-

0 items in quote

No products in the Quote Basket.

Metallography

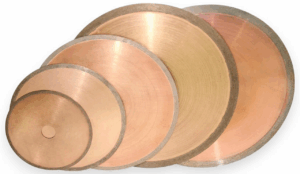

Metal Bond Diamond Discs

Metal Bond Diamond Discs, have diamond particles held firmly in place on a rigid backing by electroplated erosion resisting nickel for maximum bond strength and heat dissipation. A hard nickel alloy is used to rigidly bond a layer of sharp, blocky diamond to a steel backing. The sharp diamond particles cut cleanly with no edge rounding. Diamond Laps / Metal Bond Diamond Grinding Discs radically reduce the time required for material lapping/grinding process. Metal bond diamond grinding discs are available with either magnetic or PSA backing.

Petrographic Diamond Blades

Resin Bond Diamond Discs

Resin Bond Discs are designed removal of material/sample scratches, chips. high spots, & as well as pre-polishing on a larger variety of materials. Using a propriety technique, a high concentration of premium diamond is loaded onto each disc to provide an extremely aggressive grinding rate yet leaves an exceptionally smooth surface finish. Each disc is color coded to easily determine the diamond size of the disc. These resin bond diamond discs are guaranteed to out-perform many cloth polishing discs using loose conventional abrasive or diamond compound/slurry finishing systems. Depending on the application and process these discs on average will last for 100-200 parts/samples & maintain consistent level of performance. These are perfect for hard materials such as metals, ceramics, refractories, cement, geological rocks, glass, optics, composites, and many other materials 35 and up Rockwell C scale of hardness. All discs come with a 3M pressure-sensitive adhesive backing that bonds to backing plates, or with magnetic backing to attach to steel plates. Must be used with coolant. Not recommended for heavy stock material removal

Silicon Carbide Paper

SMART CUT® Silicon Carbide Abrasive Paper is meticulously designed for preparing metallographic specimens, incorporating superior silicon carbide grains embedded in a resilient, waterproof backing for both dry and wet grinding. This versatile paper transitions smoothly from coarse cutting to fine polishing, ensuring that specimens are precisely prepared for microscopic analysis.

Silicon Carbide Paper new

SMART CUT® Silicon Carbide Abrasive Paper is meticulously designed for preparing metallographic specimens, incorporating superior silicon carbide grains embedded in a resilient, waterproof backing for both dry and wet grinding. This versatile paper transitions smoothly from coarse cutting to fine polishing, ensuring that specimens are precisely prepared for microscopic analysis.

SMART CUT 105N Diamond, Nickel Bond Wafering Blades INTERRUPTED RIM

SMART CUT™ Series 105N more freer cutting & aggressive than continuous rim nickel bond wafering blades. Best Suited for cutting larger variety of micro-electronics packages, pcb boards, plastics, composites, soft and precious metals, fish and human bones, graphite, GRP, FR4. Core steel with memory. Always snaps back to its original shape no matter how much bent.

Standard arbor size inside diameter is ½” (12.7mm) (* we can modify arbor size of any blade to anything you want same day for a small additional fee, if needed)

SMART CUT® 2020

Diamond, Nickel Bond Cut Off Blades for Laboratory & Abrasive Cut Off Saws

Nickel Bond Diamond Cut off blades Blades usually have a single layer of diamonds, held by a tough durable nickel alloy. diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation. Recommended for cutting softer and more gummy materials, where sintered (metal bond) diamond wafering blades load up or glaze over frequently. Unlike sintered (meal bond) cutting blades where diamond is impregnated inside metal binder matrix based on bronze, copper, nickel and other alloys.SMART CUT® 205M

SMART CUT Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. Unlike standard diamond & cbn wafering blades with steel core and diamond section. Instead of having a steel core and small diamond bond edge (usually 1/8"/3.2mm). The diamond edge is all the way through the blade, from its Outside Diameter to Inside Diameter of the blade. You can use until the entire Outside Diameter of the blade is consumed.

SMART CUT® CBN WAFERING BLADES SINTERED (METAL BOND)

SMART CUT® DIAMOND WAFERING BLADES SINTERED (METAL BOND)

$0.00

SMART CUT® Fully Sintered (Metal Bond) Diamond & CBN, Wafering Blades

SMART CUT® Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. Unlike standard diamond & cbn wafering blades with steel core and diamond section. Instead of having a steel core and small diamond bond edge (usually 1/8"/3.2mm). The diamond edge is all the way through the blade, from its Outside Diameter to Inside Diameter of the blade. You can use until the entire Outside Diameter of the blade is consumed.

Smart Cut® Glass Blade

SMART CUT Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. Unlike standard diamond & cbn wafering blades with steel core and diamond section. Instead of having a steel core and small diamond bond edge (usually 1/8"/3.2mm). The diamond edge is all the way through the blade, from its Outside Diameter to Inside Diameter of the blade. You can use until the entire Outside Diameter of the blade is consumed.