Select right Diamond Blade for your application

-

Posted by

Leon Meyer

Leon Meyer

Table of Contents

ToggleSelecting the right parameters for your Precision & Ultra Thin Diamond Blade can be a very time consuming, trial & error frustrating process. The guide below has been designed to help you better understand the most important diamond blade variables, which will play a major role in performance, cutting speed, and surface finish of your Precision Diamond Blade.

Share this Article with Friend or Colleague

You should carefully evaluate key technical factors when selecting a blade. These include blade diameter, blade thickness, bond type, diamond grit size, diamond concentration, RPM, feed rate, and coolant type used in the operation. Each of these parameters must be properly matched to the material and equipment being used in order to optimize results.

Today’s materials are more complex and demanding than ever before. The wide range of ultra-hard, new-generation, composite, engineered, metallic, and exotic materials has changed how diamond blades are selected, specified, and used. Many traditional blade designs, machines, and cutting methods no longer meet the requirements of modern materials and processes. Relying on outdated technologies often results in poor cut quality, increased scrap, and frequent tool changes.

Applications such as slicing, dicing, wafering, cut-off, singulation, grooving, slotting, cross-sectioning, gang sawing, slabbing, and rough cutting all demand specialized blade technologies. These processes often involve materials that are brittle, abrasive, heat-sensitive, or highly valuable, requiring carefully selected blade designs to ensure process control and yield. Matching the blade to your material and application is no longer optional—it is a requirement for success.

This guide is designed to help you make informed, application-specific decisions, minimize trial and error, improve productivity, and reduce your overall cost per cut. By understanding the critical relationships between your material, blade, machine, and cutting parameters, you will be in a better position to select a solution that delivers repeatable, high-quality results with maximum efficiency and consistency.

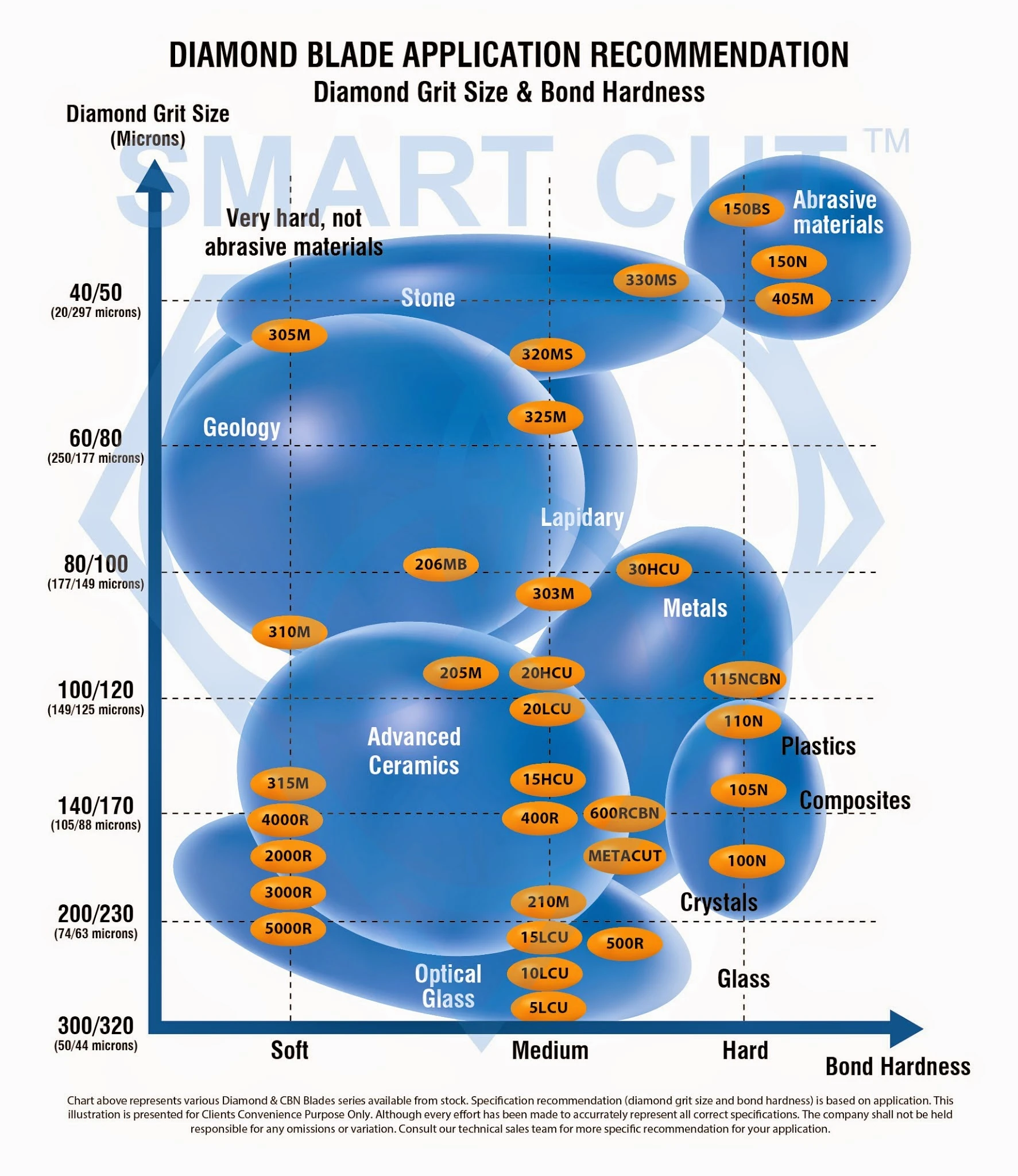

MATERIAL TO BE CUT

Materials you are planning to cut will have a large impact in the types of diamond blades you can use. If you are cutting hard alumina or sapphire, it is generally recommended that you use a soft bond, thin kerf diamond blades. However, if you are cutting abrasive materials such as sandstone or flagstone, a hard bond, thicker diamond blades may be a better solution.

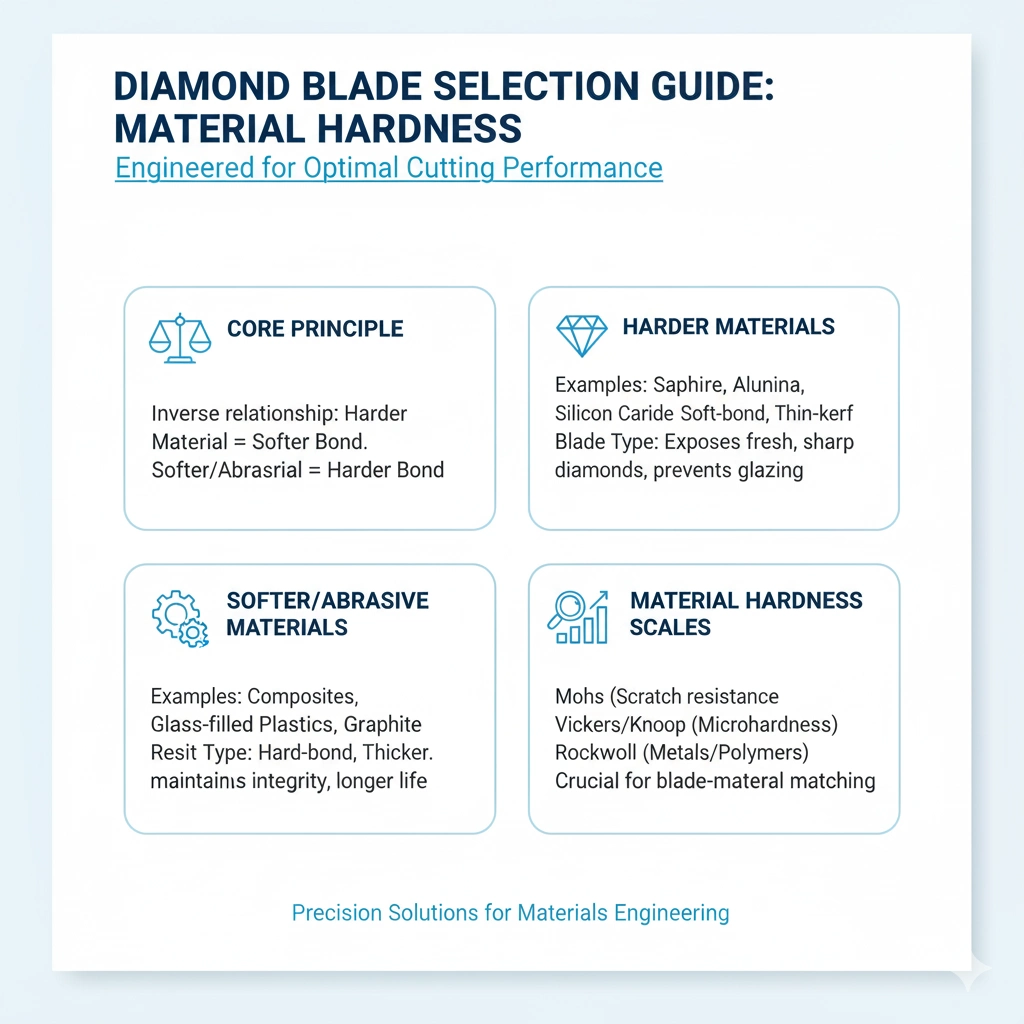

Hardness of Material

When selecting the right diamond blade for your application, one of the most important factors to consider is the hardness of the material you are cutting. Material hardness plays a direct role in determining the bond type of the diamond blade you should use, and choosing the wrong bond can result in poor performance, faster wear, and inconsistent cut quality.

Harder materials, such as sapphire, alumina, silicon carbide, or technical ceramics, require a softer bond in the diamond blade. A softer bond allows the blade to cut faster and more freely because it wears away more easily, constantly exposing fresh, sharp diamond particles. This is critical when cutting extremely hard or dense materials that would otherwise cause diamond particles to dull quickly and result in glazing of the blade.

On the other hand, softer or more abrasive materials such as composites, glass-filled plastics, or graphite require a harder bond. A harder bond resists wear, allowing the blade to last longer and maintain structural integrity over more cuts. If a soft bond were used on these materials, the blade would wear out prematurely, increasing tool changeovers and overall cost per cut.

As a general rule: the harder the material, the softer the bond; the softer or more abrasive the material, the harder the bond. This inverse relationship ensures optimal performance, maximum blade life, and consistent results across different material types.

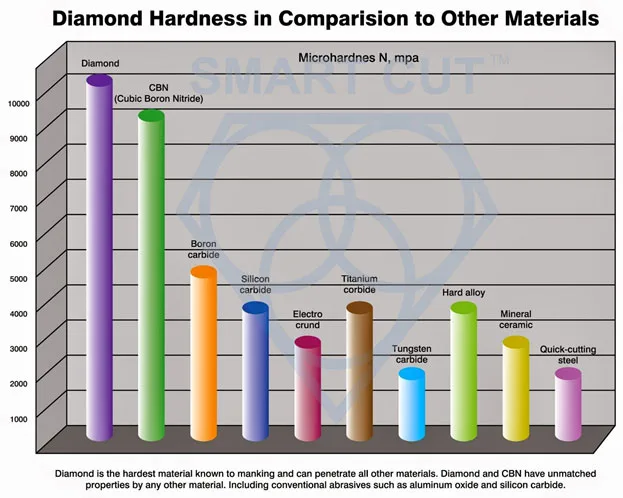

Material hardness is defined as the material’s ability to resist deformation, penetration, or scratching. There are several methods used to measure material hardness, each suited for specific material types and testing conditions. The most commonly used hardness scales include:

- Mohs Scale, which ranks materials based on their ability to scratch one another.

- Vickers and Knoop, which are microhardness tests commonly used for brittle materials and coatings.

- Rockwell, often used for metals and polymers.

- Other specialized scales designed for ceramics, thin films, and composites.

When choosing a diamond blade, it is essential to know the hardness scale of your material and its classification. This information will allow you to work with your blade manufacturer or supplier to determine the correct bond type for your application.

Further information on determining and understanding hardness of your material.

Mohs scale of Abrasion Hardness is the most simple and well known material hardness measurement and classification methods. In this scale material hardness is measured by scratch test of rubbing each material against another. All material harnesses are arranged in 10 ranks. Each rank is calibrated by a standard mineral. Below find these minerals in their rank of hardness from softest to hardest.

Diamond is the hardest material known to mankind. It can penetrate into any material. Brittle or Soft materials such as granite, advanced ceramics, and copper can be cut by diamond, without diamond particles being broken or exhibiting large pull out. However, when cutting very tough and dense materials such as cemented/tungsten carbide, the contact pressure of each diamond particle must be increased in order to allow diamond to penetrate being cut. The Hardness, Density, & Brittleness of the material being cut will determine whether the diamonds inside the diamond bond matrix need to be blocky and tough enough in order to break (rupture) material by brutal force or if they should be friable & flexible to penetrate the material by sharp points.

Mohs Scale of Hardness

1 Gypsum

2 Calcite

3 Fluorite

4 Apatite

5 Orthoclase

6 Quartz

7 Topaz

8 Corundum

10 Diamond

Proposed Scale of Hardness for Industrial Materials

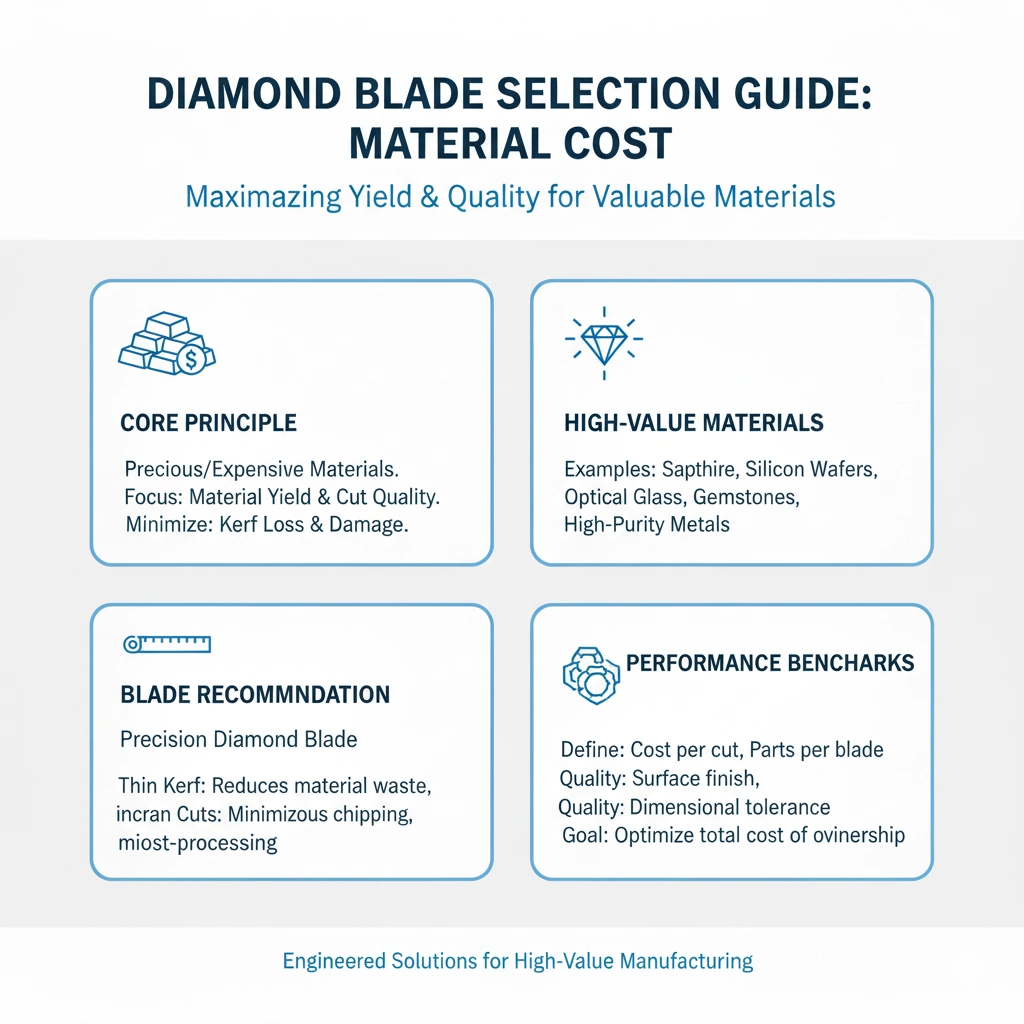

Material Cost

If the material you are cutting is precious, valuable, or expensive, such as single crystal sapphire, silicon wafers, optical glass, specialty ceramics, gemstones, or high-purity metals, then the cost of the diamond blade becomes a relatively minor factor in the overall cutting operation. In these cases, your primary focus should be on achieving maximum material yield, high-quality cuts, and process consistency, rather than reducing tool cost.

When cutting costly materials, even a small amount of kerf loss or chipping can lead to significant financial waste. The loss of usable material, damage to the part, or failure to meet dimensional tolerances often costs far more than the price of the blade itself. For this reason, it is strongly recommended to use a precision diamond blade with a thin kerf. A thinner kerf will remove less material per cut, allowing you to recover more usable sections from each workpiece, improve part yield, and reduce downstream processing requirements such as polishing or rework.

In high-value applications, the blade must also be capable of producing a clean, smooth surface finish with minimal edge chipping, microcracks, or burrs. This reduces the need for costly post-processing steps and helps ensure that each cut meets your quality standards on the first pass.

