Menu

-

0 items in quote

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

Introducing the SMART CUT® 455M Series Precision Glass Cutting Blade - Your Ultimate Solution for Flawless, Chip-Free Cuts!

Are you tired of the frustration that comes with chipping, rough surface finish and uneven cuts when working with fine glass materials? Look no further than the SMART CUT® 455M, a cutting-edge blade engineered specifically for precision glass cutting where minimizing chipping and excellent surface finish is important. Produced with high diamond concentration of high quality and fine, evenly spaced diamonds and an enhanced bonding technology, and radius on diamond edge to minimize chipping.

This blade is your key achieving flawlessly smooth and chip-free cuts. Use with together with our SMART CUT water soluble coolant for best surface finish and minimum chipping possible. Please note if you are cutting tubing then our SMART CUT® series Resin Bond Blades are better solution

In producing the bond formulation for this blade we have used our many decades of experience in developing high-precision tools for the optical glass industry to design the SMART CUT® 455M Blade that stands above the rest.

The SMART CUT Diamond Cut Off Blade comes in outside diameters ranging from 4 inches (100mm) to 14 inches (350mm).

The inside diameter options range from 5/8 inches (15.75mm) to 1.0 inch (25.4mm). Custom machining of the inside diameter to meet specific requirements is also offered, usually with same-day service.

The diamond depth/height is 8mm, and the diamond size is 180 mesh.

The blade features a high diamond concentration, ensuring efficient cutting and long blade life.

This blade is compatible with various types of cutting equipment, including tile saws, masonry saws, precision saws, and almost any saw type.

It is recommended to use SMART CUT water-soluble coolant with this blade. While water is possible, it’s not recommended for achieving optical-quality results.

The maximum RPM (Revolutions Per Minute) range for this blade varies depending on the blade diameter. It can range from 15,000 to 3,500 RPM, with the specific range corresponding to the blade diameter. Please refer to the product documentation for precise RPM guidelines.

Yes, this blade is suitable for cutting both straight and curved shapes in glass, optical glass, and some ceramic materials. Its design minimizes chipping, making it versatile for precision cutting.

This blade is typically used for wet cutting applications. It is recommended to use SMART CUT water-soluble coolant or water for optimal results. Dry cutting is generally not recommended, especially for achieving high-quality cuts.

It’s crucial to adhere to the recommended RPM range for the specific blade diameter you are using. Exceeding the maximum RPM can be dangerous and may result in blade failure. Always follow the manufacturer’s guidelines for safe operation.

While the SMART CUT Diamond Cut Off Blade is designed for a range of glass and ceramic materials, it can be used for cutting extremely hard materials such as sapphire, however the cutting rate would be slow and dressing frequent. Resin bond blade would be better solution for this application. Consult our technical support for blade recommendations for cutting such materials.

Proper care and maintenance of the blade, such as regular cleaning and ensuring it remains properly lubricated with coolant, can help prolong its lifespan and maintain cutting quality. Follow the manufacturer’s maintenance recommendations.

Yes, always follow safety guidelines when using cutting equipment and blades. Wear appropriate personal protective equipment, including safety glasses, hearing protection, and gloves. Ensure that the cutting area is well-ventilated, and follow all safety instructions provided by the equipment manufacturer.

The SMART CUT Diamond Cut Off Blade is suitable for various scales of cutting projects, including industrial applications. However, for larger projects, consider blade longevity and ensure proper cooling and lubrication for consistent performance.

The SMART CUT Diamond Cut Off Blade is engineered for precision cutting with minimized chipping and excellent surface finish. Its high diamond concentration, fine diamond particles, and unique bond formulation contribute to longer blade life and superior performance, making it a preferred choice for many applications.

Yes, this blade is designed to minimize chipping, making it suitable for cutting delicate and thin glass materials. However, it’s important to follow proper cutting techniques and use the recommended RPM range and coolant for optimal results.

Yes, the SMART CUT Diamond Cut Off Blade can be used for cutting large glass sheets or panels. Its versatility and ability to deliver smooth, chip-free cuts make it a viable choice for architectural glass cutting.

While the SMART CUT Diamond Cut Off Blade is suitable for various glass applications, including tubing, SMART CUT series Resin Bond Blades may be a better solution for cutting tubing. However if very fine “fire polish” type of finish for you is not necessary, then our sintered (metal bond) SMART CUT 455M blade would be excellent solution for your needs.

