-

0 items in quote

No products in the Quote Basket.

Shop

SMART CUT® HD Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing Silicon

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

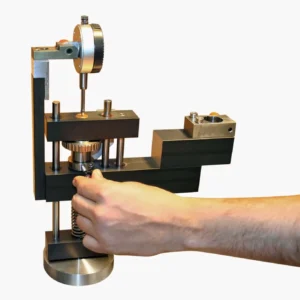

SMART CUT® HIGH PRECISION GRINDING / POLISHING HEAD

SMART CUT® LG Manual Metallurgical Grinder/Polisher with Single Wheel

SMART CUT® LP – Grinding/Polishing Machine

SMART CUT® LP – 12” (300MM)

SMART CUT® Metal Bond Diamond Discs for Large Grinding / Polishing Machines

SMART CUT® Mineral Oil

SMART CUT® Mineral Oil is a premium-grade lubricant and coolant specifically designed for precision cutting, drilling, grinding, and machining applications. It is ideal for use with a wide range of materials, particularly those with high metallic content, ceramics, precious and semi-precious stones, and other ultra-hard materials.

This mineral oil is formulated with a hydro-finished paraffin base, ensuring exceptional purity and consistent performance. It is non-dilutable, meaning it maintains its integrity and efficacy throughout its use. Rated as a food-grade oil, SMART CUT® Mineral Oil is non-toxic, non-hazardous, and non-flammable under normal conditions. With a flash point of 390°F, it provides reliable protection against heat buildup, making it suitable for demanding applications where high temperatures are a concern.

SMART CUT® Mineral Oil

SMART CUT® Mineral Oil is recommended for cutting, drilling, grinding and machining larger variety of materials such as:

- Materials with High Metallic Content

- Advanced Ceramics

- Precious & Semi Precious Stone

- Many Other Ultra Hard Materials