Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT CVD diamond micro drills are used for drilling micro holes in large variety of hard and brittle materials such as sapphire, high density ceramics, micro-circuit substrates, glass, silicon, various wafers, substrates, tubes etc

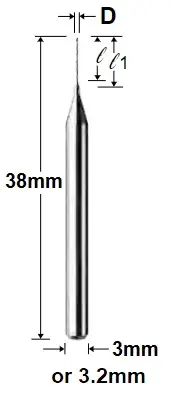

We offer large variety of standard stock & custom micro drills from 0.05mm diameter to 6mm. with 3mm and 3.2mm shanks, and various heald lengths from 0.5mm and up, and flute specifications.

CVD Diamond Micro Drills & tools consists of a microcrystalline thin film of evenly distributed diamond particles of 3-6 μm on tungsten carbide substrate. The CVD diamond layer extends the life a carbide micro drills & tools by 12 to 20 times longer, which decreases downtime due to fewer tool changes. As a physical barrier, the CVD diamond coating minimizes edge build-up and reduces wear of the tool. The diamond coating also has great thermal conductivity removing heat away from the cutting edge and increasing lubrication for better chip flow and evacuation.

Diameters Available: .0015” to .040”.

Shank diameters: 1/8”(3.175mm) and 3mm.

Head Lengths: from .020” and up

Diameter Range: 0.1mm to 3.0mm

Head Length: 0.5mm to 10mm

Body Material: Carbide

Overall Length: 1.50″

Edge Geometry: Two Flute – Four Facet Point

Diameter tolerance: +0/-0.0002″

Grit Sizes of Particles Used: 0.5 to 25 microns

Recommended RPM’s: 35,000+ to 3,000 (based on diameter of the drill and material being drilled)

Shank Diameters: 1/8″ (3.2mm) and 3mm

Recommend Coolants: water soluble coolants, oils, in some cases air or dry drilling can be done

A CVD micro drill is a specialized type of drilling tool coated with materials deposited through Chemical Vapor Deposition. This process provides the drill with enhanced properties, such as increased hardness, wear resistance, and thermal stability.

In CVD, gaseous reactants are introduced into a chamber containing the micro drills. These gases decompose at high temperatures, causing a thin, uniform coating to deposit on the surface of the drills. This enhances their performance characteristics.

CVD micro drills offer several benefits, including improved longevity, enhanced cutting efficiency, and resistance to high temperatures and abrasive materials. They are ideal for precise and demanding drilling applications.

Common coatings include titanium nitride (TiN), titanium carbonitride (TiCN), and diamond-like carbon (DLC), each providing unique benefits in terms of hardness, friction reduction, and chemical resistance.

While highly effective, CVD micro drills are particularly suited for applications requiring high precision and durability, such as in aerospace, medical, and automotive industries. They may not be necessary for more basic drilling tasks.

The choice of coating depends on the material being drilled, the drilling speed, and the desired finish quality. Consulting with a CVD micro drill expert or manufacturer can help determine the most suitable coating.

CVD micro drills should be used within their recommended operating parameters. Regular inspection for wear and tear is necessary, and they should be stored properly to avoid damage.

Depending on the drill and the extent of wear, re-coating may be possible. It’s best to consult with the manufacturer for specific guidance on re-coating options.

The lifespan varies based on the application, material drilled, and drilling conditions. However, due to their enhanced durability, CVD micro drills generally have a longer lifespan compared to uncoated drills.

CVD micro drills can vary significantly in size, but they are generally used for precision drilling where diameters are typically in the range of a few micrometers to a few millimeters.

The CVD process can enhance precision by providing a uniform coating that maintains the drill’s dimensional accuracy and sharpness. This ensures consistent performance throughout the drill’s lifespan.

Yes, CVD micro drills are often used for hard materials like ceramics, composites, and hardened steels due to their superior hardness and wear resistance.

Generally, the CVD process itself, which involves high temperatures and reactive chemicals, is conducted under controlled conditions to minimize environmental and safety risks. Proper handling and disposal of coated drills are important to avoid potential hazards.

CVD micro drills tend to be more expensive than uncoated drills due to the advanced technology and materials used. However, their longer lifespan and improved performance can offer cost savings in the long run, especially in high-precision applications.

Yes, CVD micro drills are well-suited for use in CNC machines, where their precision and durability complement the high accuracy of CNC machining.

CVD coatings can reduce friction during drilling, which in turn can reduce heat generation. This is beneficial for maintaining the integrity of both the drill and the material being drilled.

CVD micro drills should be stored in a clean, dry environment to prevent corrosion or damage. They should also be handled carefully to avoid chipping the coating.

Yes, CVD coatings can be customized in terms of thickness, composition, and other properties to suit specific drilling requirements or to target specific materials.

Wear on CVD micro drills may appear as edge rounding, chipping, or a change in color. Regular inspection under magnification can help detect wear before it significantly affects drilling performance.

CVD micro drills are widely used in industries that require high precision and durability in drilling, such as aerospace, electronics, medical device manufacturing, automotive, and mold making.

Different CVD coatings offer varying degrees of thermal stability. For instance, diamond-like carbon coatings are known for excellent thermal stability, while titanium nitride provides moderate thermal stability. The choice depends on the drilling temperature conditions.

Yes, CVD micro drills can be used for dry drilling, especially when the coating has low friction properties. However, using a coolant or lubricant can extend the life of the drill and improve the quality of the drilling process.

CVD micro drills are well-suited for high-speed drilling due to their high wear resistance and thermal stability, which prevent degradation of the drill bit at high rotational speeds.

While CVD is versatile, there are limitations based on the chemical properties of the material being coated and the compatibility of the substrate material with the high temperatures used in the CVD process.

CVD coatings are typically much harder than the base material of the drill. For example, diamond-like carbon coatings are among the hardest materials available, significantly surpassing the hardness of most metals.

Indicators include visible wear, decreased drilling performance, increased drilling forces, or damage to the coating. Regular inspection is key to determining when a drill needs replacing.

For smaller diameter drills, coatings that add minimal thickness are preferred to maintain precision. The coating choice may also depend on the material being drilled and the required drilling precision.

Sharpening CVD micro drills can be challenging due to the hardness of the coating. It often requires specialized equipment and should be done by professionals to avoid damaging the coating.

The drill tip angle is crucial for drilling performance, affecting aspects like chip removal and cutting efficiency. CVD coating does not significantly alter the angle, but it does enhance the drill’s overall performance and longevity.

The thickness of the CVD coating can impact both the durability and the precision of the drill. A thicker coating generally offers better wear resistance, but may slightly alter the dimensions of very fine drills. The optimal thickness depends on the specific application and balance between durability and precision.

The turnaround time for CVD coating can vary based on the volume of drills being processed and the specific requirements of the coating. Generally, it can range from a few days to several weeks.

While possible, CVD micro drills are primarily designed for use in precision equipment like CNC machines. Using them in handheld drills may not fully utilize their precision capabilities and could increase the risk of damage.

The CVD process, while efficient in coating, involves high energy consumption and uses chemicals that must be carefully managed. Advances in CVD technology are focusing on reducing environmental impact.

Common failure modes include coating wear, chipping or cracking of the coating, and substrate material failure due to excessive heat or force.

Optimal drilling techniques include using appropriate feed rates and speeds, ensuring proper chip evacuation, and using suitable coolants. These techniques help prevent overheating and excessive wear.

The right coolant can enhance drilling performance by reducing heat and friction, thereby extending the life of the drill. Some coolants are better suited for specific types of CVD coatings.

Yes, CVD micro drills can be used for both applications. The choice of drill geometry and coating may vary depending on the specific requirements of the drilling operation.

Optimal speed and feed rates depend on the drill size, coating type, and material being drilled. Manufacturers often provide guidelines, but these may need to be adjusted based on specific conditions.

CVD coatings are generally thicker and have higher wear resistance compared to PVD coatings. However, PVD coatings can be applied at lower temperatures, making them suitable for tools with temper-sensitive substrates. The choice between CVD and PVD depends on the specific requirements of the drilling application.

The thermal expansion properties of CVD coatings can differ from those of the drill substrate. This difference is crucial in high-temperature applications, where mismatched expansion can affect coating adherence and drill integrity.

CVD micro drills should be stored in a clean, dry, and stable environment. Handling should minimize direct contact to prevent coating damage. Using appropriate packaging and storage systems designed for precision tools is recommended.

Yes, CVD micro drills are suitable for micro-machining applications, especially in the semiconductor industry where precision and tool longevity are critical.

The CVD coating process adds to the manufacturing time due to the preparation, coating, and post-coating treatment stages. However, this is often offset by the increased tool life and performance.

Yes, CVD micro drills can be customized in terms of drill point geometry, flute design, and other features to cater to specific drilling applications and material requirements.

The electrical conductivity of certain CVD coatings, like diamond-like carbon, can be a factor in electrically sensitive applications. It’s important to choose a coating material that aligns with the electrical requirements of the application.

Advancements include the development of more environmentally friendly CVD processes, the creation of coatings with tailored properties for specific applications, and improvements in coating uniformity and adherence.

The surface roughness and texture of the coating can impact friction, heat generation, and chip evacuation during drilling. Optimizing these factors is crucial for maximizing drill performance and lifespan.

While the drills themselves are not typically hazardous, precautions should be taken to handle sharp tools safely and to manage any dust or particles generated during drilling, especially when working with hard or brittle materials.

Compared to other coating technologies, CVD can have a higher environmental impact due to its use of chemicals and high energy consumption. However, advancements are being made to reduce this impact, and the extended tool life provided by CVD coatings can contribute to overall sustainability in manufacturing processes.

Different coatings can influence the way material is removed during drilling. For example, smoother coatings might facilitate better chip flow, reducing the risk of chip packing and improving overall drilling efficiency.

Yes, CVD micro drills can be used in ultrasonic drilling, where their enhanced wear resistance and precision can be particularly beneficial in drilling brittle materials like glass or ceramics.

CVD coatings typically have a lower coefficient of friction compared to uncoated drills. This reduction in friction results in less heat generation and better overall performance.

Key factors include the surface cleanliness of the substrate, the compatibility between the substrate and the coating material, and the process parameters used during the CVD process.

Yes, CVD coatings can be applied to a variety of substrates, including carbide and ceramics, making them versatile for different drill materials.

The presence of internal cooling channels requires careful consideration during the CVD process to ensure even coating without clogging the channels. Specialized CVD techniques may be employed to coat such complex geometries.

For drilling composite materials, diamond-like carbon (DLC) and other hard, low-friction coatings are often recommended to reduce tool wear and prevent material delamination.

CVD micro drills undergo rigorous testing, including measurements of coating thickness, hardness, adhesion, as well as performance tests like drilling efficiency, wear resistance, and lifespan under simulated application conditions.

Regrinding and recoating of CVD micro drills is possible, but it requires specialized equipment and processes to ensure that the new coating adheres properly and the drill maintains its precision.

Advancements in CVD technology can initially increase costs due to the research and development required. However, over time, these advancements can lead to more efficient processes and longer-lasting drills, ultimately offering cost savings and increased value to users.

⦁ CVD Micro Drills: Made by depositing hard materials like titanium nitride or diamond-like carbon onto the drill using Chemical Vapor Deposition.

⦁ Electroplated Diamond Micro Drills: Feature a layer of diamond particles electroplated onto the drill’s surface.

⦁ PCD Micro Drills: Constructed using polycrystalline diamond, which is a synthetic diamond material sintered under high pressure and temperature.

⦁ CVD: Offers excellent hardness and wear resistance, suitable for a wide range of materials.

⦁ Electroplated Diamond: Extremely hard and wear-resistant, ideal for abrasive materials.

⦁ PCD: Exceptionally hard, wear-resistant, and thermally stable, great for long-duration cutting tasks.

⦁ CVD: Used in precision drilling applications across various industries, including aerospace and automotive.

⦁ Electroplated Diamond: Best for drilling hard, abrasive materials like glass, ceramics, and composites.

⦁ PCD: Commonly used in the machining of high-silicon aluminum, carbon-fiber-reinforced plastics, and other abrasive materials.

⦁ CVD: Good heat resistance, suitable for high-speed applications.

⦁ Electroplated Diamond: Moderate heat resistance, may not be ideal for high-temperature drilling.

⦁ PCD: Excellent heat resistance, maintains performance even in high-temperature environments.

⦁ CVD: Generally long-lasting due to their tough coating.

⦁ Electroplated Diamond: Can wear down faster, especially if diamond particles begin to dislodge.

⦁ PCD: Very durable, especially in abrasive material drilling, often having the longest lifespan among the three.

⦁ CVD: Limited by the thickness and uniformity of the coating applied.

⦁ Electroplated Diamond: The bond between the diamond and the drill body can weaken over time.

⦁ PCD: Tends to be more expensive and not as effective on ferrous materials.

⦁ CVD: Mid-range cost, offering a balance between performance and price.

⦁ Electroplated Diamond: Generally less expensive but may require more frequent replacement.

⦁ PCD: Typically the most expensive due to its material and manufacturing process, but offers cost savings over time due to durability.

⦁ CVD: Re-coating is possible but can be challenging.

⦁ Electroplated Diamond: Difficult to re-sharpen or re-coat effectively.

⦁ PCD: Can be re-sharpened, extending their usable life.

⦁ CVD Micro Drills: Good for a wide range of materials, including metals, plastics, and composites.

⦁ Electroplated Diamond Micro Drills: Excellent for very hard and abrasive materials like glass, ceramics, and stone.

⦁ PCD Micro Drills: Best suited for non-ferrous and abrasive materials like high-silicon aluminum alloys, graphite, and composites.

⦁ CVD: Involves high energy consumption and chemical use in the coating process.

⦁ Electroplated Diamond: Chemicals used in electroplating can have environmental impacts if not managed properly.

⦁ PCD: Producing synthetic diamond is energy-intensive, but the long lifespan of the drills can offset this.

⦁ CVD: Offers high precision, especially in smaller diameters.

⦁ Electroplated Diamond: Precision can vary depending on the quality of the diamond coating.

⦁ PCD: Extremely precise, especially in consistent, long-duration cutting tasks.

⦁ CVD: Favored in aerospace, automotive, and general engineering for their versatility.

⦁ Electroplated Diamond: Preferred in industries where drilling hard, brittle materials is common, such as glass and ceramics.

⦁ PCD: Popular in woodworking, metalworking, and automotive industries, especially for aluminum and composite materials.

⦁ CVD: Allows for a range of designs and can be applied to various drill geometries.

⦁ Electroplated Diamond: Limited flexibility due to the nature of the electroplating process.

⦁ PCD: Highly flexible in design, especially for specific cutting and drilling applications.

⦁ CVD: Allows for a range of designs and can be applied to various drill geometries.

⦁ Electroplated Diamond: Limited flexibility due to the nature of the electroplating process.

⦁ PCD: Highly flexible in design, especially for specific cutting and drilling applications.

⦁ CVD: Generally provide a good surface finish with minimal burring.

⦁ Electroplated Diamond: Can leave a rough finish on some materials, depending on the grit size of the diamond.

⦁ PCD: Known for producing a very smooth and high-quality surface finish.

⦁ CVD: Well-suited for high-speed and automated applications due to their durability and heat resistance.

⦁ Electroplated Diamond: Suitable for automated applications, but high-speed drilling may lead to faster wear.

⦁ PCD: Excellent for high-speed and automated drilling, particularly in abrasive materials.

The optimal RPM depends on the drill diameter, material being drilled, and the drill material. Generally, smaller drills require higher RPMs. Manufacturers often provide specific RPM recommendations for their drills.

Feed rate should be matched with drill size, material hardness, and machine capabilities. Softer materials typically allow for higher feed rates. It’s important to start with manufacturer guidelines and adjust based on material feedback and drill performance.

Water-soluble coolants are commonly used. The choice depends on the material being drilled and the drill type. For example, oil-based coolants may be better for metals, while water-based coolants are often used for composites or plastics.

Peck drilling is recommended for deep holes or when chip removal is challenging. The pecking cycle involves drilling a short distance, retracting to remove chips, and then proceeding. The depth per peck varies but is generally a few times the drill diameter.

Hard materials require lower RPMs and feed rates to prevent drill wear. Soft materials can be drilled at higher speeds. Brittle materials need careful handling to prevent cracking, often requiring lower feed rates and gentle pecking cycles.

Signs include excessive wear on the drill, poor hole quality, and unusual machine noises. Adjust by reducing speed for overheating signs, increasing speed or feed rate for insufficient chip removal, or consulting with drill manufacturers for specific adjustments.

Consider the material hardness, abrasiveness, and thermal properties. Hard materials may require drills with harder coatings, while soft materials can be drilled with standard high-speed steel drills.

Drilling at an angle or on curved surfaces requires starting with a lower feed rate to establish the hole. Using a pilot hole and ensuring the drill is rigidly held can improve accuracy.

Smaller drills generally require higher RPMs but lower feed rates due to their fragility. Conversely, larger drills can handle higher feed rates but need lower RPMs.

Store drills in a dry, clean environment. Handle them carefully to avoid damage. Regularly inspect for wear and replace as needed. Use the correct collet size and ensure proper machine alignment.

For deep holes, reduce feed rates and use peck drilling to facilitate chip removal. Ensure adequate coolant flow to prevent overheating and choose a drill geometry designed for deep hole drilling.

Use a center drill or a spotting drill to start the hole, ensuring accuracy and stability. The starting point should be marked and, if possible, slightly indented to guide the drill.

Spindle runout can cause uneven wear and hole inaccuracies. It can be minimized by regularly maintaining the drilling machine, using high-quality tool holders, and ensuring that the drill is properly seated and secured.

CNC machines offer greater precision and consistency, especially for complex or repetitive tasks. Ensure that the CNC settings (like feed rate, RPM, and peck cycles) are optimized for the micro drill and material. Manual drilling requires a steadier hand and more attention to the drilling process.

Select coatings based on material hardness and abrasiveness. For example, titanium nitride coatings are good for general purpose, while diamond coatings are better for abrasive materials like composites.

While possible, it’s challenging to achieve the same level of precision and control as with machine drilling. If using handheld drills, ensure the drill is properly aligned and use lower feed rates.

Wear appropriate safety gear, including eye protection. Ensure the workpiece is securely clamped. Be mindful of the high speeds and the potential for drill breakage, especially with very small diameters.

Thicker materials require careful consideration of heat buildup and chip evacuation. Adjust peck cycles and coolant flow accordingly. Thinner materials may require support to prevent material flexing or damage.

Use drills specifically designed for such materials. Employ lower feed rates and high RPMs for hard materials, and consider using specialized coolants. For composite materials, sharp drills and controlled peck cycles are key to prevent delamination.

Store in a dry, organized environment. Avoid dropping or mishandling the drills. Regularly inspect for wear or damage, and clean them after use to remove any residual material or coolant.

Drill bit geometry, including the point angle and flute design, significantly affects drilling performance. Acute angles and specific flute designs are better for softer materials, while obtuse angles and reinforced flutes are suitable for harder materials.

The substrate material affects the drill’s overall strength, heat resistance, and durability. Harder substrates like carbide are preferred for tougher materials, while high-speed steel can be sufficient for softer materials.

To prevent breakage, ensure proper alignment, use correct feed rates and speeds, and avoid excessive force. Using a drill press or a stable CNC setup can also reduce the risk of breakage.

High-speed drilling requires careful consideration of heat generation, chip evacuation, and drill stability. Use appropriate coolants, ensure good machine condition, and select a drill bit designed for high-speed operations.

Effective chip evacuation can be ensured by using proper coolant flow, peck drilling cycles, and choosing the right flute geometry. Keeping the drill flutes clear of debris is essential to prevent clogging and overheating.

When drilling angled or curved surfaces, start with a slower feed rate to establish the hole. Consider using a pilot drill and ensure the drill is perpendicular to the surface at the point of contact.

Secure clamping is crucial to prevent workpiece movement, which can cause inaccuracies and drill breakage. Use appropriate clamping methods that do not deform or stress the material.

Micro drills can be used for enlarging holes, but it requires precision. Start with a drill size slightly larger than the existing hole and gradually increase to the desired size to maintain accuracy and prevent drill breakage.

In layered materials, consider the differences in material properties between layers. Adjust feed rate and drilling pressure as you transition between layers, and use sharp drills to prevent delamination or material damage.

For temperature-sensitive materials, use low RPMs and high feed rates to minimize heat generation. Adequate coolant flow and peck drilling can also help in heat management.

Tab Content

Tab Content

Image | Item Number | Diameter D(mm) | Flute Length l (mm) | Head Length l1 (mm) | Get Quote |

|---|---|---|---|---|---|

213370 | 0.10 | 1.0 | 1.2 | ||

213371 | 0.12 | 1.5 | 1.7 | ||

213372 | 0.15 | 2.0 | 2.2 | ||

213373 | 0.16 | 2.0 | 2.2 | ||

213374 | 0.17 | 2.0 | 2.2 | ||

213375 | 0.18 | 2.5 | 2.7 | ||

213376 | 0.19 | 2.5 | 2.7 | ||

213377 | 0.20 | 2.5 | 2.7 | ||

213378 | 0.21 | 2.5 | 2.7 | ||

213379 | 0.22 | 2.5 | 2.7 | ||

213380 | 0.23 | 4.0 | 4.2 | ||

213381 | 0.24 | 4.0 | 4.2 | ||

213382 | 0.25 | 4.0 | 4.2 | ||

213383 | 0.26 | 4.0 | 4.2 | ||

213384 | 0.27 | 4.0 | 4.2 | ||

213385 | 0.28 | 4.0 | 4.2 | ||

213386 | 0.29 | 4.0 | 4.2 | ||

213387 | 0.30 | 5.5 | 5.7 | ||

213388 | 0.31 | 5.5 | 5.7 | ||

213389 | 0.32 | 5.5 | 5.7 | ||

213390 | 0.33 | 5.5 | 5.7 | ||

213391 | 0.34 | 5.5 | 5.7 | ||

213392 | 0.35 | 5.5 | 5.7 | ||

213393 | 0.36 | 5.5 | 5.7 | ||

213394 | 0.37 | 5.5 | 5.7 | ||

213395 | 0.38 | 5.5 | 5.7 | ||

213396 | 0.39 | 5.5 | 5.7 | ||

213397 | 0.40 | 6.0 | 6.2 | ||

213398 | 0.45 | 6.0 | 6.2 | ||

213399 | 0.50 | 6.0 | 6.2 | ||

213400 | 0.55 | 8.0 | 8.2 | ||

213401 | 0.60 | 8.0 | 8.2 | ||

213402 | 0.65 | 8.0 | 8.2 | ||

213403 | 0.70 | 8.0 | 8.2 | ||

213404 | 0.75 | 8.0 | 8.2 | ||

213405 | 0.80 | 8.0 | 8.2 | ||

213406 | 0.85 | 8.0 | 8.2 | ||

213407 | 0.90 | 8.0 | 8.2 | ||

213408 | 0.95 | 8.0 | 8.2 | ||

213409 | 1.00 | 8.0 | 8.2 | ||

213410 | 1.10 | 8.0 | 8.2 | ||

213411 | 1.20 | 8.0 | 8.2 | ||

213412 | 1.30 | 8.0 | 8.2 | ||

213413 | 1.40 | 8.0 | 8.2 | ||

213414 | 1.50 | 8.0 | 8.2 | ||

213415 | 1.60 | 8.0 | 8.2 | ||

213416 | 1.70 | 8.0 | 8.2 | ||

213417 | 1.80 | 8.0 | 8.2 | ||

213418 | 1.90 | 8.0 | 8.2 | ||

213419 | 2.00 | 8.0 | 8.2 | ||

213420 | 2.10 | 8.0 | 8.2 | ||

213421 | 2.20 | 8.0 | 8.2 | ||

213422 | 2.30 | 8.0 | 8.2 | ||

213423 | 2.40 | 8.0 | 8.2 | ||

213424 | 2.50 | 8.0 | 8.2 | ||

213425 | 2.60 | 8.0 | 8.2 | ||

213426 | 2.70 | 8.0 | 8.2 | ||

213427 | 2.80 | 8.0 | 8.2 | ||

213428 | 2.90 | 8.0 | 8.2 | ||

213429 | 3.00 | 8.0 | 8.2 |

Diamond coatings are actually grown atom by atom onto the surface of the tool. Several technologies are used to produce CVD diamond films commercially, but the primary method used for coating cutting tools is known as Hot Filament Deposition. Inside the typical coating system, an array of superheated tungsten wires are used to activate hydrogen and a carbon-containing gas (usually methane). This reactive vapor mixture will condense onto the part to be coated, producing the diamond film over the entire surface of the tool. The diamond crystal growth is carefully controlled to produce a high-purity diamond film with a microstructure suited to the machining application. The coatings are from 4 to 40 microns in thickness depending on tool diameter and application. These films are pure diamond with no binder; they are both mechanically and chemically bonded to the tool surface

We understand that your success depends on select the right diamond lapidary blade, and optimizing your parameters to best fit your applications/needs.

Largest Inventory of Diamond Lapidary Blades in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

We Are a Partner In Your Success

American Manufacturer

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Comprehensive Source of Information on Diamond Lapidary Blades

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Experience makes all the Difference

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary lapidary blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect lapidary blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

Superior Quality &

Consistency

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales