-

0 items in quote

No products in the Quote Basket.

SMART CUT® METAL BOND DIAMOND DISCS for Large Grinding / Polishing Machines

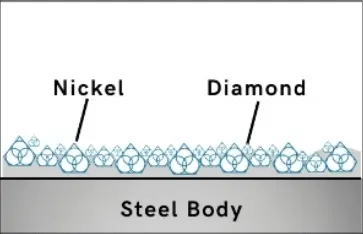

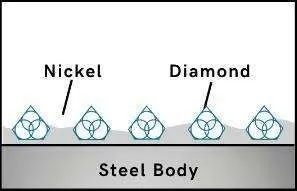

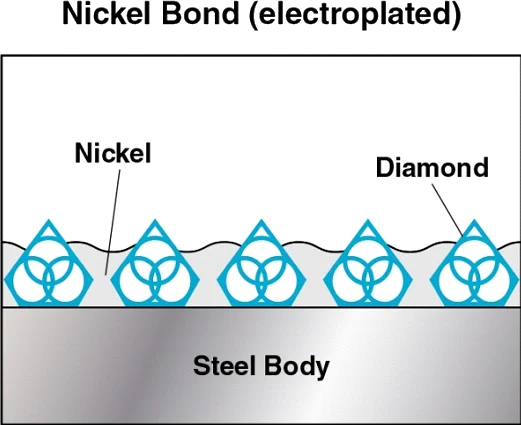

SMART CUT® metal bond (electroplated)diamond discs, have diamond particles held firmly in place on a rigid backing by electroplated erosion resisting nickel for maximum bond strength and heat dissipation. A hard nickel alloy is used to rigidly bond a layer of sharp, blocky diamond to a steel backing. The sharp diamond particles cut cleanly with no edge rounding.

DESCRIPTION

SPECIFICATIONS

INDUSTRIES USED IN

FAQ

ACCESSORIES

USAGE RECOMENDATION

DESCRIPTION

SMART CUT® Diamond Laps / Metal Bond Diamond Grinding Discs radically reduce the time required for material lapping/grinding process. An essential part of finishing process, diamond laps plays a major role in establishing the final dimensional and surface characteristics for many industrial parts. Diamond Laps are used to grind a wide variety materials including glass, optics, ceramic, plastic, composites, geological materials, stone, metals and their alloys, sintered materials, stellite, ferrite, copper, cast iron, steel etc.

SPECIFICATIONS

- Outside Diameters: 12”, 14”, 16”, 18”, 20”, 24”, and 30″

- Diamond Grit Sizes:40, 60, 80, 100, 180, 260, 360, and 600 Grit (custom grits are available upon request)

- Disks utilize highest quality diamonds electroplated onto a fiberglass substrate, coated with copper sheet.

- Backing Type: Magnetic or Adhesive can attach to with any steel plate.

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

SMART CUT Diamond Discs are designed for materials with a hardness of 35 Rockwell C scale and higher. This includes metals, ceramics, refractories, cement, geological rocks, glass, optics, composites, and many others. The key is selecting the right diamond mesh size and disc type for your specific material.

The diamond mesh size or grit size determines the aggressiveness of the disc. Coarse grits (e.g., 40) are suitable for rapid material removal, while finer grits (e.g., 200 or 1 micron) are ideal for achieving a polished surface. Consider the material’s hardness and the desired finish when selecting grit size.

Yes, SMART CUT Diamond Discs are versatile and can be used for both grinding and polishing. However, you may need to change to a finer grit disc for polishing after the initial grinding stages for optimal results.

The backing type determines how the disc attaches to your grinding or polishing equipment. Choose the backing that is compatible with your machine setup. Magnetic and adhesive PSA are common choices, but velcro and no backing options are available for specific needs.

- Start with Proper Cleaning: Ensure your workpiece is clean and free from debris before grinding or polishing to prevent contamination and scratches.

- Use Adequate Lubrication: Depending on your material and disc, use water, oil, or a compatible lubricant to cool and lubricate the grinding process.

- Apply Even Pressure: Maintain consistent pressure on the workpiece to avoid uneven wear on the disc and achieve uniform results.

- Progressive Grit Sequence: Begin with a coarser grit disc for material removal and gradually switch to finer grits for polishing. This progressive sequence minimizes surface imperfections.

- Monitor Disc Wear: Regularly inspect the disc for wear and replace it when necessary to maintain consistent performance.

- Work Safely: Always follow safety guidelines and wear appropriate protective gear, including safety glasses and gloves, when using diamond discs.

Yes, SMART CUT offers customization options. You can request specific inside diameter (ID) hole sizes, no hole configurations, and even discuss unique requirements with our team. We’re here to accommodate your specific needs.

To extend the lifespan of your discs, follow proper usage and maintenance guidelines. Avoid excessive pressure, use the correct lubrication, and periodically inspect the disc for wear. Replacing discs when they show signs of wear ensures consistent performance and longevity.

Yes, SMART CUT Resin Bond Diamond Discs are compatible with a wide variety of lapping, grinding, and polishing machines. Ensure you select the right disc size and backing type that matches your specific equipment for seamless operation.

Feel free to reach out to our expert team at SMART CUT. We’re here to assist you in selecting the right discs, providing usage recommendations, and answering any questions you may have to optimize your grinding and polishing process.

Yes, SMART CUT Diamond Discs are versatile and can be used for both wet and dry applications. Wet grinding and polishing can help control heat and reduce dust, while dry methods offer convenience. Choose the method that best suits your material and workspace conditions.

Safety is paramount. Always wear appropriate protective gear, including safety glasses, gloves, and respiratory protection if needed. Ensure that your workspace is well-ventilated, and follow safety guidelines for your specific equipment and material.

Monitor the surface finish closely. When the surface starts to exhibit a smoother, more polished appearance and the desired level of material removal is achieved, it’s time to switch to a finer grit disc for the final polishing stages.

Absolutely. SMART CUT Diamond Discs are known for their precision and consistency. They can be used for applications requiring tight tolerances, such as optics, electronics, and precision machining. Select the appropriate grit size and follow recommended procedures for achieving precision results.

Store SMART CUT Diamond Discs in a dry and clean environment to prevent contamination. Inspect them regularly for damage or wear and replace them as needed to maintain quality and safety. Follow proper cleaning procedures and lubrication recommendations during use.

Can these discs be used for curved or irregular surfaces, or are they best suited for flat surfaces?

SMART CUT Diamond Discs are versatile and can be used on both flat and curved surfaces. However, extra care may be needed to maintain even pressure and achieve consistent results on irregular shapes. Consider the disc size and backing type for the best performance on curved surfaces.

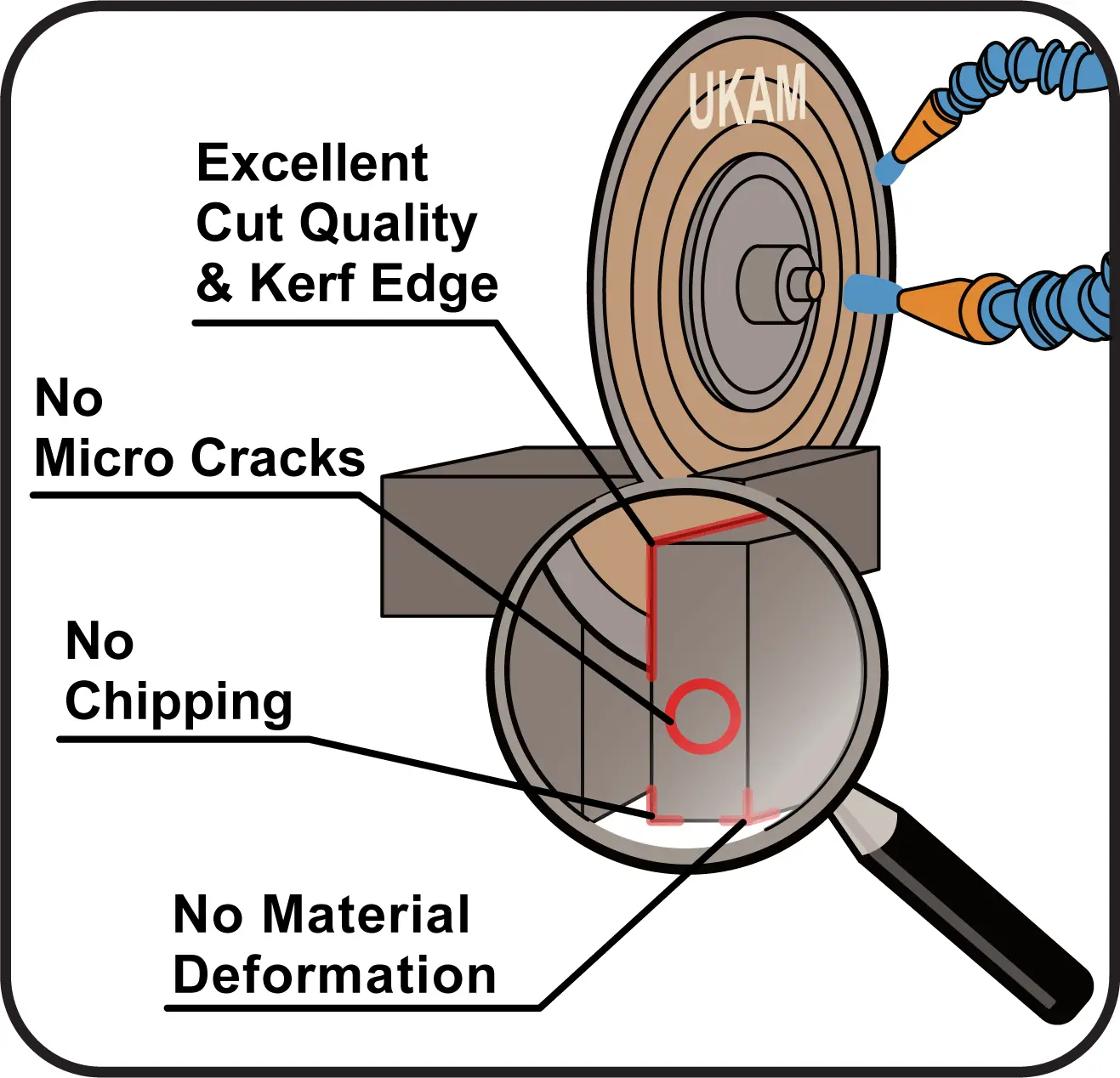

SMART CUT Diamond Discs provide longer lifespan, faster material removal, and superior surface finish compared to traditional abrasive discs. They also reduce the risk of overheating and material deformation, making them a preferred choice for high-precision applications.

Yes, SMART CUT Diamond Discs are suitable for projects of all sizes. They are used in small-scale workshops, laboratories, as well as large industrial operations. Choose the appropriate disc size and grit for your specific project and machinery.

Yes, SMART CUT Diamond Discs are well-suited for precision machining of extremely hard materials like sapphire, tungsten carbide, and other super-hard alloys. Selecting the appropriate grit size and following recommended procedures is crucial for achieving accurate and consistent results in such applications.

- Use the appropriate grit size for each stage of your process to minimize unnecessary wear.

- Maintain a consistent and moderate pressure on the workpiece to avoid excessive stress on the disc.

- Ensure proper lubrication or coolant flow to dissipate heat and prevent overheating.

- Periodically check the disc for any signs of uneven wear, damage, or clogging and replace it as needed.

- Store your diamond discs in a clean, dry environment to prevent contamination.

Yes, SMART CUT Diamond Discs can be used for edge grinding and beveling applications. Careful control of the angle and pressure is necessary to achieve the desired edge profile. Additionally, you may need to transition to finer grit discs for edge polishing.

The recommended RPM settings depend on the disc diameter, machine type, and material being worked on. Consult the manufacturer’s guidelines for your specific machine and adapt the RPM accordingly for safe and efficient operation with SMART CUT Diamond Discs.

Can these diamond discs be used for restoration or repair of optical components and glass artifacts?

Yes, SMART CUT Diamond Discs are suitable for restoration and repair of optical components, glass artifacts, and delicate surfaces. They provide the precision required for such applications and can be used to remove scratches and imperfections before final polishing.

While SMART CUT Diamond Discs can be used for both wet and dry applications, it’s essential to consider the compatibility of the disc and material with your chosen method. Some materials may yield better results with wet grinding and polishing, while others may perform well in dry conditions. Always prioritize safety and effectiveness when selecting the method.

SMART CUT Diamond Discs are typically designed for single-use due to the wear and degradation of the diamond abrasive during operation. Attempting to recondition or resurface them may not yield satisfactory results, and it’s generally more cost-effective to replace the disc when it shows signs of wear.

Absolutely. SMART CUT Diamond Discs are compatible with a wide range of equipment, including both manual and automated systems. Whether you’re operating a handheld grinder or an automated CNC machine, you can adapt SMART CUT Diamond Discs to suit your needs.

Yes, SMART CUT Diamond Discs are capable of high-precision micro-machining and intricate detailing. By selecting finer grit sizes and carefully controlling pressure and speed, you can achieve intricate and precise results, making them suitable for applications like microelectronics and precision optics.

SMART CUT Diamond Discs excel in a wide range of applications, including but not limited to material research, semiconductor manufacturing, metallography, geological sample preparation, precision optics, and aerospace component fabrication. Their versatility and precision make them a top choice across various industries.

Yes, SMART CUT Diamond Discs are suitable for both large, thick workpieces and smaller, thinner samples. By selecting the appropriate disc size and grit, you can effectively process workpieces of varying sizes and thicknesses while maintaining quality and efficiency.

The lifespan of a SMART CUT Diamond Disc depends on several factors, including the material being processed, the grit size, and the operating conditions. Typically, they have a long lifespan due to their high-quality diamond abrasives. To maximize longevity, follow proper usage guidelines, maintain consistent pressure, and replace the disc when it shows signs of wear.

Achieving a mirror-like finish on glass or optics requires careful progression through finer grit sizes and meticulous attention to detail. Start with a coarse grit for material removal and gradually transition to finer grits. Additionally, use a polishing compound or slurry designed for glass or optics to achieve the desired mirror finish.

Yes, SMART CUT Diamond Discs can be used for non-traditional applications like artistic glass shaping or sculpting. Their precision and versatility make them suitable for creating intricate and artistic designs in glass and similar materials.

Proper alignment and centering are crucial for achieving consistent results. Follow the equipment manufacturer’s guidelines for mounting and aligning discs. Ensure that the disc is securely attached and runs true to the equipment’s axis to prevent vibrations and uneven wear.

While SMART CUT Diamond Discs are primarily designed for grinding and polishing, they can be used for precision cutting, especially when combined with appropriate cutting fluid and equipment. However, for dedicated cutting applications, specialized diamond cutting discs or blades may be more suitable.

Proper disposal of used SMART CUT Diamond Discs should follow local regulations and guidelines for the disposal of abrasive materials. In some cases, used diamond discs may be considered hazardous waste due to the diamond abrasives. Consult with local authorities or waste management services for guidance on safe disposal practices.

Yes, SMART CUT Diamond Discs can be used for polishing natural stone surfaces like granite or marble countertops. Select the appropriate grit sizes and follow a progression from coarse to fine grits for effective polishing. Be sure to use a compatible stone polishing compound or slurry for the best results.

SMART CUT Diamond Discs are commonly used for preparing samples for microscopy and material analysis. Their precision and consistency make them an excellent choice for producing thin sections and polished surfaces suitable for detailed examination and analysis.