When changing or installing the blade, ensure that the cutting machine is powered off and unplugged. Follow instructions for safe blade installation, including securing the blade properly and using any recommended safety tools or procedures.

the blade can be dressed to bring it back to life. Dressing should be done on regular basis to keep the diamond particles sharp and wear away metal layer exposing the diamond particles. As long as there is diamond left on the blade it can typically still be used if you expose the diamond crystals.

The lifespan of the blade can vary depending on factors such as the type of material being cut, the RPM used, and the cutting conditions. However, the high-quality diamond particles and bond formulation are designed to provide a longer blade life compared to standard blades.

Yes, the SMART CUT Diamond Cut Off Blade is suitable for cutting some ceramic materials. It is recommended for applications where minimizing chipping and achieving a smooth surface finish are essential. Usually these blade can be used for cutting softer ceramics such as pzt, zirconia, crystals and many others. For Ultra hard ceramics such as boron nitride, silicon carbide, and alumina our resin bond series blades would be a better solution

To extend the blade’s life, it’s important to keep it clean, use the recommended coolant, dressing on periodic bases, and follow proper cutting techniques. Regularly inspect the blade for wear and replace it when necessary.

The primary applications for the SMART CUT Diamond Cut Off Blade are glass, optical glass, and some ceramic materials. While it may be suitable for other materials, it is best used for its intended applications. For cutting different materials, consider using specialized blades designed for those materials. We can produce any blade specification in very short amount of time if needed

While this blade is typically used for wet cutting applications, it is not recommended for dry cutting, especially if you aim for optimal results. Wet cutting with the recommended coolant or water helps dissipate heat and reduce dust, enhancing cutting efficiency and blade life.

The SMART CUT Diamond Cut Off Blade is versatile and can be used by both professionals and hobbyists. Its precision cutting capabilities and minimized chipping make it valuable for a wide range of applications across various industries.

When not in use, it’s advisable to store the blade in a dry and clean environment to prevent any potential corrosion. Keeping the blade clean and free from debris is essential for maintaining its performance. Regularly inspect the blade for any signs of wear or damage.

This blade is compatible with a variety of cutting equipment, its more designed for stationary saws, but can be used on handheld and portable tools if they have right rpm’s range and allow continuous flow of coolant. Its adaptability allows for flexibility in different cutting setups.

When changing the blade on a cutting machine, ensure that the machine is powered off and unplugged. Follow instructions for safe blade removal and installation, and use any recommended safety tools or procedures.

Yes, the SMART CUT Diamond Cut Off Blade is well-suited for precision cuts in glass and ceramics used in electronics manufacturing. Its ability to deliver chip-free cuts and excellent surface finish is valuable for such applications.

Like most cutting blades, the noise level during cutting operations can vary depending on the equipment and material being cut. It’s advisable to wear hearing protection when operating cutting equipment to reduce exposure to noise.

The SMART CUT Diamond Cut Off Blade is designed to minimize chipping, making it suitable for cutting delicate materials. However, for materials with fragile coatings, it’s important to exercise caution and use appropriate cutting techniques to minimize the risk of surface damage. Our resin bond series blades may be a better solution for these applications.

Yes, the SMART CUT Diamond Cut Off Blade is suitable for cutting decorative and intricate patterns in glass art projects. Its ability to deliver chip-free cuts and smooth surface finishes makes it ideal for artistic and precision work.

While basic knowledge of using cutting equipment is important, no special training or skills are typically required to operate this blade. Following guidelines for usage and safety is essential for effective and safe operation.

Disposal of used blades should be done in accordance with local regulations and environmental guidelines. Depending on the composition of the blade, recycling options may be available for the metal components. Ensure that any diamond dust or residue is disposed of safely to minimize environmental impact.

Yes, the SMART CUT Diamond Cut Off Blade can be used for precision cutting of glass and ceramic components in the automotive industry. Its ability to provide clean cuts and minimal chipping is valuable for manufacturing automotive glass and ceramics.

When storing the blade for extended periods, it’s advisable to protect it from moisture and environmental contaminants. Applying a rust inhibitor or coating to the blade can help prevent corrosion during storage.

The SMART CUT Diamond Cut Off Blade can be used for cutting glass with varying thicknesses. However, when cutting materials with significant variations in thickness, adjustments to cutting speed and technique may be necessary to achieve consistent results.

Yes, this blade can be used for cutting specialized glass materials used in the medical and laboratory industries. Its precision and minimized chipping are valuable for producing clean cuts in laboratory glassware and medical components. For thin wall tubing resin bond series blades may be better solution.

The recommended feed rate or cutting speed can vary based on the blade size, material, and specific cutting conditions. Consult our tech support for the most suitable feed rate and cutting speed for your application.

Yes, this blade can be used for cutting circular glass or ceramic pieces with precision. Its radius edge design helps achieve smoother and more precise circular cuts.

The blade itself is the primary component. Any additional accessories or attachments for specific cutting applications would need to be acquired separately. We recommend using with our These additional FAQs provide further information about the versatility, suitability, and specific applications of the SMART CUT Diamond Cut Off Blade, as well as considerations for storage and disposal. Always refer to the manufacturer’s recommendations and guidelines for the best results when using the blade.

Yes, the SMART CUT Diamond Cut Off Blade is suitable for cutting glass or ceramics with intricate designs and tight tolerances. Its precision and minimal chipping make it an excellent choice for such applications.

This blade is compatible with a wide range of cutting equipment, including CNC machines, as well as manual cutting machines. Its adaptability allows for both automated and manual cutting processes.

While this blade is primarily designed for straight cuts, it can be used for beveling or edging glass and ceramic pieces with the appropriate technique. However, for more specialized beveling applications, dedicated tools may be recommended.

After use, it’s important to clean the blade thoroughly to remove any debris or residue. Using a brush or cleaning solution specifically designed for diamond blades can help maintain performance. Regular maintenance, such as inspections and coolant replacement, is also essential.

While this blade is designed for glass and ceramic materials, cutting laminated glass with embedded metal or wire may result in premature wear of the blade. Specialized blades may be more suitable for such applications.

This blade is primarily designed for cutting rather than engraving or etching. For engraving or etching work on glass or ceramics, dedicated engraving tools or methods are typically employed.

When handling the coolant, follow the manufacturer’s safety data sheets (SDS) and recommendations. It’s important to use appropriate personal protective equipment and dispose of used coolant in accordance with local environmental regulations.

While this blade can cut glass, cutting glass bottles or containers for recycling may not be its primary intended use.

While there may not be a fixed maintenance schedule, regular blade inspections, cleaning, dressing, and coolant replacement are advisable to ensure consistent performance. Blade maintenance frequency can depend on usage intensity and the materials being cut.

The SMART CUT Diamond Cut Off Blade can be used for cutting mirrored glass or glass with reflective coatings. However, our resin bond blades would be much better solution for this application.

Yes, there are recommended cutting speeds and feed rates based on the material being cut and the specific blade size.

Yes, the SMART CUT Diamond Cut Off Blade is suitable for cutting architectural glass used in windows, doors, and glass partitions. Its precision and minimized chipping are valuable for such applications.

While this blade can cut glass and ceramics, materials with embedded fibers or reinforcement may require specialized cutting tools. Consult with the manufacturer or supplier for recommendations for such materials.

Always prioritize safety when cutting glass or ceramics. Use appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and gloves. Ensure proper ventilation in the workspace to reduce exposure to dust and coolant.

It’s recommended to follow the recommendations provided ensure safe and effective cutting. These blades should have arrow to show rotation direction

This blade is designed for precision cutting, so textured or uneven surfaces may require extra care and attention during cutting. It’s advisable to stabilize the material as needed to achieve clean cuts.

When cutting thick glass or ceramics, it’s important to use appropriate cutting techniques, adjust cutting parameters, and ensure that the equipment is well-suited for the thickness. Follow safety guidelines and wear necessary protective gear.

While the SMART CUT Diamond Cut Off Blade excels at surface cutting, cutting internal complex patterns or structures may be challenging. For such applications, consider specialized tools or methods.

Submerging the material in water or other appropriate cutting fluids is a common practice when using diamond blades for cutting glass or ceramics. It helps dissipate heat and reduce dust. Ensure the equipment is designed for wet cutting.

Spare parts and accessories, such as bushings or flanges, are often available for maintaining and replacing components of the blade. Consult with your machine manufacturer or supplier for specific replacement parts and compatibility. We also offer flanges and wheel stiffeners to fit most popular cutting equipment.

The suitability for cutting intricate patterns or inlays involving multiple materials can vary depending on the specific materials and their compatibility with the blade.

