Menu

-

0 items in quote

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® GEO TRIM SAW can help trim the Geological specimen to the required shape and size. This Table top Machine is convenient for quick sectioning the sample to get the final convenient size in the required plane. It is suitable to slice 3 samples at a time. Slide mounted samples also can be cut into thinner sizes using vise holders.

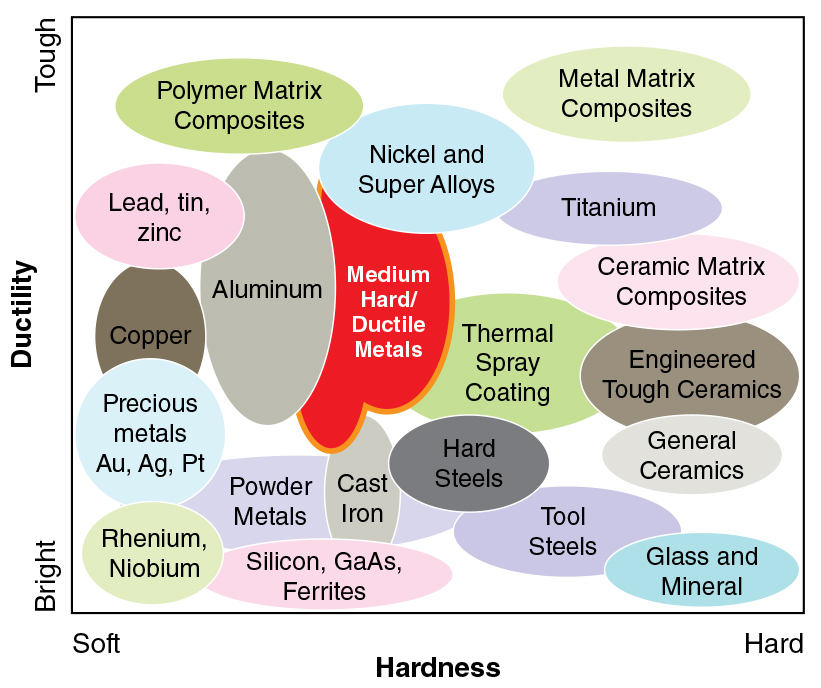

SMART CUT® 6070 Thin Section & Geology Cutting Machine / TRIM SAW is a robust tabletop cutting machine designed for applications requiring advanced thin-section preparation methods. Ideal for sectioning rocks, bricks, and stones, this versatile machine supports diamond wheels ranging from 8 to 10 inches and includes a water-cooled system for efficient cutting. The saw features a cutting capacity of up to 60 mm and is capable of producing cuts as thin as 500 microns, thanks to its continuously variable speed system, adjustable between 100 and 3000 RPM.

Equipped with a powerful 1/2 HP motor, SMART CUT® 6070 incorporates several user-friendly features, such as a built-in micrometer for precision adjustments and a manual longitudinal “Y” cutting action for enhanced control. The corrosion-proof stainless steel construction ensures durability, while the machine’s design accommodates diamond cut-off blades with a wheel mounting shaft of 31.75 mm in diameter. Safety is prioritized with an emergency stop button, a door safety limit switch, and other protective measures.

The included vacuum chuck and pump system, complete with a filter, securely hold glass slides of varying sizes, allowing for precise and stable cutting. The machine’s compact dimensions (560 mm x 650 mm x 410 mm) make it an excellent addition to any laboratory or workspace.

SMART CUT® 6070 offers reliable performance and precision in geological sample preparation, ensuring high-quality results in every application.

Smart Cut Trim GEO used in areas of application where advanced Thin Section Preparatory method is required Trim Geo works as a platform for samples with water cooling system.

INDUSTRIES USED IN:

Ferrous & Non-Ferrous Metals:

A Vacuum chuck with a Vacuum Pump with filter system is provided with the machine to hold different sizes of glass slides. These glass slides are held onto the chucks and moved across for Cutting

Your choice of one (1) quart of SMART CUT® Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT® ® Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT® coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT® KOOL lowers friction and surface tension, which increases swarf dispersion.

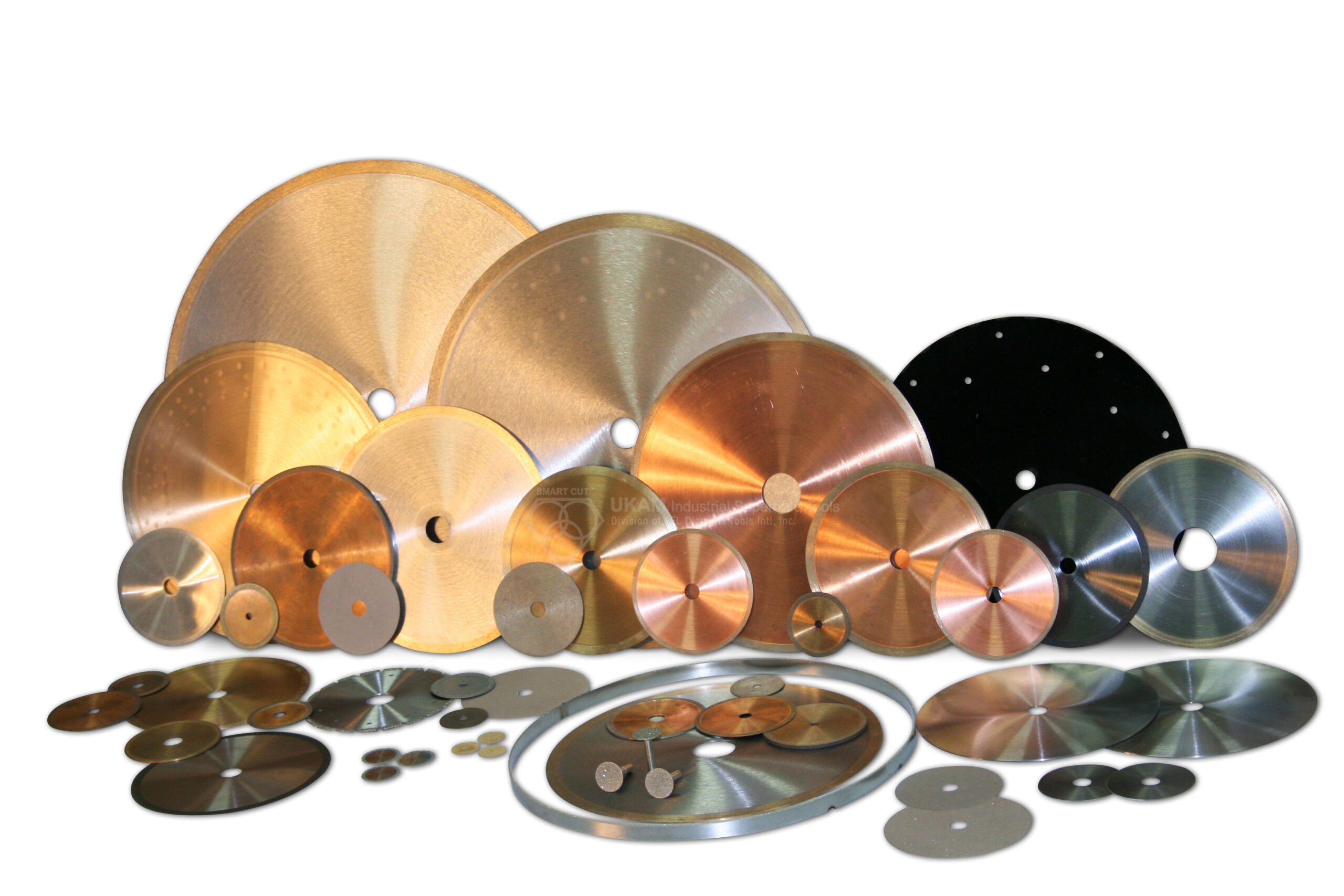

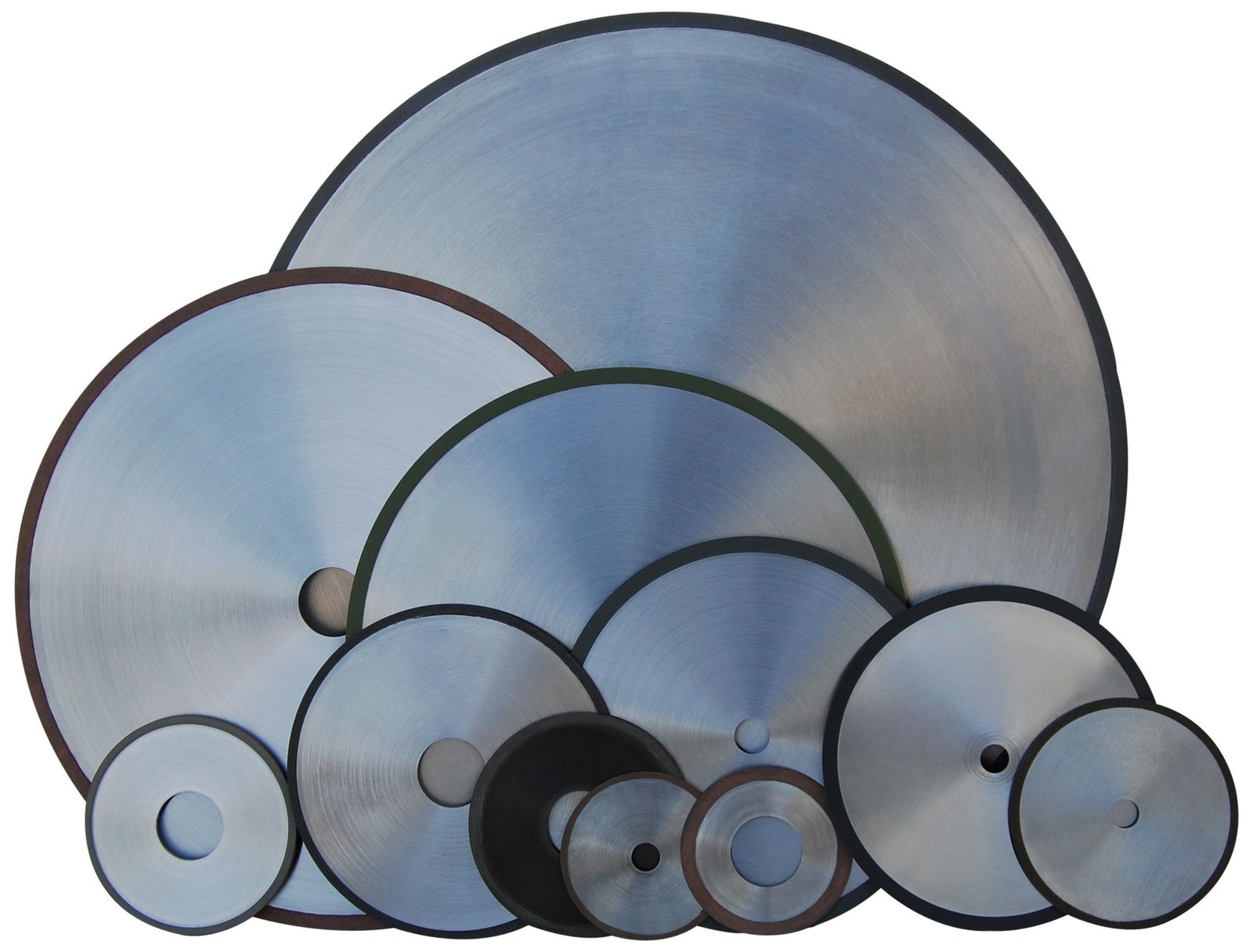

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

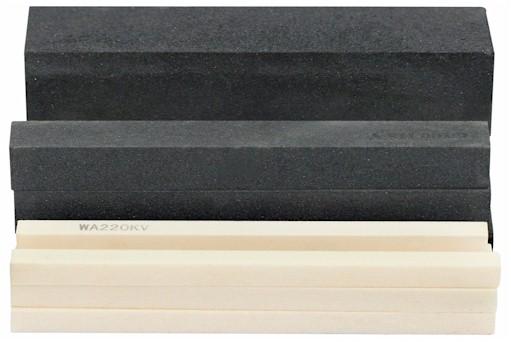

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales