Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® 6012 Miniature/Lab Precision wire saw is designed to provide a very smooth cutting for almost all kinds of materials, especially for very fragile crystals and substrates such as SrTiO3, YVO4, and GaAs etc. SMART CUT® 6012 by using either a diamond impregnated or a plain wire blade with abrasive slurry. It is an ideal saw for your needs of cutting valuable delicate and fragile crystals. It is a very helpful for your R&D and laboratory applications.

SMART CUT® 6012 has sample holder to hold samples of any shape. The sample stage can rotate at 360 degree horizontally and at 30 degree vertically. wire blade tension is adjustable to provide most accurate cutting capability.

Diamond Wire Saw offers the most gentle mechanical method for cutting virtually any material. It is most useful for cutting fragile crystals, substrates with delicate layers or any material that would be damaged when using a diamond cut off saw or any other cutting method.

INDUSTRIES USED IN:

Ferrous & Non-Ferrous Metals:

The SMART CUT® 6012 is designed primarily for cutting delicate and fragile crystals and substrates, making it ideal for R&D and laboratory applications.

Yes, while it is optimized for fragile crystals and substrates, it can provide smooth cutting for almost all kinds of materials.

3. What types of wire blades does the saw support?

The saw can utilize either a diamond impregnated wire blade or a plain wire blade with abrasive slurry.

The SMART CUT® 6012 comes with a sample holder that can hold samples of any shape, ensuring stability during the cutting process.

Yes, the sample stage can rotate 360 degrees horizontally and 30 degrees vertically.

The wire blade tension is adjustable to provide optimal cutting accuracy. Refer to the user manual for specific adjustment instructions.

Diamond Wire Sawing is the gentlest mechanical method, ensuring minimal damage to delicate materials, making it suitable for fragile crystals or substrates with delicate layers.

The sample can be attached to a holder provided with the saw. Details and best practices are available in the user manual.

The appropriate load can be adjusted using the counterbalancing weight. The mechanical downstop can be set to ensure the wire blade doesn’t exert excessive force on the sample.

The machine comes with a micrometer that aids in the precise positioning of the sample relative to the wire blade.

As the arm is lowered and the wire rotates, you’ll feel a gentle resistance when the blade contacts the sample. This tactile feedback helps prevent forceful contact that might damage the material.

Always wear safety glasses, ensure the work area is clean, and be careful not to apply excessive force when lowering the arm. Make sure to read the safety guidelines in the user manual before operating.

Yes, both diamond impregnated and plain wire blades can be purchased from the manufacturer or authorized dealers.

While designed primarily for manual operation, specific integration into automated workflows may be possible with the right setup. It’s best to consult the manufacturer for such custom solutions.

The lifespan of the wire blade depends on usage frequency and the materials being cut. Regular inspection will help determine when it’s time for a replacement.

Manufacturers typically provide training sessions, guides, or manuals for users. Contact the supplier for more details on training opportunities.

Regular checks of the wire blade, tensioning system, and moving parts are essential. The user manual will provide a detailed maintenance schedule and best practices.

The saw is designed for precision cutting, especially for delicate samples. While it can handle extended use, it’s essential to monitor the machine and ensure it doesn’t overheat or stress the wire blade.

Using a damp cloth or soft brush, gently clean any debris or residual slurry from the machine. Ensure the wire blade is clean and free from any particles. For more intensive cleaning, consult the user manual.

To ensure precise cuts and longevity of the equipment, it’s best to operate in a clean, dry environment free from excessive dust or humidity.

While the saw is compatible with various abrasive slurries, using one recommended by the manufacturer can ensure optimal cutting results.

Specific power supply requirements will be detailed in the product’s technical specifications, which can be found in the user manual or product documentation.

The rotation speed of the wire blade is typically fixed for optimal performance. If adjustable speeds are a feature, this will be mentioned in the product specifications.

Depending on the manufacturer’s offerings, there may be additional attachments or upgrades available. It’s advisable to check with the supplier or manufacturer for available options.

The maximum cutting thickness would be detailed in the product’s technical specifications. Ensure the material being cut falls within the recommended parameters to achieve the best results.

The manufacturer or supplier typically provides after-sales service. It’s recommended to contact them directly regarding any servicing or repairs.

Safety is a priority in the design of such equipment. Features might include safety locks, emergency stop buttons, or protective guards. Consult the user manual for detailed safety guidelines and features.

The wire blade’s durability depends on the materials being cut and usage frequency. However, when used appropriately and maintained well, the diamond impregnated wire blade is designed to offer an extended service life.

While the SMART CUT® 6012 is versatile, there might be certain materials it’s not optimized for. Always refer to the user manual for a list of recommended and non-recommended materials.

The SMART CUT® 6012 stands out due to its precision and capability to cut fragile materials. Specific comparisons would depend on the other models in question, but features like the 360-degree rotating sample stage give it a competitive edge.

With proper maintenance and usage, the SMART CUT® 6012 is built for longevity. The exact lifespan can vary based on usage frequency and the types of materials cut.

Absolutely. The SMART CUT® 6012 is ideal for R&D and laboratory applications, making it suitable for educational environments where precision is paramount.

Regular calibration ensures consistent and precise cuts. The frequency can vary based on usage, but a general recommendation is to calibrate it periodically, especially after extensive use.

Machine is fully assembled and ready to use out of the box

While the machine is user-friendly, it’s essential to understand its functions and safety protocols. Training, either through the manufacturer or in-house experts, is recommended.

The primary operation of the SMART CUT® 6012 is mechanical.

Disposal practices should adhere to local regulations and environmental guidelines. Check with local waste management authorities on how to dispose of used abrasive slurry.

Safety goggles, lab coats, and gloves are standard safety gear. Depending on the material being cut, additional precautions might be necessary.

We have replacement parts available

With proper use and maintenance, the risk is minimal. However, regularly inspect the blade for any signs of wear or warping.

While designed primarily for lab and R&D applications, its suitability for industrial use would depend on the specific requirements of the task.

The machine is optimized for cutting fragile materials, ensuring minimal damage and offering precise, smooth cuts, even for very thin samples.

While designed for precision and stability, its size and weight would determine its portability. It’s best to check the user manual or product specifications for details on the machine’s weight and dimensions.

The frequency of blade replacement depends on the types of materials being cut and the frequency of use. Regular inspection for signs of wear or damage can guide replacement decisions.

It’s advisable to use wire blades recommended by the manufacturer to ensure optimal performance and safety. Using third-party components might affect the machine’s performance and could void any warranties.

Most laboratory equipment is designed to work with standard electrical outlets, but always refer to the user manual for any specific electrical requirements or recommendations.

Signs like inconsistent cuts, excessive vibration, or unusual machine noises can indicate that wire tension needs adjustment. The user manual will provide guidance on this aspect.

Regular cleaning, blade inspections, tension checks, and lubrication of moving parts (if required) are essential. The user manual will provide a detailed maintenance schedule and steps.

While the machine is primarily mechanical, you should refer to the manufacturer’s documentation or contact them directly to know if any advanced control features are available.

It’s ideal for the machine to operate in a controlled environment without extreme temperature fluctuations. The product specifications or user manual might provide detailed environmental recommendations.

The SMART CUT® 6012 is designed to handle abrasive slurries and cut various materials. However, regular cleaning and maintenance are crucial to protect it from prolonged exposure to corrosive substances.

Financing or leasing options are available

The precision design and gentle mechanical cutting method of the machine ensure minimal sample loss and high-quality cuts, especially for fragile materials.

Yes, most precision equipment like the SMART CUT® 6012 comes with a user manual that outlines safety protocols and guidelines. Always follow these recommendations for safe operation.

The machine is designed for optimal performance without overheating, but users should ensure that it’s operated within the recommended time limits and settings. Additionally, the equipment might have built-in safety features to prevent overheating.

Wire blades and perhaps some other components might be considered consumables. The frequency of replacement would depend on usage.

The machine’s design focuses on precision, but automation capabilities would depend on its features. Refer to the user manual for detailed operation guidelines.

The user manual will typically provide troubleshooting steps for common issues like jams or blockages. It’s essential always to follow safety protocols when addressing such problems.

Download Operating Manuals

A sample is mounted to a sample holder and attached to a work table on the base of the saw. An appropriate load is applied by adjusting the counterbalancing weight and the mechanical downstop is set. The sample is then positioned in any starting position relative to the wire blade and then a micrometer is used for precise sample positioning. With the wire rotating, the arm is gently lowered until the wire blade touches the sample.

Your choice of one (1) quart of SMART CUT™ Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT™ Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

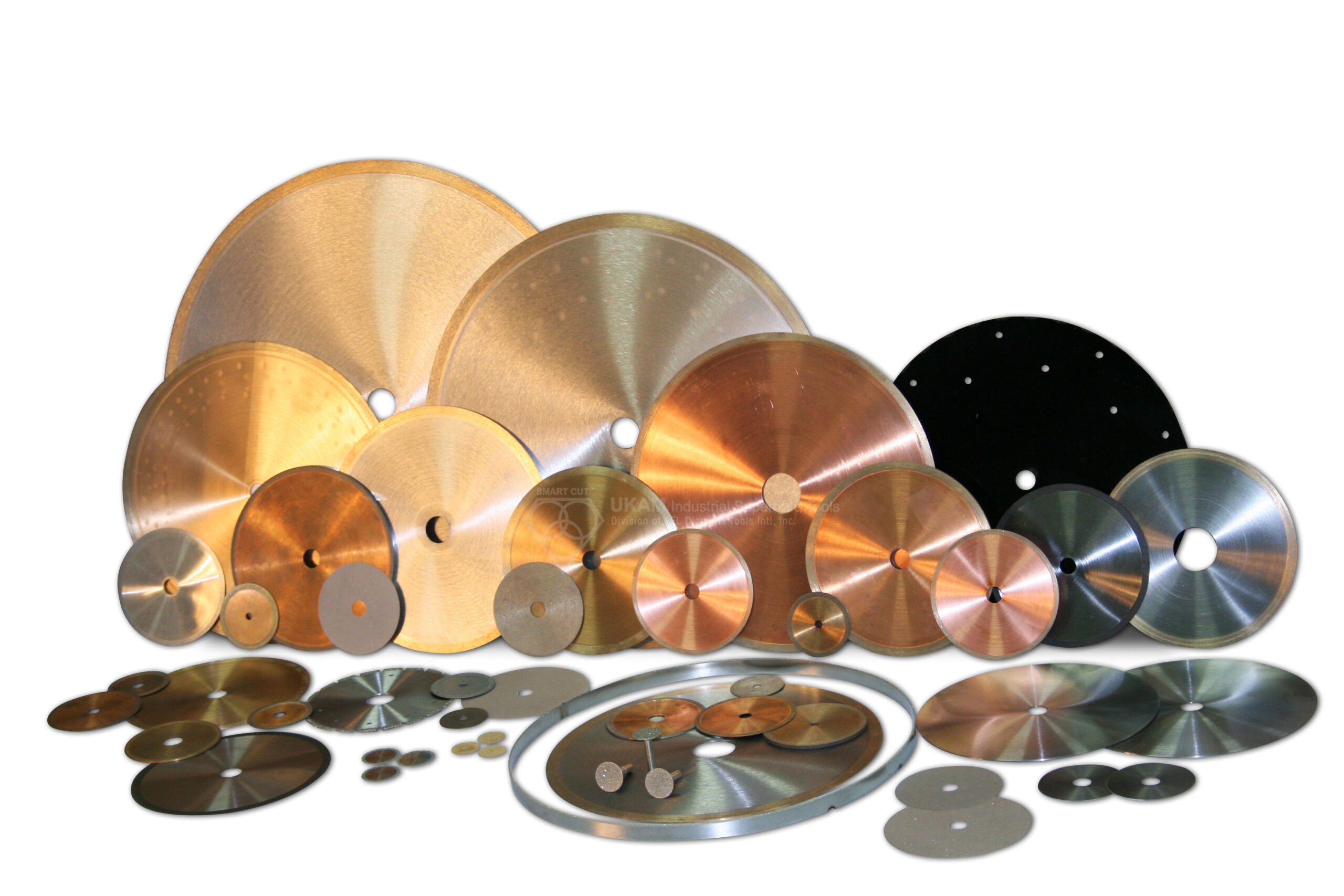

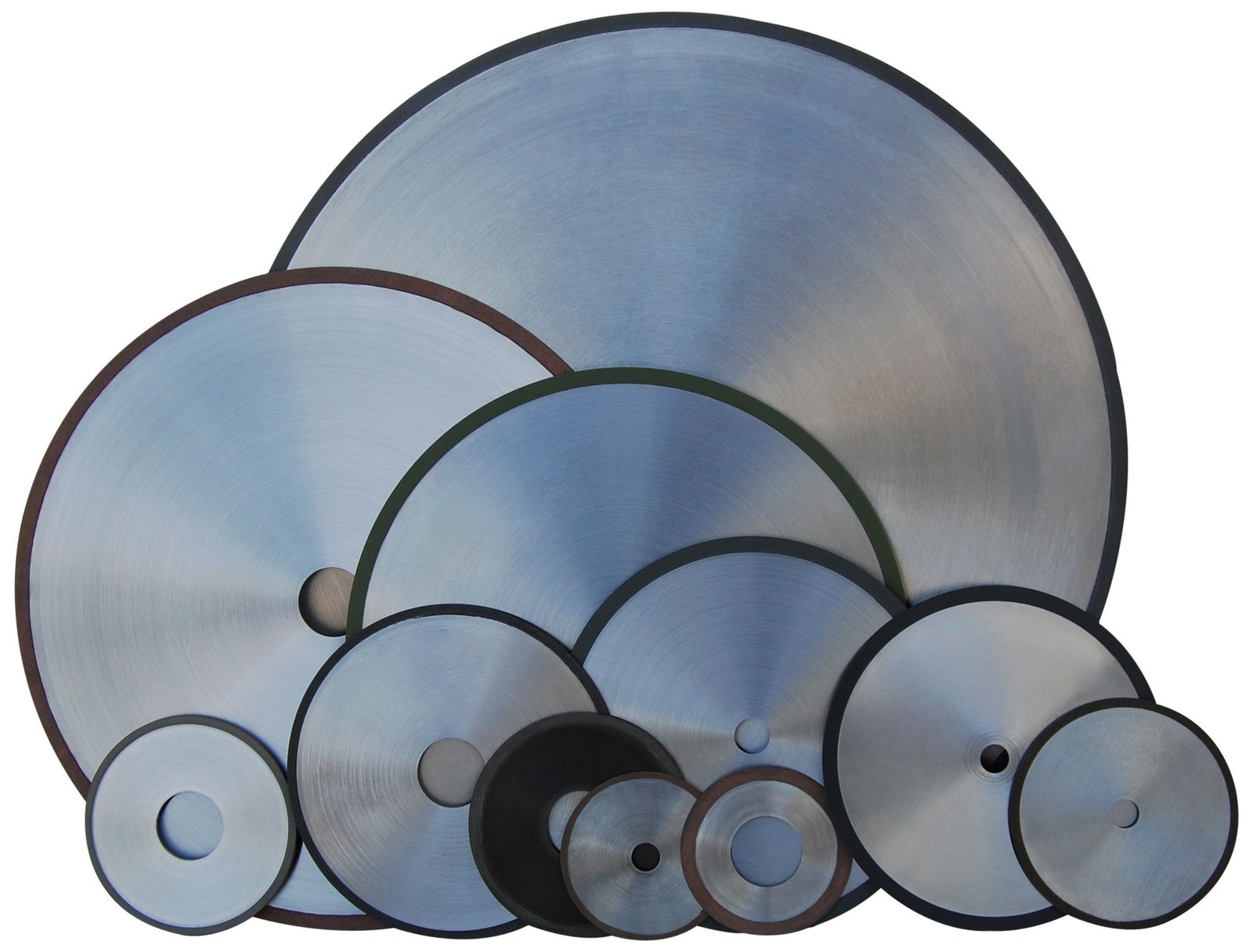

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

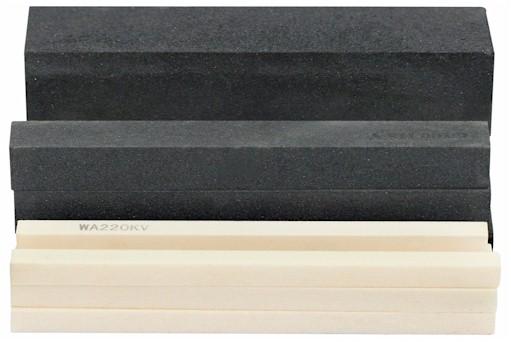

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales