-

0 items in quote

No products in the Quote Basket.

Shop

SMART CUT Diamond Counter Sinks Multi Layered Electroplated

SMART CUT® Diamond Counter Sinks are precision-engineered tools designed for creating countersink holes, expanding existing holes, breaking sharp corners, chamfering edges, and polishing pre-existing holes across a wide range of materials. These high-performance tools deliver exceptional accuracy and consistency, making them ideal for a variety of precise hole modification tasks.

Available in a range of standard specifications, SMART CUT® Diamond Counter Sinks can also be custom-manufactured to meet almost any unique application or requirement. The multi-layered electroplated diamond coating provides superior wear resistance, enhancing both tool life and cutting efficiency.

SMART CUT® 435BS

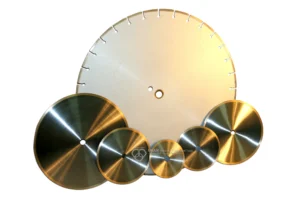

BRAISED DIAMOND CUT OFF BLADES, SLOTTED

Braised Bond is a Slotted diamond cut off wheel that replaces general purpose abrasive cut off wheels/blades. Fast & efficient cutting without use of coolant, this blade can be used on any simple hand held machine or abrasive cut off saw. Designed for large variety of "Rough Cutting" metal applications, where cut quality, surface finish, and preserving material micro structure is not important. This blade will also work on large variety of other materials including wood, plastics, composite materials, masonry and ceramics. For optimum results on steel and stainless steel, use on sheet/section material up to 3/8” thick and solid bar/bolts up to 3/4”.SMART CUT® 435BS

BRAISED DIAMOND CUT OFF BLADES, SLOTTED

SMART CUT® 435BS Braised Bond is a Slotted diamond cut off wheel that replaces general purpose abrasive cut off wheels/blades. Fast & efficient cutting without use of coolant, this blade can be used on any abrasive cut off saw, gas saws, masonry saw, chop saw, drop saw and many others. Designed for large variety of “Rough Cutting” metal applications, where cut quality, surface finish, and preserving material micro structure is not important.SMART CUT® – DIAMOND DICING / SLICING SAW

SMART CUT® 005DME MCDU

SMART CUT® 005DME Diamond Micro Drills represent a major advancement in precision micro-machining technology, specifically engineered to meet the challenges of drilling hard, brittle, and high-tech materials used across industries such as semiconductor, optics, advanced ceramics, aerospace, and medical device manufacturing.

These drills are widely used in electronics and semiconductor manufacturing for creating microscopic precision holes in wafers, essential for thermal management, electrical connectivity, and overall chip reliability. In optical engineering, they enable accurate hole placement in the assembly of lenses, mirrors, and optical components. In the medical field, they deliver consistent hole geometry and size control, which is vital for implant safety and precision assembly.

They are equally valuable in the aerospace and automotive industries, where components demand extremely tight tolerances and involve materials that are difficult to machine. The accuracy, stability, and repeatability of the SMART CUT® 005DME drills ensure defect-free holes in these critical applications, preventing system failures due to dimensional deviations.

SMART CUT® 010DME (SMCDU)

SMART CUT® 010DME Diamond Micro Drills represent a major advancement in precision micro-machining technology, specifically engineered to meet the challenges of drilling hard, brittle, and high-tech materials used across industries such as semiconductor, optics, advanced ceramics, aerospace, and medical device manufacturing.

These drills are widely used in electronics and semiconductor manufacturing for creating microscopic precision holes in wafers, essential for thermal management, electrical connectivity, and overall chip reliability. In optical engineering, they enable accurate hole placement in the assembly of lenses, mirrors, and optical components. In the medical field, they deliver consistent hole geometry and size control, which is vital for implant safety and precision assembly.

They are equally valuable in the aerospace and automotive industries, where components demand extremely tight tolerances and involve materials that are difficult to machine. The accuracy, stability, and repeatability of the SMART CUT® 010DME drills ensure defect-free holes in these critical applications, preventing system failures due to dimensional deviations.

SMART CUT® 015DSE

SMART CUT Series 015DSE Multi Layered Electroplated solid drills are flat cylinder shape with transition angle. These miniature diamond drills have high diamond concentration and give a smother, faster drilling action with minimum heat generation. The multiple layers of diamond coating which provides best diamond adhesion in the bond matrix. This provides longer life span, compared to standard and comparable electroplated miniature drills. Higher level of consistency and better surface finish. Most popular type of diamond drills for drilling small holes for jewelry (stone, glass, & many other materials). Multiple layers of diamond provide longer drilling life, faster & freer drilling. Available from stock from 0.75mm to 2.5mm