-

0 items in quote

No products in the Quote Basket.

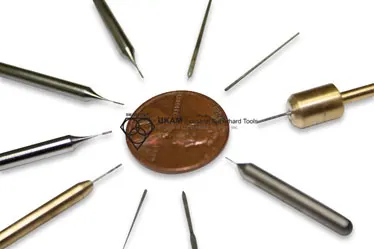

Shank Adapters for Diamond Drills

Shank adapters are essential accessories designed to ensure compatibility between your diamond core drills and a wide range of drilling equipment. Since diamond drills are manufactured with various mounting configurations—typically featuring female threaded connections—shank adapters serve as an intermediary interface, allowing the drill to be securely mounted onto machines with different chuck or spindle specifications.

By utilizing the appropriate shank adapter, operators can adapt the shank or thread of a diamond core drill to fit the spindle, chuck, or collet of their drilling machine, enabling seamless integration without compromising stability or performance. This versatility not only maximizes the utility of your existing diamond drills but also reduces the need for multiple drill types for different machines.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Shank adapters are particularly valuable in multi-machine environments where drills must be interchanged between equipment with varying mount designs. They provide a cost-effective, flexible solution for extending the compatibility and functionality of your precision diamond tools across multiple platforms.

SPECIFICATIONS

Tab Content

FREQUENTLY ASKED QUESTIONS

A diamond core drill shank adapter is a tool accessory designed to adapt the shank of your diamond core drill or other tools to match the chuck or spindle of your drilling machine. This ensures compatibility between the drill and the drilling equipment.

You need a shank adapter to make sure that your diamond core drill can be used with drilling machines that have different chuck or spindle sizes. It allows you to connect your drill securely to the equipment, ensuring efficient and accurate drilling.

The shank adapter features male threads that match the female threads on your diamond core drill. On the other end, it has the appropriate shank diameter and male thread size to fit into the chuck or spindle of your drilling machine. This adapter bridges the gap between the drill and the machine.

Yes, by using shank adapters, you can use the same diamond core drill with different drilling machines, even if they have varying chuck or spindle sizes. This versatility saves you the cost of purchasing multiple drills for different machines.

We offer several shank adapter options based on shank diameter and male thread size. Choose the adapter that matches the specifications of your diamond core drill and the chuck or spindle of your drilling machine. Refer to the product description and item

number to make the correct selection.

Installing a shank adapter is straightforward. Screw the male threaded end of the shank adapter into the female threads of your diamond drill. Ensure it’s securely tightened to avoid any wobbling during operation.

Yes, these shank adapters can be used with any other tool that has a 5/8″-11″ thread, making them versatile and suitable for various applications.

The prices for our diamond core drill shank adapters vary based on the specifications. Please refer to the provided item numbers and descriptions for detailed pricing information.

These shank adapters are designed to fit into drill press chucks with 5/8″-11″ threads. Ensure that your drill press chuck has the corresponding thread size for compatibility.

Yes most of our shank adapters have hole in center this can be used to run coolant through the center or help push material from the drill.

Our shank adapters are machined on precision CBN machines to have high precision tolerances and no to minimum run out.

Can I use these shank adapters with cordless drills, or are they only compatible with drill presses?

While these shank adapters are designed to fit into drill

press chucks, they can also be used with cordless drills that have compatible chuck sizes and threads. Make sure to check your cordless drill's specifications for

compatibility.

Yes, our shank adapters are typically made from high-quality materials such as hardened steel to ensure durability and long-lasting performance, even in demanding drilling applications.

To determine the correct shank adapter size, you should know the shank diameter and male thread size of your diamond core drill or tool. Match these specifications with the options listed in the product description to select the appropriate shank adapter.

Yes, these shank adapters are suitable for both wet and dry drilling applications, making them versatile for various construction and drilling projects.

Yes, these shank adapters are designed for ease of use and quick

installation. You can easily replace or switch them between different drills and machines

as needed, allowing for efficient workflow and adaptability.

These shank adapters are designed to be compatible with diamond core drills and tools that have 5/8″-11″ threads. They should work with most standard diamond core drills, but if you have concerns about compatibility with a specific brand or model, please contact us for clarification.

INDUSTRIES USED IN

Tab Content

ACCESSORIES

Showing 1 – -1 of 13 results Showing all 13 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Name | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $15.39 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $15.99 | Max: Min: 1 Step: 1 | |||

5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads… | $22.46 | Max: Min: 1 Step: 1 | |||

5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads… | $26.72 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $39.47 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $39.47 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $154.87 | Max: Min: 1 Step: 1 | |||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $154.87 | Max: Min: 1 Step: 1 | |||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $235.00 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 |

USAGE RECOMMENDATION

Tab Content

Features:

-

Enhanced Compatibility – Connects diamond core drills with female threads to machines with different spindle sizes or types.

Enhanced Compatibility – Connects diamond core drills with female threads to machines with different spindle sizes or types.

-

Operational Flexibility – Enables the same drill to be used across multiple drilling platforms.

Operational Flexibility – Enables the same drill to be used across multiple drilling platforms.

-

Cost-Effective – Eliminates the need for duplicate drills for each machine type.

Cost-Effective – Eliminates the need for duplicate drills for each machine type.

-

Precision Engineering – Manufactured to tight tolerances to ensure secure, vibration-free operation during high-speed or high-torque drilling.

Precision Engineering – Manufactured to tight tolerances to ensure secure, vibration-free operation during high-speed or high-torque drilling.

-

Durable Construction – Made from high-grade steel or hardened alloys for long service life, even under demanding drilling conditions.

Durable Construction – Made from high-grade steel or hardened alloys for long service life, even under demanding drilling conditions.

-

Easy Installation – Allows for quick tool changes without special tools or modifications.

Easy Installation – Allows for quick tool changes without special tools or modifications.

Advantages:

-

Universal Compatibility

Allows a single diamond core drill to be used with multiple machines that have different spindle, chuck, or mounting thread sizes—significantly increasing flexibility and reducing the need for additional tooling.

Universal Compatibility

Allows a single diamond core drill to be used with multiple machines that have different spindle, chuck, or mounting thread sizes—significantly increasing flexibility and reducing the need for additional tooling.

-

Operational Flexibility – Enables the same drill to be used across multiple drilling platforms.

Operational Flexibility – Enables the same drill to be used across multiple drilling platforms.

-

Extended Tool Utility

Enhances the versatility and service life of your diamond core drills by enabling them to be used on different equipment platforms, even when original equipment compatibility is limited.

Extended Tool Utility

Enhances the versatility and service life of your diamond core drills by enabling them to be used on different equipment platforms, even when original equipment compatibility is limited.

-

Simplified Inventory Management

Reduces the variety of tools and accessories required in stock. Operators can standardize their tooling and adapt to various machines using interchangeable adapters.

Simplified Inventory Management

Reduces the variety of tools and accessories required in stock. Operators can standardize their tooling and adapt to various machines using interchangeable adapters.

-

Quick Changeover

Speeds up setup and tool change times. Shank adapters allow for fast transitions between machines without the need for retooling or purchasing entirely new drill bits.

Quick Changeover

Speeds up setup and tool change times. Shank adapters allow for fast transitions between machines without the need for retooling or purchasing entirely new drill bits.

-

Enhanced Drilling Stability

Precision-machined for exact fit and alignment, ensuring optimal balance, minimal runout, and reduced vibration during operation—critical for achieving accurate holes and maintaining tool integrity.

Enhanced Drilling Stability

Precision-machined for exact fit and alignment, ensuring optimal balance, minimal runout, and reduced vibration during operation—critical for achieving accurate holes and maintaining tool integrity.

-

Increased Productivity

By enabling tool interchangeability and reducing downtime, shank adapters support higher production efficiency and improved workflow continuity across departments and machines.

Increased Productivity

By enabling tool interchangeability and reducing downtime, shank adapters support higher production efficiency and improved workflow continuity across departments and machines.

-

Long-Term Durability

Manufactured from hardened alloy or heat-treated steel for high mechanical strength and resistance to torque, wear, and corrosion—ensuring long-lasting performance even in harsh environments.

Long-Term Durability

Manufactured from hardened alloy or heat-treated steel for high mechanical strength and resistance to torque, wear, and corrosion—ensuring long-lasting performance even in harsh environments.

-

Support for Wet and Dry Drilling

Fully compatible with both water-cooled and dry drilling systems, supporting a wide range of applications and operating conditions.

Support for Wet and Dry Drilling

Fully compatible with both water-cooled and dry drilling systems, supporting a wide range of applications and operating conditions.

-

Customization Available

Adapters can be produced with custom thread types, lengths, diameters, or mounting designs to meet non-standard, proprietary, or legacy equipment requirements.

Customization Available

Adapters can be produced with custom thread types, lengths, diameters, or mounting designs to meet non-standard, proprietary, or legacy equipment requirements.

Showing 1 – -1 of 3 results Showing all 3 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Name | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

5/8"-11" thread. Fits into drill press chuck. Shank adapter threads… | $22.46 | Max: Min: 1 Step: 1 | |||

5/8"-11" thread. Fits into drill press chuck. Shank adapter threads… | $22.46 | Max: Min: 1 Step: 1 | |||

5/8"-11" thread. Fits into drill press chuck. Shank adapter threads… | $26.72 | Max: Min: 1 Step: 1 |

Related Products

SMART CUT® 6055 Precision Automatic Diamond Cut-Off Saw

SMART CUT® 6045 Sectioning Saw

SMART CUT® SM Polishing and Grinding Head

SMART CUT® AMF Water Soluble Coolant

Advanced Materials Formula

Super Premium water soluble synthetic coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

SMART CUT® Water Soluble Coolant – Advanced Materials Formula is a high-performance, fully synthetic, aqueous-based coolant specifically engineered for precision machining in the most demanding applications. Designed to excel in the cutting and grinding of advanced materials such as ceramics, composites, optics and ultra-hard, brittle materials. This premium coolant/lubricant optimizes removal rates while delivering superior surface finishes.Recently Viewed Products

ARE YOU USING RIGHT DIAMOND CORE DRILLS & TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND CORE DRILLS & TOOLS?

Knowledge Center

02

Jun

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will...

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind...

02

Jun

Diamond Tools Guide – Selecting Right Drills & Tools for your application

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms,...

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency....

02

Jun

Micro Drilling Guide

Share this Article with Friend or Colleague

In order for you to get the most out of your diamond micro drill or carbide / high speed steel micro drill, we strongly urge you to read...

02

Jun

Selecting Right Drilling Equipment for your Application. What you features & functionality you should look for?

Share this Article with Friend or Colleague

There are hundreds or even thousands of different drilling equipment options. Selecting the right equipment for a specific application involves carefully considering several variables and attributes of the...

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

https://ukam.com/wp-content/uploads/2024/07/diamond-drill-troublehsooting-guide.mp4

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide...

09

Sep

Understanding & Calculating Return on Investment for Diamond Core Drills & Other Tools

The term "ROI" (Return On Investment) is widely used across industries, often interpreted differently depending on the context. However, few truly understand what ROI represents and its specific implications, particularly in the context of diamond...

09

Sep

Understanding Tradeoffs – Searching for Perfect Diamond Drill & Tool

Choosing the right diamond drill or tool can significantly impact efficiency, cost, and quality. However, this is not a simple and clear-cut process. Selecting the optimal drill or tool involves navigating a complex landscape of...

19

Sep

Why Use Diamond Drills?

Diamond, known as the hardest material on Earth, enables diamond drills and tools to grind away material at a micro (nano) scale. This extreme hardness allows diamond tools to effectively work on materials with a...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin, high precision cutting blades, precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use