Tab Content

Image | Name | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $15.39 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $15.99 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $39.47 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $39.47 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 |

Image | New Item No: | Diameter | Kerf Thickness | Arbor Size (Inside Diameter) | Price | Quantity | Add to Cart |

|---|---|---|---|---|---|---|---|

4" | .060” (1.52mm) | 5/8” (15.87mm) | $90.47 | Max: Min: 1 Step: 1 | |||

5" | .060” (1.52mm) | 5/8” (15.87mm) | $102.53 | Max: Min: 1 Step: 1 | |||

6" | .060” (1.52mm) | 5/8” (15.87mm) | $117.64 | Max: Min: 1 Step: 1 | |||

7" | .060” (1.52mm) | 5/8” (15.87mm) | $128.43 | Max: Min: 1 Step: 1 | |||

8" | .060” (1.52mm) | 5/8” (15.87mm) | $155.32 | Max: Min: 1 Step: 1 | |||

10" | .060” (1.52mm) | 5/8” (15.87mm) | $172.90 | Max: Min: 1 Step: 1 | |||

12” | .080” (2.0mm) | 1.0” (25.4mm) | $235.80 | Max: Min: 1 Step: 1 | |||

14” | .080” (2.0mm) | 1.0” (25.4mm) | $275.10 | Max: Min: 1 Step: 1 |

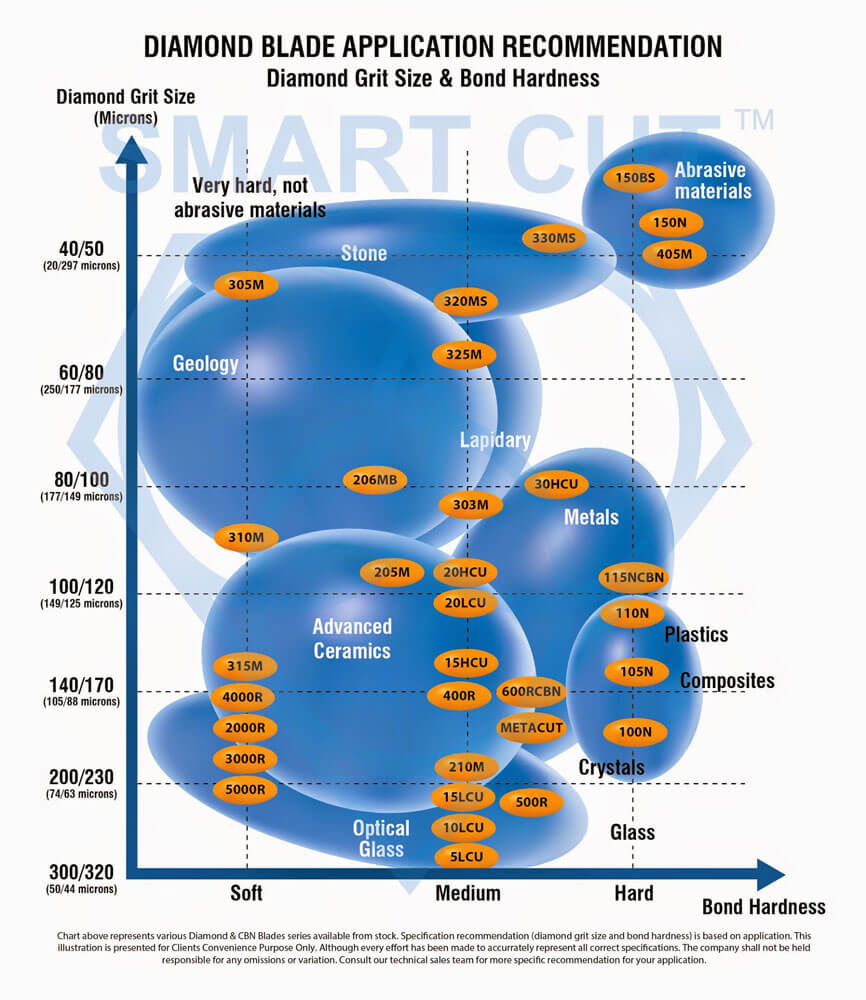

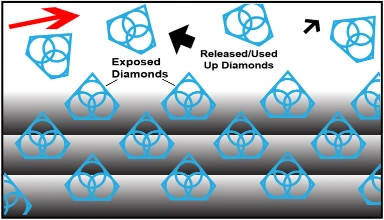

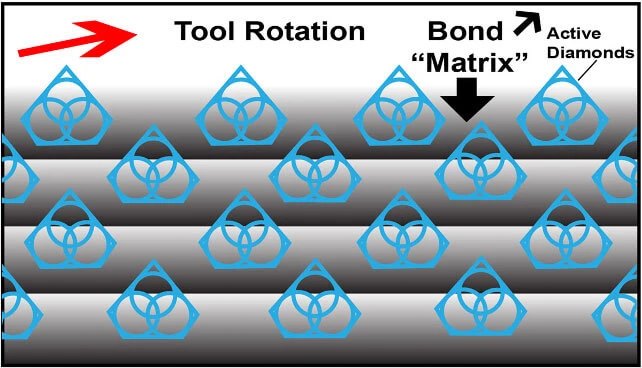

Sintered (metal bonded) diamond tools have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal bonded diamond tools are “impregnated” with diamonds. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, advanced ceramics, optics, glass, granite, tile and etc. The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting. Sintered (metal bonded) diamond tools are recommended for machining hard materials from 45 to 75 on rockwell scale (5 to 9.5 on mohe’s scale of hardness).

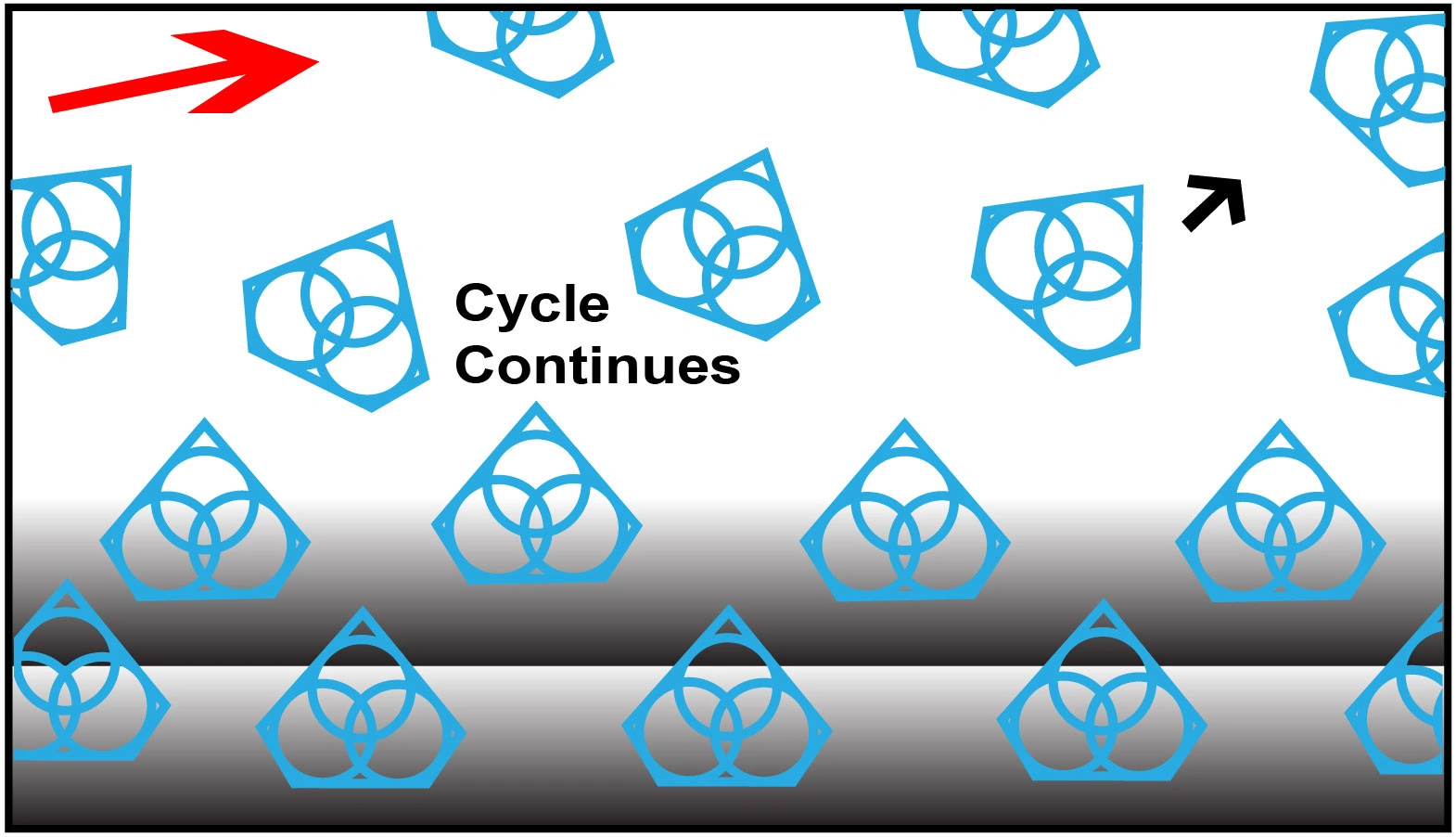

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Diamond Blades with SMART CUT® technology make any work much faster & easier, Thousands of sharp and high quality diamond particles oriented and evenly distributed on both matrix, allow cutting action to be completed by applying little or only moderate amount of pressure even on the most toughest and challenging materials. Freeing the user from constantly having to dress and renew the diamond layer.

Diamond & CBN Blades with SMART CUT® technology require minimum dressing, the bond renews itself. The innovative bond formulation allows these blades to maintain faster and freer cutting speed, and efficiency without glazing, ensuring consistent performance and long blade life

SMART CUT® series 455MS blades made utilizing SMART CUT® technology are much more aggressive then conventionally blades. They can cut faster, while still leaving behind a smooth surface finish.

SMART CUT® blades will outlast almost all other blades on the market today. The longer life can be attributed not only the higher diamond depth, but to higher diamond quality used. Advanced diamond distribution an orientation techniques, and proprietary bond chemistry. Combined with our competitive prices you re sure to obtain the best value and return on investment possible.

SMART CUT® Series Diamond Blades have hundreds of diamond layers impregnated inside the metal matrix. Unlike Many Other Blade Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

SMART CUT® Series Sintered (metal bond) blades are the best investment you can make! Although they may cost more than other sintered (metal bond), blades. Designed for users that understand and appreciate quality. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Sectioning/Wafering Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is significantly slower cutting speed. Low diamond concentration is recommended and widely used for cutting ultra hard and brittle materials.

Low Diamond Concentration - Typically low concentration wafering blades should be for cutting ultra hard and brittle materials such as ceramics and glass. In Low Concentration Wafering Blades, diamond works by fracture process. Pressure on each diamond crystal/particle is higher which provides enough stress to chip off small flakes in the cut.

High Diamond Concentration - High concentration diamond wafering blades are recommended for cutting metals, plastics and polymers. In this application, materials cut by a plowing mechanism. In this applications diamond plough through the material, work hardened strips of materials become brittle and break off. The greater number of diamond by volume, the quicker the cutting action will be. Increasing the number of diamond s also lowers the per unit force. For metals where it is possible to induce deep deformation layers, a lower per unit force is desirable to reduce the deformation during the cut.

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain, and material microstructure damage you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in material micro damage. If you are cutting fragile, more delicate materials then finer mesh size diamond wafering blades are recommended.

Wafering blade thickness typically ranges from .006” to .040” (1mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material/sample due to the thickness of blade passing though the material/sample. Blade thickness is important for users requiring most minimal amount of material loss during sectioning. For example if the user requires precision position of the cutting plane relative to the detail on the sample (IC circuit for example), a thinner and smaller diameter blade would be best for this application. Blades ranging from 3” to 5” (75mm to 125mm) in diameter and thickness .006” to .015” (0.2mm to 0.4mm) would be bet suited for this purpose. There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, load/feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker wafering blades are more stiff and can whistand higher loads/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as in University laboratory.

Typically wafering blade diameters range form 3” (75mm) to 8” (200mm). Wafering blade diameter should be selected based on material diameter and thickness being cut. Smaller diameter wafering blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and heavier samples at higher loads and speeds than smaller blades.

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness. Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire and alumina generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Metal bonding offers long life and durability, while resin bonding creates less heat, provides better surface finish and is well suited for cutting hard, delicate or brittle materials.

Load/Feed Rate applied to wafering blades typically vary from 10-1000 grams. Generally, harder specimens are cut at higher loads and speeds (e.g. ceramics and minerals) and more brittle specimens are cut at lower loads and speeds (e.g. electronic silicon substrates). The Speeds/RPM’s you are using, shape/geometry of the specimen, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Most wafering blades are used between 50 to 6,000 RPM’s Typically harder and more denser materials such as Silicon Carbide, are cut at higher RPM’s/speeds Where more brittle materials such as silicon wafers and gallium arsenide are cutting at lower RPM’s. Low Speed saws RPM’s are typically limited from 0 to 600 RPM’s. Where high speed saws offer much large variety of cutting speeds from 0 to 6,000 RPM’s.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales