-

0 items in quote

No products in the Quote Basket.

Shop

SMART CUT® SIMPLE PRECISION GRINDING / POLISHING HEAD

SMART CUT® Single Row Diamond Cup Wheel

SMART CUT® Turbo Diamond Cup Wheel Sintered (Metal Bond)

SMART CUT® AMF Water Soluble Coolant

Advanced Materials Formula

Super Premium water soluble synthetic coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

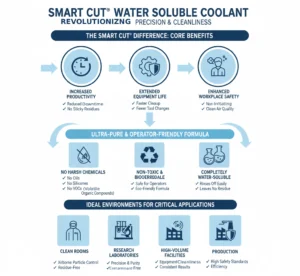

SMART CUT® Water Soluble Coolant – Advanced Materials Formula is a high-performance, fully synthetic, aqueous-based coolant specifically engineered for precision machining in the most demanding applications. Designed to excel in the cutting and grinding of advanced materials such as ceramics, composites, optics and ultra-hard, brittle materials. This premium coolant/lubricant optimizes removal rates while delivering superior surface finishes.SMART CUT® Water Soluble Coolant

(General Materials Formula)

High-Performance Fully Synthetic Coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

SMART CUT® Water Soluble Coolant (General Materials Formula) is a fully synthetic, non-oily, and non-foaming coolant and lubricant engineered to meet the rigorous demands of slicing, dicing, drilling, sectioning, wafering, grinding, and polishing operations involving hard and brittle materials. This advanced formula has been specifically developed for use with ceramics, precision optics, quartz, silicon, sapphire, and other materials commonly found in semiconductor, photonics, and materials research applications.SMART CUT® Water Soluble Dicing Coolant

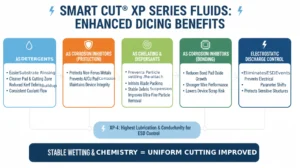

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

SMART CUT™ Series 2000

SMART CUT® Series 2000 are the highest quality & most commonly used Resin Bond Diamond Cut off Blades / Cut Off Wheels available today. Designed specifically for cutting a wide array of materials such as soda lime and borosilicate glass tubing, along with ultra hard and brittle materials such as ceramic tubing materials like Al203, silicon carbide, sapphire, and tungsten carbide, & exotic metals. These blades also handle metals and alloys with ease. While they can be used dry, employing coolant is advised to achieve the best results.

The resin bond diamond cut off blades / cut off wheels excel in delivering superior cut quality compared to other diamond cutting blade, making them ideal for applications where cut quality and surface finish is highly important. They are designed to operate at higher speeds to minimize heat generation and improve surface finishes.

SMART CUT® resin bond diamond wheels are engineered to maximize blade life while maintaining your desired cut quality and speed. These blades offer numerous advantages, including unmatched cut quality that often eliminates the need for secondary finishing operations. They feature a faster and freer cutting speed, generate less heat, and apply minimal stress to the material.