Diamond Core Drills & Tools for Glass & Quartz Industry

Diamond Core Drills & Drilling Tools for Glass & Quartz Industry

Diamond Drills, Tools & Accessories from .001" to 48" in Diameter.

UKAM Industrial Superhard Tools is a Leading Manufacturer a full range of Diamond Core drills, Drilling Tools from .001" to 48" Diameter, for drilling just about any type of Glass & Quartz Materials.

Diamond Drills, Tools, & Accessories are available from inventory in many different specifications, outside & inside diameters, drilling depths, bond types, diamond mesh sizes, mountings, & tolerances. Custom Manufacturing to fit your particular requirements with 1 week or less lead time (non minimum order)

Glass & Quartz Materials

- Soda Lime Glass

- Borosilicate Glass

- Ceramic Glass

- Quartz Glass

- Pyrex

- Stained Glass

- Art Glass

- Glass Assemblies

- Float Glass

- Fused Silica/fused Quartz

- Automotive Glass

- Flat Glass

- 1737f

- B270/crown Glass

- Automotive Glass

- Hollow Glass

Stock

Thin Wall Diamond Core Drills

105DE SMART CUT® Series

105DE SMART CUT® Series Thin Wall Multi-Layered Electroplated Diamond Core Drills, Manufactured by UKAM Industrial are Multi Layered. They have 3 layers of diamonds, not just 1 layer of diamonds like conventional electroplated drills. This provides longer drilling life, smoother surface finish, faster and freer drilling action, & more consistent performance.

100DE SMART CUT® Series

100DE SMART CUT® Series Thin Wall Multi-Layered Electroplated Diamond Core Drills, Manufactured by UKAM Industrial are Multi Layered. They have 3 layers of diamonds, not just 1 layer of diamonds like conventional electroplated drills. This provides longer drilling life, smoother surface finish, faster and freer drilling action, & more consistent performance.

115DE SMART CUT® Series

Thin Wall Diamond Core Drills, Sintered (Metal Bond). UKAM Industrial Superhard Tools Sintered (metal bond) Diamond Core Drills are the Finest Quality Diamond Core Drills manufactured in the world. Diamond held in a metal matrix bond for drilling, glass, alumina, quartz, ruby, yag, silica, silicon, graphite, composites and other hard abrasive non metallic ceramics. Wall Thickness: 1.2mm (.047”) provide, long lasting, faster drilling (RPM), and minimum heat generation performance.

120DE SMART CUT® Series

SMART CUT® Thin Wall Diamond Core Drills – the ultimate solution for precision drilling in hard materials. These sintered (metal bond) diamond core drills are engineered to provide unmatched performance, durability, and efficiency, They can be used in almost all diamond drilling application ranging from very soft & abrasive materials to ultra hard materials.

SMART CUT® Diamond Bottoming / Non-Coring (no core formation) Diamond Drills with 5/8-11” Female Thread

SMART CUT® series high precision tolerance and accuracy non core formation sintered (metal bond) diamond drills. Each Diamond Core Drill steel body is machined from a single piece of steel on high precision CNC machine. This provides Very Precision Tolerances, Accuracy, & Consistency. Diamond Height (depth) of 10mm, insure that these drills provide highest possible diamond drill life in industry

Stock

Heavy Wall Diamond Core Drills & Other Tools

SMART CUT® 135DB

MART CUT® 135DB Braised Bond Diamond Core Drills & Non Core Formation Drills with a 5/8-11″ Female Thread – the ultimate solution for precision drilling in a wide range of materials. These high-quality core drills can be used both wet or dry and are designed to meet the demanding needs of professionals and DIY enthusiasts alike, offering exceptional performance and durability.

SMART CUT® 140dm Diamond Core Bits / Drill Bits For Concrete & Allied Materials (Wet Only)

Drilling Life: 650+ holes* on most materials. 30% more Diamond than conventional drills. Diamond Drill life will vary depending on material, drilling depth, coolant & drilling equipment used as well as operator experience.

SMART CUT® Diamond Counter Sinks Multi Layered Electroplated

Used to create conical holes, expanding existing holes, breaking corners and chamfering holes and polishing existing holes in a large variety of materials. Available from stock in many specifications and we can also custom manufacture to fit almost any application/requirement.

SMART CUT® Diamond Carving Points

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond carving points. These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms, milling, deburring, Thread grinding.

Stock

Diamond Minature Drills

SMART CUT® 025DTE

MINATURE TWISTED ELECTROPLATED DIAMOND SOLID DRILLS

Twisted diamond drills are typically used for drilling pearls and enlarging/reaming holes in large variety of other materials. Provide faster drilling speeds, than most other type of diamond drills. Also very popular for drilling pearls.

SMART CUT® 020DHE

MINATURE ELECTROPLATED DIAMOND HOLLO CORE DRILL

The hollow core shape provides extra stability for deep drilling. Available from stock in 1mm to 3.5mm OD. Electroplated miniature hollow core drills consists of steel tube with diamond coating on the tip These are available in stock from 1mm to 3.5mm diameter. These must be used for drilling completely through the material. The hollow core shape provides extra stability for deep drilling applications and can also be used for extracting very small and thin diameter cores from materials such as rocks, ceramics, glass, composites, bone metals and many others. The shank diameter is slightly smaller then Diamond Core Drill outside diameter. Custom manufacturing is available. We can produce the miniature plated hollow core drills in any diameter, drill depth, wall thickness, diamond grit size to better fit your particular requirements

SMART CUT® 015DSE

SMART CUT Series 015DSE Multi Layered Electroplated solid drills are flat cylinder shape with transition angle. These miniature diamond drills have high diamond concentration and give a smother, faster drilling action with minimum heat generation. The multiple layers of diamond coating which provides best diamond adhesion in the bond matrix. This provides longer life span, compared to standard and comparable electroplated miniature drills. Higher level of consistency and better surface finish. Most popular type of diamond drills for drilling small holes for jewelry (stone, glass, & many other materials). Multiple layers of diamond provide longer drilling life, faster & freer drilling. Available from stock from 0.75mm to 2.5mm

SMART CUT® 030DSM

METAL BOND (SINTERED) DIAMOND SOLID DRILLS

SMART CUT 030DSM, Metal Bond (Sintered) Diamond Solid Drills have hundreds of layers of diamond impregnated inside the metal matrix. Will last significantly longer than electroplated diamond solid drills. Recommended for drilling Ultra Hard Materials (harder than 8 on mohes scale or 60 on Rockwell Scale. Available in stock from 0.8mm to 6mm diameter.

Stock

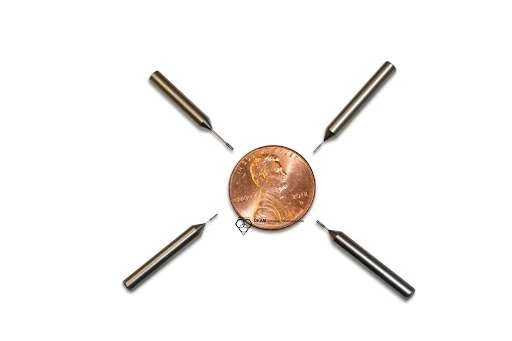

Diamond Micro Drills

SMART CUT® 010DME (SMCDU) Diamond Micro Drills

SMART CUT 010DME diamond micro drills are produced using electroplated (nickel bond) galvanic plating process. These tools can be used for drilling and machining large variety of materials such as Precision Optics, Silicon Carbide, Boron Nitride, Boron Carbide, Alumina Ceramics, Silicon, Sapphire & Yag, Glass, Quartz, & Pyrex Tubing & Many Other Applications.

SMART CUT® 005DME (MCDU) Diamond Micro Drills

SMART CUT 005DME diamond micro drills are produced using electroplated (nickel bond) galvanic plating process. These tools can be used for drilling and machining large variety of materials such as Precision Optics, Silicon Carbide, Boron Nitride, Boron Carbide, Alumina Ceramics, Silicon, Sapphire & Yag, Glass, Quartz, & Pyrex Tubing & Many Other Applications.

SMART CUT® Diamond & CBN Micro Drills, Sintered (Metal Bond)

SMART CUT® sintered (metal bond) diamond&cbn micro drills are used for drilling larger variety of materials. Sintered (Metal Bond) Drills will outlast nickel bond (electroplated), PCD, CVD, carbide and all other drills by as much as several hundred times and retain its edge form and geometry. While provide high degree of consistent performance even for ultra hard and superhard materials, and minimum chipping. In addition to drilling microscopic holes these also can be used for milling and grinding. Used on High Speed Air Spindles and other high speed machining equipment. These micro Tools are available in diamond and cbn.

Custom Tools

Diamond Micro & Minature Core Drills

SMART CUT® MICRO & MINATARE DIAMOND CORE DRILLS

SMART CUT® Micro & Minature Diamond Core Drills, are sintered (metal bond) are designed for drilling very small diameter holes in large variety of ultra hard and brittle materials. Such as drilling glass, optical glass, silicon, ceramic, piezo, sapphire and other crystalline materials. CVD Diamond Micro Drills & tools consists of a microcrystalline thin film of evenly distributed diamond particles of 3-6 μm on tungsten carbide substrate. The CVD diamond layer extends the life a carbide micro drills & tools by 12 to 20 times longer, which decreases downtime due to fewer tool changes

SMART CUT® Micro & Minature Core Drills

Micro & Minature Sintered (Metal Bond) diamond core drills are producted with almost any outside or inside diameter starting from .018" (0.45mm), with almost any type of mounting type. These can be used for deeper drilling or coring samples & many other applications.

Custom Tools

Diamond Routers, Diamond Points, Profile Tools, & Milling Tools

Large variety of diamond & cbn tools from stock and made to your specifiction using all bond types. Products include:

- Carving Points

- Mounted Points

- Diamond Counter Tools

- Grinding Pins

- Routers

- ID Grinding Points

- Jig Grinding Mandrels

- Countersinks

- Counter Bores

- Milling Tools

- Generating Tools

- Face Grinding Tools

- Chamfer Tools

- Radius Tools

- Profiling Tools

- Ball Nose Tools

- Ball Nose Tools

- Bottom Grinding Tools

- Reamers

- Honing Tools

- Honing Tools

- Endmills

- Threading Tools

STOCK

Drilling Accessories

Water Swivel Adapters

Water Swivel Adapters (also known as drill head assemblies) are to supply high water, coolant, or air through the center of your diamond drills. Water Swivel Adapters/Drill Head Assemblies cools both diamond drills and material in zone of drilling.

Dressing Sticks

Dressing Sticks are available from stock to fit all types of diamond, cbn, abrasive wafering & cut off blades and sectiong saws. Such as Buehler.

Shank Adapters

Fits into drill press chuck allows the diamond drill to fit into drilling machine chuck or collets available with 3/8″

Drilling Templates

Drilling templates allow minimize drill vibration, makes sure proper positioning of the drill, insuring accuracy and minimum chipping. These are

DIMOND CORE DRILLS & OTHER TOOLS

Custom Manufacturing Capabilities

Have a Unique Requirement?

Let Us Make Custom Diamond Drill Or Tool Specifically Designed For Your Application/ Requirements Just About Any Diamond/Cbn Can Be Designed And Manufactured Per Your Drawing Or Specifications

No Minimum

Order Quantity

Fast Lead

Times

Precision Tolerances

Free

Consultation

Limitless

Possibilities

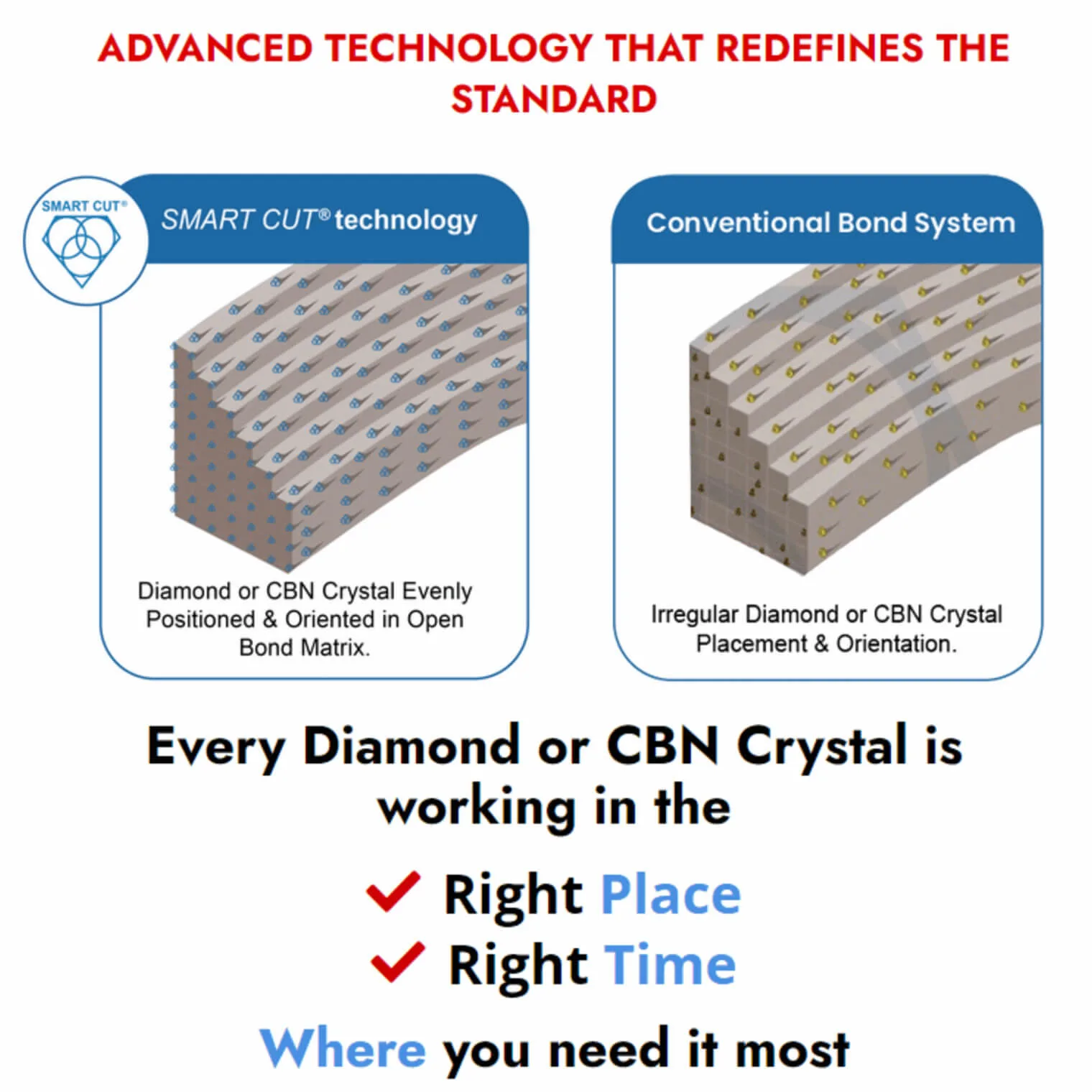

SMART CUT® technology

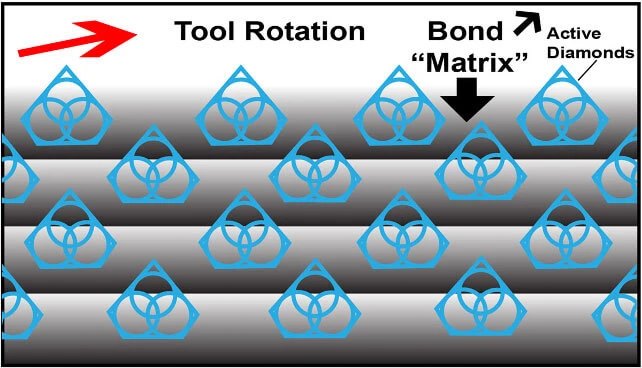

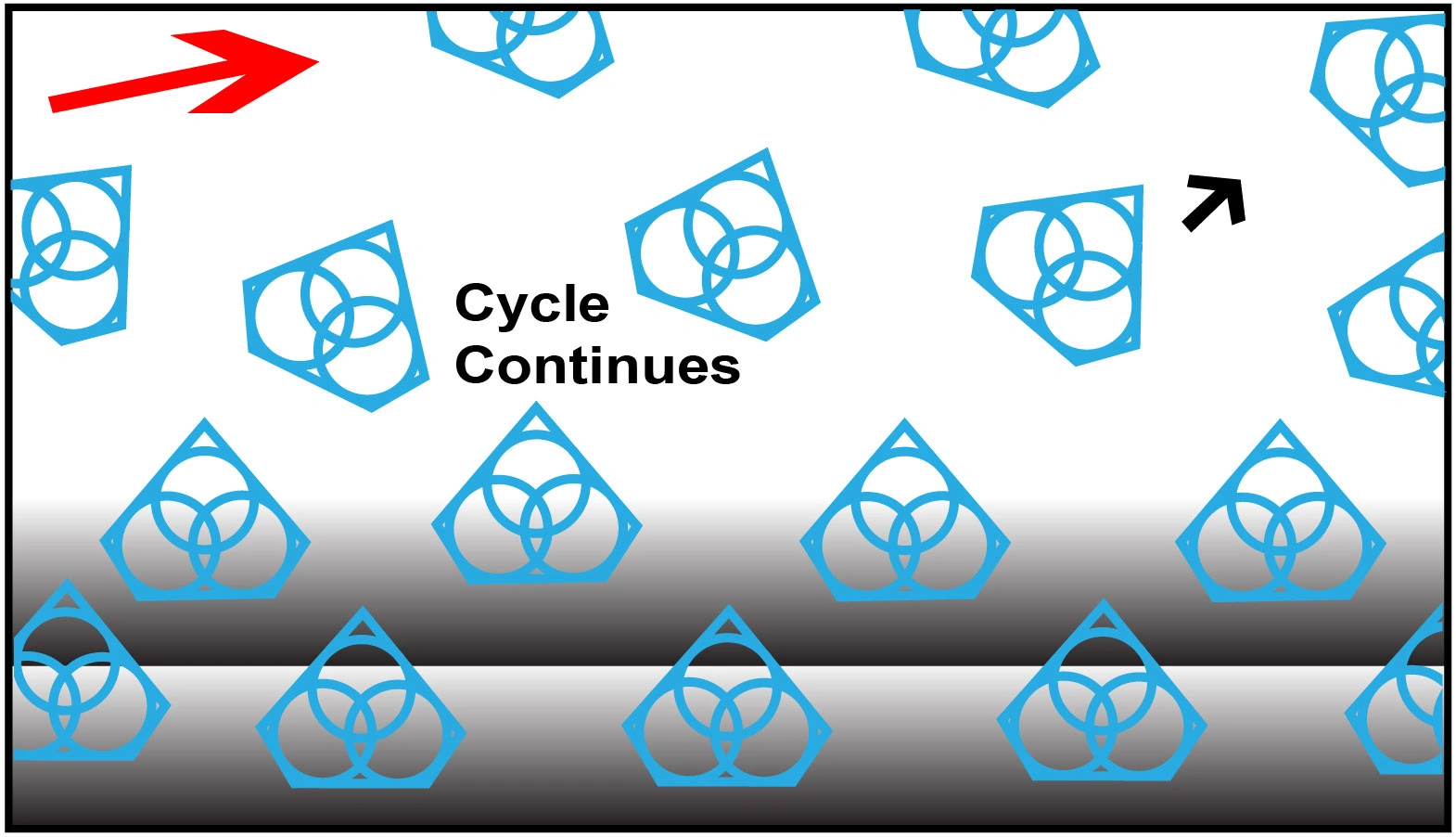

How SMART CUT ® Bond Works?

Sharpest And Finest Quality Diamonds

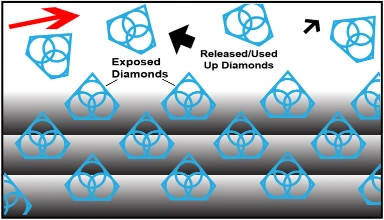

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superiror Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

- Custom Manufacturing

- Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

We understand that your success depends on select the right diamond & CBN blade, and optimizing your parameters to best fit your applications/needs.

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Diamond Drills & Tools in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary drill chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect drill life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after drilling.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools