-

0 items in quote

No products in the Quote Basket.

Diamond Drills

SMART CUT® SERIES 301M

SMART CUT® SERIES 301M lapidary blades have undergone significant enhancements to elevate their performance and durability. Engineered with an increased diamond concentration and a reinforced steel core enriched with higher carbon content, these blades exhibit improved tension memory. This structural enhancement ensures that the blades maintain their integrity and alignment during rigorous cutting operations, thereby extending their lifespan and reliability.

The incorporation of a solid diamond sintered kerf in the design not only enhances the cutting capability but also optimizes coolant flow across the blade. This feature is pivotal in maintaining the blade’s temperature, reducing wear, and facilitating smoother cuts. The enhanced design ensures superior performance, particularly when cutting challenging materials such as agate, petrified wood, or jade, where precision and smoothness are critical.

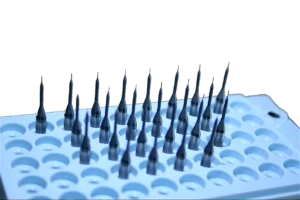

CVD Micro Drills

Micro Drills

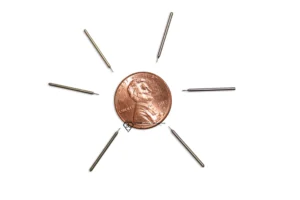

SMART CUT® CVD diamond micro drills are used for drilling micro holes in large variety of hard and brittle materials such as sapphire, high density ceramics, micro-circuit substrates, glass, silicon, various wafers, substrates, tubes etc We offer large variety of standard stock & custom micro drills from 0.05mm diameter to 6mm. with 3mm and 3.2mm shanks, and various heald lengths from 0.5mm and up, and flute specifications.PCD (Polycrystalline) Micro Drills

Diamond Micro Drills

SMART CUT® PCD (Polycrystalline Diamond) Micro Drills are precision-engineered tools designed for applications that demand exceptional hardness, wear resistance, and dimensional accuracy. They are available starting from 0.4 mm in diameter, with a wide selection of head lengths and standard shank diameters of 3 mm and 3.2 mm. Each drill features a sintered polycrystalline diamond tip bonded to a carbide or tungsten substrate, providing superior rigidity, heat resistance, and extended tool life. These micro drills are widely used in the semiconductor, electronics, EDM electrode manufacturing, and die and mold industries. In semiconductor production, they are used for machining monocrystalline silicon, inspection and cleaning jigs, and precision fixture fabrication. In EDM electrode manufacturing, they are ideal for drilling graphite electrodes and other hard-to-machine materials that quickly wear down conventional tools.SMART CUT Diamond Counter Sinks Multi Layered Electroplated

SMART CUT® Diamond Counter Sinks are precision-engineered tools designed for creating countersink holes, expanding existing holes, breaking sharp corners, chamfering edges, and polishing pre-existing holes across a wide range of materials. These high-performance tools deliver exceptional accuracy and consistency, making them ideal for a variety of precise hole modification tasks.

Available in a range of standard specifications, SMART CUT® Diamond Counter Sinks can also be custom-manufactured to meet almost any unique application or requirement. The multi-layered electroplated diamond coating provides superior wear resistance, enhancing both tool life and cutting efficiency.

SMART CUT® 005DME MCDU

SMART CUT® 005DME Diamond Micro Drills represent a major advancement in precision micro-machining technology, specifically engineered to meet the challenges of drilling hard, brittle, and high-tech materials used across industries such as semiconductor, optics, advanced ceramics, aerospace, and medical device manufacturing.

These drills are widely used in electronics and semiconductor manufacturing for creating microscopic precision holes in wafers, essential for thermal management, electrical connectivity, and overall chip reliability. In optical engineering, they enable accurate hole placement in the assembly of lenses, mirrors, and optical components. In the medical field, they deliver consistent hole geometry and size control, which is vital for implant safety and precision assembly.

They are equally valuable in the aerospace and automotive industries, where components demand extremely tight tolerances and involve materials that are difficult to machine. The accuracy, stability, and repeatability of the SMART CUT® 005DME drills ensure defect-free holes in these critical applications, preventing system failures due to dimensional deviations.

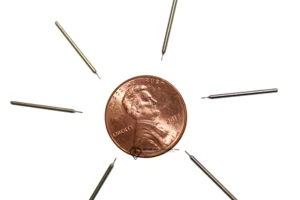

SMART CUT® 010DME (SMCDU)

SMART CUT® 010DME Diamond Micro Drills represent a major advancement in precision micro-machining technology, specifically engineered to meet the challenges of drilling hard, brittle, and high-tech materials used across industries such as semiconductor, optics, advanced ceramics, aerospace, and medical device manufacturing.

These drills are widely used in electronics and semiconductor manufacturing for creating microscopic precision holes in wafers, essential for thermal management, electrical connectivity, and overall chip reliability. In optical engineering, they enable accurate hole placement in the assembly of lenses, mirrors, and optical components. In the medical field, they deliver consistent hole geometry and size control, which is vital for implant safety and precision assembly.

They are equally valuable in the aerospace and automotive industries, where components demand extremely tight tolerances and involve materials that are difficult to machine. The accuracy, stability, and repeatability of the SMART CUT® 010DME drills ensure defect-free holes in these critical applications, preventing system failures due to dimensional deviations.

SMART CUT® 015DSE

SMART CUT Series 015DSE Multi Layered Electroplated solid drills are flat cylinder shape with transition angle. These miniature diamond drills have high diamond concentration and give a smother, faster drilling action with minimum heat generation. The multiple layers of diamond coating which provides best diamond adhesion in the bond matrix. This provides longer life span, compared to standard and comparable electroplated miniature drills. Higher level of consistency and better surface finish. Most popular type of diamond drills for drilling small holes for jewelry (stone, glass, & many other materials). Multiple layers of diamond provide longer drilling life, faster & freer drilling. Available from stock from 0.75mm to 2.5mm