Menu

-

0 items in quote

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® Diamond Sintered Metal Bond Cut Off Blades are meticulously engineered for petrographic sample preparation. These blades offer unmatched accuracy, minimal material deformation, precision and durability, making them an essential tool for geologists, petrologists, and materials scientists.

SMART CUT® petrographic blades feature a high concentration of premium-quality diamonds impregnated in side of soft bond bronze based matrix. This design ensures a smooth, swift cutting action, prolonged blade life, and minimal amount of material deformation even under rigorous laboratory conditions.

Unlike standard diamond blades designed for hard materials like granite or porcelain, these blades have a different bond matrix and diamond concentration. They are optimized for the unique requirements of petrographic samples, offering minimal material deformation and maximum precision.

While these blades are specifically designed for petrographic samples, they can be used for cutting a wide range of materials, including hard minerals, rocks, shale, and concrete. They provide clean, precise cuts without chipping or cracking, making them versatile for various cutting needs.

These blades are designed to fit a variety of petrographic cut-off machines, such as BUELER, STRUERS, LECO, and many others. They are suitable for use in laboratory settings and are compatible with equipment commonly used in petrography and sample preparation.

While these blades are commonly used in laboratory settings, they can also be used in the field, provided you have the appropriate equipment for field cutting and sample preparation. Their precision and durability make them a valuable tool for both laboratory and field applications in petrography.

The lifespan of these blades can vary depending on factors such as the type of material being cut, cutting speed, and maintenance practices. Under typical laboratory conditions and with proper care, they can have a long lifespan. Depending on frequency of use these blade can last for years if infrequently used or many months if used frequently on daily basis.

Selecting the right blade size and specifications depends on the type of samples you are working with and the equipment you are using. It’s advisable to consult with experts in petrography or the blade manufacturer for guidance on choosing the most suitable blade for your specific application.

Yes, these blades are designed to handle a wide range of petrographic samples, including extremely hard or abrasive materials. Their diamond concentration and specialized bond matrix allow for efficient cutting without excessive wear or deformation.

These blades are designed to minimize heat generation during cutting, which is crucial for preserving the integrity of petrographic samples. However, it’s essential to ensure that your cutting equipment is properly cooled and lubricated to further control heat generation.

Yes, these blades are capable of cutting samples with embedded minerals or inclusions. Their precision and minimal material deformation make them suitable for detailed petrographic analysis, even when samples contain various minerals or inclusions.

These blades are available in various sizes and kerf thicknesses to accommodate different sample dimensions. You can select a blade size and specification that suits your specific cutting requirements, whether you’re working with small or large, thick or thin petrographic samples.

Compared to traditional cutting methods, these blades offer superior precision, minimal material deformation, and reduced sample preparation time. This results in higher-quality petrographic samples, allowing for more accurate analysis and research.

These blades can be used for both wet and dry cutting applications. Wet cutting may help further reduce heat generation and minimize dust, making it a suitable option for certain petrographic sample preparation tasks.

The recommended cutting speed may vary depending on the material being cut and the specific equipment in use.

While these blades are typically used for straight cuts, they can be used for cutting irregularly shaped samples with careful handling and precise equipment adjustments. However, achieving precise results with irregular shapes may require additional expertise and equipment modifications.

To prolong the lifespan of these blades, it’s recommended to store them in a dry and clean environment and protect them from physical damage. Additionally, following proper cleaning procedures after use can help maintain their cutting efficiency.

Yes, these blades are suitable for both research and educational purposes in academic settings. Their precision and durability make them valuable tools for petrography courses, research projects, and sample preparation in academic laboratories.

Yes, these blades are capable of producing thin sections with precision. Their minimal material deformation and high-quality cutting make them suitable for creating very thin sections for detailed petrographic analysis.

These blades are versatile and can be used for cutting a wide range of petrographic samples, including soft materials. Their design minimizes material deformation, ensuring that even soft samples are cut cleanly and accurately.

