Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

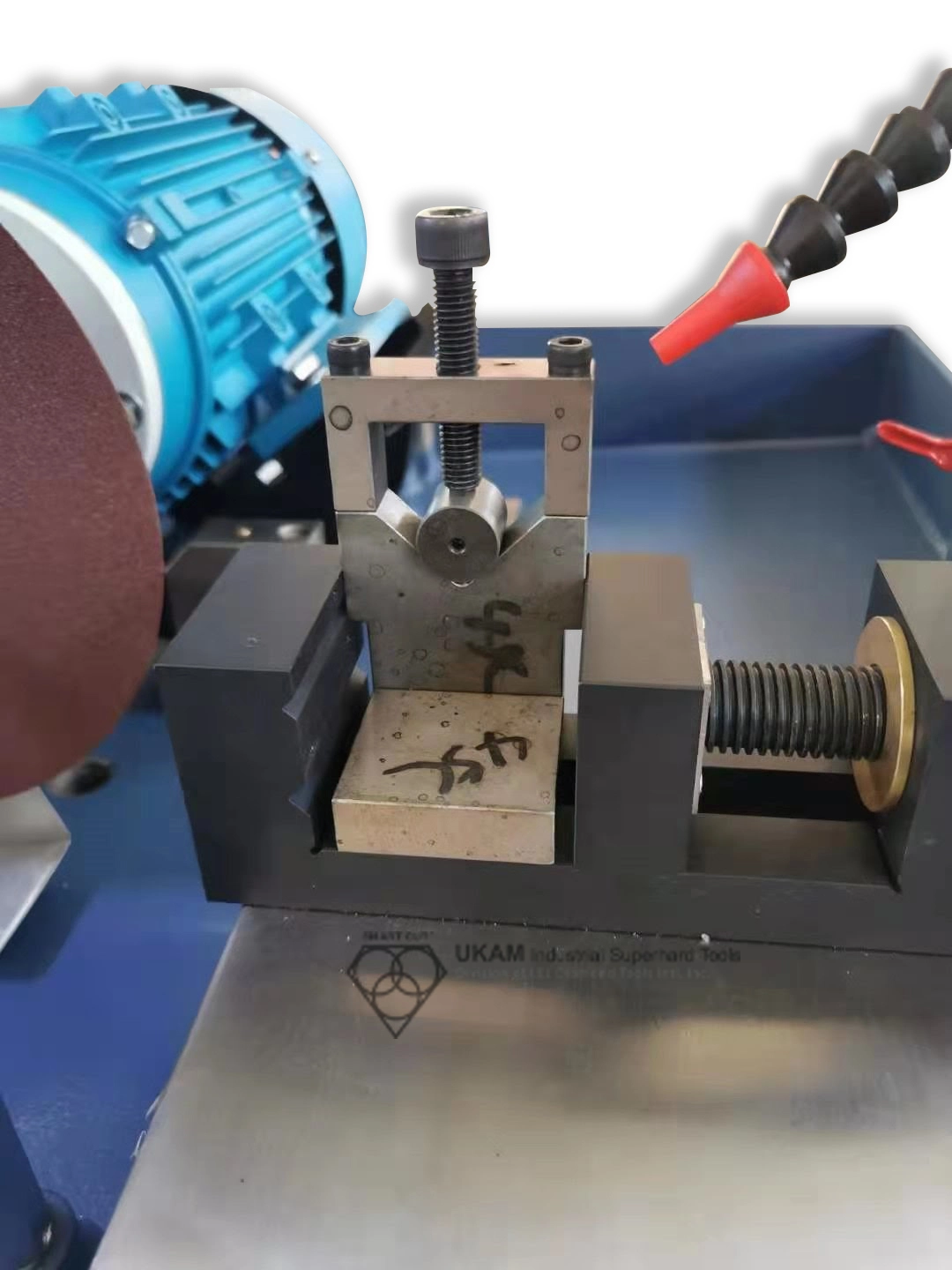

SMART CUT® Resin Bond Abrasive Cut Off Blades specifically designed for metallography and sample preparation are meticulously engineered with aluminum oxide or silicon carbide particles embedded in a phenolic binder. These blades are specifically formulated to achieve the optimal surface finish required for metallographic preparations. Available in diameters ranging from 250mm to 400mm, and inside diameters of 1.25” and 32mm. These abrasive cut-off wheels are tailored for precision in metallography and sample preparation. They provide sharp, clean cuts with minimal material deformation, making them perfect for a wide range of materials in both laboratory and industrial settings.

Designed to operate optimally with coolant, SMART CUT® abrasive wheels set the standard for quality in cutting metallurgical specimens. They efficiently produce cross-sections that typically require little to no additional treatment prior to metallographic analysis, ensuring that the structure and metallurgical properties of the specimens remain intact.

Select from an extensive range of dozens specialized blades, each tailored for specific applications. Our silicon carbide wheels are expertly formulated for cutting non-ferrous and non-metallic materials, while the aluminum oxide wheels are crafted for ferrous materials. Coarser grits provide efficient cutting of heavier sections, reducing heat generation and increasing speed. Conversely, finer grits yield superior surfaces and minimize burning on delicate materials. Soft wheels are designed to degrade more quickly, constantly exposing fresh cutting surfaces—this makes them ideal for slicing through hard materials. In contrast, hard wheels degrade more slowly, offering extended wear and are best suited for softer materials.

Tab Content

Tab Content

Tab Content

Tab Content

Tab Content

Image | Item Number | Diameter (mm/inch) | Thickness (mm/inch) | Arbor (mm/inch) | Hardness | Recommended for Cutting | Quantity | Get Quote |

|---|---|---|---|---|---|---|---|---|

250 (9.84) | 1.6 (0.063) | 32 (1.26) | 20R-30R | Low carbon, mild and extra mild steels, treated steels with medium cross sections, case hardened steels | Max: Min: 1 Step: 1 | |||

300 (11.81) | 2.5 (0.098) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

350 (13.78) | 2.5 (0.098) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

400 (15.75) | 2.5 (0.098) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

250 (9.84) | 1.6 (0.063) | 32 (1.26) | 40R | Treated steels, stainless steel, refractory steels, alloyed cast iron | Max: Min: 1 Step: 1 | |||

300 (11.81) | 2.5 (0.098) | 32 (1.26) | 40R | Max: Min: 1 Step: 1 | ||||

350 (13.78) | 2.5 (0.098) | 32 (1.26) | 40R | Max: Min: 1 Step: 1 | ||||

400 (15.75) | 2.5 (0.098) | 32 (1.26) | 40R | Max: Min: 1 Step: 1 | ||||

250 (9.84) | 1.6 (0.063) | 32 (1.26) | 40R-50R | Nickel-based superalloys, carburized steels, treated steels with fragile coatings, hardened high carbon steels | Max: Min: 1 Step: 1 | |||

300 (11.81) | 2.5 (0.098) | 32 (1.26) | 40R-50R | Max: Min: 1 Step: 1 | ||||

350 (13.78) | 2.5 (0.098) | 32 (1.26) | 40R-50R | Max: Min: 1 Step: 1 | ||||

400 (15.75) | 2.5 (0.098) | 32 (1.26) | 40R-50R | Max: Min: 1 Step: 1 | ||||

200 (7.87) | 1.5 (0.059) | 32 (1.26) | 20R-30R | Non-ferrous materials, aluminum & aluminum alloys, copper & copper alloys, white, gray and spheroidal cast irons | Max: Min: 1 Step: 1 | |||

250 (9.84) | 1.5 (0.059) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

300 (11.81) | 1.8 (0.071) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

350 (13.78) | 2.3 (0.091) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

400 (15.75) | 2.3 (0.091) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 |

SMART CUT® Rubber Bond Abrasive Cut-Off Blades are expertly designed for metallography and sample preparation, blending advanced rubber bonding technology with high-grade abrasive materials. These blades are exceptionally well-suited for processing a range of materials, from ferrous and non-ferrous metals to delicate and brittle materials that demand meticulous handling to preserve their structural integrity.

Featuring an innovative rubber bond, these SMART CUT® Rubber Bond Abrasive Cut-Off Blades significantly enhance flexibility and shock absorption, which substantially reduces both vibration and noise during operation. This contributes to smoother operations and extends the blade's lifespan by minimizing the risks of cracks or breaks under stress. The cutting performance of the rubber bond is distinguished by its ability to make clean, precise cuts with minimal heat generation, thereby maintaining the unaltered metallurgical properties of the sample for precise analysis.

Crafted from sheets of natural rubber using the traditional calendered method, SMART CUT® Rubber Bond Abrasive Cut-Off Blades blades possess a unique composition that renders them ideal for high-quality, cool, burn-free sectioning on metallographic samples. We offer sample wheels tailored to meet your specific sectioning applications for evaluation.

Custom specifications are available upon request, often requiring only small order quantities and featuring very fast lead times. We offer sample wheels tailored to meet your specific sectioning applications for evaluation.

Image | Item Number | Diameter (mm/inch) | Thickness (mm/inch) | Arbor (mm/inch) | Hardness | Recommended for Cutting | Quantity | Get Quote |

|---|---|---|---|---|---|---|---|---|

250 (9.84) | 1.6 (0.063) | 32 (1.26) | 20R-30R | Delicate ferrous metals, precision alloys, electronic and aerospace materials | Max: Min: 1 Step: 1 | |||

300 (11.81) | 2.5 (0.098) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

350 (13.78) | 2.5 (0.098) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

400 (15.75) | 2.5 (0.098) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

250 (9.84) | 1.6 (0.063) | 32 (1.26) | 40R | Hardened tool steels, titanium alloys, and advanced ceramic materials | Max: Min: 1 Step: 1 | |||

300 (11.81) | 2.5 (0.098) | 32 (1.26) | 40R | Max: Min: 1 Step: 1 | ||||

350 (13.78) | 2.5 (0.098) | 32 (1.26) | 40R | Max: Min: 1 Step: 1 | ||||

400 (15.75) | 2.5 (0.098) | 32 (1.26) | 40R | Max: Min: 1 Step: 1 | ||||

250 (9.84) | 1.6 (0.063) | 32 (1.26) | 40R-50R | Composite materials, fiberglass, and high-strength alloys | Max: Min: 1 Step: 1 | |||

300 (11.81) | 2.5 (0.098) | 32 (1.26) | 40R-50R | Max: Min: 1 Step: 1 | ||||

350 (13.78) | 2.5 (0.098) | 32 (1.26) | 40R-50R | Max: Min: 1 Step: 1 | ||||

400 (15.75) | 2.5 (0.098) | 32 (1.26) | 40R-50R | Max: Min: 1 Step: 1 | ||||

200 (7.87) | 1.5 (0.059) | 32 (1.26) | 20R-30R | Non-ferrous metals such as aluminum, bronze, and copper alloys | Max: Min: 1 Step: 1 | |||

250 (9.84) | 1.5 (0.059) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

300 (11.81) | 1.8 (0.071) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

350 (13.78) | 2.3 (0.091) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 | ||||

400 (15.75) | 2.3 (0.091) | 32 (1.26) | 20R-30R | Max: Min: 1 Step: 1 |

|

Attribute |

Resin Bond (Aluminum Oxide) |

Resin Bond (Silicon Carbide) |

Rubber Bond (Aluminum Oxide) |

Rubber Bond (Silicon Carbide) |

|---|---|---|---|---|

|

|

|

|

||

|

Abrasive Material |

Aluminum Oxide |

Silicon Carbide |

Aluminum Oxide |

Silicon Carbide |

|

Bond Type |

Resin (phenolic, epoxy) |

Resin (phenolic, epoxy) |

Rubber (natural or synthetic) |

Rubber (natural or synthetic) |

|

Cutting Speed |

High |

High |

Moderate |

Moderate |

|

Flexibility |

Low |

Low |

High |

High |

|

Heat Resistance |

Moderate |

Moderate |

High |

High |

|

Water Resistance |

Low |

Low |

High |

High |

|

Durability |

High |

High |

Moderate |

Moderate |

|

Material Compatibility |

Hard, brittle materials |

Very hard materials |

Softer, more sensitive materials |

Softer, more sensitive materials |

|

Cut Quality |

Smooth, minimal deformation |

Smooth, minimal deformation |

Very smooth, minimal chipping |

Very smooth, minimal chipping |

|

Application |

Dry cutting |

Dry cutting |

Wet or dry cutting |

Wet or dry cutting |

|

Cost |

Low to Moderate |

Low to Moderate |

Moderate to high |

Moderate to high |

|

Maintenance |

Low |

Low |

Moderate |

Moderate |

|

Noise Level |

Higher |

Higher |

Lower |

Lower |

|

Thermal Stability |

Good |

Good |

Excellent |

Excellent |

|

Impact Resistance |

Low |

Low |

Moderate |

Moderate |

|

Cutting Precision |

High |

High |

Moderate |

Moderate |

|

Suitability for Delicate Materials |

Poor |

Poor |

Excellent |

Excellent |

|

Wear Rate |

Moderate |

Moderate |

High |

High |

|

Vibration Damping |

Low |

Low |

High |

High |

|

Environmental Suitability |

Best in controlled environments |

Best in controlled environments |

Versatile in various settings |

Versatile in various settings |

|

Ease of Use |

Easy for skilled operators |

User-friendly for all levels |

User-friendly for all levels |

User-friendly for all levels |

Recommended abrasive cut-off wheel types with various metal hardness categories, using either resin or rubber bonds with aluminum oxide or silicon carbide:

|

Metal Type and Hardness |

Recommended Wheel Type |

Abrasive Material |

Bond Type |

Reason for Recommendation |

|---|---|---|---|---|

|

Ferrous Metals <15 HRC (Soft Material) |

Resin Bond Cut-Off Wheel |

Aluminum Oxide |

Resin |

Aluminum oxide provides efficient cutting for soft ferrous metals; resin bond offers durability. |

|

Ferrous Metals 30-50 HRC (Medium Soft Material) |

Resin Bond Cut-Off Wheel |

Aluminum Oxide |

Resin |

Balances cutting efficiency and durability for medium soft metals. |

|

Ferrous Metals 50-58 HRC (Medium Hard Material) |

Resin Bond Cut-Off Wheel |

Silicon Carbide |

Resin |

Silicon carbide ensures sharp and durable cutting for medium hard metals. |

|

Ferrous Metals 60-70 HRC (Hard Material) |

Resin Bond Cut-Off Wheel |

Silicon Carbide |

Resin |

Best for hard materials, maintaining sharpness and durability under extreme conditions. |

|

Ferrous Metals >70 HRC (Very Hard Material) |

Resin Bond Cut-Off Wheel |

Silicon Carbide |

Resin |

Silicon carbide's extreme hardness and sharpness handle the toughest cutting jobs. |

|

Non-Ferrous Metals (Cast Iron, Bronze, Copper, Aluminum) |

Rubber Bond Cut-Off Wheel |

Aluminum Oxide |

Rubber |

Aluminum oxide's versatility and the rubber bond's flexibility suit softer non-ferrous metals, reducing heat and chipping. |

|

Non-Ferrous Metals (Titanium) |

Rubber Bond Cut-Off Wheel |

Silicon Carbide |

Rubber |

Silicon carbide's sharpness and rubber's thermal resistance are ideal for tough, lightweight metals like titanium. |

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

WE ARE A PARTNER IN YOUR SUCCESS

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

AMERICAN MANUFACTURER

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Save Money Save up to 650%

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

Advanced Technology

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Let Us Help You

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales