-

0 items in quote

No products in the Quote Basket.

Sectioning

Large Diameter Resin Bond Cutoff Blades Between 250mm to 400mm.

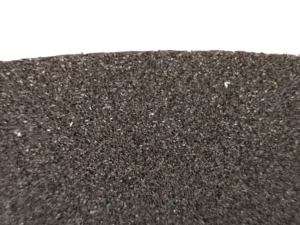

SMART CUT® Rubber Bond Abrasive Cut-Off Blades are expertly designed for metallography and sample preparation, blending advanced rubber bonding technology with high-grade abrasive materials. These blades are exceptionally well-suited for processing a range of materials, from ferrous and non-ferrous metals to delicate and brittle materials that demand meticulous handling to preserve their structural integrity.

Featuring an innovative rubber bond, these SMART CUT® Rubber Bond Abrasive Cut-Off Blades significantly enhance flexibility and shock absorption, which substantially reduces both vibration and noise during operation. This contributes to smoother operations and extends the blade's lifespan by minimizing the risks of cracks or breaks under stress. The cutting performance of the rubber bond is distinguished by its ability to make clean, precise cuts with minimal heat generation, thereby maintaining the unaltered metallurgical properties of the sample for precise analysis.

Crafted from sheets of natural rubber using the traditional calendered method, SMART CUT® Rubber Bond Abrasive Cut-Off Blades blades possess a unique composition that renders them ideal for high-quality, cool, burn-free sectioning on metallographic samples. We offer sample wheels tailored to meet your specific sectioning applications for evaluation.

Diamond Rotary Dresser

Diamond Rollers are used to form grinding wheels for many different kinds of mass production. Shorter dressing time and long tool life leads to high productivity and consistent process conditions. Many kinds of conventional grinding wheels, and in special cases super-hard grinding wheels, can be dressed with this dressing method. Dressing rollers can be classified under Diamond profile dressing rollers and Diamond form dressing rollers. Diamond profile dressing rollers are ued to share grinding wheels in shortest amount of time. Profile form dressing rollers are used to from simple and high complex profile contours.