While it’s possible to cut samples with different hardness levels in a single run using these blades, it’s essential to adjust cutting parameters to accommodate the variation in material properties. Careful consideration and expertise are required to achieve the desired results when cutting samples with varying hardness.

Regularly cleaning the blades and inspecting them for wear are essential maintenance procedures. Additionally, ensuring that the blades are properly lubricated and cooled during cutting can help prolong their lifespan and maintain cutting efficiency.

Yes, these blades are engineered to provide consistent cutting performance over their lifespan when used correctly and maintained properly. Their design and diamond concentration are optimized for durability and precision.

These blades can be used with automated or CNC (Computer Numerical Control) cutting equipment, provided that the equipment is designed to accommodate diamond sintered metal bond blades. Compatibility may vary depending on the specific machine, so it’s advisable to verify with the equipment manufacturer or supplier.

These blades are designed to minimize environmental impact and do not produce harmful byproducts during cutting. However, it’s important to handle any waste materials generated during the cutting process according to local environmental regulations and best practices.

While these blades themselves do not have safety features, it’s crucial to follow laboratory safety protocols, wear appropriate personal protective equipment (PPE), and ensure that the cutting equipment is in proper working order to maintain a safe working environment.

These blades can be used in the presence of water or cutting fluids for wet cutting applications. Wet cutting can help reduce heat generation and minimize dust, making it a suitable option for certain petrographic sample preparation tasks.

Yes, these blades are versatile and can be used for cutting petrographic samples of varying sizes. They are available in different diameters and kerf thicknesses to accommodate a wide range of specimen dimensions.

These blades are engineered to minimize chipping and fragmentation during cutting, making them suitable for brittle materials. However, it’s important to use appropriate cutting parameters and techniques to ensure clean and precise cuts when working with brittle samples.

Yes, these blades are capable of cutting composite materials containing both soft and hard components. Their design allows for precise cutting through such materials, provided that cutting parameters are adjusted accordingly.

These blades are designed to have standard dimensions for easy integration into most petrographic cut-off machines. However, it’s essential to ensure that the blade is properly aligned and securely installed according to the manufacturer’s instructions to achieve optimal cutting performance.

Yes, these blades are suitable for both cross-section and longitudinal section cuts of petrographic samples. Their precision and minimal material deformation make them versatile for various sample preparation needs in petrography.

These blades are designed to minimize damage to delicate or valuable petrographic samples. However, it’s advisable to exercise caution and expertise when cutting such samples to ensure their integrity is preserved during the cutting process.

While these blades are typically used for cutting flat or planar surfaces, they can be used for samples with some irregular surface features. Achieving clean and precise cuts on samples with significant topography may require additional techniques and expertise.

Yes, these blades are ideal for cutting samples that will undergo subsequent analysis, such as microscopy or spectroscopy. Their precision and minimal material deformation ensure that the cut surfaces are suitable for detailed analysis techniques.

Specific cutting speeds may vary depending on the material being cut. It’s advisable to consult the manufacturer’s guidelines or seek expert advice to determine the recommended cutting speeds for specific petrographic materials.

Manufacturers or suppliers often provide helpful cutting tips, best practices, and application-specific guidance to help users achieve the best results with these blades. Feel free to reach out to them for valuable insights into optimizing your cutting processes.

These blades are primarily designed for straight cuts, but with careful handling and adjustments, they can be used for sectioning cylindrical or irregularly shaped samples. Achieving precise results with irregular shapes may require additional expertise and equipment modifications.

These blades are designed to provide a smooth surface finish on cut petrographic samples, minimizing the need for additional polishing. However, the final surface quality may depend on factors such as blade condition, cutting parameters, and material hardness.

Yes, these blades are well-suited for cutting geological samples with high mineralogical diversity. Their precision and minimal material deformation make them suitable for samples containing various minerals, allowing for accurate petrographic analysis.

These blades are engineered to provide a smooth and swift cutting action, which helps reduce noise and vibration during the cutting process. However, the level of noise and vibration may still depend on the specific equipment and cutting parameters used.