SMART CUT Diamond Discs can be used with both portable hand-held grinders and polishers as well as stationary machines. Their versatility allows for adaptability to various equipment types, making them suitable for a wide range of applications and setups.

SMART CUT Diamond Discs typically do not require dressing or conditioning before use. They are precision-manufactured to provide consistent performance out of the box. However, if you encounter any irregularities or inconsistencies, consult the manufacturer’s guidelines for specific recommendations on conditioning or truing the disc.

SMART CUT Diamond Discs are not typically used for faceting gemstones, as faceting requires specialized lapidary equipment and diamond laps. However, they can be used for other lapidary applications, such as shaping and polishing cabochons or flat surfaces on minerals and gemstones.

SMART CUT Diamond Discs are designed to maintain their flatness and shape with proper use. Avoid applying excessive pressure and use proper lubrication or coolant to dissipate heat and prevent overheating, which can lead to disc deformation. Regularly inspect the disc for any signs of wear or uneven wear patterns.

SMART CUT Diamond Discs can be used for beveling edges on glass and other materials. To achieve consistent bevels, set the angle and depth on your grinding or polishing equipment to match your desired bevel profile. Begin with a coarser grit disc for material removal, then gradually switch to finer grits for smoother bevels. Maintain a consistent feed rate and pressure to ensure uniform results.

Yes, SMART CUT Diamond Discs are suitable for applications involving composite materials like carbon fiber and fiberglass. Choose the appropriate grit size for your specific composite material, and follow recommended procedures to achieve precise cutting, grinding, and polishing results.

SMART CUT Diamond Discs are commonly used for thinning and sectioning semiconductor wafers. To thin a wafer, start with a coarser grit disc for material removal, then switch to finer grits for polishing. Be sure to use proper cooling and lubrication to prevent heat buildup, which can damage the wafer. Follow industry-specific guidelines for semiconductor thinning processes.

Cleaning SMART CUT Diamond Discs is essential to prevent cross-contamination between materials. Use a compatible cleaning solution or solvent, such as acetone or isopropyl alcohol, to remove residue. Gently scrub the disc surface with a soft brush or cloth, taking care not to damage the diamond abrasive. Rinse thoroughly with clean water and allow the disc to dry completely before reuse.

SMART CUT Diamond Discs are suitable for precision grinding and polishing of ceramics used in dental and medical applications. Select the appropriate grit size and follow recommended procedures to achieve the desired surface finish and precision required for dental crowns, orthopedic implants, and similar applications.

To control the removal rate with SMART CUT Diamond Discs, consider the following:

- Adjust the grit size: Coarser grits remove material more quickly, while finer grits offer finer control.

- Control pressure and feed rate: Adjust the pressure and feed rate to regulate the material removal rate.

- Monitor material thickness: Measure the material thickness during the process to ensure you achieve the desired level of removal.

Yes, SMART CUT Diamond Discs can be used for polishing hardened steel and achieving a mirror-like finish on precision components. Start with a coarse grit disc for material removal, then progressively switch to finer grits for polishing. Proper lubrication and consistent pressure are essential for obtaining a mirror finish on hardened steel.

To select the ideal SMART CUT Diamond Disc for your project, consider factors such as material hardness, desired finish, and equipment type. Consult the manufacturer’s guidelines, which often provide recommendations and guides for disc selection based on material and application. If in doubt, you can reach out to our experts for personalized guidance.

Achieving flatness and parallelism in precision components with SMART CUT Diamond Discs involves:

- Using a precision machine with proper alignment and control.

- Choosing the appropriate grit sizes and a progressive sequence for material removal and polishing.

- Ensuring consistent pressure and feed rate during the process.

- Regularly inspecting the workpiece to monitor progress and adjust as needed.

SMART CUT Diamond Discs can be used for high-temperature applications to some extent, but it’s essential to manage heat effectively. Proper cooling and lubrication are crucial to prevent overheating and damage to the diamond abrasive. Use cooling systems compatible with your equipment for such applications.

Yes, SMART CUT Diamond Discs can be used for precision surface finishing of 3D-printed parts made from various materials. Select the appropriate grit size and follow recommended procedures to achieve the desired surface finish and dimensional accuracy on 3D-printed components.

When working with brittle materials like ceramics or glass, take the following precautions:

- Use a gentle touch and minimal pressure to reduce the risk of cracking.

- Maintain proper cooling and lubrication to dissipate heat and prevent thermal stress.

- Consider using a finer grit disc for smoother material removal, which reduces the risk of chipping.

- Handle workpieces with care to avoid accidental damage during the process.

SMART CUT Diamond Discs can be used for contour grinding and polishing on irregularly shaped workpieces. To achieve uniform results, focus on the following techniques:

- Maintain a consistent angle and pressure relative to the contour’s shape.

- Use slow and controlled movements to prevent uneven wear.

- Progress through a sequence of grit sizes, starting with coarser grits for material removal and transitioning to finer grits for polishing.

- Adapt your technique to the specific contours and shapes of the workpiece for even coverage.

SMART CUT Diamond Discs can be suitable for applications requiring sub-micron level precision, such as semiconductor manufacturing and nanotechnology research. To achieve such precision, select the finest available grit size and follow meticulous procedures for material removal and polishing. Additionally, ensure your equipment is capable of sub-micron level control.

Yes, SMART CUT Diamond Discs can be used for restoration and conservation work on historical artifacts and sculptures made of stone or other materials. They are valuable tools for removing damage, corrosion, or unwanted layers while preserving the original material. Follow best practices for restoration and consult with conservation experts when working on valuable or culturally significant items.

When transitioning from one grit size to another with SMART CUT Diamond Discs, consider the following:

- Ensure that the workpiece is thoroughly cleaned and free from residue from the previous grit.

- Adjust the machine settings and feed rate if needed to match the new grit’s characteristics.

- Start with the coarsest grit size in the sequence and progressively move to finer grits.

- Pay attention to the material removal rate and adjust pressure and speed accordingly for optimal results.

SMART CUT Diamond Discs can be used for applications involving ferrous metals like stainless steel or hardened steel alloys. However, consider using specialized diamond discs designed for ferrous materials to achieve the best results, as these materials can be more abrasive and wear down diamond abrasives more quickly.

Achieving sharp edges and precise corners with SMART CUT Diamond Discs involves careful control and technique:

- Use smaller disc sizes or diamond tools specifically designed for edge work.

- Pay close attention to the angle and pressure applied to the workpiece near edges and corners.

- Transition to finer grits as you approach the desired sharpness.

- Consider using additional tools or techniques, such as hand polishing, for fine detailing on corners and edges.

SMART CUT Diamond Discs can be used for removing old coatings or paint layers from various surfaces. To do this effectively and safely:

- Use an appropriate grit size based on the coating or paint material.

- Ensure proper ventilation and wear protective gear to minimize exposure to dust and fumes.

- Use a suitable dust collection system or wet method to control dust and contaminants.

- Be cautious when removing lead-based paint or hazardous coatings, and follow environmental regulations and safety guidelines.

Yes, SMART CUT Diamond Discs are commonly used for sample preparation in metallurgy and material science. They are suitable for cutting and grinding metallographic specimens. Select the appropriate disc size and grit for your specific metallurgical samples and follow recommended procedures for precise and consistent results.

To achieve perfectly flat and parallel surfaces on large workpieces with SMART CUT Diamond Discs:

- Ensure the workpiece and machine are properly aligned and leveled.

- Choose a disc size that adequately covers the workpiece.

- Use a progressive sequence of grit sizes, starting with coarser grits for material removal.

- Employ a cross-grinding pattern to maintain flatness.

- Regularly check for flatness and parallelism using precision measurement tools.

Yes, SMART CUT Diamond Discs can be used for precision grinding and polishing of semiconductor silicon wafers for the electronics industry. They are suitable for achieving the flatness and surface finish required for semiconductor manufacturing. Follow industry-specific guidelines and procedures for silicon wafer processing.

Yes, SMART CUT Diamond Discs are compatible with automated robotic systems for high-throughput manufacturing or testing applications. They can be integrated into automated setups for consistent and efficient material processing. Ensure proper equipment compatibility and programming for robotic operation.

SMART CUT Diamond Discs can be used for shaping and profiling natural stone surfaces like granite or marble in architectural and sculptural applications. Select the appropriate disc size, profile, and grit for your specific stone shaping needs. Proper technique and equipment setup are essential for achieving precise and artistic results.

When working with heat-sensitive materials using SMART CUT Diamond Discs:

Use a fine grit size to minimize heat generation.

Employ water-based cooling or lubrication to control temperature.

Monitor the workpiece and disc temperature to prevent overheating.

Minimize dwell time on the material to reduce heat exposure.

SMART CUT Diamond Discs can be used for achieving precise dimensions and tolerances in precision machining applications. To maintain dimensional accuracy:

- Use the appropriate grit size for material removal and precision finishing.

- Control pressure, feed rate, and machine settings for accuracy.

- Periodically check and measure the workpiece dimensions to ensure they meet the desired tolerances.

- Inspect the SMART CUT Diamond Disc for wear or irregularities that may affect precision.

SMART CUT Diamond Discs can be used for restoration and conservation work on delicate artifacts made of materials like porcelain, ceramic, or glass. Their precision and versatility make them suitable for removing damage, restoring intricate details, and achieving the desired finish on delicate surfaces. Handle artifacts with care to avoid accidental damage during the restoration process.

Yes, SMART CUT Diamond Discs can be used for grinding and polishing advanced engineering ceramics like silicon nitride or alumina, commonly used in aerospace and high-tech industries. Their precision and consistency make them suitable for achieving the required surface finish and dimensional accuracy on these materials.

SMART CUT Diamond Discs can be employed for precision thinning and sectioning of semiconductor packages and components. Key considerations include:

- Selecting an appropriate disc size and grit for the semiconductor material.

- Using proper cooling and lubrication to prevent heat-related damage.

- Employing precise equipment with control over thickness and parallelism.

- Following industry standards and guidelines for semiconductor thinning and sectioning.

SMART CUT Diamond Discs can be used for polishing optical lenses, mirrors, or prisms to achieve optical-grade surfaces. Techniques include:

- Starting with coarser grits for material removal and progressing to finer grits for polishing.

- Using optical-grade polishing compounds or slurries.

- Employing controlled pressure, speed, and fluid management to minimize surface imperfections.

- Inspecting the optical surfaces for clarity and precision at each stage of the process.

Yes, SMART CUT Diamond Discs can be used for precision finishing of ceramic or metal injection-molded (MIM) components used in industries like automotive and medical devices. They provide the required precision and surface finish for such applications. Follow recommended procedures for achieving the desired results on MIM components.

To achieve extremely smooth and mirror-like surfaces on semiconductor wafers using SMART CUT Diamond Discs for final polishing:

- Use the finest grit size available.

- Ensure precise machine control and alignment.

- Apply a high-quality semiconductor polishing slurry.

- Use proper cooling and lubrication.

- Monitor the surface finish closely and inspect with optical measurement tools for desired results.

SMART CUT Diamond Discs can be used for precision sharpening and honing of cutting tools like carbide inserts or high-speed steel (HSS) tools. They offer the precision required for achieving sharp cutting edges. Select the appropriate grit size and follow recommended procedures for tool sharpening.

Yes, SMART CUT Diamond Discs are compatible with various types of grinding and polishing equipment, including both single and double-sided machines. They are versatile and can be adapted to different equipment configurations, making them suitable for a wide range of applications.

SMART CUT Diamond Discs can be used for grinding and polishing composite materials used in the aerospace industry, including carbon fiber-reinforced composites and composite panels. Proper grit selection and technique are essential for achieving the desired results on these materials while preserving their structural integrity.

Yes, SMART CUT Diamond Discs can be used for precision finishing of optical components with complex shapes, including aspheric or freeform lenses. Their versatility and precision make them suitable for achieving the required surface profiles and optical quality on such components. Careful control of pressure, speed, and fluid management is essential for optimal results.

To use SMART CUT Diamond Discs for removing burrs and sharp edges from metal or plastic parts in manufacturing processes:

- Select a disc with an appropriate grit size for the material and burr size.

- Set up the equipment with controlled pressure and feed rate.

- Gently deburr the edges by moving the part against the disc at the desired angle.

- Inspect the part for the removal of burrs and sharp edges and make adjustments as needed.

Yes, SMART CUT Diamond Discs can be employed for precision machining of ceramics and composites used in the dental industry for restorations and prosthetics. They provide the necessary precision and surface finish for dental applications. Follow recommended procedures for dental material processing.

Safety precautions for using SMART CUT Diamond Discs in industrial settings include:

- Wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and respiratory protection if necessary.

- Ensuring proper ventilation to control dust and fumes.

- Using dust collection or wet methods to minimize airborne particles.

- Following manufacturer guidelines for equipment operation and maintenance.

- Monitoring and controlling equipment settings to prevent accidents.

- Providing training and awareness to personnel regarding the safe use of diamond discs.

SMART CUT Diamond Discs can be used for surface modification or texturing of materials to enhance adhesion or optical properties. By selecting the appropriate grit size and texture pattern, you can achieve desired surface characteristics for specific applications. Proper technique and control are crucial for achieving consistent results.

SMART CUT Diamond Discs can be utilized for deburring and edge rounding of metal components in industries like automotive and aerospace manufacturing. They are effective tools for removing sharp edges and achieving smoother, safer edges on metal parts. Follow recommended procedures and safety guidelines for edge rounding applications.

Yes, SMART CUT Diamond Discs can be used for precision lapping and polishing of optical flats and prisms used in interferometry and optical testing. They are well-suited for achieving the flatness and surface quality required for precise optical measurements. Follow recommended procedures and monitor the optical quality during the process.

SMART CUT Diamond Discs are available in various thicknesses to suit different applications. Typical thicknesses can range from a few millimeters to several millimeters. Custom thicknesses may also be available upon request to meet specific application requirements.

SMART CUT Diamond Discs can be used for precision machining of materials with high thermal conductivity, such as copper or aluminum. However, consider using specialized diamond discs designed for non-ferrous metals to achieve the best results, as these materials can be abrasive and may require specific diamond characteristics.

The recommended RPMs for SMART CUT Resin Bond Diamond Discs typically vary depending on the disc’s diameter and the specific material being processed. As a general guideline, start with a lower RPM setting and gradually increase it while monitoring the material removal rate and the disc’s performance. Consult the manufacturer’s guidelines and equipment specifications for precise RPM recommendations based on your application.

It is essential to use an appropriate coolant or lubrication when using SMART CUT Resin Bond Diamond Discs. Water-based coolants are commonly used because they dissipate heat effectively, prevent thermal damage to the diamond abrasive, and help flush away debris and swarf. Using the right coolant ensures a longer disc lifespan, improved material removal, and better surface finish. Always follow manufacturer recommendations for coolant selection and application.

The amount of pressure applied when using SMART CUT Resin Bond Diamond Discs depends on various factors, including material hardness, disc grit size, and the desired material removal rate. As a general guideline, start with light to moderate pressure and gradually increase it as needed while monitoring the disc’s performance. Excessive pressure can lead to premature wear and reduced disc life, so it’s crucial to find the right balance. Follow manufacturer guidelines and recommendations for specific pressure ranges based on your application.

SMART CUT Resin Bond Diamond Discs are typically designed to rotate in a clockwise direction. The rotation direction matters because it affects the cutting or grinding action and the quality of the finished surface. Ensure that the disc is mounted on your equipment in the correct orientation as specified by the manufacturer. Using the correct rotation direction helps achieve optimal results and extends disc life.

Dressing SMART CUT Resin Bond Diamond Discs is essential for maintaining their performance and longevity. Dressing involves removing glazing, worn abrasive particles, and debris from the disc’s surface to expose fresh diamond abrasives. You can dress the disc using a dressing stick or a diamond dressing tool. The frequency of dressing depends on the specific application and the disc’s condition. Regularly inspect the disc and dress it when you notice reduced cutting or grinding efficiency, uneven wear, or surface imperfections.

Cleaning SMART CUT Resin Bond Diamond Discs is crucial to prevent cross-contamination between different materials and maintain consistent performance. To clean the disc, follow these steps:

- Remove the disc from the equipment.

- Use a compatible cleaning solution or solvent, such as acetone or isopropyl alcohol.

- Gently scrub the disc surface with a soft brush or cloth to remove residue.

- Rinse the disc thoroughly with clean water.

- Allow the disc to dry completely before reuse.

Proper cleaning ensures that the disc remains free from contaminants and maintains its cutting or grinding efficiency. It also helps prevent material transfer between different workpieces, which is particularly important in applications where cleanliness is critical.

For specific recommendations on RPMs, coolants, pressure, rotation direction, dressing, and cleaning tailored to your application and material, consult the manufacturer’s guidelines or reach out to their technical support team for expert assistance.

Yes, SMART CUT Resin Bond Diamond Discs can be used with variable-speed equipment. Adjusting the RPM during operation can help optimize the cutting or grinding process. Here’s how to do it:

- Start with a lower RPM setting.

- Gradually increase the RPM while monitoring material removal and disc performance.

- Pay attention to the sound of the operation; a high-pitched whine may indicate excessive RPM.

- Adjust the RPM to achieve the desired material removal rate and surface finish.

- Refer to the manufacturer’s recommendations for RPM ranges based on disc diameter and material type.

It is advisable to avoid using coolants or lubricants that are incompatible with the materials being processed or that can adversely affect the disc’s resin bond. Some materials and applications may require specialized coolants or lubricants, so consult the manufacturer’s guidelines for compatibility and recommendations. Avoid using coolants or lubricants containing corrosive or abrasive substances that can damage the disc or compromise the quality of the workpiece.

Yes, it is possible to apply too much pressure when using SMART CUT Resin Bond Diamond Discs, and doing so can have adverse consequences. Excessive pressure can lead to:

- Premature wear and reduced disc lifespan.

- Increased heat generation, which may cause thermal damage to the diamond abrasive and the workpiece.

- Poor surface finish and the risk of material deformation.

- Higher energy consumption and potential equipment strain. To avoid these issues, start with light to moderate pressure and gradually increase it as needed while monitoring the disc’s performance. Follow manufacturer recommendations for specific pressure ranges based on your application.

SMART CUT Resin Bond Diamond Discs are typically designed to rotate in a clockwise direction. The rotation direction is essential because it can affect the cutting or grinding action and the quality of the finished surface. Using the correct rotation direction specified by the manufacturer helps achieve optimal results. While some applications may tolerate counterclockwise rotation, it’s generally recommended to follow the manufacturer’s guidelines to ensure consistent performance and extend disc life.

Signs that indicate SMART CUT Resin Bond Diamond Discs may need dressing include:

- Reduced cutting or grinding efficiency.

- Uneven wear patterns on the disc’s surface.

- Surface imperfections on the workpiece.

- Glazing or clogging of the diamond abrasive. Dressing should be performed as needed based on these signs. There is no fixed schedule for dressing, as it depends on the specific application, material, and disc condition. Regularly inspect the disc during operation, and when you observe any of these signs, initiate the dressing process to restore the disc’s cutting or grinding efficiency.

Failing to properly clean SMART CUT Resin Bond Diamond Discs after use can have several consequences:

- Cross-contamination between different materials, leading to compromised results and quality issues.

- Residue buildup on the disc’s surface, reducing cutting or grinding efficiency.

- Increased friction and heat generation, potentially damaging the diamond abrasive and the workpiece.

- Reduced disc lifespan due to abrasive particles and contaminants embedded in the disc. Improper cleaning can negatively impact subsequent operations by affecting the quality, accuracy, and efficiency of the work. To avoid these issues, always follow the recommended cleaning procedure, ensuring the disc is thoroughly cleaned and dried before reuse.

SMART CUT Resin Bond Diamond Discs can be used with ultrasonic or vibratory equipment for precision grinding and polishing. When using these setups, consider the following special considerations:

- Ensure compatibility between the disc and the equipment to avoid excessive vibration or stress.

- Pay attention to the frequency and amplitude settings to optimize the grinding or polishing action.

- Use the appropriate coolant delivery system to maintain consistent lubrication.

- Monitor the condition of the disc closely, as ultrasonic or vibratory equipment can introduce unique wear patterns.

While water-based coolants are commonly recommended for use with SMART CUT Resin Bond Diamond Discs, alternative cooling methods like air cooling or mist cooling can be used in certain applications. Here are some considerations:

- Air cooling may be suitable for dry grinding applications with reduced heat generation.

- Mist cooling can provide localized cooling, but it’s important to control mist delivery to prevent excessive moisture or residue buildup on the disc.

- Ensure that the cooling method you choose is compatible with the material being processed and does not compromise disc performance.

- Monitor disc temperature and performance when using alternative cooling methods to ensure effective heat control.

Pressure recommendations for SMART CUT Resin Bond Diamond Discs can vary depending on material hardness, grit size, and specific application requirements. While a universal pressure setting may work in some cases, it’s generally advisable to adjust the pressure based on the material and application. Light to moderate pressure is often recommended as a starting point and can be gradually increased as needed. Consult the manufacturer’s guidelines for pressure recommendations tailored to your specific material and application.

SMART CUT Resin Bond Diamond Discs are typically designed for clockwise rotation, as specified by the manufacturer. Reverse rotation is generally not recommended unless explicitly stated in the manufacturer’s guidelines. While there may be specific situations where reverse rotation could be advantageous, it’s important to consult with the manufacturer or technical support to ensure that it won’t compromise disc performance or safety.

Dressing SMART CUT Resin Bond Diamond Discs involves removing glazing, worn abrasive particles, and debris to maintain their cutting or grinding performance. Best practices for dressing include:

- Using a diamond dressing tool or dressing stick compatible with resin bond discs.

- Dressing the disc while it is stationary to avoid damage.

- Applying light pressure and making several passes to achieve uniform dressing.

- Dressing as needed based on signs of reduced efficiency or uneven wear. The dressing frequency can indeed vary based on the material type, as some materials generate more swarf or glazing than others. Regularly inspect the disc during operation and dress it as soon as you notice signs of reduced performance.

Failing to dress SMART CUT Resin Bond Diamond Discs regularly can have several consequences:

- Reduced cutting or grinding efficiency due to glazing and worn abrasive particles.

- Uneven wear patterns on the disc’s surface, leading to inconsistent results.

- Surface imperfections on the workpiece caused by uneven abrasion.

- Longer processing times and increased energy consumption. Improper dressing can negatively impact the quality, accuracy, and efficiency of the work. To avoid these issues, maintain a regular dressing schedule based on the specific application and material type.

Specific cleaning agents or solvents recommended for cleaning SMART CUT Resin Bond Diamond Discs can include acetone, isopropyl alcohol, or compatible cleaning solutions. It’s important to use chemicals that are safe for the disc’s resin bond and diamond abrasive. Exercise caution when handling cleaning agents, and follow safety guidelines and regulations regarding their use and disposal. Avoid using harsh chemicals that may damage the disc or pose health and environmental risks.

ACCESSORIES

Showing 1 – -1 of 16 results Showing all 16 results Showing the single result No results found

Sort by Name A – Z

Filters Sort results

Reset Apply

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Color: 5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads into 5/8″-11″ female thread of diamond drill. Can be used with any other tool with 5/8″-11″ thread. | $26.72 | Max: Min: 1 Step: 1 | |||

Color: 5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads into 5/8″-11″ female thread of diamond drill. Can be used with any other tool with 5/8″-11″ thread. | $22.46 | Max: Min: 1 Step: 1 | |||

1 Gallon Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

1 Quart Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

5 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

55 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White For use on diamond tools 150 to 220 Grit Size. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $15.39 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $39.47 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $39.47 | Max: Min: 1 Step: 1 | |||

$154.87 | Max: Min: 1 Step: 1 | ||||

$154.87 | Max: Min: 1 Step: 1 | ||||

$235.00 | Max: Min: 1 Step: 1 |

USAGE RECOMENDATION

Step 1: Safety Precautions

- Before starting, ensure that you are wearing appropriate safety gear, including safety glasses, ear protection, and dust masks if necessary. Additionally, make sure your machinery and workspace are well-ventilated.

Step 2: Equipment Preparation

- Mount the diamond lap disc onto your grinding or lapping machine. Ensure that it is securely fastened and aligned properly with the workpiece.

Step 3: Workpiece Preparation

- Prepare the workpiece you intend to grind or lap. It should be clean and free of contaminants, and any rough or uneven surfaces should be properly prepared.

Step 4: Lubrication and Cooling

- Depending on your application and material, you may need a coolant or lubricant to prevent overheating. Water, oil, or specialized grinding fluids can be used for cooling and lubrication. Make sure the coolant system is set up and functioning properly.

Step 5: Adjust Machine Settings

- Set the appropriate machine parameters such as speed, pressure, and depth of cut. These settings will depend on the material being worked on, the desired finish, and the specific diamond grit size of the disc.

Step 6: Grinding or Lapping Process

- Start the machine and bring the diamond lap disc into contact with the workpiece.

- Apply gentle and consistent pressure to the workpiece. Avoid excessive force, as it can lead to uneven grinding or overheating.

- Move the workpiece across the diamond lap disc in a controlled manner. The direction and pattern may vary depending on your specific requirements. Follow any recommended patterns or guidelines for your application.

- Continuously monitor the grinding process and inspect the workpiece to ensure it meets your desired specifications.

Step 7: Coolant Management

- Keep an eye on the coolant or lubricant to ensure that it remains effective throughout the process. Refill or replace it as needed to maintain proper cooling and lubrication.

Step 8: Final Inspection

- Once the desired surface finish and dimensions are achieved, stop the machine and inspect the workpiece. Ensure that it meets your quality standards. If necessary, make any final adjustments.

Step 9: Cleanup

- Turn off the machine and clean the workspace. Remove any debris, coolant, or grinding residue.

Step 10: Maintenance

- Properly clean and maintain the diamond lap disc to extend its lifespan. Store it in a dry and cool environment when not in use.

Usage Recommendations:

- Use the appropriate diamond grit size for your application. Finer grits provide smoother finishes, while coarser grits are more suitable for material removal.

- Monitor the grinding process closely to prevent overheating, which can damage both the workpiece and the diamond lap disc.

- Take care to avoid excessive pressure, as it can lead to uneven material removal and reduce the life of the disc.

- Keep the workpiece and the diamond lap disc well-lubricated and cooled, especially when working with heat-sensitive materials.

Step 11: Material Compatibility

- Ensure that the Diamond Lap you are using is compatible with the material you are working on. Different materials may require specific diamond formulations or grit sizes for optimal results.

Step 12: Dressing the Diamond Lap

- Periodically, you may need to dress or condition the diamond lap disc to maintain its cutting efficiency. This involves exposing fresh diamond abrasive by removing any buildup of swarf or glazing on the disc’s surface. Use a diamond dressing tool for this purpose.

Step 13: Workpiece Holding

- Properly secure the workpiece to prevent movement or vibration during the grinding or lapping process. Use appropriate fixtures or clamps if necessary.

Step 14: Workpiece Inspection

- Inspect the workpiece before and after grinding or lapping to ensure it meets your quality standards. Use measuring instruments like calipers or micrometers to check dimensions and surface finish.

Step 15: Workpiece Rotation

- If applicable, periodically rotate the workpiece to ensure even wear on the diamond lap disc. This can help maintain consistent grinding results.

Step 16: Gradual Pressure Increase

- When starting a grinding operation, begin with light pressure and gradually increase it as needed. This approach prevents sudden material removal and minimizes the risk of workpiece damage.

Step 17: Wheel Dressing Frequency

- Depending on the application, you may need to dress the diamond lap disc more frequently when working on harder or more abrasive materials. Pay attention to signs of reduced cutting efficiency.

Step 18: Safety Checks

- Regularly inspect the grinding machine and diamond lap disc for any signs of wear or damage. Replace worn-out or damaged components promptly to ensure safe and efficient operation.

Step 19: Operator Training

- Ensure that the machine operators are properly trained in the use of diamond laps and the associated equipment. Proper training can help prevent accidents and ensure consistent results.

Step 20: Record Keeping

- Maintain records of your grinding or lapping processes, including machine settings, diamond lap disc specifications, workpiece details, and any issues encountered. This documentation can be valuable for troubleshooting and process optimization.

Step 21: Troubleshooting

- If you encounter issues such as uneven grinding, excessive heat, or poor surface finish, troubleshoot the problem systematically. Check machine settings, coolant flow, workpiece condition, and diamond lap disc condition to identify and address the root cause.

Step 23: Workpiece Material Hardness

- Be aware of the hardness of the material you are working on. Softer materials may require a different approach or grit size compared to harder materials. Adjust your parameters accordingly.

Step 24: Surface Finish Requirements

- Understand the specific surface finish requirements for your application. Finer grit diamond laps will produce smoother finishes, while coarser grits are more suitable for rough material removal. Choose the appropriate grit size accordingly.

Step 25: Avoid Overlapping

- When grinding or lapping in multiple passes, try to avoid excessive overlap between passes. Overlapping can lead to uneven material removal and create surface irregularities.

Step 26: Workpiece Thickness

- Consider the thickness of the workpiece. Thinner materials may require special attention to prevent warping or distortion during the grinding process.

Step 27: Cleaning and Maintenance

- After each use, clean both the diamond lap disc and the machine to remove any accumulated debris, coolant, or swarf. Regular maintenance ensures the longevity of your equipment.

Step 28: Workpiece Support

- Depending on the size and shape of the workpiece, ensure that it is properly supported to prevent flexing or vibration during the grinding process. Adequate support helps maintain dimensional accuracy.

Step 29: Dressing Frequency

- Monitor the condition of the diamond lap disc’s abrasive surface. Dress it as needed to maintain consistent performance. Frequent dressing may be required for heavy-duty applications.

Step 30: Consult Application Experts

- If you are new to using Diamond Laps or have a complex application, consider consulting experts or engineers with experience in your specific industry. They can provide valuable insights and recommendations for optimizing your process.

Step 31: Safety Continues

- Always prioritize safety throughout the entire process. Ensure that all safety measures are in place, and operators are trained in safe operating procedures.

Step 32: Document Process Changes

- If you make any adjustments to the process, machine settings, or diamond lap disc specifications, document these changes. Keeping a record of changes helps maintain consistency and traceability.

Step 33: Quality Control

- Implement a robust quality control process to verify that the finished workpieces meet your desired specifications. This may involve measuring critical dimensions and assessing surface finish.

Step 34: Experimentation and Optimization

- Don’t be afraid to experiment with different parameters, such as machine speed, pressure, and coolant flow, to optimize your grinding or lapping process for the best results.

Step 35: Machine Alignment

- Ensure that your grinding or lapping machine is properly aligned and calibrated. Misalignment can lead to uneven wear on the diamond lap disc and affect the quality of your work.

Step 36: Workpiece Orientation

- Pay attention to the orientation of your workpiece. Depending on the desired finish and dimensions, you may need to adjust the workpiece’s orientation relative to the diamond lap disc.

Step 37: Dressing Techniques

- Learn and apply various diamond lap dressing techniques, such as single-point or rotary dressing, to maintain the sharpness and effectiveness of the abrasive diamonds.

Step 38: Dressing Tools

- Choose the appropriate dressing tool for your diamond lap disc. Dressing tools can vary in shape and material, and selecting the right one is essential for achieving desired results.

Step 39: Avoid Cross-Contamination

- Prevent cross-contamination by thoroughly cleaning the machine and work area when switching between different materials. Residue from one material can negatively affect the performance on another.

Step 41: Depth of Cut Control

- Maintain control over the depth of cut during the grinding process. Consistent depth of cut helps achieve uniform results and reduces the risk of overgrinding.

Step 42: Edge Protection

- Be cautious when approaching edges or corners of the workpiece. Excessive pressure on edges can lead to chipping or damage. Consider using edge protection techniques if necessary.

Step 43: Workpiece Cooling

- If your workpiece is prone to thermal damage, use efficient cooling methods, such as through-spindle coolant or a separate cooling system, to control temperatures during the process.

Step 44: Tool Balancing

- Ensure that the diamond lap disc is balanced properly on the machine spindle. Imbalanced discs can cause vibrations and reduce the quality of the finished workpiece.

Advantages

- Flexible Resin Bonded Diamond Disc.

- High Concentration of Diamond Mixed in Resin.

- Magnetic Backing

- Fast Grinding

- Removes Chips and Scratches

- Replaces Cork / Pumice

- Needs Only Water for Coolant

- Center Hole or No Hole

- Long Lasting

- Takes place of Cork with Pumice

Features

- Fast Material Removal: SMART CUT® diamond discs are highly efficient at removing material quickly. Their sharp diamond particles allow for rapid grinding and lapping, which can significantly reduce processing time compared to traditional methods.

- Minimum Heat Generation:SMART CUT® diamond discs are designed to dissipate heat effectively, preventing excessive heat buildup during the grinding process. This is important because excessive heat can lead to material damage or distortion, making it especially useful for applications where temperature control is critical.

- Clean & Inexpensive Process: Diamond grinding is a clean and precise process that produces high-quality surfaces with minimal debris and contamination. It reduces the need for post-processing steps, saving time and costs.

- Precision Tolerance: SMART CUT® diamond discs can achieve high levels of precision and accuracy, making them suitable for applications requiring tight dimensional tolerances, such as precision optics, medical devices, and aerospace components.

- Universal Application: SMART CUT® diamond discs can be used to grind a wide variety of materials, including glass, ceramics, plastics, composites, metals, alloys, and more. This versatility makes them valuable in various industries. Such asglass, ceramic automotive, aerospace, precision optics, composites, medical devices, semiconductor manufacturing, and more, making them versatile and valuable tools.

- Custom Manufacturing: Diamond laps can be customized to fit specific machinery with various arbor hole sizes. They can also be manufactured using different types of diamond (natural, synthetic, or CBN) and diamond mesh/grit sizes, providing flexibility to match specific application requirements.

- Wide Range of Grit Sizes: Diamond laps are available in a range of grit sizes, from fine microns to coarser 40 grit, allowing you to select the appropriate abrasive level for your application.

- Magnetic or PSA Backing: SMART CUT® diamond discs can be purchased with either magnetic or PSA (Pressure-Sensitive Adhesive) backing, offering flexibility in how they can be mounted to your machinery.

- Long Service Life: SMART CUT® Metal bond diamond grinding discs are known for their durability and long service life. The electroplated diamond particles are securely bonded to a steel backing, ensuring that the abrasive material lasts for an extended period, even under heavy use.

- Consistent Performance: SMART CUT® metal bond diamond discs provide consistent and repeatable performance, delivering uniform results throughout their lifespan. This consistency is crucial for maintaining quality and precision in manufacturing processes.

6070040, 6070040- 1, 6080060, 6050060, 6070060, 6070080, 6070100, 6070180, 6060240, 6080240, 6080240-1, 6070260, 6070360, 6080325, 6050325, 6060600, 6080600, 6070600, 6061200, 6081200, 6061800, 6081800, 6051800, 6063000, 6083000, 6090040, 6090080, 6090180, 6090260, 6090600, 6100040, 6100060, 6100080, 6100100, 6100180, 6100360, 6100600, 6670040, 6670080, 6670180, 6670260, 6670360, 6670600, 6110040, 6110080, 6110260, 6110360, 6110600, 6120060, 6120240, 6120325, 6121200, 6121800, 6123000, 6120600

Showing 1 – -1 of 55 results Showing all 55 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Outside Diameter | Backing Type | Inside Diameter | Diamond Micron Size | Diamond Grit Size | Get Quote |

|---|---|---|---|---|---|---|---|

12" (300mm) | Magnetic Backing | With Hole | 40 | ||||

12" (300mm) | Adhesive Backing | No Hole | 160 | 60 | |||

12" (300mm) | Magnetic Backing | No Hole | 160 | 60 | |||

12" (300mm) | Adhesive Backing | With Hole | 160 | 60 | |||

12" (300mm) | Magnetic Backing | With Hole | 160 | 60 | |||

12" (300mm) | Magnetic Backing | With Hole | 80 | ||||

12" (300mm) | Magnetic Backing | With Hole | 100 | ||||

12" (300mm) | Magnetic Backing | With Hole | 180 | ||||

12" (300mm) | Adhesive Backing | No Hole | 70 | 240 | |||

12" (300mm) | Magnetic Backing | No Hole | 70 | 240 | |||

12" (300mm) | Adhesive Backing | With Hole | 70 | 240 | |||

12" (300mm) | Magnetic Backing | With Hole | 260 | ||||

12" (300mm) | Magnetic Backing | With Hole | 360 | ||||

12" (300mm) | Magnetic Backing | No Hole | 45 | 325 | |||

12" (300mm) | Adhesive Backing | With Hole | 45 | 325 | |||

12" (300mm) | Adhesive Backing | No Hole | 30 | 600 | |||

12" (300mm) | Magnetic Backing | No Hole | 30 | 600 | |||

12" (300mm) | Magnetic Backing | With Hole | 30 | 600 | |||

12" (300mm) | Adhesive Backing | No Hole | 15 | 1200 | |||

12" (300mm) | Adhesive Backing | With Hole | 15 | 1200 | |||

12" (300mm) | Adhesive Backing | No Hole | 9 | 1800 | |||

12" (300mm) | Magnetic Backing | No Hole | 9 | 1800 | |||

12" (300mm) | Adhesive Backing | No Hole | 9 | 1800 | |||

12" (300mm) | Adhesive Backing | No Hole | 6 | 3000 | |||

12" (300mm) | Magnetic Backing | No Hole | 6 | 3000 | |||

16" (406.4mm) | Magnetic Backing | With Hole | 40 | ||||

16" (406.4mm) | Magnetic Backing | With Hole | 80 | ||||

16" (406.4mm) | Magnetic Backing | With Hole | 180 | ||||

16" (406.4mm) | Magnetic Backing | With Hole | 260 | ||||

16" (406.4mm) | Magnetic Backing | With Hole | 600 | ||||

18" (457.2mm) | Magnetic Backing | With Hole | 40 | ||||

18" (457.2mm) | Magnetic Backing | With Hole | 60 | ||||

18" (457.2mm) | Magnetic Backing | With Hole | 80 | ||||

18" (457.2mm) | Magnetic Backing | With Hole | 100 | ||||

18" (457.2mm) | Magnetic Backing | With Hole | 180 | ||||

18" (457.2mm) | Magnetic Backing | With Hole | 360 | ||||

18" (457.2mm) | Magnetic Backing | With Hole | 600 | ||||

20" (508mm) | Magnetic Backing | With Hole | 40 | ||||

20" (508mm) | Magnetic Backing | With Hole | 80 | ||||

20" (508mm) | Magnetic Backing | With Hole | 180 | ||||

20" (508mm) | Magnetic Backing | With Hole | 260 | ||||

20" (508mm) | Magnetic Backing | With Hole | 360 | ||||

20" (508mm) | Magnetic Backing | With Hole | 600 | ||||

24" (609.6mm) | Magnetic Backing | With Hole | 40 | ||||

24" (609.6mm) | Magnetic Backing | With Hole | 80 | ||||

24" (609.6mm) | Magnetic Backing | With Hole | 260 | ||||

24" (609.6mm) | Magnetic Backing | With Hole | 360 | ||||

24" (609.6mm) | Magnetic Backing | With Hole | 600 | ||||

29.5" (749.3mm) | Magnetic Backing | With Hole | 160 | 60 | |||

29.5" (749.3mm) | Magnetic Backing | With Hole | 70 | 240 | |||

29.5" (749.3mm) | Magnetic Backing | With Hole | 45 | 325 | |||

29.5" (749.3mm) | Magnetic Backing | With Hole | 15 | 1200 | |||

29.5" (749.3mm) | Magnetic Backing | With Hole | 9 | 1800 | |||

29.5" (749.3mm) | Magnetic Backing | With Hole | 6 | 3000 | |||

29.5" (749.3mm) | Magnetic Backing | With Hole | 30 | 600 |

These diamond laps/ metal bond diamond grinding discs can be purchased with either magnetic or PSA backing. We can make any arbor (ID) hole size to fit your particular machinery. Diamond Laps can be manufactured using either Natural Diamond, Synthetic Diamond, or CBN (cubic boron nitride) to better fit your application. Diamond laps using any diamond mesh/grit size from as fine as few microns to as course as 40 grit can be made as well.

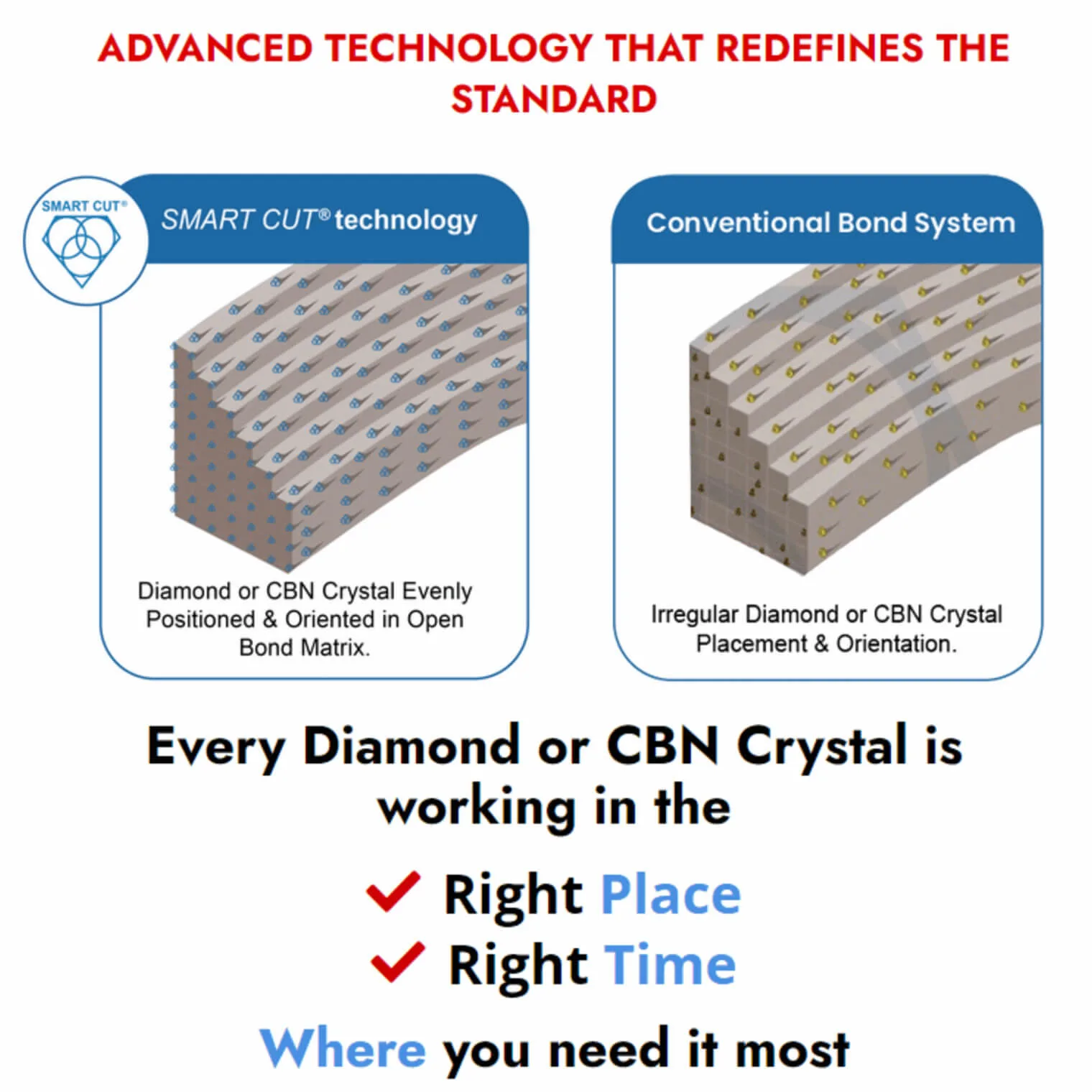

How SMART CUT® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Step 2

Diamonds or CBN Crystals

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside.

Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Faster & Freer Action

Diamond Discs made utilizing SMART CUT® technology are much more aggressive than your conventional Tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

Longer Life

In most cases tools manufactured utilizing SMART CUT technology, will outlast other conventional nickel bonded diamond CBN. SMART CUT diamond CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

More Consistent Performance

SMART CUT Electroplated Diamond Discs have high quality diamonds even coated material body Unlike Many Other Discs they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials.

Manufactured Using The Highest Quality Raw Materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Best Performance & Value on the Market

SMART CUT Electroplated Diamond Discs are the best investment you can make! Although they may cost more than electroplated (nickel bond) Discs. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

Why Choose Us?

Optimize your application to ultimate level of efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

Read More

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

WE ARE A PARTNER IN YOUR SUCCESS

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

AMERICAN MANUFACTURER

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Save Money Save up to 650%

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

Advanced Technology

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Let Us Help You

Related Products

SMART CUT® Resin Bond Diamond Discs for Grinding & Polishing Machines

SMART CUT® Resin Bond Diamond Polishing Discs

Resin Bond Diamond Discs

Resin Bond Discs are designed removal of material/sample scratches, chips. high spots, & as well as pre-polishing on a larger variety of materials. Using a propriety technique, a high concentration of premium diamond is loaded onto each disc to provide an extremely aggressive grinding rate yet leaves an exceptionally smooth surface finish. Each disc is color coded to easily determine the diamond size of the disc. These resin bond diamond discs are guaranteed to out-perform many cloth polishing discs using loose conventional abrasive or diamond compound/slurry finishing systems. Depending on the application and process these discs on average will last for 100-200 parts/samples & maintain consistent level of performance. These are perfect for hard materials such as metals, ceramics, refractories, cement, geological rocks, glass, optics, composites, and many other materials 35 and up Rockwell C scale of hardness. All discs come with a 3M pressure-sensitive adhesive backing that bonds to backing plates, or with magnetic backing to attach to steel plates. Must be used with coolant. Not recommended for heavy stock material removal

DIAMOND LAPS

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond laps & polishing discs. Below you will find information, specifications & prices on all laps & polishing discs we offer for this application. Contact us for volume pricing. We can also produce any custom diamond wheel per your specification. Contact us Today for Free Quote!

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools help with detailed tasks like engraving and finishing, providing good control and helping you work efficiently....

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin, high precision cutting blades, precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use