-

0 items in quote

No products in the Quote Basket.

SMART CUT® 6020

Diamond / Abrasive Cut off Saw

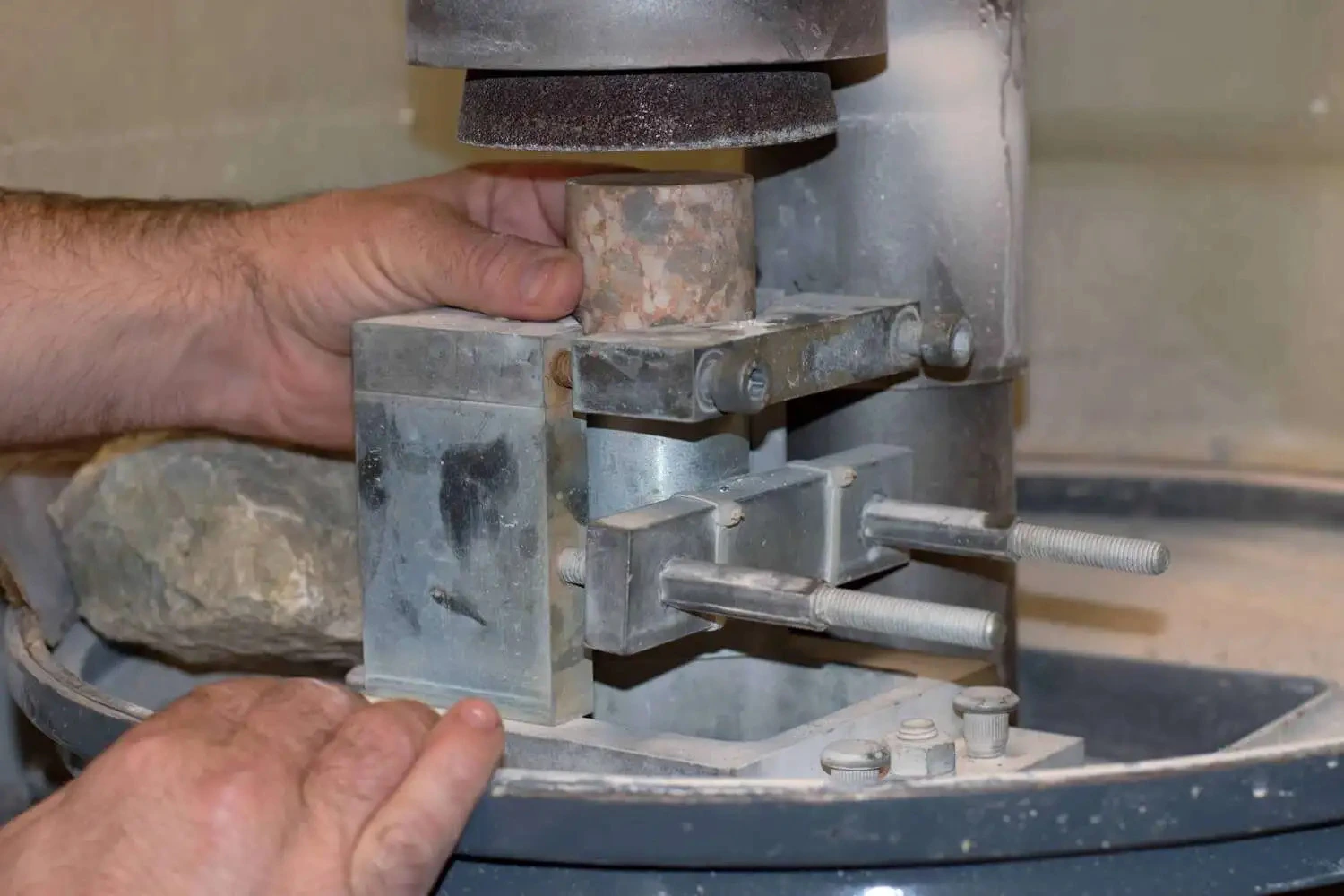

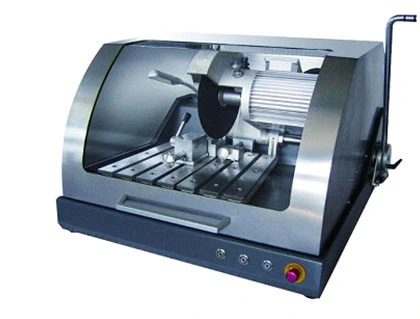

SMART CUT® 6020 is versatile manual diamond / abrasive cut-off saw designed for low to high volume applications. Designed for cutting large variety of materials such as ferrous & non ferrous metals, ceramics, glass, rocks, composites, & many others. Samples/Material is held in 2 off cam lock vices & cooled using the large recirculation tank to produce high quality metallurgical sections. It accommodates blades 10″ in diameter, allowing a wide variety of sample shapes and sizes up to 3.15″ (80 mm) thick to be sectioned.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

ACCESSORIES

OPERATING MANUALS

DESCRIPTION

A side port allows cutting of longer samples such as bar stock. Machine comes with recirculation tank and 2 cam lock vices. Additional holding fixtures are available for almost any application. Electronic Motor break system to stop the Motor and the cutting wheel immediately once the Cutting is stopped (also comes standard/included in the price). This machine is available as a bench top unit or with full floor standing base unit (which is included in the price). The large workspace and versatile vising options, this bench top abrasive cutter’s simple design enables quick and easy positioning for rapid sectioning of large variety of materials / samples. Machine can be used with large variety of Abrasive Cut off Blades, Diamond & CBN Cut Off Blades, & other types of blades. Variable speed option is available from 1,000 to 3,500 RPM’s to cut just about any type of material. The manual feature of this bench top abrasive cutting machine allows you to “feel” the cut quality.

SMART CUT® 6020 features the large cutting window for this class of bench top manual abrasive cutting machine as well as bright yet energy efficient LED lighting. This enables highly visible, clear, and unobstructed viewing of samples, cut location, vising, and cut progress. Perfect for Manufacturing and R & D Organizations on a Budget

SPECIFICATIONS

- Rust proof Steel construction

- 3HP (2.2 k.w), 3 Phase Motor

- Cutting capacity up to 80 mm(Standard size) for standard steels (may not be applicable to all the materials)

- Corrosion Resistant Cutting Chamber for a long product lifetime

- Motor Speed 2800 rpm

- Cut-off wheel size up to 10″ (250 mm)

- Wheel Flange Size 32mm

- Simple Control Panel with 4 Switches – Start, Stop, Coolant, Tube light and Emergency Stop button with Key and Safety Switch

- Ergonomic Cutting Handle

- Easy Flow Cutting Chamber

- Splash Proof, corrosion resistant with see through hood

- Cooling by two water jets to provide optimum cooling

- Inbuilt movable recirculation coolant tank with 50 liters capacity

- One large drain for coolant recirculation

- 1/3 HP Coolant Pump

- Small opening in the side wall for long jobs

- Safe and clear illumination LED Light

- Cam-lock Vise Set

- T Slot Bed: 60mm x 190mm with 8mm T-Slot

- Voltage: 415V/50 Hz (L1+L2+L3+N+E)

- Machine Size : 750x850x1550mm (LxDxH)

- Machine Weight: 170kg

ADVANTAGES

- Ergonomic cutting handle

- Cam vise set

- Large drain for coolant recirculation

- Rust proof Steel construction

- Start button with key for safety

- Easy Flow Cutting Chamber

- Fluorescent light in the working area provides

- Small opening in the side wall for long jobs

- Safe and clear illumination

- Cooling by two water jets to provide optimum cooling

- Corrosion Resistant Cutting Chamber for a long product lifetime

- Simple Control Panel with 4 Switches – Start, Stop, Coolant, Tube light and Emergency Stop button with Key and Safety Switch and Amp Meter

- Sturdy floor model cutter for Metallographic sectioning Metals, Ceramic and mineral samples

- Splash Proof, corrosion resistant with see through hood

- Inbuilt movable recirculation

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

Bream Motor system is a feature to stop the Motor and the cutting wheel immediately once the Cutting is stopped metal. This is now standard feature that comes included in standard package (cost of the machine) free of charge

This is an additional Safety Feature that prohibits the operator from opening the Door of the cutting chamber unless the cutting process has stopped. This is one of the most popular add on features and is highly recommended

Yes we work with large variety of material holding fixture manufacturers and also can produce in-house large variety of custom material holding solutions based on your requirements.

You are welcome to send us your material sample; we can cut it per your instructions and provide a video of the process. Depending on the application a small fee may be

assessed for the test cutting which is reimbursable upon purchase of the machine

minimum material thickness machine can cut is 10mm or tube 5mm diameter. This machine is designed for larger metallurgical or ceramics, composite, glass, plastic samples. For very small diameter and fragile samples we have other precision table top cutting machines available for this application

Maximum diameter this machine can hold is 80mm (3.15mm) diameter. The machine also comes with a side port to accommodate longer materials/samples that do not fully fit into the cutting chamber

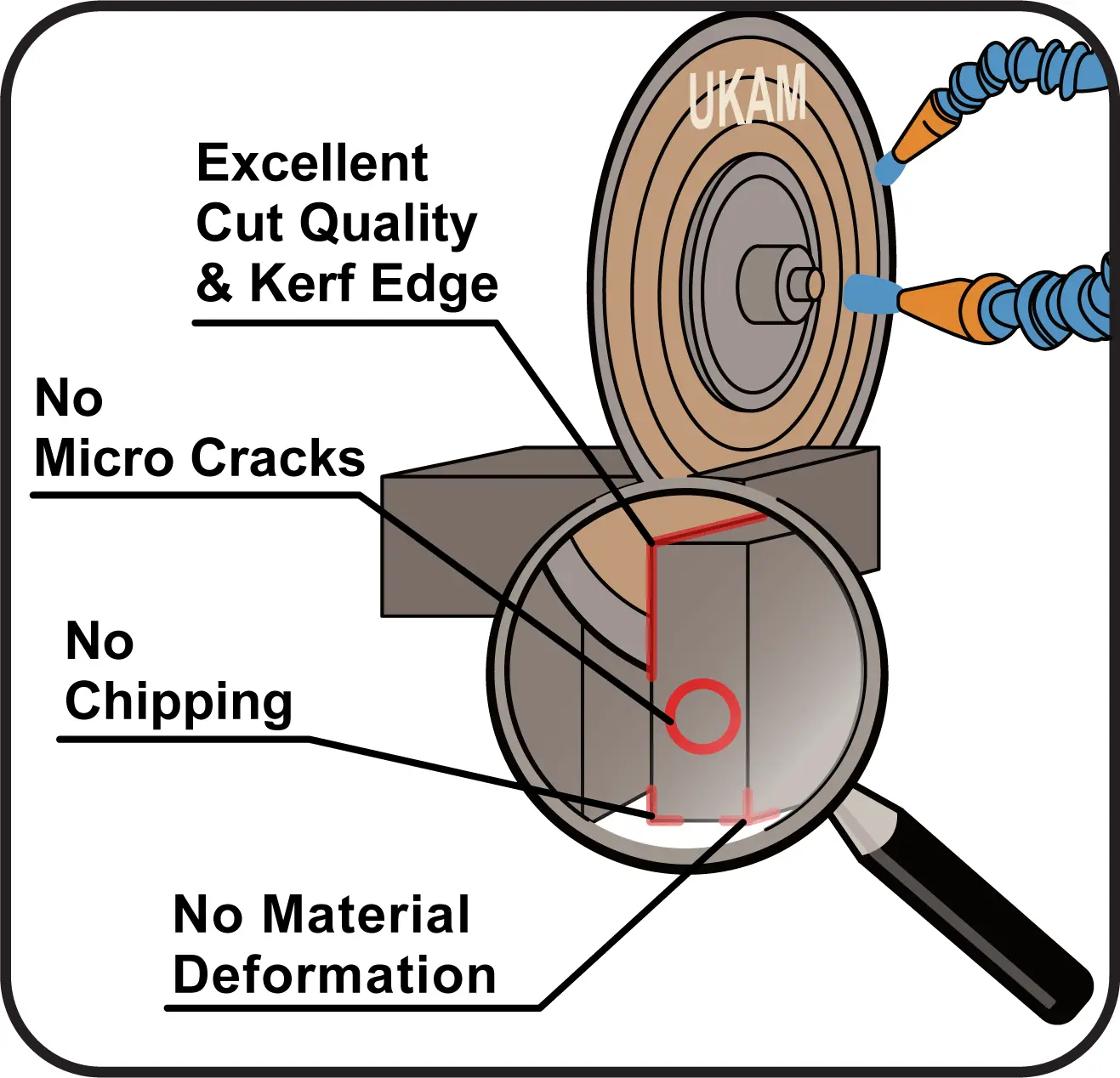

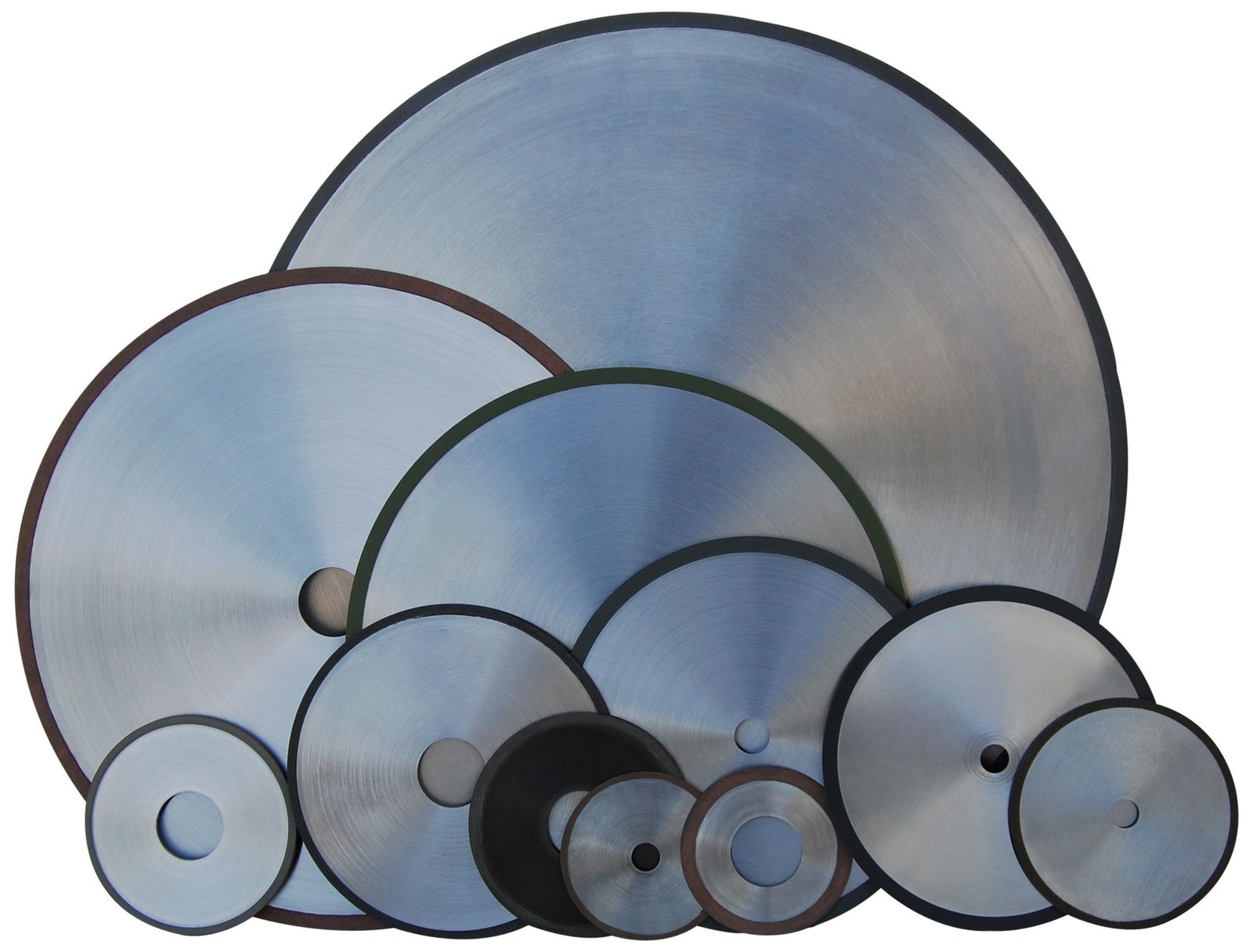

Cut quality will highly depend on selection of the right blade for your application. Other important variables, listed in order of importance are; selecting the right RPM range for your material, selecting the right coolant, selecting the right vise/sample holding fixture, feed rate, and cutting method. Abrasive cut off blade are available in alumina oxide and silicon carbide and are used for sectioning most ferrous and non ferrous metals. Diamond & CBN cut off blade are also available and will provide much longer life and e best cut quality and the least amount of deformation with the majority of ultra hard and brittle materials, as well as glass and optics applications. Nickel bond blades provide the best quality of cut with soft and gummy materials such as composites, fibers, and soft metals.

This depends on material diameter, shape, composition, hardness. Most material samples can be cut in just a few minutes with no material deformation.

This machine uses a manual lever to push the motor and blade into the material hold together in place by vice or other fixture. The blade comes down on the material and the operator is able to “feel the cut”. Automatic feed for the Z axis is available as on option for this machine

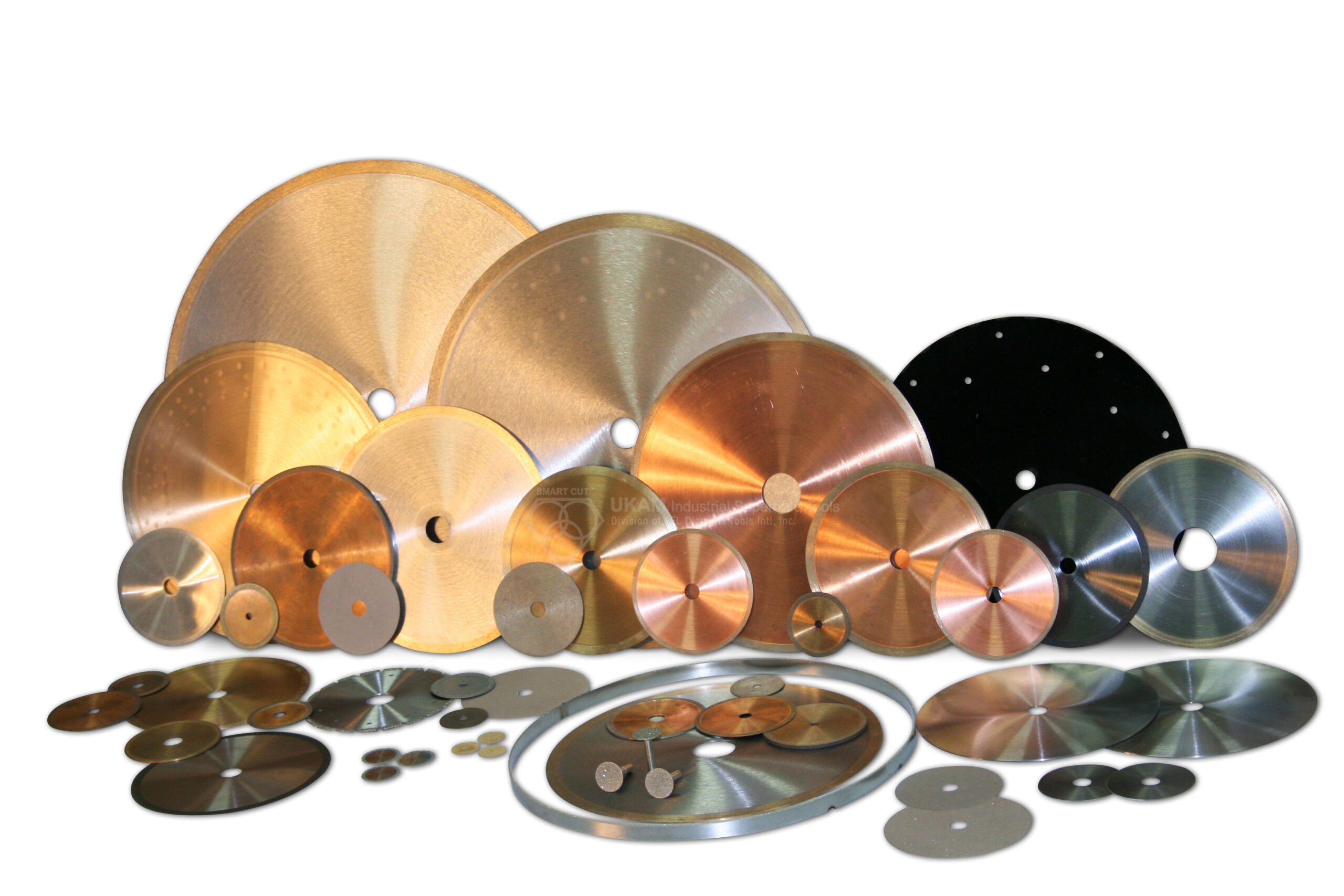

Yes, any blade that has an outside diameter from 8” to 10″, thickness from .032″ (0.8mm) to .080” (2.0mm) and 1.25″ or 32mm inside diameter will work on this machine regardless of who the original supplier/manufacturer is.

Yes, you can use any blade type on this machine as long as it fits into the table slot. Again, blades with an outside diameter from 8” to 10″, thickness from .030″ to .080″, and 1.25” or 32mm inside diameter can be accommodated. Make sure to use the appropriate RPM and coolant that is recommended for that blade spec.

package of 10 abrasive cut off wheels or One (1) diamond/cbn wafering blade is included free of charge with the purchase of any machine. You can select any blade diameter this machine can accept which is between 8 and 10″, any thickness, bond type, diamond size, concentration, etc. You can choose the blade that is best suited for your

Blade cost depends on blade diameter, bond type, and diamond type. Blade cost varies from as low as $20 to $250 depending on the blade diameter bond type, abrasive/diamond type, thickness & specification. Abrasive Cut off wheels cost very little, followed by diamond cut off wheels and CBN cut off wheels. For diamond Resin bond & CBN blades cost more that sintered (metal bond) diamond cut off blades, and Nickel bond cut off blades cost less than all of their counterparts.

Blade life depends on material hardness, density, porosity, abrasiveness, material diameter & geometry, RPM, coolant, feed rate, experience of the operator, & the angle material is introduced into the cutting area. Typically blade life is shorter on hard, very dense materials such as silicon nitride and very abrasive materials such as sandstone.

Most often required spares for most clients: 1. Vise, 2. LED Light, 3. Coolant Jet, 4. Start & Stop Push Button, 5. Door Damper. These and all other spare parts are available in stock

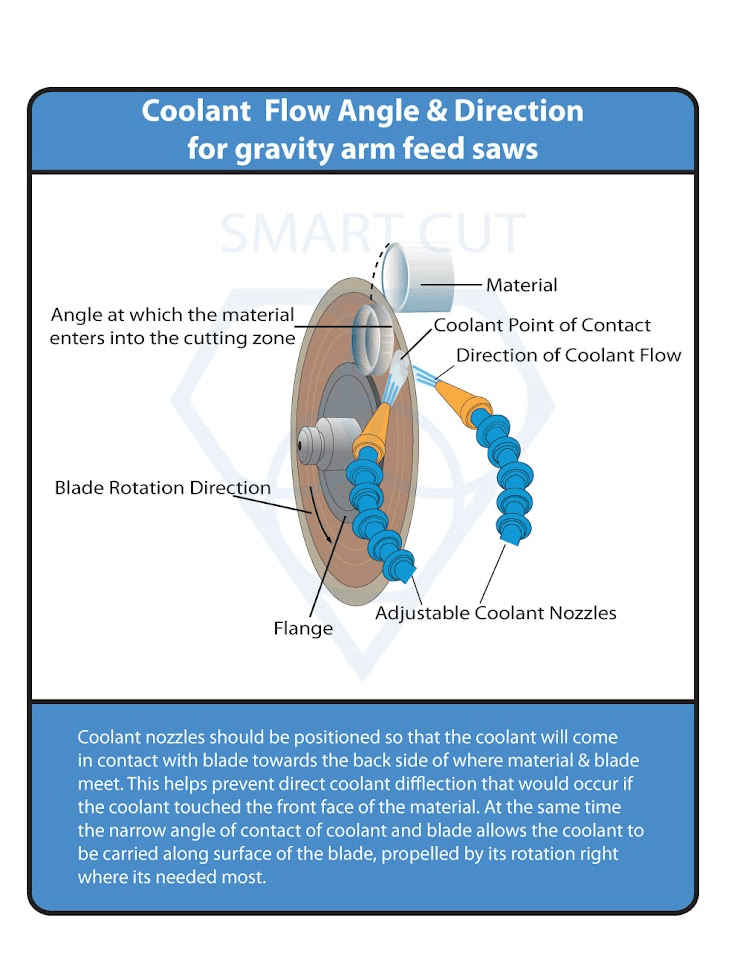

There are two coolant nozzles that provide consistent coolant pressure to the cutting zone. The coolant nozzles position can be adjusted as needed

The distance between blade and motor is 138mm. Allowing for longer parts to be sectioned on this machine.

Yes financing & leasing options are available through a third party to qualified applicants in North America

MGM – Varvel Italy (very popular and widely used motor manufacturer)

When used with our full enclosure cover, the operator and surrounding environment will be safe from any coolant splash or micro material particles exiting the cutting area.

Any type of coolant such as synthetic (water soluble) oil, other oil based coolants, and water can be used with the machine (although not recommended as it has no rust prohibitors). Machine also can be used without coolant

We recommend stopping every hour minutes and let the machine cool down for a few minutes. If the machine is used for very large periods of time without interruption (such as 2+ hours), the motor can burn out and/or other parts of the machine can be adversely

How easy is it to learn how to use this machine? (What skills or training should the operator have?)

The SMART CUT 6020 is very straight forward and easy to use. No machining knowledge or experience is required, just basic understanding of safety rules and the materials being cut.

This machines offers similar features as standard laboratory abrasive cut off saws such as Buehler, Struers and Leco at significantly lower price. The machine comes standard with many features that our competitors would charge for every option. We strive to provide the best value possible for our clients

We do not utilize outside sales representatives in order to maintain smaller overhead, and hence pass down the savings to our clients in the form of lower prices for our machines and consumables. We find that direct sales and technical support from our trained technical and engineering staff in our location is far more knowledgeable and superior than any outside sales rep can provide. If you would like to view this machine in operation for your particular application, feel free to send us your material with cutting instructions. Test cutting will be done to your satisfaction and filmed. The video will be uploaded to Youtube for your private viewing.

Two (2) years parts and labor. All repairs to be done at out location in Valencia, CA USA, or if needed we can send the parts to you. The warranty does not cover machine

damage due to misuse or neglect.

No formal training program is available at this time, however if needed, we can provide simple training for any of your staff at our location for a fee.

Our technical and engineering staff has many years experience in working with a large variety of materials and applications. What is considered “new process development” for some organizations is just another days job for us. We do our best to share our experience with our clients and help solve even the most difficult cutting challenges free of charge. However, if we find that your application requires a lot of engineering time, and/or testing, this can be done on a fee basis that depends on time spent, or a flat fee. We will provide a quote for these services before engaging in the project.

Our client base spans over 22 different industries and 40 countries around the world. Clients include everything from Fortune 500 companies, to one-man labs/shops, as well as space & science organizations, universities, national laboratories, commercial labs, aerospace manufacturers, packaging suppliers, steel companies, automotive manufacturers, bio science companies, medical device manufacturers, dental implant companies, hospitals, fish & wildlife organizations, material research, advanced and nano technology entrepreneurs, and much more.

We offer our best prices (same prices) to all of our clients regardless of their size, stature, or affiliation. You will find our prices are very competitive in the marketplace

ACCESSORIES

OPERATING MANUALS

Download Operating Manuals

Base Cabinet/Stand Included with machine

SMART CUT® 6020 is comes cabinet/stand with space to accommodate the recirculation tank and tools. You can use without the cabinet/stand, but it comes already included in the price.

Recirculating Coolant Tank

Recirculating Coolant Tank fully integrates with SMART CUT® 6020 machine & has a powerful pump for excellent cooling during cutting & is included w mahcine

3 Coolant Nozzles

Machine features 3 adjustable coolant nozzles to make sure sufficient coolant pressure is provided to the cutting zone

SMART CUT® COOLANTS

Your choice of one (1) quart of SMART CUT® Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT® Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

LARGEST SELECTING OF DIAMOND &

CBN WAFERING BLADES AVAIALBLE

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

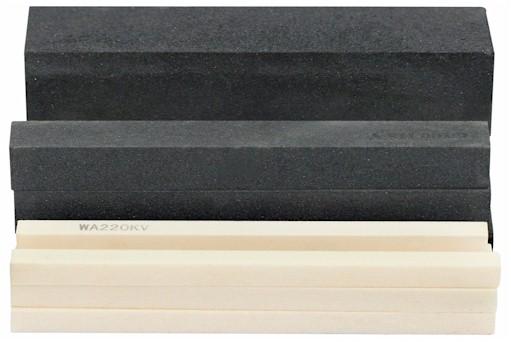

THE RIGHT DRESSING STICK FOR YOUR APPLICATION

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

SMART CUT™ 1010 – Diamond/Abrasive Cut Off Saw

SMART CUT® 1030

SMART CUT® 1035

SMART CUT® 1050

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and applications....

02

Jun

Diamond Wire Advantages & Application

Diamond Wire saws provide the most accurate cutting with the least amount of material deformation and chipping of material.

Share this Article with Friend or Colleague

HOW DIAMOND WIRE WORKS

Today diamond wire sawing is preferred by majority...

02

Jun

Troubleshooting Diamond Sawing Problems

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application, we...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering blades,...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high accuracy. To...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to understand...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use