While these blades are specialized for petrographic applications, they can be used for cutting a range of geological materials. However, if you require blades for cutting construction materials, it’s advisable to consider specialized blades designed for that purpose.

Yes, you can typically consult with experts or technical support personnel from the manufacturer or supplier regarding specific cutting challenges or unique applications of these blades. They can provide valuable insights and guidance to help you achieve the best results for your particular needs in petrography.

These blades are capable of cutting small and delicate petrographic samples with precision. However, for extremely small or fragile samples, it’s important to use appropriate cutting techniques and equipment to minimize the risk of damage.

When handling these blades, it’s essential to exercise caution to prevent accidental cuts or damage. Proper storage in a dry and clean environment, along with securing the blades during transport, can help ensure safety and prevent any damage to the blades.

These blades can be used for cutting samples that have undergone treatments or coatings like epoxy impregnation or resin embedding. However, the choice of blade and cutting parameters may need to be adjusted based on the specific treatment and material properties.

To reduce waste and optimize blade usage, consider carefully planning your cutting operations to minimize unnecessary cuts and material loss. Additionally, proper blade maintenance and handling can extend their lifespan, reducing the need for frequent replacements.

These blades can be used for cutting historical or valuable petrographic samples, but it’s crucial to exercise extreme care and expertise to preserve the integrity of the specimens during the cutting process. Specialized techniques may be required for such delicate samples.

These blades are designed to handle abrasive materials, including those containing minerals like quartz. Their diamond concentration and specialized bond matrix make them suitable for cutting samples with high levels of abrasiveness.

While these blades are primarily used for straight cuts, they can be employed to create customized sample shapes or sizes with the right cutting techniques and expertise. Precision and care are essential for achieving the desired results.

When using these blades in conjunction with other sample preparation equipment, such as grinders or polishers, it’s important to ensure that the equipment is compatible with diamond sintered metal bond blades and that the processes are coordinated to achieve the desired sample preparation results.

These blades can be used for cutting samples that have undergone heat treatments or annealing processes. However, the specific cutting parameters and techniques may need to be adjusted based on the material’s altered properties due to such treatments.

To reduce the generation of airborne dust or particles during cutting, consider using wet cutting techniques, which involve the use of water or cutting fluids. Wet cutting helps suppress dust and keeps the work environment cleaner.

These blades are generally suitable for cutting samples with volatile or sensitive components. However, if there are concerns about potential chemical interactions, it’s advisable to consult with experts or conduct a compatibility test before cutting to ensure the sample’s integrity.

These blades are designed to minimize material deformation and are suitable for cutting samples with a high degree of friability. However, extra care may be required to prevent crumbling or sample loss during cutting.

Yes, these blades are suitable for cutting samples that require extremely high levels of accuracy and minimal material loss, as required for isotope analysis and other precise analytical techniques. Their precision cutting minimizes material deformation and loss.

The selection of the appropriate cutting depth may depend on the specific application and sample type. Consult with experts or follow manufacturer recommendations to determine the optimal cutting depth for your petrographic samples.

Yes, these blades can be used for cutting samples in ongoing research projects where consistent and reproducible results are critical. Their precision and minimal material deformation contribute to reliable and consistent cutting performance.

These blades can be used for cutting samples that have undergone chemical treatments. However, it’s essential to consider the effects of the chemical treatments on the material properties and adjust cutting parameters accordingly to achieve clean and accurate cuts.

These blades can be used for cutting samples that require specialized analytical techniques, such as cathodoluminescence or electron microprobe analysis. The high-quality cuts produced by these blades contribute to reliable results in advanced analytical methods.

Yes, these blades can be used for cutting samples that will undergo further analysis using non-destructive techniques. The precision and quality of the cuts produced by these blades ensure that the samples are suitable for subsequent non-destructive analytical methods.

These blades can be used for cutting samples that are part of interdisciplinary research projects involving multiple scientific fields. Their versatility and precision make them valuable tools for researchers working at the intersection of different disciplines.

These blades can be used for cutting samples intended for public outreach and education in science centers or geological museums. Careful cutting techniques can help create visually appealing and informative sample sections for educational displays.

SMART CUT Diamond Sintered Metal Bond Cut Off Blades are specifically engineered for petrographic sample preparation, offering an exceptionally smooth surface finish. In contrast, standard stone and tile blades are designed for cutting construction materials and may leave rougher surface finishes.

SMART CUT Diamond Sintered Metal Bond Cut Off Blades provide superior cut quality, characterized by minimal material deformation, precise cuts, and reduced risk of chipping or cracking. Standard stone and tile blades, while suitable for their intended applications, may not deliver the same level of precision and quality when cutting petrographic samples.

Yes, SMART CUT Diamond Sintered Metal Bond Cut Off Blades are designed to produce surfaces suitable for detailed petrographic analysis without the need for extensive additional polishing. Standard stone and tile blades typically require additional polishing to achieve comparable surface quality for scientific analysis.

The specialized design of SMART CUT Diamond Sintered Metal Bond Cut Off Blades minimizes material deformation during cutting. This is achieved through a high concentration of premium-quality diamonds impregnated in a soft bond bronze-based matrix. In contrast, standard stone and tile blades may exert more force on the material, leading to greater deformation.

Yes, the advantages of using SMART CUT Diamond Sintered Metal Bond Cut Off Blades for achieving high-quality surface finishes in petrographic samples include reduced material deformation, precise cuts, and minimal chipping or cracking. These characteristics make them the preferred choice for petrologists, geologists, and materials scientists when compared to standard stone and tile blades designed for construction purposes.

SMART CUT Diamond Sintered Metal Bond Cut Off Blades are engineered for durability and consistent cutting performance over their lifespan when used correctly and maintained properly. They maintain their high-quality surface finish and cut quality even after extended use. In contrast, standard stone and tile blades may experience a decline in performance and may require more frequent replacement to maintain consistent cut quality.

Samples cut with SMART CUT Diamond Sintered Metal Bond Cut Off Blades exhibit a smoother and more precise surface finish, making them ideal for detailed petrographic analysis. In contrast, samples cut with standard stone and tile blades may have rougher surfaces, which can be less suitable for scientific examination and may require additional time-consuming polishing steps to achieve a comparable finish.

The superiority of SMART CUT Diamond Sintered Metal Bond Cut Off Blades in terms of surface finish and cut quality is particularly evident when working with geological and petrographic samples. These blades excel in maintaining the integrity of the sample structure, even in materials with varying mineralogical compositions, irregularities, and delicate features. Standard stone and tile blades may not provide the same level of precision in these specialized applications.

Yes, SMART CUT Diamond Sintered Metal Bond Cut Off Blades are designed to minimize the need for secondary operations like polishing. Their exceptional cut quality and surface finish often reduce or eliminate the time-consuming polishing steps required when using standard stone and tile blades. This efficiency can significantly streamline the sample preparation process in petrographic analysis.

When choosing between SMART CUT Diamond Sintered Metal Bond Cut Off Blades and standard stone and tile blades, researchers and petrologists should consider factors such as the type of samples, the required precision, the need for minimal material deformation, and the potential time savings. For applications where surface finish and cut quality are paramount, especially in petrographic analysis, SMART CUT Diamond Sintered Metal Bond Cut Off Blades are the preferred choice due to their specialized design and superior performance in achieving high-quality results.

Image | Name | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $15.39 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $15.99 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $39.47 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $39.47 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 |

Tab Content

Whether slicing through hard minerals, rocks, shale, or concrete, these blades deliver clean, precise cuts, free of chipping, cracking. Their versatility makes them ideal for a wide range of petrographic materials, ensuring minimal sample deformation and maximum structural integrity.

The fine diamond grit size is carefully selected to balance cutting speed with cut quality. This results in reduced sample preparation time without sacrificing the quality of the cut, essential for efficient laboratory workflow. Save time on secondary operations such as polishing.

These SMART CUT® Blades are designed to fit a variety of petrographic cut-off machines such as BUELER, STRUERS, LECO and many others. Their standard dimensions allow for easy integration into existing laboratory setups, ensuring seamless operation.

Image | New Item Number | Diameter | Kerf Thickness | Arbor Size / Inside Diameter | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|

3063218 | 6" (150mm) | .032” (0.80mm) | ½” (12.7mm) | $174.00 | Max: Min: 1 Step: 1 | ||

3083217 | 8" (200mm) | .043” (1.14mm) | ½” (12.7mm) | $214.00 | Max: Min: 1 Step: 1 | ||

3083218 | 8" (200mm) | .054” (1.37mm) | ½” (12.7mm) | $214.00 | Max: Min: 1 Step: 1 | ||

3083240 | 10” (254mm) | .060” (1.52mm) | 1.25” | $214.00 | Max: Min: 1 Step: 1 | ||

3083242 | 10” (254mm) | .060” (1.52mm) | 32mm | $214.00 | Max: Min: 1 Step: 1 | ||

3083248 | 12" (300mm) | .075” (1.9mm) | 1.25” 32mm | $275.00 | Max: Min: 1 Step: 1 | ||

3083250 | 12" (300mm) | .075” (1.9mm) | 1.25” 32mm | $275.00 | Max: Min: 1 Step: 1 | ||

3083244 | 12” (300mm) | .051” (1.29mm) | 1.25” | $285.00 | Max: Min: 1 Step: 1 | ||

3083246 | 12” (300mm) | .051” (1.29mm) | 32mm | $285.00 | Max: Min: 1 Step: 1 | ||

3083254 | 14” (350mm) | .051” (1.29mm) | 1.25” | $295.00 | Max: Min: 1 Step: 1 | ||

3083256 | 14” (350mm) | .085” (2.15mm) | 32mm | $295.00 | Max: Min: 1 Step: 1 | ||

3083252 | 14” (350mm) | .051” (1.29mm) | 1.25” 32mm | $305.00 | Max: Min: 1 Step: 1 | ||

3083262 | 16” (400mm) | .085” (2.15mm) | 1.25” 32mm | $325.00 | Max: Min: 1 Step: 1 | ||

3083264 | 16” (400mm) | .085” (2.15mm) | 32mm | $325.00 | Max: Min: 1 Step: 1 | ||

3083258 | 16” 400mm) | .051” (1.29mm) | 1.25” | $345.00 | Max: Min: 1 Step: 1 | ||

3083260 | 16” 400mm) | .051” (1.29mm) | 32mm | $345.00 | Max: Min: 1 Step: 1 |

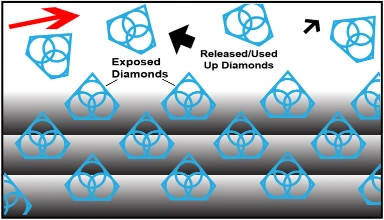

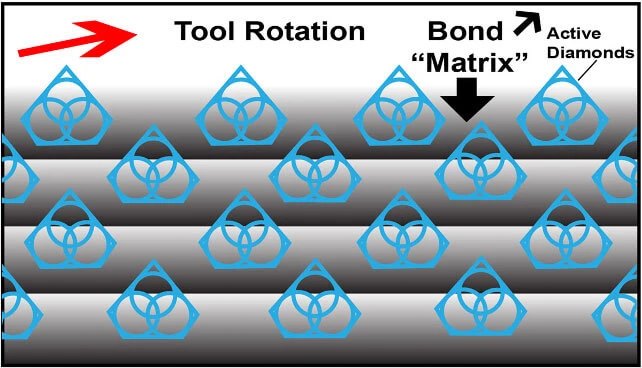

Sintered (metal bonded) diamond tools have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal bonded diamond tools are “impregnated” with diamonds. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, advanced ceramics, optics, glass, granite, tile and etc. The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting. Sintered (metal bonded) diamond tools are recommended for machining hard materials from 45 to 75 on rockwell scale (5 to 9.5 on mohe’s scale of hardness).

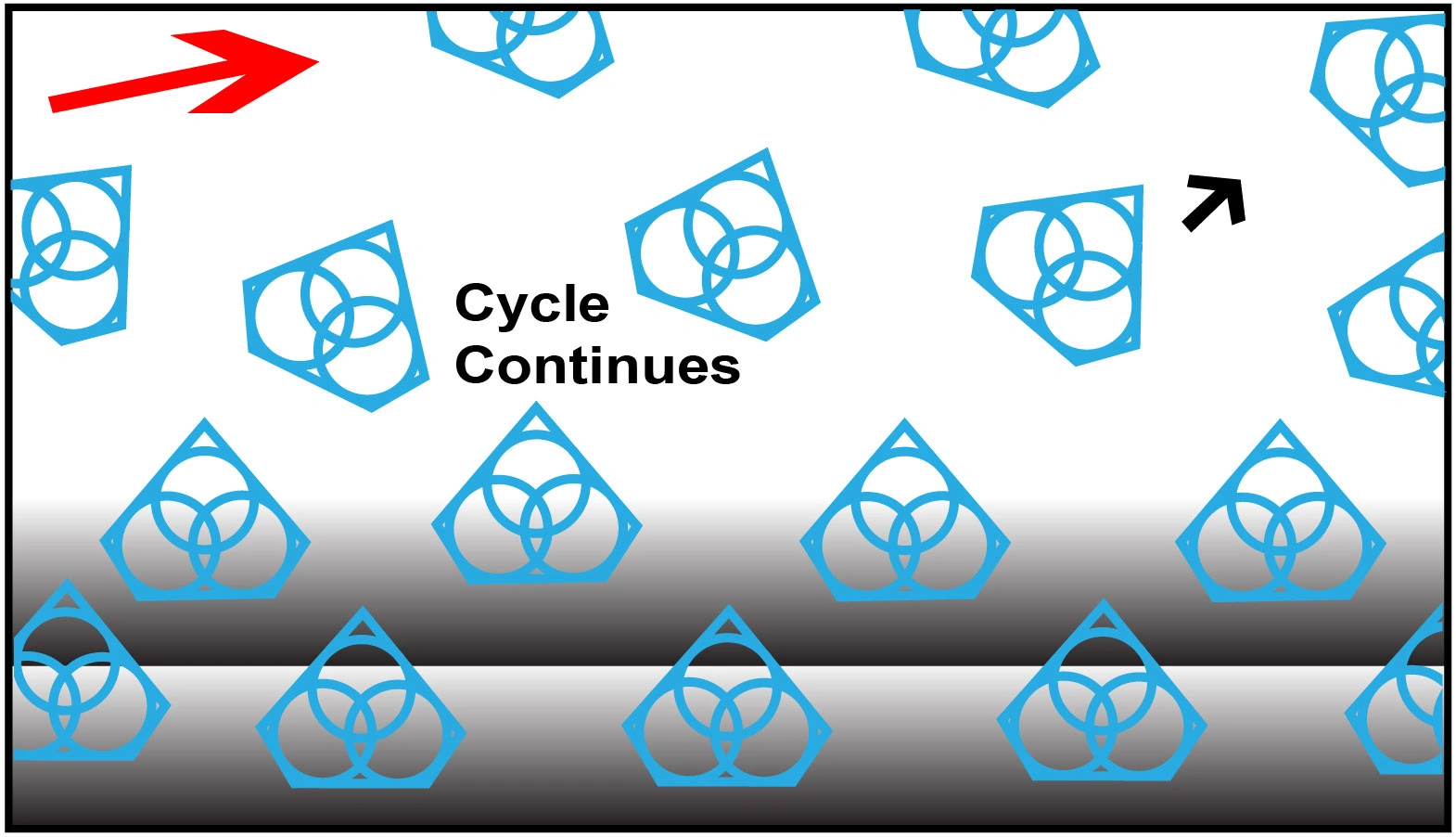

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Diamond & CBN Blades with SMART CUT® technology require minimum dressing, the bond renews itself.

SMART CUT® blades made utilizing SMART CUT® technology are much more aggressive then conventionally blades. They can cut faster, while still leaving behind a smooth surface finish.

SMART CUT® blades will outlast almost all other blades on the market today. The longer life can be attributed not only the higher diamond depth, but to higher diamond quality used. Advanced diamond distribution an orientation techniques, and proprietary bond chemistry. Combined with our competitive prices you re sure to obtain the best value and return on investment possible.

SMART CUT® Sintered (Metal Bond) Diamond Blades have hundreds of diamond layers impregnated inside the metal matrix. Unlike Many Other Blade Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials.

SMART CUT® Sintered (metal bond) blades are the best investment you can make! Although they may cost more than other sintered (metal bond), blades. Designed for users that understand and appreciate quality. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Sectioning/Wafering Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is significantly slower cutting speed. Low diamond concentration is recommended and widely used for cutting ultra hard and brittle materials.

Low Diamond Concentration - Typically low concentration wafering blades should be for cutting ultra hard and brittle materials such as ceramics and glass. In Low Concentration Wafering Blades, diamond works by fracture process. Pressure on each diamond crystal/particle is higher which provides enough stress to chip off small flakes in the cut.

High Diamond Concentration - High concentration diamond wafering blades are recommended for cutting metals, plastics and polymers. In this application, materials cut by a plowing mechanism. In this applications diamond plough through the material, work hardened strips of materials become brittle and break off. The greater number of diamond by volume, the quicker the cutting action will be. Increasing the number of diamond s also lowers the per unit force. For metals where it is possible to induce deep deformation layers, a lower per unit force is desirable to reduce the deformation during the cut.

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain, and material microstructure damage you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in material micro damage. If you are cutting fragile, more delicate materials then finer mesh size diamond wafering blades are recommended.

Wafering blade thickness typically ranges from .006” to .040” (1mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material/sample due to the thickness of blade passing though the material/sample. Blade thickness is important for users requiring most minimal amount of material loss during sectioning. For example if the user requires precision position of the cutting plane relative to the detail on the sample (IC circuit for example), a thinner and smaller diameter blade would be best for this application. Blades ranging from 3” to 5” (75mm to 125mm) in diameter and thickness .006” to .015” (0.2mm to 0.4mm) would be bet suited for this purpose. There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, load/feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker wafering blades are more stiff and can whistand higher loads/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as in University laboratory.

Typically wafering blade diameters range form 3” (75mm) to 8” (200mm). Wafering blade diameter should be selected based on material diameter and thickness being cut. Smaller diameter wafering blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and heavier samples at higher loads and speeds than smaller blades.

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness. Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire and alumina generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Metal bonding offers long life and durability, while resin bonding creates less heat, provides better surface finish and is well suited for cutting hard, delicate or brittle materials.

Load/Feed Rate applied to wafering blades typically vary from 10-1000 grams. Generally, harder specimens are cut at higher loads and speeds (e.g. ceramics and minerals) and more brittle specimens are cut at lower loads and speeds (e.g. electronic silicon substrates). The Speeds/RPM’s you are using, shape/geometry of the specimen, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Most wafering blades are used between 50 to 6,000 RPM’s Typically harder and more denser materials such as Silicon Carbide, are cut at higher RPM’s/speeds Where more brittle materials such as silicon wafers and gallium arsenide are cutting at lower RPM’s. Low Speed saws RPM’s are typically limited from 0 to 600 RPM’s. Where high speed saws offer much large variety of cutting speeds from 0 to 6,000 RPM’s.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales