Precision Saws

Precision Cutting Saws / Machines For

Industry and Research & Development

we manufacture and offer large varity of precision cutting machines for Laboratory & Industry. Typical applications include Research & Development, Sample Preparation, Failure Analysis, Materials Research, & many other industrial applications.

Examples include: ceramics, composites, plastics, quartz, metals, petrographic samples, and graphite. From high capacity cutitng of very large work pieces to precision sectioning of the most delicate samples

- Diamond Wire Saws & Dicing Saws

- High Speed Saws

- Cutting Saws for tubes & Rods

- Petrographic Sample Preparation

- Cutting Machines For Large Composite Flat Panels

- Simple Laboratory Cutting Machines

- General Purpose Cutting Saws

- Precision Low Speed Saws

- Low Speed to Medium Speed Saws

- Medium Speed to High Speed Saws

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

ENTRY LEVEL / SIMPLE

Laboratory Cutting Machines

These are Variable speed cutting machines and use the same specification diamond, cbn, or abrasive wafering blades as precision sectioning/wafering (laboratory saws). Sectioning is done by hand by pushing the sample/material into the rotating blade or placing it into optional sample vice. Vice is pushed into the blade by hand or using optional gravity weight feed. These are well suited for applications where high degree of accuracy is not required. Their low cost makes this a very attractive option for organizations on a very limited budget

SMART CUT® 4002 XP

SMART CUT® 4002 XP is simple manual entry level laboratory cutting machine that is very affordably priced. Variable speed from 400 to 3,000 RPM’s. Maximum Cut Depth: 1" (25.4mm) Accepts 3", 4" blades

SMART CUT® 6001 XP

SMART CUT® 6001 XP is simple manual entry level laboratory cutting machine that is very affordably priced. Variable speed from 400 to 3,000 RPM’s. Maximum Cutting Depth: 1.75" (45mm) Accepts 4", 5", 6", blades

SMART CUT® 19001

SMART CUT® 19001 band saw is entry level lab cutting machine that is very affordably priced. Constructed of a high impact polymer, the lightweight Diamond Band Saw is designed for medium precision, efficient cutting of hard and brittle materials, soft metals and polymers.

GENERAL PURPOSE

Cutting Saws

SMART CUT® 1000 Heavy Duty Versatile Masonary Saw

provides a very inexpensive way for fast, and easy cutting of large variety of materials (when using the right diamond, cbn or abrasive cut off blade). We can provide the right blade to best fit almost any application. From stone, ceramic, glass, brick, block, composite materials, metals, and etc. Uses up to 14'' (350mm) diameter blade.

SMART CUT® 1005 Heavy Duty Versatile tile Saw

SMART CUT® 1005 heavy duty wet tile saw features a robust 1-1/2 HP induction motor capable of handling a broad range of materials. provides a very inexpensive way for fast, and easy cutting of large variety of materials (when using the right diamond, cbn or abrasive cut off blade). We can provide the right blade to best fit almost any application.

SMART CUT® 1010 General Purpose Cutting Saw

SMART CUT® 1010 is a Simple & Low Cost Manual Cutting machine for Sectioning of a wide variety of materials This machine will accept any 10″ blade that has a 5/8″ arbor. Maximum cutting Depth: 3.5''. The large saw table gives you plenty of room for oversize materials, measuring 19-3/4″ L X 12″ W. Single Speed: 1,750

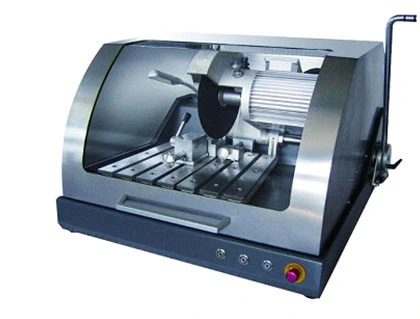

LOW SPEED

Precision Saws

SMART CUT® 4005

SMART CUT® 4005 is a small, low- speed, precision cut-off machine for sectioning all types of materials. Maximum sample/material size: 30 mm OD diameter. The cutting speed is continuously variable from 0 to 600 RPM. The required specimen size can be set with an accuracy of + 0.003 mm, by means of LCD digital micrometer, and the cutting pressure can be selected independent of the weight of the specimen. The machine also allows an option for sectioning/cutting with gang operation (several blades) cutting at the same time.

SMART CUT® 6005

SMART CUT® 6005 is a small, low- speed, precision cut-off machine for sectioning all types of materials. Maximum sample/material size: 55 mm OD diameter. The cutting speed is continuously variable from 0 to 600 RPM. The required specimen size can be set with an accuracy of + 0.003 mm, by means of LCD digital micrometer, and the cutting pressure can be selected independent of the weight of the specimen. The machine also allows an option for sectioning/cutting with gang operation (several blades) cutting at the same time.

SMART CUT® 6008

SMART CUT® 6008 is a small, low- speed, precision cut-off machine for sectioning all types of materials. Maximum sample/material size: 50 mm OD diameter. The cutting speed is continuously variable from 60 to 600 RPM. Blade Diameters from 3” to 5”. Gravity feed weights - Advanced PLC Touch Screen - Micrometer Cross Feed - Automatic cut-off Switch - Clear Safety Splash Guard - Built in re-circulation tank Included

SMART CUT® 6009

SMART CUT® 6009 is a small, low- speed, precision cut-off machine for sectioning all types of materials. Maximum sample/material size: 50 mm OD diameter. The cutting speed is continuously variable from 60 to 600 RPM. Blade Diameters from 3” to 5”. Gravity feed weights - Advanced PLC Touch Screen - Micrometer Cross Feed - Automatic cut-off Switch - Clear Safety Splash Guard - Built in re-circulation tank Included

LOW SPEED TO MEDIUM SPEED

Precision Saws

SMART CUT® 6040

SMART CUT® 6040 is an versatile low to medium speed laboratory cutting saw that comes with a lot of options and is very affordably priced, Designed for Precision sectioning of ceramics, minerals, metals, printed circuit boards, bones, composite substrates, electronic packages, and many other materials up to 2.0" (50mm) in diameter. The saw has powerful (400W) 0.53 HP motor, running at variable speed of 50 to 1,500 RPM’s

SMART CUT® 6035

SMART CUT® 6035 is a Modern Precision Laboratory Cutting Saw that can accommodate large variety of material shapes, sizes and applications. A wide range of material sample holding fixtures/chucks and rotating vises. The machines large RPM range from 150 to 2,000 RPM. Allow sectioning of larger variety of materials

SMART CUT® 6010

SMART CUT® 6010 is an versatile low to medium speed laboratory cutting saw that comes with a lot of options and is very affordably priced, Designed for Precision sectioning of ceramics, minerals, metals, printed circuit boards, bones, composite substrates, electronic packages, and many other materials up to 2.0″ (50mm) in diameter. The saw has powerful 1/4 HP motor, running at variable speed of 50 to 1,500 RPM’s allow for most samples to be sectioned faster then most low speed saws, with low rpm’s for fragile samples. SMART CUT 6010 has large variety of working holding fixtures to hold almost any material/sample which is already included in the price of machine.

SMART CUT® 6045

SMART CUT® 6045 is a versatile, high-precision sectioning saw designed for cutting a wide range of materials including circuit boards, glass, ceramics, composites, semiconductors, hard metals, and rocks.

Medium Speed to High Speed

Precision Saws

SMART CUT® 6050

SMART CUT® 6050 Precision Laboratory Precision Saw is a variable speed cutting machine that can adjust the rpm’s and feed rate to the material being cut. The Machine is variable speed from 60 to 1,000 RPM’s and blade diameters from 4” to 7”. The display is clear and the function layout is reasonable. This machine can accommodate large variety of material shapes, sizes and applications. A wide range of material sample holding fixtures/chucks and rotating vises.

SMART CUT® 6018

SMART CUT® 6018 Automatic Laboratory Precision Saw is a variable speed cutting machine that can adjust the rpm’s and feed rate to the material being cut. The Machine is variable speed from 500 to 3,000 RPM’s. With the touch screen control, the display is clear and the function layout is reasonable. The feed of cutting can be controlled by controlling the blade feed or by cutting table feed and adjust according to the different materials or user preference. The machine will cut automatically according to programmable parameters.

SMART CUT® 6025 - Manual Low & High Speed Sectioning Saw

SMART CUT® 6025 Saw is an versatile manual precision laboratory cutting saw that is affordably priced, Designed for Fast & Precision sectioning with minimum deformation of printed circuit boards, ceramic substrates, electronic packages, and many other materials up to 2" (50mm) in diameter. The saw has powerful 1.0 hp (750 W) motor. Available variable speed of 500 to 3,000 RPM or 100 to 800 RPM (your choice).

SMART CUT® 6025 - Automatic/Manual Low & High Speed Sectioning Saw

SMART CUT® 6025-A Automatic/Manual Saw is an versatile manual precision laboratory cutting saw that is affordably priced, Designed for Fast & Precision sectioning with minimum deformation of printed circuit boards, ceramic substrates, electronic packages, and many other materials up to 2" (50mm) in diameter. The saw has powerful 1.0 hp (750 W) motor. Available variable speed of 500 to 3,000 RPM or 100 to 800 RPM (your choice).

SMART CUT® 6055

Precision Automatic Diamond Cut-Off Saw

SMART CUT® 6055 is a high-precision, fully automatic diamond cut-off saw designed for cutting materials with exceptional accuracy, repeatability, and minimal sample damage.

DIAMOND WIRE DICING

Precision Saws

SMART CUT® 6012 Precision Endless Wire Saw 2" Travel

SMART CUT® 6012 Miniature/Lab Precision wire saw is designed to provide a very smooth cutting for almost all kinds of materials, especially for very fragile crystals and substrates such as SrTiO3, YVO4, and GaAs etc. SMART CUT™ 6012 by using either a diamond impregnated or a plain wire blade with abrasive slurry. It is an ideal saw for your needs of cutting valuable delicate and fragile crystals. It is a very helpful for your R&D and laboratory applications

SMART CUT® Slicing / Dicing Saw

Precision diamond dicing / slicing saw is designed for Laboratory, and R & D use. This saw can be used for dicing or cutting all kinds of materials up 4" diameter wafer or rectangular material up to 8" length x 4" width x 1"in depth saw is fully computer controlled with position accuracy of 0.01 mm or better.

SMART CUT® 6035

Small precision diamond wire saw for cutting sample ≤ 2" diameter or square up to 50mm in thickness. It is designed to provide smooth cutting for many kinds of materials, especially for fragile crystals and TEM or IC samples by using a 0.28mm diameter x 15-meter long diamond impregnated wire. It is an ideal cutting tool for material research, TEM sample preparation, and IC failure analysis.

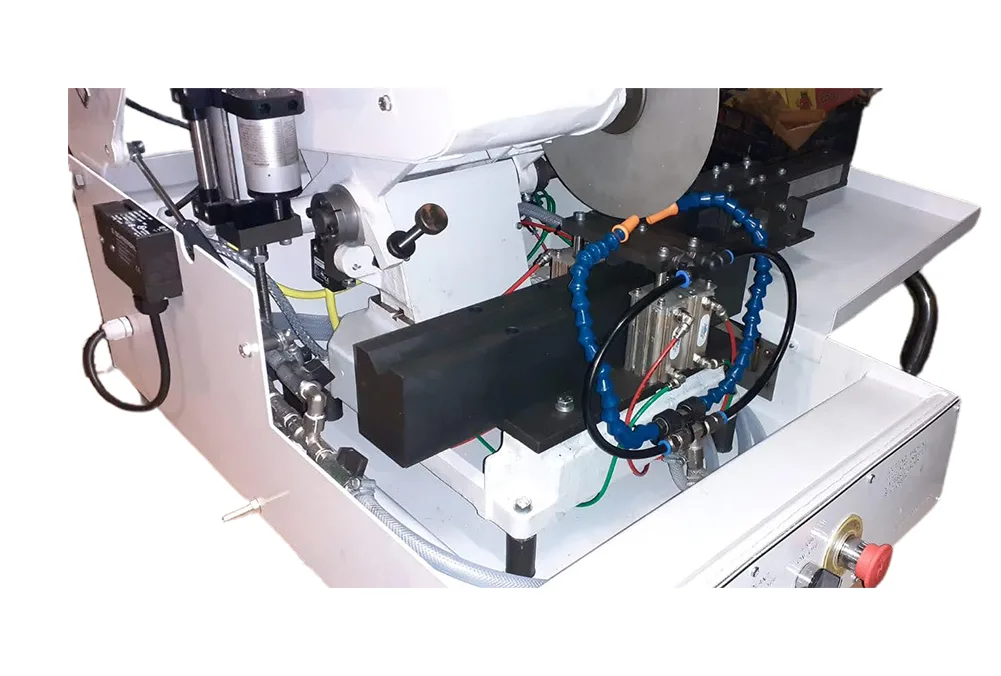

HIGH SPEED

Precision Saws

SMART CUT® 6030

SMART CUT® 6030 is an versatile automatic precision section saw with 2 axis control, designed for cutting all types of materials with ease. SMART CUT 6030 offers a cutting capacity of 40mm diameter with height adjustment of the wheel of 40mm offering wheel wear compensation. Variable speed 100 to 4,000 RPM, automated Y movement adds to the convenience.

SMART CUT® 6015

SMART CUT® 6015 is an versatile automatic precision section saw designed for cutting all types of materials with ease. It allows for the cutting of all types of materials with selected cutting wheels offering low deformation cutting. SMART CUT 6015 offers three axis control allows for multi – cutting of samples and ease of setting up in a range of vices available for the 250mm x 200mm T slot bed., up to 2.0" (50mm) in diameter. The saw has powerful 1 HP motor, variable speed of 100 to 5,000

SMART CUT® 6011

SMART CUT® 6011 is designed for precision cutting all type of materials up to 3" diameter. The saw is equipped with 8" diameter diamond blade and touch-push panel to achieve automatic control. The system features an integral coolant recirculation system which extends blade life and clears cutting debris to improve cutting rate and surface quality. Material is fed into the blade by several different methods by use of table attachments.

CUTTING SAWS FOR TUBES & RODS

Precision Saws

SMART CUT® 2001

SMART CUT® 2001 is designed for precision cutting of tubes and rods made from glass, quartz, ceramics, semiconductor materials, composites or metals using diamond or abrasive wheels. Proven to be durable, reliable and economical. Can be used with thin diamond slicing blades for delicate cutting with minimum chipping. Accommodates diamond slicing and abrasive cut off blades up to 14" diameter.

SMART CUT® 1015

SMART CUT® 1020

SMART CUT® 7001

cutting machines has been studied and planned to solve any cutting matter for hard metal bars manufacturers, tool grinders, tools manufactures (milling cutters for metal, cutters for wood, taps, reamers, carbide tips, punches, dies, brazed tools, blades for planes, carbide components, etc..) and special tools manufacturers. cutting precision and the easy set up to adjust the shape. The cutting machine has been designed to carry out both automatic single cut and automatic production ones, with bar-loaders allowing autonomous cut management, without any operator. The cutting machine can automatically work various diameters and different lengths on the same bar,

SMART CUT® 7002

SMART CUT® 7002 Heavy Duty Automatic Rod & Tubbing Cutting Machine. A fully automatic cutting machine used for mass production. This is widely use for cutting carbide, glass, ceramic, quartz rods, and tubing

SMART CUT® 1020

designed to accommodate raw materials up to 48" in length. The various models cut stock as small as 0.100" in diameter up to 3.0". Multi-Blade cutting system makes all cuts simultaneously and automatically separates end cuts from finished pieces. Production rates range from 400 to 6000 parts per minute. Capable of cutting tubes or rods of glass, quartz, carbon, ceramics, plastics, fibre glass, hybrid and exotic materials and most metals. If it is a rod or a tube it can be cut on this system

SMART CUT® 7005

SMART CUT® 7005 is Designed for high-performance and precision, our Tube & Rod Cutting Machine is the ultimate solution for industries demanding exact cuts and efficient material handling. This machine is engineered to slice through large variety of tube and rod rod materials such as: carbide and high-speed steel rods, ceramic, glass, composites, and many others with high degree of accuracy and speed, making it an indispensable tool for manufacturers in aerospace, automotive, metal fabrication, and tool-making sectors.

ABRASIVE & DIAMOND

Cut Off Machines

SMART CUT® 1010

SMART CUT® 1010 is an versatile manual diamond / abrasive cut off saw, designed for cutting large variety of materials such as ferrous & non ferrous metals, ceramics, glass, rocks, composites, & many others.

SMART CUT® 6020

SMART CUT® 6020 is versatile manual diamond / abrasive cut-off saw designed for low to high volume applications. Samples/Material is held in 2 off cam lock vices & cooled using the large recirculation tank to produce high quality metallurgical sections. It accommodates blades 10" in diameter, allowing a wide variety of sample shapes and sizes up to 3.15" (80 mm) thick

SMART CUT® 1045

SMART CUT® 1045 is a manual, sturdy floor model general purpose cutter. Large space in the cutting zone offers flexibility to use wide variety of fixtures. Cutting action possible by lowering the arm ( Z movement) and longitudinal table movement (Y axis) through cutting plane (Y- movement). Additional side movement (X – movement) option is of advantage. Lockable Z movement wheel position offers extra convenience. Suitable for variety of applications including small gears, medium sized auto components and shafts. Cutting capacity up to 80mm

SMART CUT® 1050

SMART CUT® 1050 Cutting action: Automatic “Y” movement (Table) with servo system. PLC with graphical Touch screen display, Pre set Programming & data storage upto 25 programs.

SMART CUT® 1030

Automatic large plus heavy-duty cutting machine with integral construction. Standard Y automation. Plus cutting for burn free cutting. Preset parameters for consistency.

SMART CUT® 1035

SMART CUT® 1035 cut off machine with Advanced Touch Screen Panel- Cycle Start, LED Light, Emergency Stop, Start Button with Door Safety Limit Switch and Pre Set Programme

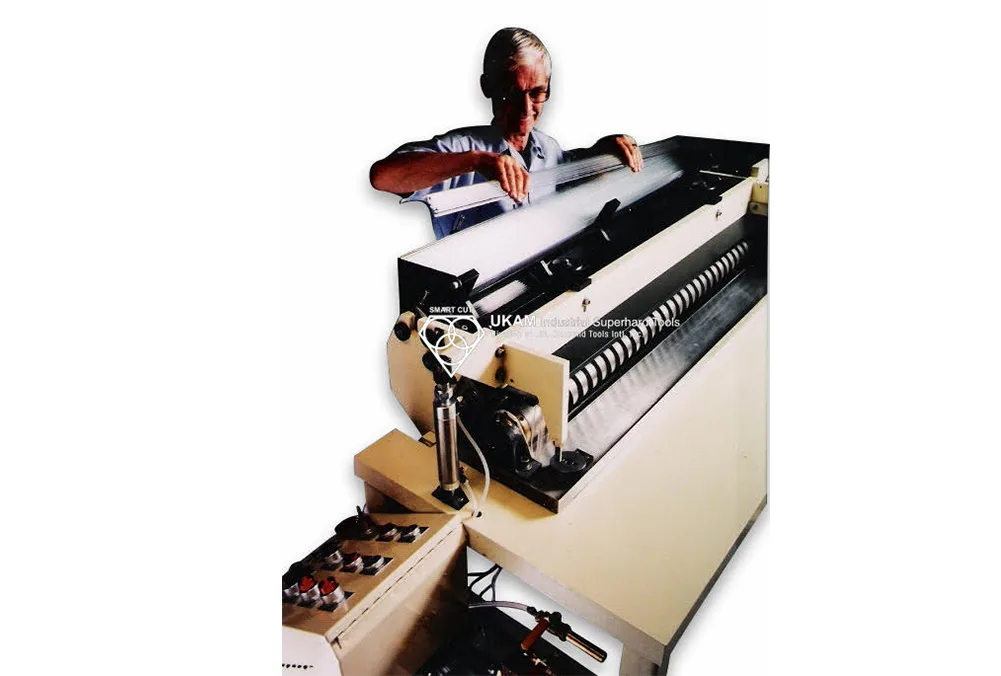

Precision Cutting Saws

For Large Composite / Flat Panels

Are designed for cutting sample coupons such as PCB Boards, FR4 composite panels, ceramic substrates, electronic packages, plate material, composites, optics or flat glass pieces, ultra hard material tiles and other glass, carbon fiber, honeycomb, and many other materials. That are too large to fit on other high precision cutting machines. We offer large variety of machine specifications from manual to fully automatic cutting with high accuracies and repeatability.

SMART CUT® 1600 Saw

Advanced composite plate saws achieve precise cutting in a diverse range of materials to prepare highly accurate composite test specimens. saws cut up to 55 mm material thickness and are available in three standard models, accommodating cleared panel sizes:

SMART CUT® 1800 Saw

High Precision Cutting Machine for precise cutting of Composite Panels, Coupons, and test specimens. The machine allows high precision cutting of very large and long composite test specimens to accuracy of 25 microns. Material is clamped to the steel table which glides toward the blade on high precision linear rails. Machine is equipped with HMI tough screen control that allows the operator to control the Speed, Start & stop the motor.

SMART CUT® 1805 Saw

High Precision Cutting Machine for precise cutting of Composite Panels, Coupons and test specimens. The machine allows high precision cutting of large and long composite test specimens to accuracy up to 25 microns.

Precision Cutting Saws

For Petrographic Sample

SMART CUT® 2005

Precision Thin Section Cutting and Grinding Machine. Thin is a Table Top Cutting and Grinding Machine. Used in areas of application where advanced Thin Section Preparatory method is required. Thin section preparation requires highly advanced preparatory equipment. Thin Geo works as a platform for both Cutting and Grinding of samples up to 30 microns or less. Two different areas for Cutting and Grinding in the same machine give additional advantage of using a compact system for both processes instead of going for two different machines. Thin Geo can accommodate Diamond cutting wheels of different diameter from 6" to 10". The Cup grinding wheel diameter can vary from 6" to 8"

SMART CUT® 2010

Table Top Petrology Cutting Machine used for sectioning of various types of Rock, Ore, Fossil, Ceramic and other Geological Samples. Used in areas of advanced Petrology and Mineralogy application. Bigger working space to accommodate bigger size of geological samples,

SMART CUT® 6070

Thin Section Cut-Off and Trim Saw is a compact, bench-top unit for the preparation of geological thin sections. The saw is ideal for cutting bulk rocks and thinning mounted sections of rock. Pre-thinning of slides to selected thickness Cutting up to 500mm microns, cutting up 60mm diameter sample. The machine does sectioning and sample grinding as well using cup wheel accepts 8" to 10" blade or cucp wheel

SMART CUT® 16001

SMART CUT® 14001 are entry level laboratory cutting saw that are very affordably priced, Fast & Accurate sectioning of large variety materials. Coolant is stored below and applied to sample by rotating the blade. Saw table has a large working area and no inhibiting lip. Bull dog grip vise holds all material shapes and swings back out of the way for hand sectioning.

SMART CUT® 12001

SMART CUT® 1201 are entry level laboratory cutting saw that are very affordably priced, Fast & Accurate sectioning of large variety materials. Coolant is stored below and applied to sample by rotating the blade. Saw table has a large working area and no inhibiting lip. Bull dog grip vise holds all material shapes and swings back out of the way for hand sectioning.

SMART CUT® 1040

The Automatic Extra-Large Heavy-Duty Cutting Machine is specifically designed for precision sectioning of petrography samples and other large materials. Its robust construction, featuring an integral sliding door system, ensures operator safety while accommodating large-envelope material handling.

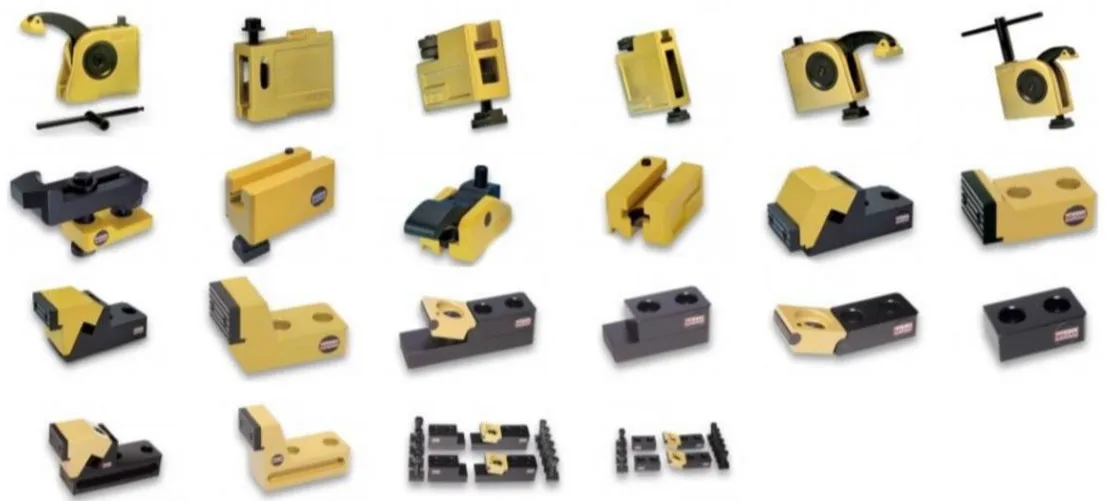

PRECISION SAWS

Accessories

Chucks, Vices & Holding Fixtures for Low & Medium Speed Saws

We offer many different chucks, vices, & holding fixtures are available for many low and medium speed saws such such

Chucks, Vices & Holding Fixtures for Laboratory/Abrasives Saws

Universal Vices & clamps are available to fit the T slot table of most laboratory/abrasive cut off saws such as

Sectioning, Slicing, Dicing, Coring, Drilling, Micro Drilling Services

We offer sectioning and cutting services for large variety of materials for organizations that don’t have the necessary equipment, process

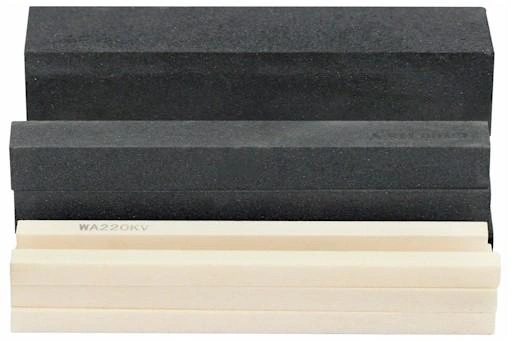

Dressing Sticks

Dressing Sticks are available from stock to fit all types of diamond, cbn, abrasive wafering & cut off blades and

Blade Stiffeners

Wheel Stiffeners provide stability, rigidity & additional support for your blades. They help in prventing the blade from loosing wobbling

Diamond Wire Blades

Diamond Wire for almost all laboratory and larger diamond wire saws. Used for cutting large variety of ultra hard to

Ultra Thin & High Precision Cutting Blades for Industry & Sample Preparation

Diamond, Cubic Boron Nitride, Abrasive, Carbide. 3" (75mm) to

Why Work With Us

Save Money Save up to 650%

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

Umatched Technical Support

WE ARE A PARTNER IN YOUR SUCCESS

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

Advanced

Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Precision Saws

- Obtain More Consistent Results

- Save Time & Money

- improve Surface Finish

- Preserve True Material Microstructure

- Improve Consumable Life & Overall Performance

- Reduce & eliminate Material Deformation