-

0 items in quote

No products in the Quote Basket.

DIAMOND TOOL ACCESSORIES

Shank Adapters for Diamond Drills

used to create conical holes, expanding existing holes, breaking corners and chamfering holes and polishing existing holes in a large variety of materials. Available from stock in many specifications and we can also custom manufacture to fit almost any application/requirement.

Multi-Layered Electroplated Diamond Countersinks are designed for countersinking operation in materials such as Glass, Quartz, Composites, Graphite Epoxy, Carbon, Boron, Fiberglass, Marble, and many other materials.

SMART CUT® Drilling Templates

SMART CUT® HD Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing Silicon

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

SMART CUT® Mineral Oil

SMART CUT® Mineral Oil is a premium-grade lubricant and coolant specifically designed for precision cutting, drilling, grinding, and machining applications. It is ideal for use with a wide range of materials, particularly those with high metallic content, ceramics, precious and semi-precious stones, and other ultra-hard materials.

This mineral oil is formulated with a hydro-finished paraffin base, ensuring exceptional purity and consistent performance. It is non-dilutable, meaning it maintains its integrity and efficacy throughout its use. Rated as a food-grade oil, SMART CUT® Mineral Oil is non-toxic, non-hazardous, and non-flammable under normal conditions. With a flash point of 390°F, it provides reliable protection against heat buildup, making it suitable for demanding applications where high temperatures are a concern.

SMART CUT® Precision Gang Arbors & Hubs

SMART CUT® AMF Water Soluble Coolant

Advanced Materials Formula

Super Premium water soluble synthetic coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

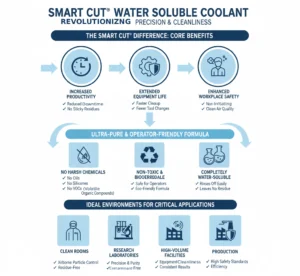

SMART CUT® Water Soluble Coolant – Advanced Materials Formula is a high-performance, fully synthetic, aqueous-based coolant specifically engineered for precision machining in the most demanding applications. Designed to excel in the cutting and grinding of advanced materials such as ceramics, composites, optics and ultra-hard, brittle materials. This premium coolant/lubricant optimizes removal rates while delivering superior surface finishes.SMART CUT® Water Soluble Coolant

(General Materials Formula)

High-Performance Fully Synthetic Coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

SMART CUT® Water Soluble Coolant (General Materials Formula) is a fully synthetic, non-oily, and non-foaming coolant and lubricant engineered to meet the rigorous demands of slicing, dicing, drilling, sectioning, wafering, grinding, and polishing operations involving hard and brittle materials. This advanced formula has been specifically developed for use with ceramics, precision optics, quartz, silicon, sapphire, and other materials commonly found in semiconductor, photonics, and materials research applications.SMART CUT® Water Soluble Dicing Coolant

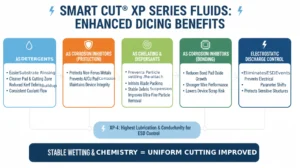

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

Water Swivel Adapters

SMART CUT® Water Swivel Adapters, also known as drill head assemblies, are precision-engineered components essential for delivering a continuous, pressurized flow of water, coolant, or air directly through the center of your diamond core drills and other hollow-shaft rotary tools. This internal coolant delivery method provides direct lubrication at the cutting interface, ensuring the most effective heat dissipation and friction reduction where it matters most—at the point of contact between the tool and the material.

By channeling coolant through the core of the tool, these adapters help maintain stable cutting temperatures, reduce thermal expansion, and significantly minimize the risk of cracking, delamination, burning, and tool loading. This results in dramatically extended tool life—in some in many cases over 350% +—as well as faster drilling speeds, reduced downtime, and superior material finish and dimensional accuracy. The integration of SMART CUT® Water Swivel Adapters into your operation will substantially enhance process efficiency and consistency, particularly when working with heat-sensitive, brittle, or high-precision materials.

Universally compatible, these adapters are designed to seamlessly fit a wide range of drilling systems, CNC machines, manual drill presses, and automated drilling equipment. They are available in multiple shaft diameters, thread types, and mounting configurations, and are engineered to mate precisely with diamond drill collets and chuck systems.