-

0 items in quote

No products in the Quote Basket.

SMART CUT® 4005

Low Speed Saw

SMART CUT® SMART CUT® 4005 Low-Speed Saw is a small, precision cut-off machine designed for sectioning a wide range of materials with high efficiency and accuracy. It is built to be incredibly easy to operate, with quick specimen fixation and size setting, allowing users to begin cutting in just minutes. The workpiece is securely fastened in a holder mounted on a movable arm, ensuring stable and precise cutting during the entire operation.

Equipped with a continuously variable cutting speed, the SMART CUT® 4005 maintains a constant speed under varying loads, ensuring reliable results regardless of material type. With a maximum specimen size of 30 mm in diameter, this machine provides versatility for a variety of cutting applications. The specimen size is set with exceptional accuracy of ±0.003 mm via an integrated LCD digital micrometer, making it ideal for high-precision tasks. Additionally, the cutting pressure is adjustable independently of the specimen weight, allowing users to fine-tune the cutting conditions to suit different materials and requirements.

One of the standout features of the SMART CUT® 4005 is its geonometer, which allows users to cut materials at various angles with high precision. This feature is particularly valuable for applications that require angular cuts, such as when working with brittle crystals, ceramics, or specialized samples. The geonometer provides easy adjustment of cutting angles, ensuring the machine can handle a wide range of specimen orientations, enhancing its versatility for specialized cutting needs.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

The machine also comes with an LCD digital display that shows the exact cutting speed (RPM) in real-time, allowing operators to monitor the process and make adjustments as needed. The SMART CUT® 4005 is designed for budget-conscious users without compromising on performance, offering equal precision, productivity, and versatility to well-known brand-name low-speed saws at a significantly lower price. This makes it an excellent choice for both production and R&D facilities, especially those working within tight budget constraints.

In addition to its cutting precision, the SMART CUT® 4005 supports gang operation, enabling up to 4 blades to cut simultaneously, which is ideal for sectioning brittle materials, ceramics, and TEM samples. The cutting process is liquid-cooled, with coolant continuously draining back into the coolant tank, ensuring that the cutting area remains cool and the specimens are protected from heat damage. After cutting, the specimen is safely deposited into a basket within the coolant tank, preventing drying and ensuring easy retrieval.

The SMART CUT® 4005 comes with a range of essential components, including an adjustable balance weight, goniometric specimen holder, blade flanges, graphite and aluminum plates, a wax rod for specimen mounting, and an AC power cord. It is compatible with blades ranging from 3” to 4” (75mm to 101mm) in diameter, and one diamond or CBN wafering blade is included free of charge in any specification.

An automatic shut-off feature ensures unattended operation, providing added convenience and safety. Users can select between a quart of SMART CUT® water-soluble coolant or mineral oil to optimize the cutting process. The machine also includes a two-year limited warranty (excluding rusting and damage due to carelessness or neglect), offering peace of mind along with excellent value.

Offering the best return on investment in terms of consumables, the SMART CUT® 4005 Low-Speed Saw delivers superior precision and versatility at an affordable price, making it the top choice for R&D and production facilities looking for a reliable and cost-effective sectioning saw.

Start saving money today and experience the performance and precision of the SMART CUT® 4005, a high-quality machine designed to meet your cutting needs without the high cost.

SPECIFICATIONS

- Speed range: varies from 0 – 600 rpm DC with digital display

- Power: 110 and 220 AC switch-able for worldwide

- High toque DC motor (70W) to allow multi-blade cutting operation

- Position accuracy: 005mm

- travel distance: 25.4 mm by LCD digital micrometer ( 50 mm with adjusting sample holder)

- Water-proof LCD digital micrometer with reading of 001 mm and accuracy of 0.003 mm

- Blade Diameter: 3″ to 4″ (75mm to 101mm) OD

- Automatic shut off: allow the saw to run

- Warranty: two years limited, not including rusting and damage due to carelessness or customer neglect

- Package dimension: 19″ x 15″ x 15″

- Shipping weight: 32lbs

ADVANTAGES

- Minimal Blade Load / Very Simple to Use

- Best performance & price per cut

- Universal Application / Adjusts to fit any application

- Improve Cutting/Sectioning Speed

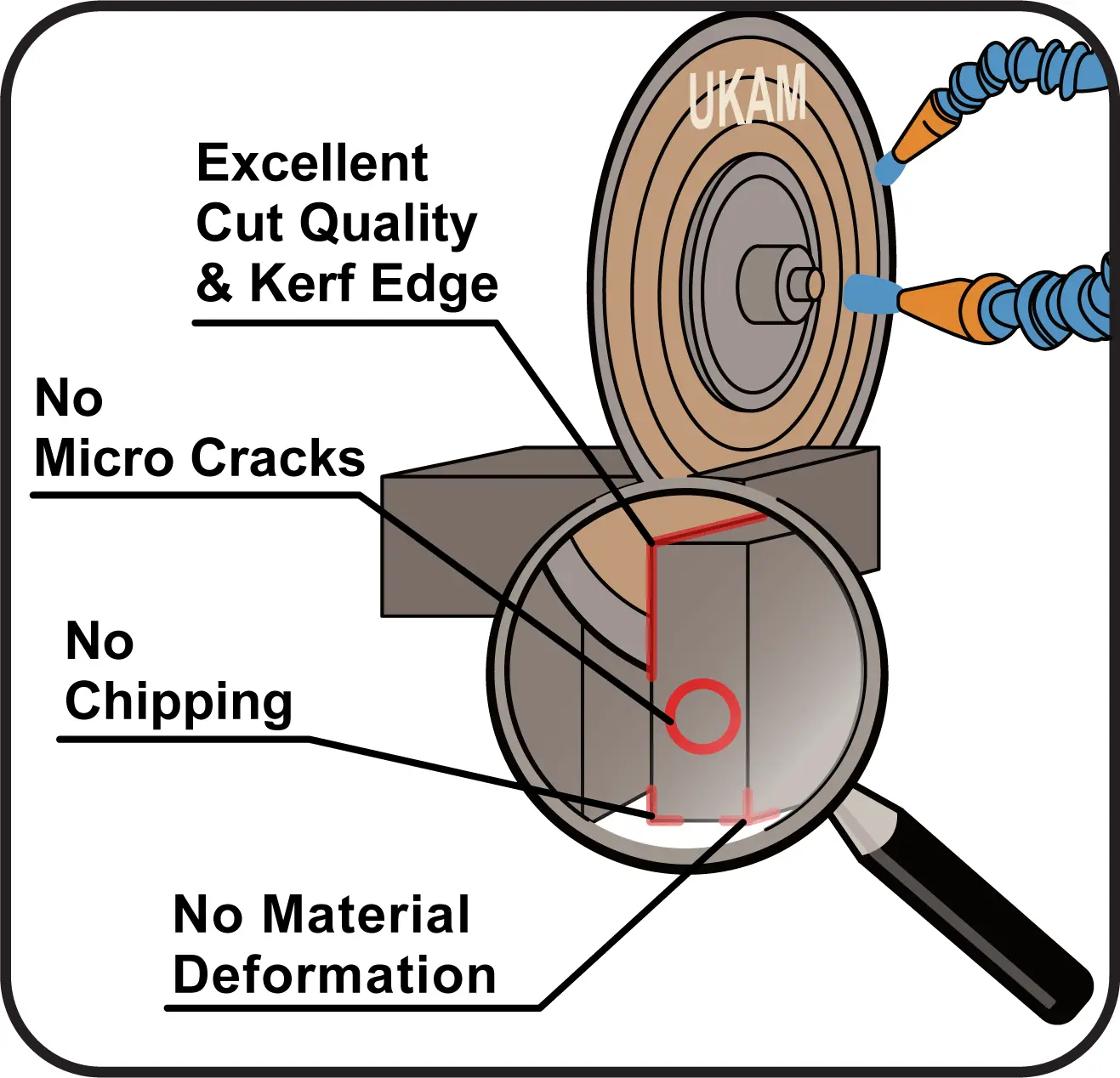

- Minimize Material Structure Deformation

- Improve Surface Finish Quality / Minimize Burrs on Edges

- Reduce Material Loss

- Gang Sawing Capability

- Perfect for Organizations on a Budget

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

The SMART CUT® 4005 is a small, low-speed, precision cut-off machine designed for sectioning all types of materials.

These parameters can be easily set using the LCD digital micrometer and will only take a few minutes.

The maximum specimen size is 30 mm in diameter.

The motor is designed to ensure that the selected speed remains constant regardless of the load.

Yes, the machine allows for gang operation with up to 4 blades cutting simultaneously.

It’s perfect for brittle crystals, ceramics, and TEM samples.

Once the cutting operation is complete, the specimen falls into a basket in the coolant tank, preventing it from drying and making retrieval easy.

The coolant tank is designed to be easily removable, making both the retrieval of the finished specimens and cleaning straightforward.

The cutting speed range varies from 0 to 600 rpm, with a digital display showing the exact RPM.

The machine is switch-able between 110 and 220 AC, making it suitable for worldwide use.

Yes, the SMART CUT® 4005 is known to be the most affordable low-speed sectioning saw available, providing equal precision, productivity, and versatility as other well-known brands but at a significantly lower price.

The machine is compatible with blades ranging from 3″ to 4″ (75mm to 101mm) in outer diameter.

Yes, the saw has an automatic shut-off feature that allows it to run until the cutting operation is complete.

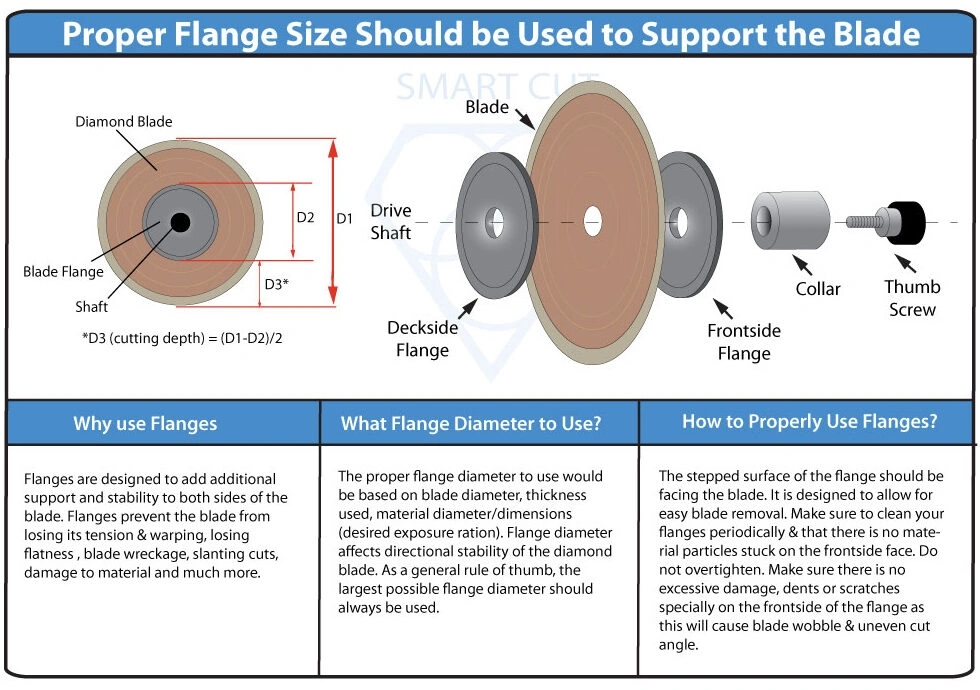

The package includes various components such as the Low Speed Diamond Saw, Adjustable Balance Weight, Goniometric Specimen Holder, Blade Flanges of various diameters, Graphite and Aluminum Plates, Wax Rod for mounting, AC Power Cord, and much more. Refer to the product listing for a complete breakdown.

The machine comes with guidance on how to select the right diamond wafering blade suitable for your specific application.

The machine comes with a two-year limited warranty. However, rusting and damage due to carelessness or customer neglect are not covered.

The water-proof LCD digital micrometer provides readings with an accuracy of 0.003 mm, allowing for precise setting and measurement of the specimen size.

The cutting process on the SMART CUT® 4005 is liquid-cooled, with the cooling liquid continuously draining back into the coolant tank to ensure optimum temperature during sectioning.

The machine comes with a quart of SMART CUT water-soluble coolant, either in advanced materials formula or Mineral Oil. The mix ratio is 1:20, meaning one part coolant to 20 parts water, which can produce up to 5.7 gallons of coolant mixture.

The machine includes various sizes of blade flanges to accommodate different blade sizes and applications, ensuring a secure and balanced fit for each blade.

Guidance is provided on how to select the right diamond wafering blade suitable for specific applications. The choice may depend on material type, desired section thickness, and other factors.

The high-torque DC motor (70W) ensures consistent and powerful cutting performance, even when utilizing the multi-blade gang operation feature.

Yes, besides the automatic shut-off after the cutting operation, the machine’s design ensures the specimen falls safely into a basket in the coolant tank, minimizing potential hazards.

The adjustable balance weight helps to ensure consistent cutting pressure across the specimen. It can be set and adjusted based on the specimen’s size and type.

The Dressing Stick is used to maintain and condition the wafering blade, ensuring smooth and efficient cutting performance.

In case of any issues, it is recommended to refer to the user manual or contact our technical support for troubleshooting and assistance.

The machine has package dimensions of 19″ x 15″ x 15″, making it compact and suitable for various work environments.

The shipping weight of the machine is 32lbs, making it relatively lightweight for its capabilities.

Yes, the product listing provides part numbers for standard and optional items, which can be used to order replacements or additional accessories.

Yes, the SMART CUT® 4005 offers a combination of precision and versatility, making it perfect for both R&D and production facilities, especially those on a budget.

It is advisable to regularly check the coolant for contamination or depletion. The frequency of replacement will depend on usage, but ensure it’s always at the optimum level and consistency for efficient cooling.

The SMART CUT® 4005 is designed to section a wide range of materials.

While the machine accepts blades ranging from 3″ to 4″ in diameter, it’s always best to use recommended blades to ensure optimal performance and safety.

Regular cleaning, ensuring the coolant is refreshed as needed, and using the Dressing Stick to condition the blade are key maintenance practices. It’s also important to inspect for any signs of wear or damage periodically.

While the SMART CUT® 4005 is designed for easy operation, initial training or familiarization with the machine’s functionalities will ensure safe and efficient usage.

The machine allows for sectioning/cutting with up to 4 blades simultaneously, which is facilitated by its high-torque DC motor. This feature is especially beneficial for materials like brittle crystals and TEM samples.

These plates typically serve as base or support platforms during the cutting process, ensuring stability and minimizing potential damage or inaccuracies during sectioning.

Always wear appropriate safety gear, including safety glasses and gloves. Ensure the protective splash cover is closed during operation, and familiarize yourself with the emergency shut-off and safety features of the machine.

Dispose of used coolant according to local environmental and waste disposal regulations. Avoid pouring it down regular drains.

Yes, the LCD digital micrometer is waterproof, ensuring it remains functional and accurate even in wet conditions.

Once the cutting operation is complete, the saw will automatically stop, preventing unnecessary wear on the blade and ensuring safety.

The SMART CUT® 4005 typically comes with standard items included in the package. However, some minor assembly may be required. Always refer to the user manual for guidance.

The adjustable balance weight helps in maintaining consistent cutting pressure, ensuring precision and uniformity in the cut.

It is essential to match the blade to the material being cut. The machine offers various blade options depending on the application, including diamond, CBN, Silicon Carbide, and Alumina Oxide blades. Users can refer to guidance materials or consult with experts to determine the best blade for their needs.

The liquid-cooled cutting process and the coolant system minimize the risk of overheating. However, it’s always advisable to give the machine breaks during extensive cutting sessions and ensure the coolant is functioning optimally.

Yes, various replacement parts, from blade flanges to o-rings, are available. Users can contact the manufacturer or authorized dealers for more details.

The cutting speed of the SMART CUT® 4005 is continuously variable, but for safety and consistency, it’s best to adjust the speed when the machine is not actively cutting.

In the event of a power interruption, the machine will stop. Once power is restored, users should carefully inspect the machine and specimen before resuming operation.

While the SMART CUT coolant is recommended for optimal performance, users can utilize other coolants but should ensure they are compatible with the machine’s specifications and the materials being cut.

Yes, the SMART CUT® 4005 is designed with user safety in mind, and it incorporates safety features to protect against electrical surges or overload conditions.

OPERATING MANUALS

Download Operating Manuals

ACCESSORIES

Showing 1 – 2 of 2 results Showing all 2 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Name | Price | Quantity | Add to cart |

|---|---|---|---|---|

$30.00 | Max: Min: 1 Step: 1 | |||

$540.00 | Max: Min: 1 Step: 1 |

The machine also allows an option for sectioning/cutting with gang operation (several blades) cutting at the same time (up to 4 blades). Perfect for brittle crystals, ceramics, and TEM samples. The cutting process is liquid-cooled with the cooling liquid draining back continuously into the coolant tank.

When the cutting operation is finished the cut-off wheel stops and the specimen falls into a basket in the coolant tank thus protecting the specimen from drying and making retrieval easy. The coolant tank is very easy to remove and both the retrieval of the finished specimens and the cleaning of the coolant tank are therefore simple and straightforward.

SMART CUT® 4005 is Most Affordable Low Speed Sectioning Saw available on the market today. Providing equal Precision, Productivity and Versatility as well know Brand Name Low Speed Saws, at significantly lower price. Perfect for Production and R & D facilities on a Budget. Compare to any other Low Sectioning / Wafering Saw. START SAVING MONEY TODAY!

Features:

- Easy to operate with quick specimen fixation and size setting

- Designed for precision cutting of various materials

- Small, low-speed, precision cut-off machine

- Maximum specimen size: 30 mm diameter

- Continuously variable cutting speed

- Motor maintains constant speed under any load

- Specimen size accuracy of ±0.003 mm via LCD digital micrometer

- Adjustable cutting pressure independent of specimen weight

- LCD digital display shows exact cutting speed (RPM)

- Two-year limited warranty (excludes rusting and damage due to carelessness or neglect)

- Most affordable low-speed sectioning saw on the market

- Compatible with 3″ to 4″ (75mm to 101mm) diameter blades. One diamond or cbn wafering blade is included free of charge any specificaiton

- Automatic shut-off feature for unattended operation

- Includes components like adjustable balance weight, goniometric specimen holder, blade flanges, graphite and aluminum plates, wax rod for mounting, and AC power cord

- Suitable for both R&D and production facilities, especially on a budget

- Comes with a choice of one quart of SMART CUT® water-soluble coolant or mineral oil

- Supports gang operation with up to 4 blades cutting simultaneously

- Waterproof LCD digital micrometer for reliable operation in wet conditions

- Adjustable balance weight ensures consistent cutting pressure and precision

- Best Performance & Price Consumables provide best return on investment

Working Arm

Balance Weight

Two-dimension Clamp

Principal Shaft

Digital display for speed

Knob for adjusting speed

Power switch

Diamond blade

Door of Lubricating Water Trough

Position-Limit Switch

Sliding Seat

Micrometer

Lubricating Water Trough

Goniometer

This low-speed saw is equipped with an advanced goniometer and goniometric specimen holder, providing precise control over specimen angles during cutting, grinding, and polishing operations.

The goniometer allows the operator to adjust and measure the specimen’s angle accurately, ensuring optimal positioning for high-precision tasks. The specimen holder securely maintains the material at the desired angle throughout the process, preventing any movement or misalignment that could affect the result.

These features are essential when working with delicate materials, such as ceramics, glass, or composites, that require specific orientation during cutting to prevent stress or damage. The ability to set and maintain precise angles leads to improved cut quality, cleaner finishes, and better overall sample preparation. This is especially important in industries like semiconductor manufacturing, optical testing, or metallography, where exact angles are critical for achieving optimal results.

Unlike many standard low-speed saws, which focus on basic cutting functions, our machine incorporates the goniometer and specimen holder to provide the flexibility and accuracy needed for high-precision applications.

Gang Operation (4 blades cut simultaneously)

Machine offers an efficient blade setup that supports dicing multiple slices in parallel, significantly improving productivity and throughput. The spacious design accommodates blades with a 10mm thickness and a 60mm diameter, providing ample room to work with thicker and larger materials. This increased blade space allows for the simultaneous cutting of multiple slices in parallel, enhancing the machine’s ability to handle high-volume, high-precision tasks.

This feature is particularly advantageous in applications where large numbers of slices need to be processed quickly and accurately, such as in semiconductor wafering, thin-sectioning for materials research, or high-precision industrial cutting. The ability to dice multiple slices at once reduces the time spent on each job and increases overall output, which is critical for meeting production deadlines or scaling operations.

By allowing for multiple slices to be cut at once, the machine maximizes efficiency while maintaining the precise, clean cuts required for high-quality results. This capability is not commonly found in all low-speed saws, which are typically designed for single-slice cutting. The larger blade space combined with the goniometer and specimen holder offers a unique advantage for industries that need to process many slices in a single pass without compromising on accuracy or finish.

Cross Mount Vice

Cross mount vice on this machine is essential for securely holding the specimen during cutting, grinding, or polishing operations. It ensures that the material is tightly clamped, preventing any movement during the process. This is particularly important when working with delicate or brittle materials that need to be firmly secured to avoid shifting or damage. The vice allows for precise adjustments in both horizontal and vertical directions, enabling accurate positioning of the specimen relative to the cutting tool.

By allowing fine adjustments along both axes, the vice ensures that the material is aligned correctly, which is crucial for achieving precise cuts and consistent results. This feature is especially useful when performing complex or angled cuts, as it works in conjunction with the goniometer to position the specimen at the exact angle required for the task.

Additionally, the vice improves overall efficiency by enabling quick material setup and repositioning, which helps streamline the workflow and reduces downtime. The vice is versatile enough to accommodate various specimen sizes and shapes, allowing the machine to handle different tasks without requiring additional setup.

Mini Vice

Mini Vise (1 1/4″ x 3/4″ jaw width; 1″ max. jaw opening) is a standard feature on this machine, designed to provide precise clamping for smaller or more delicate specimens. Its compact size and functionality make it an ideal choice for tasks requiring tight, secure holding of materials that are too small for larger vices or clamps. The 1 1/4″ x 3/4″ jaw width allows for a firm grip on the specimen without causing damage or distortion, even during high-precision cutting or grinding operations.

The 1″ max. jaw opening ensures that the vise can accommodate a variety of small materials, from thin wafers to fine components. This feature is particularly valuable when working with fragile materials or when precise positioning of the specimen is crucial. Its small size makes it versatile for use in applications where larger vices may be too cumbersome or unnecessary.

The mini vise serves to securely hold the specimen in place while the operator adjusts for accurate cuts.

Digital Micrometer Head 1" Travel 0.003 mm accuracy

- Digital Micrometer Head

- Reads to 0.001 mm (50 millionths of an inch)

- 0.003 mm accuracy

- Instant inch/millimeter conversion

- Spherical face spindle

- Automatic power-off

- Water Proof, meet with IP54 standard

- Each unit comes complete with a SR44 battery (offers 1 year of life under normal use), key spanner, and operation manual

Position Thickness & Accuracy:

The cutting thickness of the material is precisely controlled through the use of a high-precision digital micrometer head, which offers 1″ travel and 0.003mm accuracy. This micrometer ensures that each slice is cut to the exact thickness required, providing consistent, reliable results across various materials. The digital micrometer head can read to 0.001mm (50 millionths of an inch), giving users extremely fine resolution for detailed measurements.

The LCD micrometer features a waterproof design, meeting the IP54 standard, ensuring it remains functional even in wet or harsh environments. Its instant inch-to-millimeter conversion allows for quick unit changes, making it versatile for different measurement needs. Additionally, the micrometer includes a spherical face spindle, which ensures uniform contact with the material, reducing errors caused by uneven surfaces.

With automatic power-off functionality, the micrometer preserves battery life and minimizes the risk of power loss during operation. It comes complete with a SR44 battery, which offers a one-year life under normal use, a key spanner, and an operation manual for ease of use and maintenance.

The thinnest cutting thickness achievable with this micrometer is 0.35mm, enabling precise slicing of even the most delicate materials. This ensures minimal material loss and maximum efficiency when cutting thin wafers, precision samples, or ultra-thin sections, especially for industries requiring high-quality cuts, such as semiconductor and optics.

Cutting Width:

The cutting width of the slice can be adjusted from 1mm to 24mm, offering versatility in various applications. By simply adjusting the LCD digital micrometer, users can control the cutting width with accuracy. The micrometer’s easy-to-read digital display makes it simple to make these adjustments with confidence and precision. Whether you need to slice materials into uniform thin strips or require varying thicknesses for different applications, the digital micrometer ensures that each cut adheres to the desired specifications. This feature is perfect for industries that require precise control over cut dimensions, such as in precision dicing, wafering, or sample preparation.

Enclosure (Optional)

The enclosure for a low-speed sectioning saw helps protects the operator from debris, coolant splashes, and particles, while containing toxic materials to prevent exposure. The enclosure also improves cooling and lubrication by directing coolant precisely to the cutting zone. Transparent materials in the enclosure allow for easy monitoring of the cutting process while maintaining safety.

It helps reduce noise, creating a quieter work environment, and contains dust and debris, minimizing cleanup. The enclosure maintains environmental control by preventing contamination and stabilizing temperature, ensuring consistent cut quality. By shielding the blade from environmental factors, it prolongs its lifespan and improves cutting precision.

Standard Package

What is included with each machine

| Part # | Standard items included on package | Qty. | Picture |

| UKAMLS01 | Low Speed Diamond Saw | set |  |

| UKAMLS02 | Adjustable Balance Weight with Shaft at Back Side | 1 |  |

| UKAMLS03 | Balance Weight at Front Side | 1 |  |

| UKAMLS25 v | Goniometric Specimen Holder 1001 | 1 |  |

| UKAMLS05 | One Pair of Blade Flanges, 35 mm dia. (1.4″) | 1 |  |

| UKAMLS021 | Mini Vise (1 1/4″ X 3/4″ Jaw Width; 1″ Max. Jaw Opening) | 1 |  |

| UKAMLS06 | One Pair of Blade Flanges, 46 mm dia. (1.8″) | 1 |  |

| UKAMLS07 | One Pair of Blade Flanges, 62 mm dia. (2.45″) | 1 |  |

| UKAMLS08 | Graphite Plate | 2 |  |

| UKAMLS09 | Aluminum Plate | 2 |  |

| UKAMLS010 | Wax Rod for Mounting Sample | set |  |

| UKAMLS011 | One Fuse, Two M4 Screws | 1 set |  |

| UKAMLS013 | AC Power Cord | 1 |  |

| UKAMLS014 | Screw Driver | set |  |

| UKAMLS015 | O-ring of Driving Motor | set |  |

| UKAMLS016 | 1 quart of SMART CUT water soluable coolant (advanced materials) formula or Mineral Oil (your choice) mix ration 1:20 (1 part coolant, 20 parts water) will make 5.7 gallons of coolant | 1 |  |

| UKAMLS017 | Lubricant Tub | 1 |  |

| UKAMLS018 | Collection Net | 1 |  |

| Select Right Wafering Blade for your application | 4″ x .012″ x 1/2″ Diamond or CBN Wafering Blade. Sintered (metal bond) any specification. How to select the Right Diamond Wafering Blade for your application >>> | 1 |  |

| 4BC1 | 4′ X .013″ X 1/2″ 1A8 diamond wafering blade. all diamond from OD to ID blade will work until there is nothing left from the blade entire OD is consumed (will typically last as much as 3 to 4) blades together | 1 |  |

| 4SicB | 4″ X .015″ (0.4mm) X 1/2″ Silicon Carbide cut off blade | 1 |  |

| 4al203 | 4″ x .015″ (0.4mm) x 1/2″ Alumina Oxide cut off blade | 1 |  |

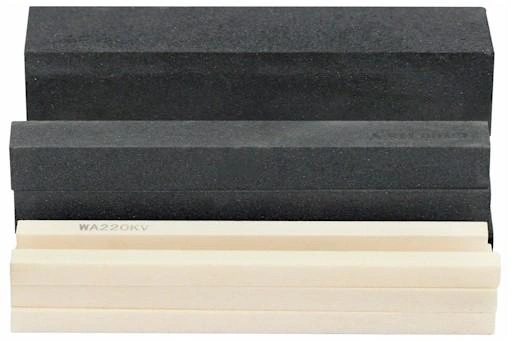

| Dressing Stick (1/2″ x 1/2″ x 6″) alumina oxide white color 120, 220, or 320 grit (depending on your blade selection) | 1 |  |

ACCESSORIES (Optional Not Included in the Price)

|

ACCESSORIES - Optional items (not included in the standard package) |

Quantity |

Picture |

|---|---|---|

|

90 Degree Cross Vise |

Optional |

|

|

Blade Spacer for Dicing Multiple Slices of Samples in parallel. 10 mm in Thickness; 60 mm in Diameter |

Optional |

|

SMART CUT® Coolants

Your choice of one (1) quart of SMART CUT® Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT® Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

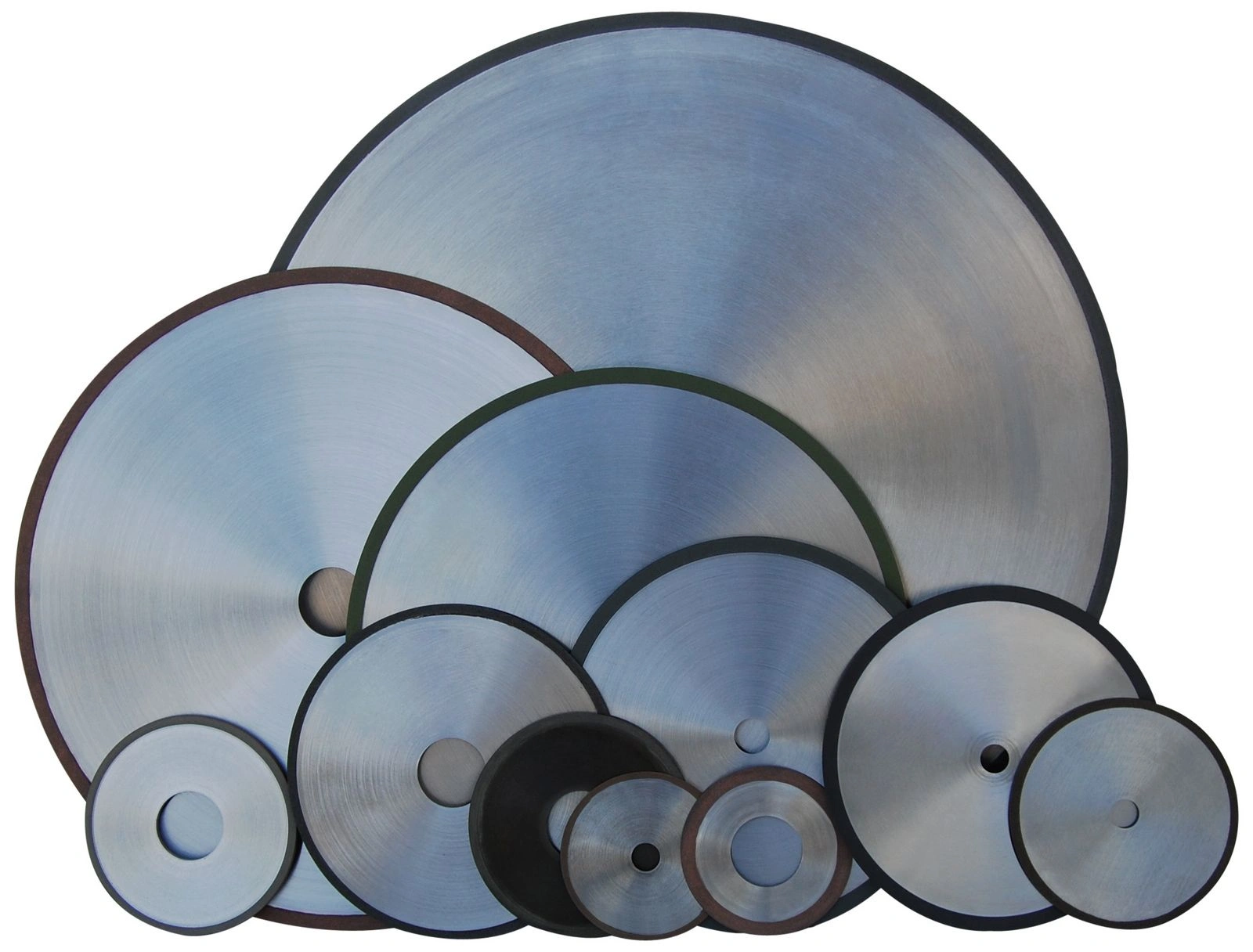

LARGEST SELECTING OF DIAMOND & CBN WAFERING BLADES AVAIALBLE

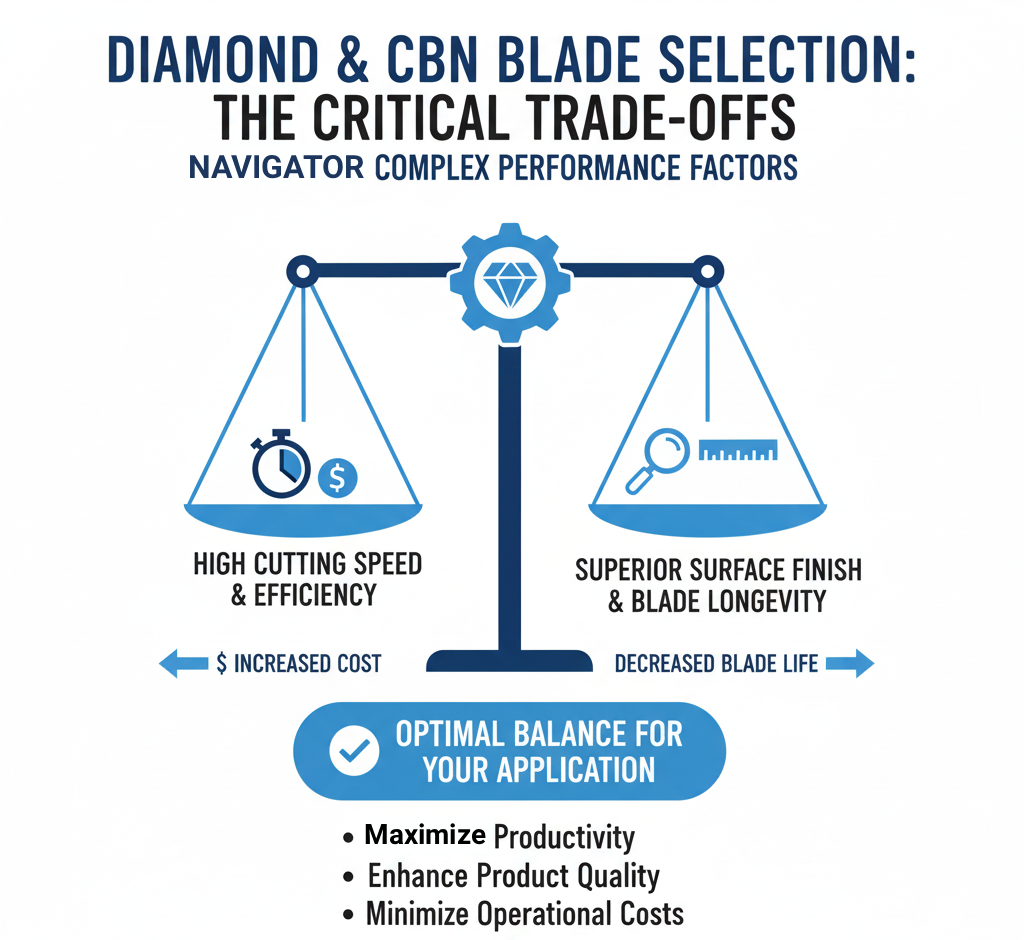

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

THE RIGHT DRESSING STICK FOR YOUR APPLICATION

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

SMART CUT® 6008 LOW SPEED SAW

Item # UKAMLS02 SMART CUT® 6005 – Low Speed Saw

Item # 8054010 SMART CUT® 6010 – Sectioning Saw

SMART CUT® 6035 – PRECISION CUTTING SAW

SMART CUT® 6040 – PRECISION CUTTING SAW

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Diamond & CBN Wafering Blade Case Studies

This study evaluates the cutting performance of SMART CUT® Diamond & CBN Wafering Blades compared to Conventional Wafering Blades under identical test conditions. The objective was to measure differences...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

02

Nov

Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...