Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

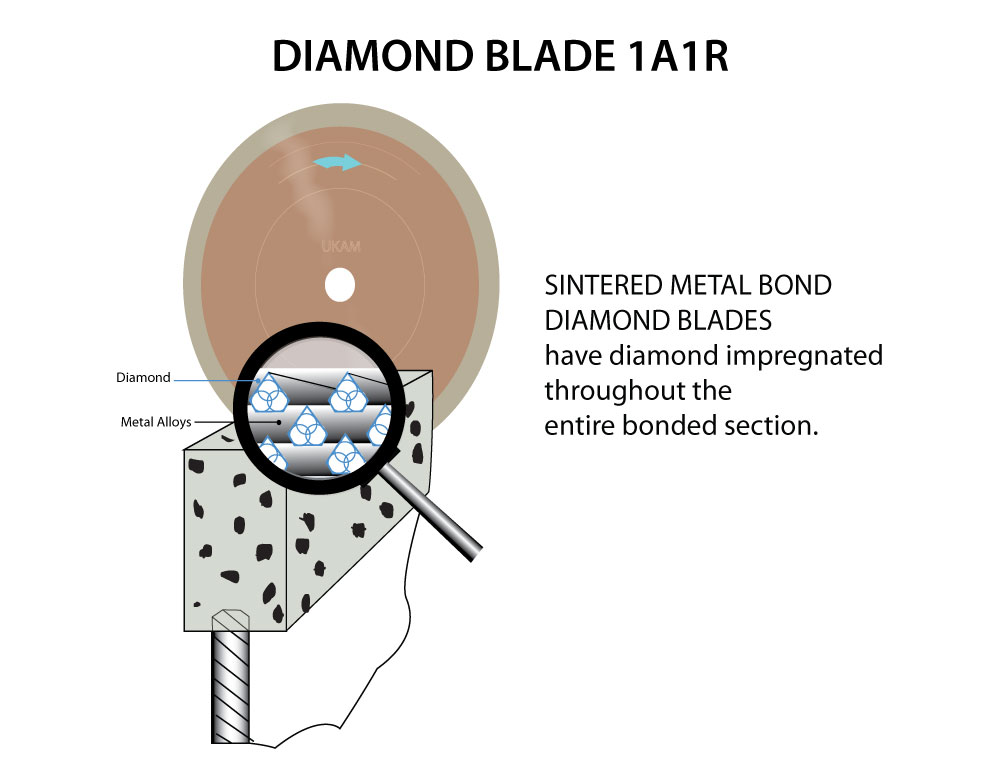

300M Professional Diamond Blade is a UKAM Industrial premium quality blade. The SMART CUT® series 300M Professional will provide smooth surface finish and is designed for cutting all types of lapidary materials (precious & semi precious stones) when waste must be held to a minimum and speed of cut is essential. The SMART CUT® series 300M series diamond blades last longer and will cut faster that ordinary notched rim, plated diamond blades. They can be used at maximum arbor speeds. This is the most inexpensive sintered (metal bond) blades & most wide used on market today.

Diamond Blade is premium quality sintered (metal bond) blade. Available from 4″ to 36″ OD. Series 300M Professionalwill provide smooth surface finish and is designed for cutting all types of lapidary materials (precious & semi precious stones) when waste must be held to a minimum and speed of cut is essential. Diamond Height (depth): 5mm

Experienced operator skills are required for maximum performance. SMART CUT™ water soluble coolant or mineral oil is recommended, however water with a rust inhibitor can be used. A full diamond sintered blade. The 4″ through 14″ blades are continuous rim, the 16″ through 24″ sizes are segmented rim blades. Designed for Lapidary Application Only. For other applications, consult us on correct blade to use.

Bond Type: Sintered (Metal bond)

Edge Type: Continuous Rim

Application: Lapidary, Glass

Diamond Grit Size: 80/100 mesh and 100/120 mesh depending on diameter and kerf thicness

Diamond Type: Synthetic

Diamond depth: 5mm

Blade Outside Diameters: 4″ (101.6mm) to 14″ (350mm)

Kerf Thickness: .014″ (0.35mm) to .070″ (1.77mm)

Saws Used On:

+ Trim Saws

+ Slab Saws

+ Tile Saws Saws

+ Gang Saws

The SMART CUT Series 300M is a line of sintered (metal bonded) diamond lapidary blades designed for efficient cutting of materials such as sapphire, agate, emerald, ruby, opal, petrified wood, glass, and more.

They offer a longer lifespan, faster cutting speed, even wear, and consistent performance. With hundreds of layers of diamonds, they stand up well under aggressive conditions, offer a super smooth finish, and are cost-effective in the long run.

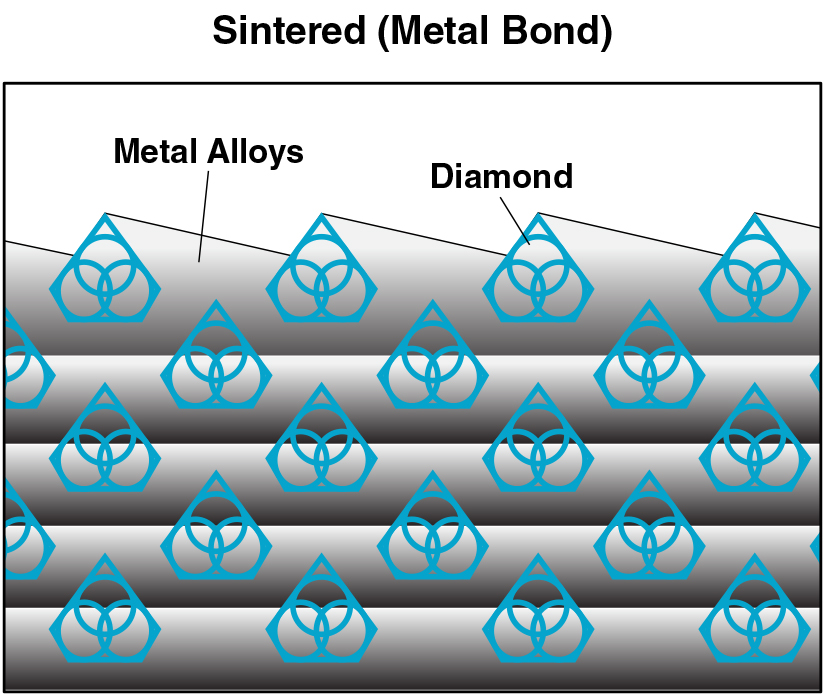

Diamonds in these blades are furnace-sintered in a matrix made of various metals. The process involves controlled heating rate, applied pressure, sintering temperature, and holding time, resulting in a blade that can cut efficiently and last longer.

While other blade types have only a single layer of diamond on the surface, the SMART CUT Series 300M has hundreds of layers of diamonds impregnated inside the metal matrix. This provides consistent performance, faster cutting speed, and longer blade life

Consider factors such as diamond concentration, diamond particle/grit size, blade thickness, outside diameter, bond hardness, bond type, feed rates, and blade speeds/RPMs. Each blade in the series is suited for different materials and applications.

Yes, sintered (metal bonded) diamond tools are recommended for cutting hard materials ranging from 45 to 75 on the Rockwell Scale (5 to 9.5 on the mohs scale of hardness).

Yes, the series includes blades with diameters ranging from 4” to 14”. Each blade’s specifications, such as diamond thickness and arbor size, can vary.

Make sure to use the blade at recommended speeds/RPMs, and apply the appropriate feed rates. Also, ensure that the blade is suited for the material you are cutting.

This is a premium quality blade by UKAM Industrial with a high diamond concentration designed specifically for cutting lapidary materials where minimal waste and speed of cut are essential.

It’s designed to cut all types of lapidary materials including precious and semi-precious stones like sapphire, agate, emerald, ruby, opal, petrified wood, glass, and more.

Unlike other diamond blades that only have a single layer of diamond, sintered blades are “impregnated” with hundreds of layers of diamonds within the metal matrix. This means they wear evenly, last longer, and cut faster than most other blades.

Its sintered (metal bond) technology, incorporated with SMART CUT™ technology, ensures the best cutting performance possible, offering the best value and performance per cut.

Yes, the 4″ through 14″ blades have a continuous rim, while the 16″ through 24″ sizes are segmented rim blades.

SMART CUT™ water-soluble coolant or mineral oil is recommended. However, water with a rust inhibitor can also be used.

Yes, experienced operator skills are required for maximum performance.

Absolutely. While they might cost more upfront compared to other blades, in the long run, their prolonged life, consistent performance, and faster cutting speed ensure they provide the best value for your money.

Multiple layers mean that as the outer layer of diamonds wears out, a new layer is exposed, allowing for consistent cutting performance and prolonged blade life.

The blade thickness typically ranges from .014” (0.35mm) to .085” (2.0mm). The thickness matters because it determines the amount of material loss during cutting, especially when working with valuable materials like gemstones or meteorites.

Generally, smaller diameter blades are thinner and prone to bending, while larger diameter blades, being thicker, are used for cutting larger pieces at higher speeds.

Bond hardness determines the ability of the bond matrix to hold diamonds. A harder bond increases diamond retention capabilities, making it suitable for cutting harder materials.

Yes, the blade can be provided with bushings for a smaller arbor, and the current arbor size can also be expanded by specialized machining process to almost any arbor size/inside diameter you require.

Feed rate is the force applied to the blade to cut the material. This will vary depending on blade diameter, material hardness, and other factors. The right feed rate ensures optimal cutting speed and blade longevity.

Most lapidary blades operate between 4,000 to 1,000 RPM’s. Harder and denser materials are cut at higher RPMs, whereas more brittle materials are cut at lower RPMs.

Blade compatibility largely depends on the arbor size of your cutting machine and rpm’s. Ensure your machine’s arbor size matches the blade’s inside diameter

Sintered (metal bonded) blades are more durable, last longer, and offer consistent performance compared to electroplated or notched blades.

This particular blade is not designed for cutting such hard materials. We have other blade for this application available

Proper maintenance, using the recommended coolant, and ensuring correct feed rates and speeds, and dressing when needed will prolong the life of your blade.

All blades need to be dressed sooner or later. These blades are no exception. However these blades will require lot less dressing then other blades not designed for lapidary application. If blade needs constant dressing in order to continue cutting this usually means its not designed for this specific application.

The primary advantage is the superior cutting performance due to the multiple layers of diamonds. This ensures a longer blade life, faster cutting speeds, and a more consistent performance throughout the blade’s lifespan.

While it’s possible to use water with a rust inhibitor, it’s recommended to use SMART CUT™ water-soluble coolant or mineral oil for optimal blade performance and longevity.

Yes, these blades are specifically designed for lapidary applications. For other applications, it’s essential to consult with the manufacturer to get the appropriate blade.

The 4″ through 14″ blades are continuous rim blades, designed for precise cuts with minimal chipping. The 16″ through 24″ sizes are segmented rim blades, designed for faster cutting in larger materials, with a slight trade-off in finish smoothness.

In SMART CUT blades, diamonds are furnace-sintered in a matrix of metals. This matrix is created using controlled heating rates, applied pressure, and sintering temperature specific to the metal combination. This precise method ensures superior diamond retention and blade performance.

Yes. Always wear protective eyewear, gloves, and ensure the working area is well-ventilated. It’s also essential to check the blade for any damages before use and to use the blade at recommended speeds.

Consider factors like your desired cutting speed, material hardness, thickness, and shape, as well as the experience of the operator. Thicker blades can withstand higher feed rates and are more forgiving to operator errors.

Higher diamond concentration usually leads to a longer blade life and faster cutting speeds. However, the right concentration is essential based on the hardness of the material you’re cutting. These blades have low diamond concentration but higher then normal tile blades

The diamond mesh size determines the cutting speed, cut quality, surface finish, and the level of chipping. This blade has 100/120 mesh which is lot finer then standard tile blade which usually have 40/50 mesh but lot coarser then finer diamond size blades such as 220 mesh and higher which is meant for cutting glass and other fragile materials. Choosing the right diamond particle size is crucial for achieving desired results.

The bond hardness determines the bond matrix’s ability to retain diamonds. A harder bond increases diamond retention capabilities. The bond type, especially metal bonding, offers prolonged life and durability, making it optimal for lapidary applications.

Feed rate is the force applied to push the blade through the material. It varies based on blade diameter, material type, and kerf thickness. Ensuring the correct feed rate for your application can prevent blade wear and achieve a cleaner cut.

Blade speed is typically dictated by the material’s hardness and brittleness. Harder materials like Sapphire require higher RPMs, while more brittle materials like glass require lower RPMs. Always refer to the manufacturer’s recommendations for optimal speeds.

While these blades are versatile, they are specifically designed for lapidary applications. Cutting materials outside of this range, especially without consulting the manufacturer, can lead to reduced blade performance and potential safety hazards.

Some blades benefit from a break-in process to ensure even diamond exposure and extended blade life. Always refer to the manufacturer’s recommendations when using a blade for the first time.

While the blades might fit on other machinery, for optimal safety and performance, it’s recommended to use them on equipment designed for lapidary work.

These blades are designed to fit a variety of machines, but it’s essential to ensure the blade diameter and arbor size match your equipment. Adapters or bushings can sometimes be used to accommodate different sizes.

As blades wear, they might not cut as efficiently or produce as smooth a finish. Regularly inspecting and maintaining your blade ensures consistent quality.

For specific warranty or guarantee details, always refer to the product packaging or consult the manufacturer directly.

Store the blade in a dry, cool place away from direct sunlight. It’s also advisable to protect the blade from potential impacts or bending.

Reduced cutting efficiency, visible physical damage, or uneven wear patterns are indications that the blade may need servicing or replacement.

Yes this process is called dressing. This is done by using dressing stick making alumina oxide or silicon carbide dressing stick soft about 100 grit. Cut the dressing stick like loaf of bred thin slices. Please consult our guide on dressing blades.

SMART CUT technology focuses on using a sintered (metal bond) process with multiple layers of diamonds impregnated inside the metal matrix. This ensures a more consistent, faster, and longer-lasting cut compared to other blade types.

Yes, it’s recommended to use the SMART CUT™ water-soluble coolant or mineral oil. However, water with a rust inhibitor can also be used.

Diamond concentration affects both the life and cutting speed of the blade. A higher diamond concentration can offer better cutting performance but may wear the bond faster.

Always wear safety goggles, gloves, and protective clothing. Ensure the material is securely clamped, and the blade is properly attached to the machine. Never force the blade through the material; let it cut at its own pace.

Blade thickness determines the amount of material removed due to the blade passing through the material. Thinner blades remove less material but may be more prone to bending, while thicker blades are more rigid and forgiving to operator errors.

Regularly clean the blade to remove any debris or buildup. Check for signs of wear or damage before each use. Using the recommended coolants can also prolong the blade’s life.

These blades are recommended for materials ranging from 45 to 75 on the Rockwell Scale (5 to 9.0 on Mohs scale of hardness). Always ensure you’re using the right blade for your material.

While these blades are versatile, they’re specifically designed for lapidary materials. Avoid cutting metals, plastics, or other ultra hard materials that are harder then 9 on mohes scale

The metal bond surrounds the diamonds and wears away over time, continuously exposing new diamonds. This ensures the blade retains its cutting ability longer than blades with a single layer of diamond.

Stop the machine immediately. A wobbling or bending blade can be a sign of damage or wear. Check the blade for any visible issues and ensure it’s properly attached to the machine.

While most lapidary blades operate between 4,000 to 1,000 RPMs, harder materials like Sapphire require higher RPMs. More brittle substances, such as glass, require lower RPMs. Always refer to the manufacturer’s guidelines or consult experienced lapidary professionals for specific materials.

Depending on the material and application, sintered (metal bonded) blades may last up to 50 to 100 times longer than other diamond lapidary blade types.

These blades are designed primarily for stationary cutting machines. If considering handheld use, make sure the blade is sufficiently thick and you can provide the recommended rpm’s

These blades have medium soft bond. Bond hardness determines the bond matrix’s ability to hold diamonds. As bond hardness increases, its diamond retention capability improves, influencing the blade’s performance.

When new blades usually do not require dressing before starting to use. Dressing after some time of use will help maintain consistent level of performance. This helps to expose the initial diamond layer for optimal cutting performance. However, always follow the manufacturer’s recommendations.

Slower cutting speeds, increased chipping, or uneven cuts are signs that the blade may be getting dull and might need sharpening or replacement.

Larger diameter blades are typically thicker and used for cutting larger materials at higher speeds than smaller blades. However, smaller diameter blades are thinner and more prone to bending and warping.0

Segmented rim blades allow for faster cutting and better heat dissipation. They can also handle tougher materials. Continuous rim blades, on the other hand, offer smoother cuts, especially on delicate materials.

Feed rate varies based on blade diameter, kerf thickness, and material hardness. Generally, harder materials require higher feed rates, while softer or more brittle materials need slower rates. Adjustments should be made based on observation and experience.

Yes, as long as the blade fits the machine’s specifications and the machine is in good working condition. Always ensure the blade is securely attached and operates at the recommended RPMs. Also keep in mind the kerf thickness of the blade you are using, flange diameter and blade exposure.

Yes, the use of water with a rust inhibitor is recommended if not using the SMART CUT™ water soluble coolant or mineral oil. Always follow manufacturer guidelines on rust inhibitor selection.

SMART CUT™ technology offers enhanced cutting performance and efficiency by optimizing the distribution and concentration of diamonds within the blade, leading to faster cuts, smoother finishes, and longer blade life.

These blades are designed specifically for lapidary applications. Also can be used for other applications such as cutting various rocks and glass, porcelain and softer ceramics. For other applications, consult the manufacturer for the most suitable blade.

If the blade bends or warps, it may no longer cut accurately or safely. In such cases, it is advisable to stop using the blade and consider a replacement. Always ensure proper usage to minimize the risk of bending or warping.

Over time, the metal bond holding the diamonds will wear, continuously exposing new diamonds. However, if the blade becomes dull before the metal bond wears out, it may be possible to sharpen the blade. Consult with a professional or the manufacturer for guidance.

Signs include slower cutting, increased material chipping, and visible reduction in the diamond layer. To maximize lifespan, ensure the blade is used at the correct RPMs, is adequately cooled, and is used on suitable materials.

Higher diamond concentrations often lead to longer blade life and faster cutting speeds. Meanwhile, grit size affects the quality and speed of the cut. Larger grits may cut faster but might leave rougher finishes, while finer grits result in smoother finishes but may cut slower.

Always wear protective eyewear and gloves. Ensure the blade is securely attached, the workspace is well-lit and free from obstructions, and the blade is regularly checked for signs of wear or damage. Always cut at recommended RPMs and ensure proper cooling is in place.

Due to their design, these blades are intended to minimize waste, especially when cutting valuable materials. Their cutting efficiency and precision are optimized for minimal material loss.

Not recommended for several reasons. First these are very low concentration blades. They have 3 times smaller amount of diamond concentration then blade designed for sample preparation. Also they have much coarser diamond size then blades for sample preparation. Furthermore the diamond quality is lower then blades designed for that purpose, and bond hardness and tolerances different.

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

SMARTC2G | 1 Gallon Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | ||

SMARTC1G | 1 Quart Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | ||

SMARTC4A | 5 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | ||

SMARTC7A | 55 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 | ||

UKAMDRST10 | 1/2″ x 1/2″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $8.65 | Max: Min: 1 Step: 1 | ||

UKAMDRST11 | 1.0″ x 1.0″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | ||

UKAMDRST13 | 1/2″ x 1/2″ x 6.0″ White For use on diamond tools 150 to 220 Grit Size. | $8.65 | Max: Min: 1 Step: 1 | ||

UKAMDRST4 | 1.0″ x 1.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $15.39 | Max: Min: 1 Step: 1 | ||

UKAMDRST5 | 2.0″ x 2.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $39.47 | Max: Min: 1 Step: 1 | ||

UKAMDRST7 | 1.0″ x 1.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | ||

UKAMDRST8 | 2.0″ x 2.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $39.47 | Max: Min: 1 Step: 1 |

Image | Name | Diameter | Inside Diameter | Description | Price | Quantity | Add to cart | |

|---|---|---|---|---|---|---|---|---|

30mm | 1/2″ | Flanges for Accessories | $70.00 | Max: Min: 1 Step: 1 | ||||

30mm | 5/8″ | Flanges for Accessories | $70.00 | Max: Min: 1 Step: 1 | ||||

40mm | 1/2″ | Flanges for Accessories | $75.00 | Max: Min: 1 Step: 1 | ||||

40mm | 5/8″ | Flanges for Accessories | $75.00 | Max: Min: 1 Step: 1 | ||||

45mm | 1/2″ | Flanges for Accessories | $80.00 | Max: Min: 1 Step: 1 | ||||

45mm | 5/8″ | Flanges for Accessories | $80.00 | Max: Min: 1 Step: 1 |

| Blade Diameter | Recommended RPM | Blade Diameter | Recommended RPM |

|---|---|---|---|

| 4″ (100mm) | 4,000 | 16″ (400mm) | 1,000 |

| 5″ (125mm) | 3,438 | 18″ (450mm) | 1,000 |

| 6″ (150mm) | 2,675 | 20″ (500mm) | 900 |

| 8″ (200mm) | 2,000 | 22″ (550mm) | 825 |

| 10″ (250mm) | 1,600 | 24″ (600mm) | 700 |

| 12″ (300mm) | 1,325 | 30″ (762mm) | 550 |

| 14″ (350mm) | 1,140 | 36″ (914mm) | 500 |

Best performance and life will result when the blades are operated in the range of 3150 to 500 surface feet per minute. Optimum performance and life will be obtained at the 5000 s.f.m. For your convenience we present the following chart of optimum RPM of shaft for each blade size.

Any diamond blade may occasionally require dressing of the edge to remove surplus metal or glazing to expose new diamond particles. You can dress by making a few cuts in an old 220 grit grinding wheel or a dressing stick made specifically for this purpose. Use coolant with this procedure. The SMART CUT diamond bond is designed to minimize this procedure. By using enough coolant and following the suggested procedures, you can’t rest assured this will require the minimal amount of time as compared to most blades.

Disposing of coolant used in lapidary work, such as water or water-based cutting fluids, should be done in an environmentally responsible manner. Follow these steps to properly dispose of coolant after cutting lapidary materials:

Consult our Illustrated Diamond Blade Trouble Shooting Guide which shows all the possible issues people experience when using blades and how to fix and prevent them

Image | Item | Diameter OD | Diamond Thickness TH | Diamond Height | Arbor ID | Suggested List Price | Internet Price (1pc) | 3 pcs (each) | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

23-4000W | 4" (101.6mm) | .014" (0.35mm) | .20" (5mm) | 5/8" | $44.00 | $32.00 | $29.81 | Max: Min: 1 Step: 1 | ||

23-4001W | 4" (101.6mm) | .014" (0.35mm) | .20" (5mm) | 1/2" | $44.00 | $32.00 | $29.81 | Max: Min: 1 Step: 1 | ||

23-4002W | 4" (101.6mm) | .020" (0.5mm) | .20" (5mm) | 5/8" | $46.00 | $34.00 | $30.81 | Max: Min: 1 Step: 1 | ||

23-4003W | 5" (125mm | .020" (0.5mm) | .20" (5mm) | 5/8" | $48.00 | $35.00 | $32.81 | Max: Min: 1 Step: 1 | ||

23-4004W | 6" (152.4mm) | .014" (0.35mm) | .20" (5mm) | 1/2" | $50.00 | $37.00 | $34.81 | Max: Min: 1 Step: 1 | ||

23-4005W | 6" (152.4mm) | .014" (0.35mm) | .20" (5mm) | 5/8" | $50.00 | $36.00 | $34.81 | Max: Min: 1 Step: 1 | ||

234005W | 6" (152.4mm) | .020" (0.5mm) | .20" (5mm) | 5/8" | $52.00 | $38.00 | $35.00 | Max: Min: 1 Step: 1 | ||

23-4006W | 6" (152.4mm) | .020" (0.5mm) | .20" (5mm) | 1/2" | $52.00 | $38.00 | $35.00 | Max: Min: 1 Step: 1 | ||

23-4007W | 6" (152.4mm) | .032" (0.81mm) | .20" (5mm) | 5/8" | $55.00 | $40.00 | $36.00 | Max: Min: 1 Step: 1 | ||

23-4008W | 6" (152.4mm) | .040" (1mm) | .20" (5mm) | 5/8" | $60.00 | $45.00 | $41.90 | Max: Min: 1 Step: 1 | ||

23-4008BW | 7" (177.8mm) | .050" (1.27mm) | .20" (5mm) | 5/8" | $78.00 | $54.00 | $50.00 | Max: Min: 1 Step: 1 | ||

23-4009W | 8" (203.2mm) | .025" (0.64mm) | .20" (5mm) | 5/8" | $66.00 | $49.00 | $43.27 | Max: Min: 1 Step: 1 | ||

23-4010W | 8" (203.2mm) | .032" (0.81mm) | .20" (5mm) | 5/8" | $68.00 | $50.00 | $46.31 | Max: Min: 1 Step: 1 | ||

23-4011W | 8" (203.2mm) | .060" (1.52mm) | .20" (5mm) | 5/8" | $79.00 | $55.00 | $51.30 | Max: Min: 1 Step: 1 | ||

23-4012W | 9" (228.6mm) | .060" (1.52mm) | .20" (5mm) | 5/8" | $83.00 | $60.00 | $54.82 | Max: Min: 1 Step: 1 | ||

23-4013W | 10" (254mm) | .032" (0.81mm) | .20" (5mm) | 5/8" | $73.00 | $54.00 | $49.68 | Max: Min: 1 Step: 1 | ||

23-4014W | 10" (254mm) | .040" (0.81mm) | .20" (5mm) | 5/8" | $76.00 | $56.00 | $51.90 | Max: Min: 1 Step: 1 | ||

23-4015W | 10" (254mm) | .050" (1.27mm) | .20" (5mm) | 5/8" | $99.00 | $74.00 | $68.31 | Max: Min: 1 Step: 1 | ||

23-4016W | 12" (304.8mm) | .065" (1.65mm) | .20" (5mm) | 5/8" | $182.00 | $136.00 | $124.36 | Max: Min: 1 Step: 1 | ||

23-4017W | 14" (354mm) | .070" (1.77mm) | .20" (5mm) | 1"-3/4" B | $207.00 | $154.00 | $139.80 | Max: Min: 1 Step: 1 |

Sintered (Metal bonded) diamond blades are “impregnated” with diamonds. Diamonds sintered and multiple (hundreds) layers of diamonds impregnated inside the metal matrix. Electroplated and other types of diamond blades for lapidary application have only one layer of diamond that stays on the surface. Diamonds in a sintered (metal bond) diamond blade are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. The compacted materials are then hot pressed or sintered to full density. Heating rate, applied pressure, sintering temperature and holding time, are all controlled according to the matrix composition. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, agate, emerald, ruby, opal, petrified wood, glass, and etc.

The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting.

Sintered (metal bonded) diamond tools are recommended for cutting hard materials from 45 to 75 on Rockwell Scale (5 to 9.5 on mohs scale of hardness). It is more wear resistant and holds diamond well in place, usually producing the highest yield/cutting & best price per cut ratio.

They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

They wear evenly, and are known for their long life & consistency. Sintered (metal bonded) diamond blades are the latest technology available in Diamond Blades. And represent the BEST VALUE & PERFORMANCE PER CUT.

They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

Sintered (metal bonded) lapidary blades are the best investment you can make! Although they may cost more than electroplated (nickel bond), hot or colled rolled or some notched lapidary blades, sintered (metal bond) blades will more than pay for themselves in terms of:

Other Bond type blades may cost less, and at first glance may seem like the most cost effective alternative. However, they will cost you more in the long run. Depending on material and application, sintered (metal bonded) blades may last as much as 50 to 100 other diamond lapidary blade types put together. You can't get more life out of any other blade !!! Instead of constantly putting blades on and off the saw, you will save money by using one blade. This means cost per cut, sintered (metal bond) blades are the best choice

Other Blade Types have only one layer of diamond coated on metal core. Diamonds sit only on the surface. When this diamond portion is peeled off, the blade will slow down, cut on the side (not cut straight) or stop working (cutting) altogether. While other blade types may provide acceptable level of performance softer lapidary materials such as topaz, turquoise, amethyst, and etc. They will immediately burn out on harder materials such as agates, petrified wood, sapphire and etc. Metal bonded blades are sintered and impregnated inside the metal matrix. Multiple (hundreds) layers of diamonds are impregnated inside the metal matrix. Unlike Blade Types, metal bond blades wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance from sintered (metal bonded) blades.

Are you using the right blade for your application?

many Clients wast valueable time & money by using incorrect blades for their application.

Learn what variables you should consider when chosing your next lapidary blade

Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Lapidary Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is slower cutting speed. Low diamond concentration is recommended and widely used for cutting harder materials

Lapidary blade thickness typically ranges from .014” (0.35mm) to .085” (2.0mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material due to the thickness of blade passing though the material. Blade thickness is important for users requiring most minimal amount of material loss cutting specially when cutting very valuable materials such as gemstones or meteorites There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker blades are more stiff and can whistand higher/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as students and beginning users.

Feed rate is amount of force applied to the blade to go through material being cut. This will typically vary depending on blade diameter, kerf thickness & material being cut. Generally, harder materials are cut at higher feed rates and speeds (such a precious and semi precious stones) and more softer and brittle materials are cut at lower loads and speeds (such as glass, quartz). The Speeds/RPM’s you are using, shape/geometry of the material, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Most lapidary blades are used between 4,000 to 1,000 RPM’s Typically harder and more denser materials such as Sapphire, are cut at higher RPM’s/speeds Where more brittle materials such as as glass are cutting at lower RPM’s. Most rim saws RPM’s are typically limited from 1,000 to 4,000 RPM’s. Slabbing saws 500 to 1000 rpm’s. And trim saws from 3,000 to 6,000 rpm’s.

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in chipping and surface finish. If you are cutting fragile, more delicate materials then we have available from stock finer mesh size diamond blades. If you need to cut as fast as possible and surface finish is not a concern we also offer much coarser cutting blades for this application.

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness. Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Typically lapidary blade diameters range form 4” (100mm) to 8” (200mm) for trimming and 10” (254mm) and up are usually used for slabbing. The diameter should be selected based on material diameter and thickness being cut. Smaller diameter blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and pieces of material at higher loads and speeds than smaller blades Blade Inside Diameter - Most trim saws and tile saws has 5/8” arbor these are for blades 4” to 10” OD. Larger cutting machines such as 12” to 18” OD usually have 1” arbor. We can provide bushings to smaller arbor. We can also expand the current arbor size to anything you want same day.

Metal bonding offers long life and durability, and is the best bond type to use for lapidary applications.

Are you using the right blade for your application?

Many clients waste valuable time & money by using incorrect blades for their applications. Learn what variables you should consider when choosing your next lapidary blade

Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Lapidary Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is slower cutting speed. Low diamond concentration is recommended and widely used for cutting harder materials

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in chipping and surface finish. If you are cutting fragile, more delicate materials then we have available from stock finer mesh size diamond blades. If you need to cut as fast as possible and surface finish is not a concern we also offer much coarser cutting blades for this application

Lapidary Blade thickness typically ranges from .014” (0.35mm) to .085” (2.0mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material due to the thickness of blade passing though the material. Blade thickness is important for users requiring most minimal amount of material loss cutting specially when cutting very valuable materials such as gemstones or meteorites

There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker blades are more stiff and can whistand higher/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as students and beginning users.

Typically lapidary blade diameters range form 4” (100mm) to 8” (200mm) for trimming and 10” (254mm) and up are usually used for slabbing. The diameter should be selected based on material diameter and thickness being cut. Smaller diameter blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and pieces of material at higher loads and speeds than smaller blades Blade Inside Diameter - Most trim saws and tile saws has 5/8” arbor these are for blades 4” to 10” OD. Larger cutting machines such as 12” to 18” OD usually have 1” arbor. We can provide bushings to smaller arbor. We can also expand the current arbor size to anything you want same day

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness. Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Metal bonding offers long life and durability, and is the best bond type to use for lapidary applications

Feed rate is amount of force applied to the blade to go through material being cut. This will typically vary depending on blade diameter, kerf thickness & material being cut. Generally, harder materials are cut at higher feed rates and speeds (such a precious and semi precious stones) and more softer and brittle materials are cut at lower loads and speeds (such as glass, quartz). The Speeds/RPM’s you are using, shape/geometry of the material, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Most lapidary blades are used between 4,000 to 1,000 RPM’s Typically harder and more denser materials such as Sapphire, are cut at higher RPM’s/speeds Where more brittle materials such as as glass are cutting at lower RPM’s. Most rim saws RPM’s are typically limited from 1,000 to 4,000 RPM’s. Slabbing saws 500 to 1000 rpm’s. And trim saws from 3,000 to 6,000 rpm’s.

We understand that your success depends on select the right diamond lapidary blade, and optimizing your parameters to best fit your applications/needs.

Largest Inventory of Diamond Lapidary Blades in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

We Are a Partner In Your Success

American Manufacturer

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Comprehensive Source of Information on Diamond Lapidary Blades

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Experience makes all the Difference

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary lapidary blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect lapidary blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

Superior Quality &

Consistency

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

We understand that your success depends on select the right diamond lapidary blade, and optimizing your parameters to best fit your applications/needs.

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Largest Inventory of Diamond Lapidary Blades in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

“ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY”

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary lapidary blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect lapidary blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

We understand that your success depends on select the right diamond & CBN blade, and optimizing your parameters to best fit your applications/needs.

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Largest Inventory of Diamond Drills & Tools in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary drill chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect drill life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after drilling.

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

SMART CUTTM Series - 330MS Wide Slot Segment Design - Diamond Depth (Height): 8mm SMART CUT Series 330MS Wide spacing between segments. Designed for fast and more aggressive cutting, where chipping and very smooth cut loss is not essential. And loss of material is not critical. Perfect for medium to hard lapidary materials, and less experienced blade users.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales