-

0 items in quote

No products in the Quote Basket.

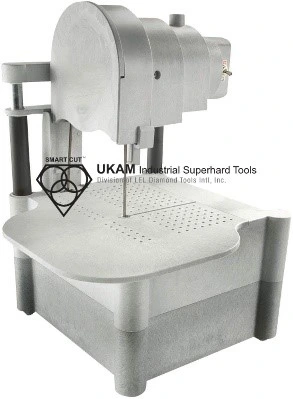

SMART CUT® 19001

BAND SAW

Fast & Precision sectioning of large variety materials. SMART CUT® 19001 BAND SAW will minimize material loss that’s always a concern when cutting deep inside cuts. Band Saw stands 17.5″ tall. The work surface is 13.25″ deep and 1.75″ wide. Distance from the blade to the housing is 5 1/2″ inches. This allows a substantial piece of material to be maneuvered freely on the work surface.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

The housing cover is removed from its track exposing the upper pulley of the blade. After blade replacement and/or adjustments are made the cover easily slips back into place.

Samples can be safely hand fed into the blade with or without the standard specimen guide. The diamond plated, steel core blades are designed for long life under normal conditions. Easy blade access and replacement procedures, make occasional saw maintenance extremely simple. Coolant is contained in a reservoir at the base of the saw. Made in U.S.A. Comes with one FREE Diamond Band Saw Blade (Electroplated) Nickel Bonded.

- Platform Area: One square foot

- Motor Speed: 2850 rpm

- Blade Speed: 40 mph

- Coolant System: Recirculating tap water

- Blade Dimensions: 37″ circumference, .020″ wide, .140″ deep.

SPECIFICATIONS

- Motor: 1/3 HP Direct Drive DC

- Blade Speed: 40 mph

- Motor Speed: 2850 RPM

- Blade Dimensions: 37” circumference, 0.020” wide, 0.140” deep

- Sample Working Area: 13.25” depth x 1.75” width

- Platform Area: 1 square foot

- Fluid Capacity: 10” x 9” reservoir

- Dimensions: 18” x 14” x 12”

- Shipping Weight: 15 lbs

ADVANTAGES

Tab Content

INDUSTRIES USED IN

Tab Content

FAQ

Tab Content

OPERATING MANUALS

Tab Content

ACCESSORIES

Tab Content

Features

Compact & Versatile Design

- Stands at 17.5” tall, allowing for a compact yet powerful tool.

- Generous work surface dimensions of 13.25” depth and 1.75” width.

- A 5.5” clearance from the blade to the housing enables easy maneuvering of substantial material pieces.

High-Performance Diamond Band Saw Blade

- Electroplated nickel-bonded blade ensures durability and extended life.

- Free Diamond Band Saw Blade included with every purchase.

User-Friendly Maintenance

- Quick and easy blade replacement with a removable housing cover.

- Minimal downtime for adjustments or maintenance procedures.

Efficient Coolant System

- Recirculating tap water system ensures clean and precise cuts.

- Coolant reservoir is conveniently located at the base of the saw.

Small, lab bench size

Rugged, corrosion-proof construction

Powerful motor cuts fast and won’t bog down under load

Minimum coolant splash for clean cutting

Easy access coolant tray for fast and easy clean-up

Quick adjustable blade guide keeps the blade tracking properly

Large work table for cutting samples from the bulk

Sample guide for straight, flat surfaces

Economically priced

Item # 560267 - SMART CUT® 19001 BAND SAW (115v) only

Related Products

SMART CUT® 4005 – Low Speed Saw

SMART CUT® 6035 – PRECISION CUTTING SAW

SMART CUT® 6040 – PRECISION CUTTING SAW

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

02

Jun

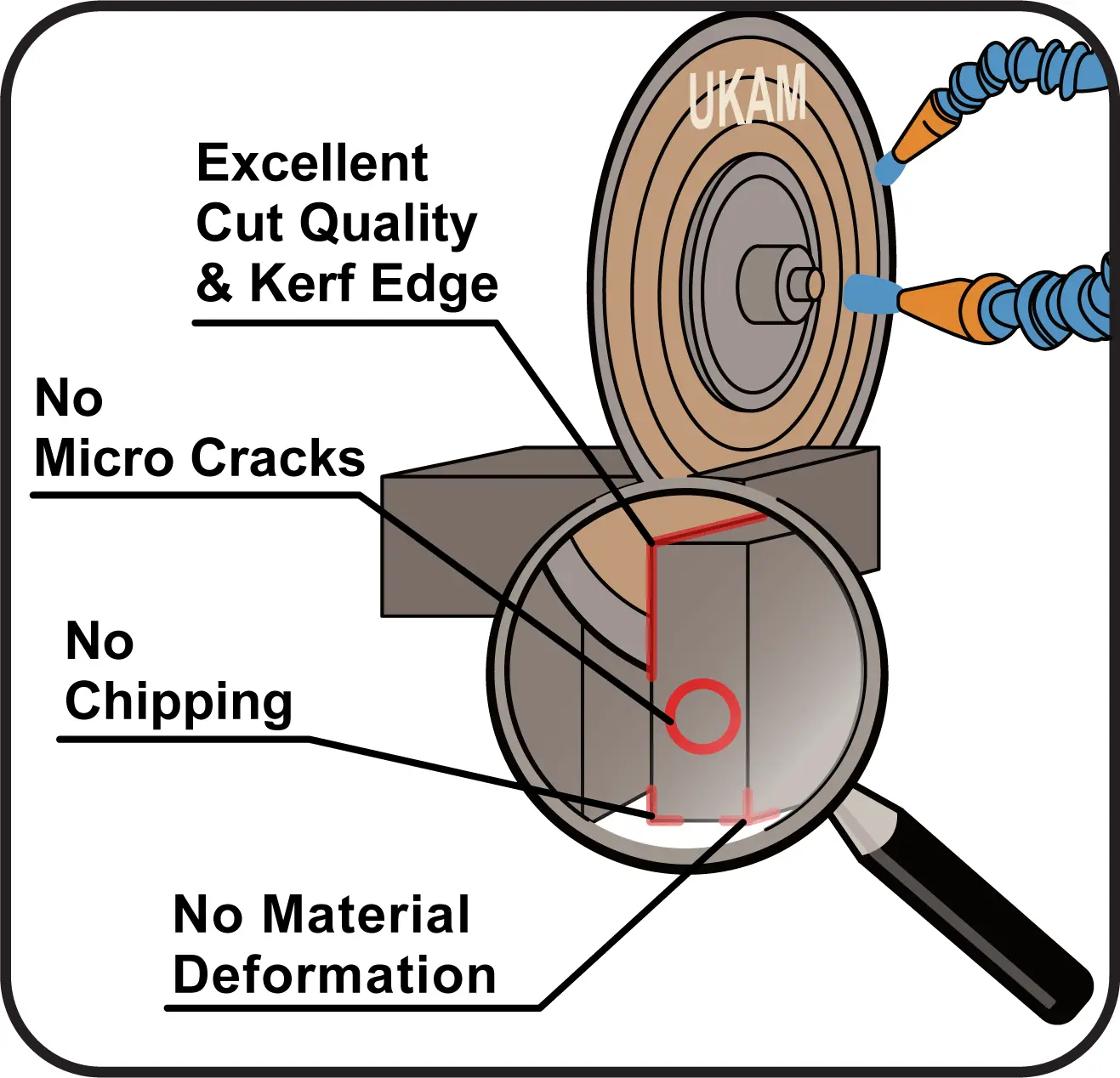

Diamond Wire Advantages & Application

Diamond Wire saws provide the most accurate cutting with the least amount of material deformation and chipping of material.

Share this Article with Friend or Colleague

HOW DIAMOND WIRE WORKS

Today diamond wire sawing is preferred by...

02

Jun

Troubleshooting Diamond Sawing Problems

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin, high precision cutting blades, precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use