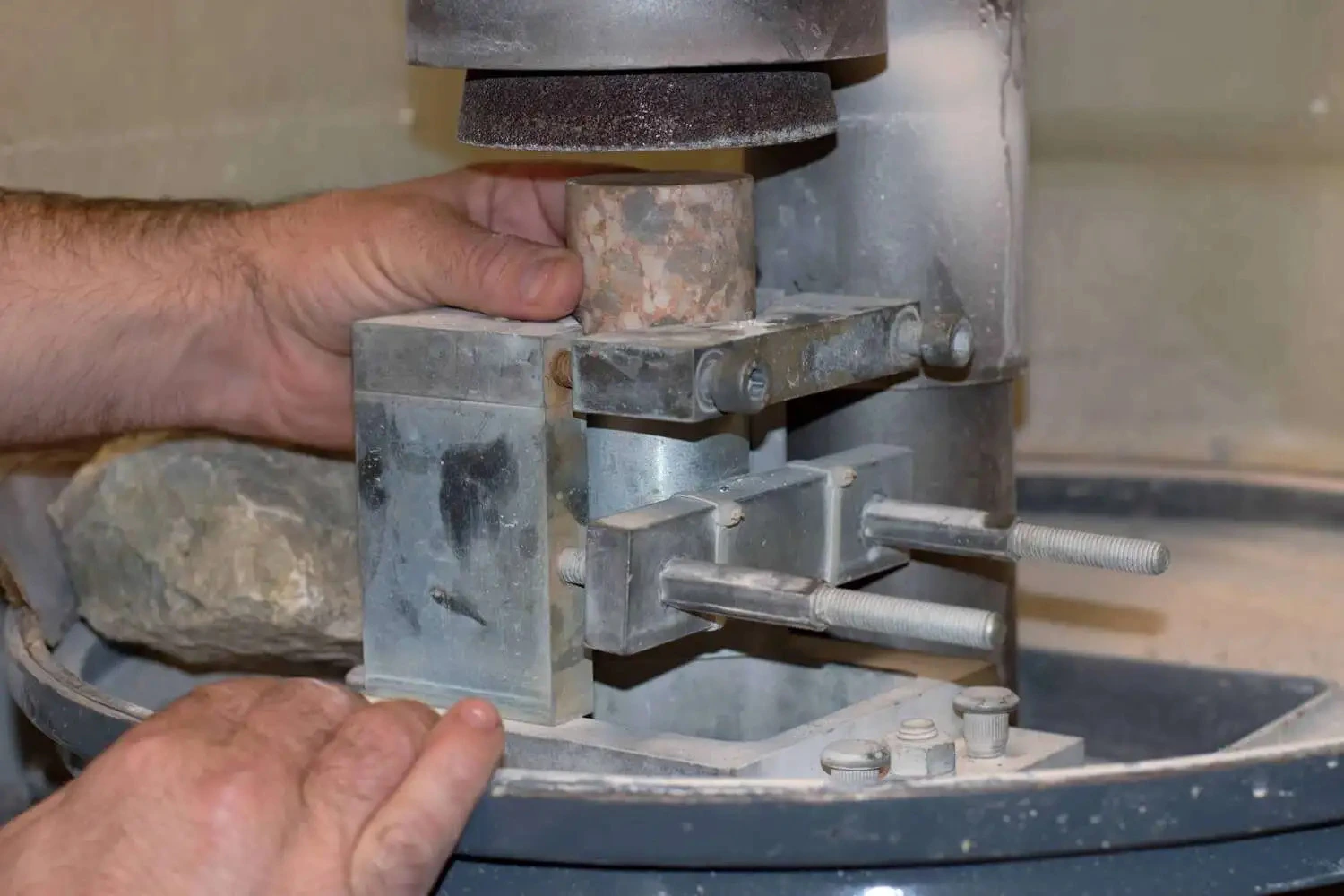

Introducing our SMART CUT Diamond Wheel Stiffeners, the ultimate solution for enhancing the performance and longevity of your ultra thin and high precision diamond & CBN cutting blades and diamond wheels. These stiffeners are precision machined for hard tool steel, ensuring they provide the optimal support and stability your diamond & CBN as well as other abrasives wheels need during operation.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

The wheel stiffeners evenly distribute the pressure applied to the wheel, minimizing wear and tear and extending the life of your wheels.

Our Diamond Wheel Stiffeners are made to order to fit your particular outside wheel diameter and inside diameter and are incredibly easy to install and are compatible with a wide range of grinding wheel sizes and types. They are also resistant to corrosion and other forms of damage, ensuring they will last for years to come.

Invest in our Diamond Wheel Stiffeners today and experience the difference in your grinding performance. Your wheels will run smoother, last longer, and deliver the precise results you need, every time.

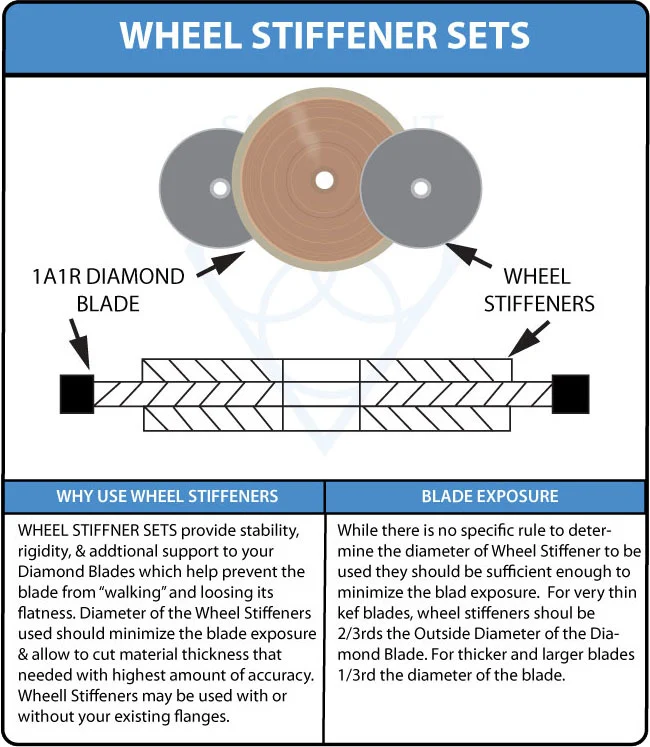

Why Use Wheel Stiffeners?

Wheel stiffeners provide stability, rigidity and additional support to your diamond blades which help prevent the blade from “walking” and loosing its flatness. Diameter of the wheel stiffeners used should minimize the blade exposure & allow to cut material thickness that needed with highest amount of accuracy. Wheel stiffeners may be used with or without your existing flanges.

How to determine the right Wheel Stiffener Diameter?

While there is no specific rule to determine the diameter of the wheel stiffener. They should be sufficient enough to minimize blade or wheel exposure. For very thin kerf blades, wheel stiffeners should be 2/3rd the Outside Diameter of the Blade or Wheel. For thicker and larger blades 1/3rd the diameter of the blade.

SPECIFICATIONS

Diameters Available: 1” (25.4mm) to 20” (500mm)

Thickness: .020” (0.5mm) to .250” (6.35mm)

Inside Diameter: .125” (3.2mm) to 5” (125mm)

Lead Time: 4 to 5 work days

FREQUENTLY ASKED QUESTIONS

Diamond Wheel Stiffeners are precision-machined supports made from hard tool steel, designed to provide stability and support to ultra-thin and high-precision diamond & CBN cutting blades and diamond wheels.

Wheel stiffeners help prevent the blade from “walking” and losing its flatness by providing additional support and stability. This ensures the highest level of accuracy when cutting material.

For very thin kerf blades, wheel stiffeners should be 2/3rd the Outside Diameter of the Blade or Wheel. For thicker and larger blades, 1/3rd the diameter of the blade is sufficient.

Yes, the Wheel Stiffeners can be used with or without your existing flanges.

The Wheel Stiffeners are available in diameters ranging from 1” (25.4mm) to 20” (500mm), with thicknesses from .020” (0.5mm) to .250” (6.35mm), and Inside Diameters from .125” (3.2mm) to 5” (125mm).

The lead time for the Wheel Stiffeners is typically 4 to 5 work days.

The advantages of using the SMART CUT Diamond Wheel Stiffeners include increased stability, reduced vibration, improved versatility, extended blade life, minimized run out, improved accuracy, and reduced chipping.

The Wheel Stiffeners are easy to install. Simply attach them to your diamond & CBN cutting blades or diamond wheels according to the manufacturer’s instructions.

Yes, the SMART CUT Diamond Wheel Stiffeners are resistant to corrosion and other forms of damage, ensuring they will last for years to come.

Yes, the Wheel Stiffeners are suitable for both wet and dry cutting applications.

The Wheel Stiffeners provide additional support and stability to your blades, preventing them from flexing or wobbling during operation. This helps to minimize blade exposure and ensures a more accurate cut.

Yes, by minimizing the vibration and wobble of your blades, the Wheel Stiffeners help to reduce noise during operation, creating a quieter work environment.

Yes, the Wheel Stiffeners are compatible with a wide range of blade and wheel brands and can be customized to fit your specific needs.

The Wheel Stiffeners are made from high-quality materials and are resistant to corrosion and other forms of damage, ensuring they will last for years to come with proper care and maintenance.

Yes, the Wheel Stiffeners are designed to be compatible with a wide range of grinding wheel sizes and types. You can specify the required sizes to ensure a perfect fit for your particular blades and wheels.

Yes, our Diamond Wheel Stiffeners are made to order, so you can specify the outside wheel diameter and inside diameter to fit your specific needs.

The Wheel Stiffeners are designed to enhance the performance of ultra-thin and high-precision diamond & CBN cutting blades and diamond wheels, making them suitable for cutting a wide range of materials, including metal, glass, ceramics, and more.

Yes, by providing additional support and stability to your cutting blades, the Wheel Stiffeners help to minimize wear and tear, extend the life of your blades, and improve the accuracy of your cuts, resulting in a more efficient cutting process.

INDUSTRIES USED IN

Tab Content

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Advantages

- Increase Stability

- Reduce Vibration

- Improved Versatility

- Extend Blade Life

- Minimize Run Out

- Improve Accuracy

- Reduce Chipping

Related Products

Precision Arbors

Flanges for Blades

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected diamonds...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

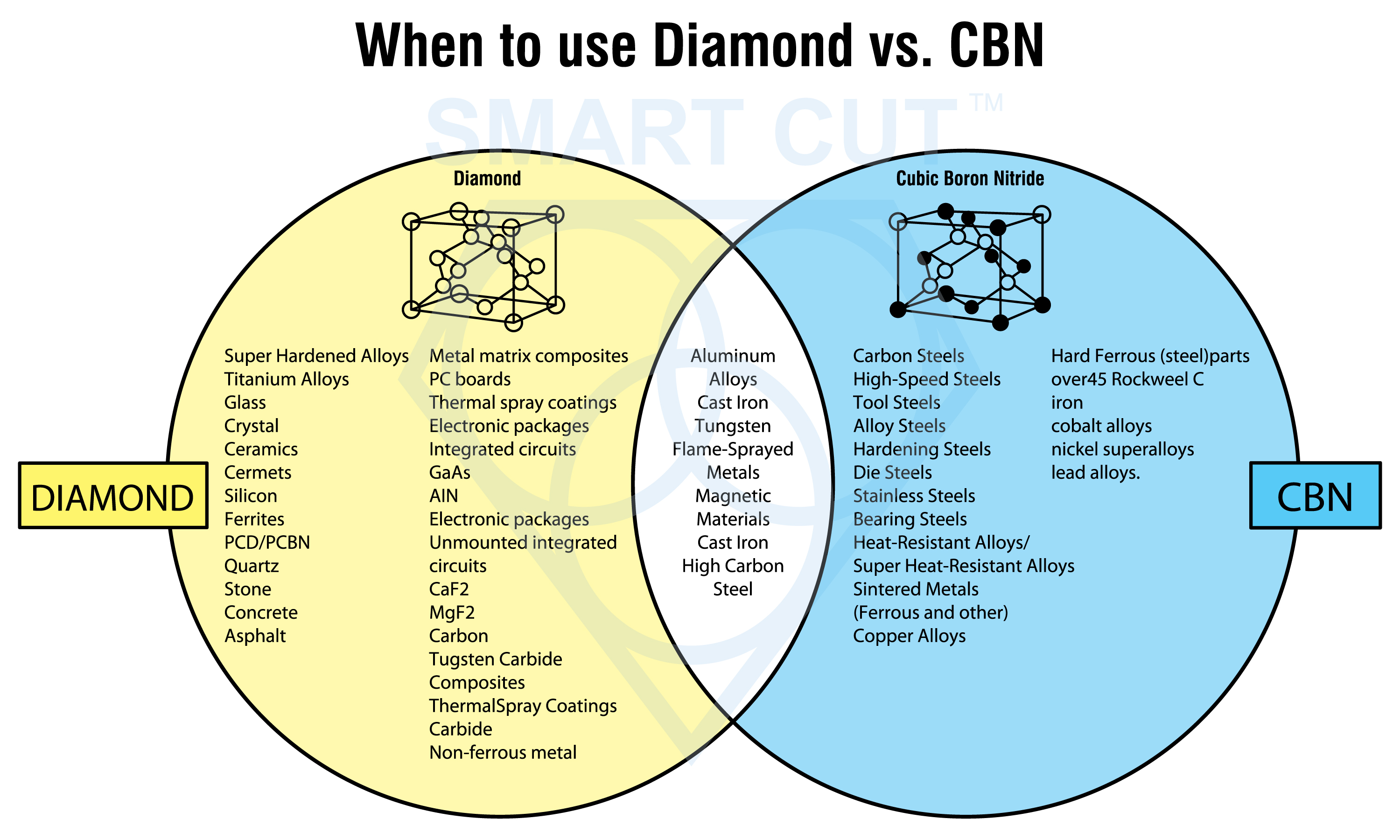

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

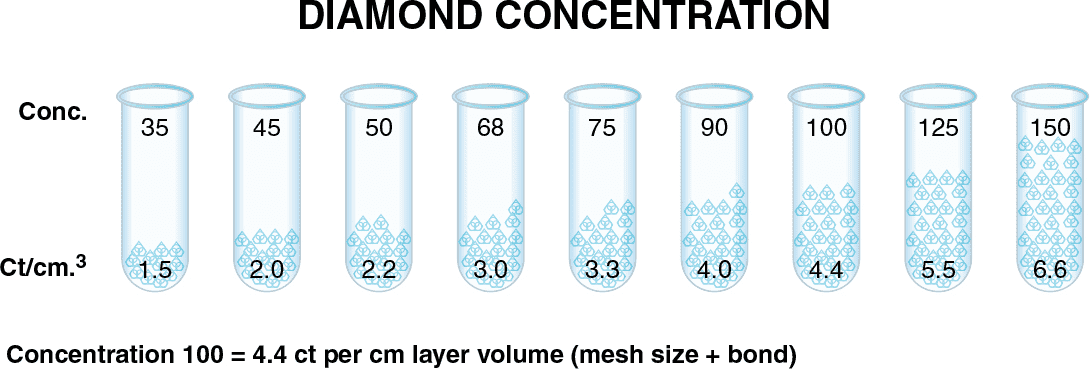

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

02

Jun

Diamond Tool Coolants Why, How, When & Where to Use

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

17

May

Get to Know the Diamond Tool Bond Types and Which to use for your application

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools help with detailed tasks like engraving and finishing, providing good control and helping you work efficiently....