Before beginning your cutting operation, it is wise to establish a clear set of performance benchmarks. You should define the target cost per cut, including the value of the material removed, the expected number of parts per blade, and the acceptable surface finish or dimensional tolerance. This helps you evaluate the total cost of ownership of the blade in relation to the value of the material and the quality requirements of the finished part.

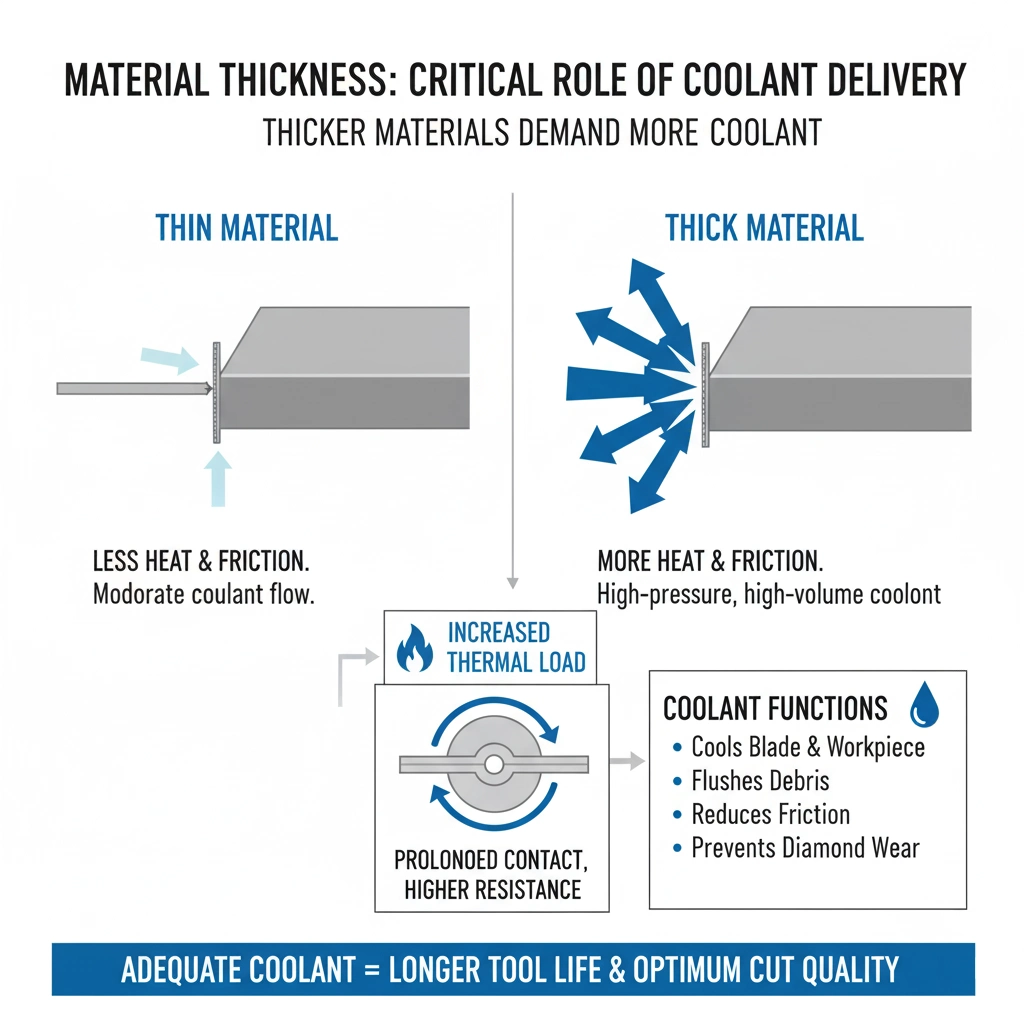

Material Thickness

The thicker the material you are planning to cut, the greater the demand for effective coolant delivery and water pressure becomes. As material thickness increases, the cutting process generates more heat and friction due to prolonged blade-to-material contact and increased cutting resistance. This makes coolant flow and pressure critical components of the cutting setup, directly impacting blade performance, tool life, and cut quality.

When cutting thick sections of hard or brittle materials such as glass, quartz, ceramics, stone, or metals, the diamond blade must remove more material over a longer path. This results in higher thermal loads, which can cause blade glazing, warping, or premature diamond wear if not properly controlled. Inadequate cooling will also increase the risk of thermal cracking, microfractures, and chipping in the workpiece, especially for heat-sensitive materials.

To maintain stable performance, it is essential to use high-pressure, high-volume coolant delivery. Coolant serves multiple functions: it cools the blade and workpiece, flushes out debris, reduces friction, and prevents diamond particles from becoming embedded or dulled. As material thickness increases, these roles become more important, and insufficient coolant flow can quickly lead to tool failure or unacceptable cut quality.

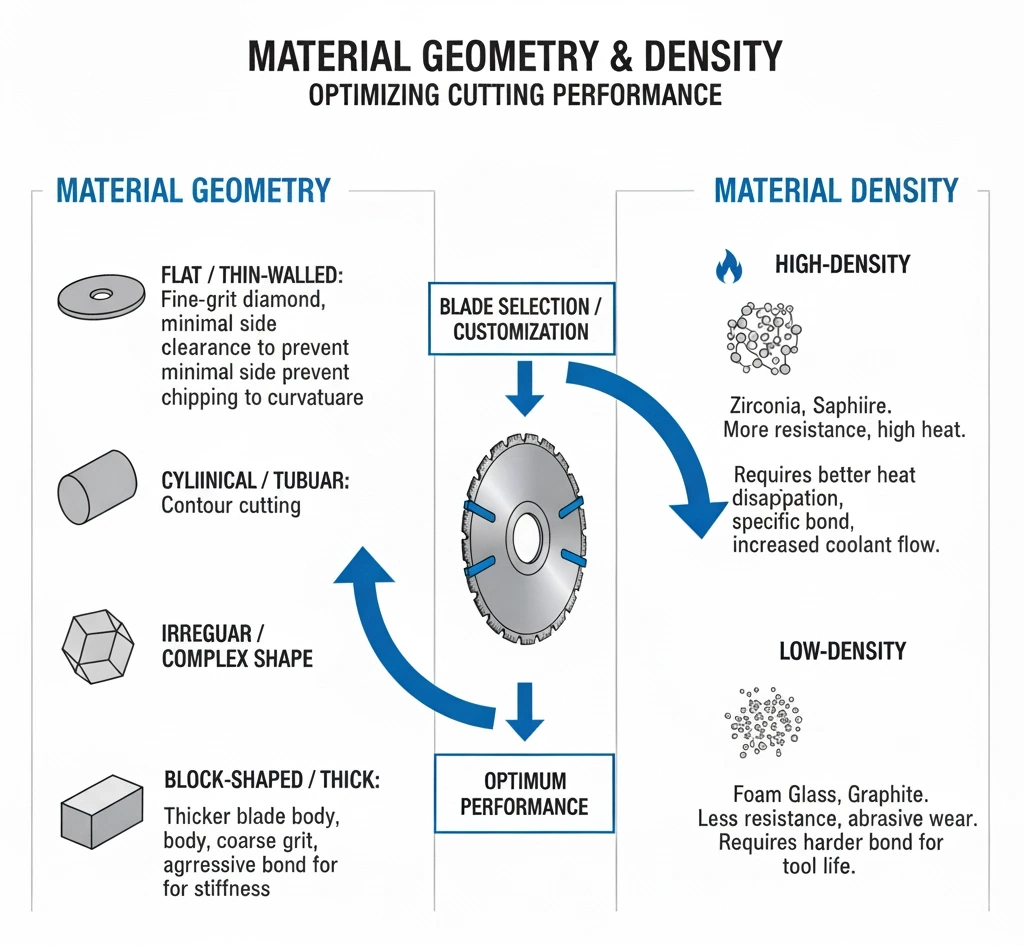

Material Geometry & Density

Material geometry and density play a central role in selecting the right diamond blade for your application. Every material differs in its density, hardness, internal structure, and chemical composition. These differences affect how the material interacts with the blade during the cutting process. As a result, a diamond blade and cutting parameters that work well on one material may fail completely or produce unacceptable results on another.

To achieve optimum cutting performance, each diamond blade should be selected—or ideally customized to match the unique characteristics of the specific material being cut. This includes not only its density and hardness, but also its shape, size, geometry, and brittleness. Cutting a dense, brittle material such as zirconia or sapphire requires a very different approach than cutting a ductile, low-density material like foam glass or graphite.

The geometry of the material whether it is flat, cylindrical, irregular, tubular, thin-walled, or block-shaped will significantly influence the type of blade required and how it is applied. For example, cutting a thin disc may require a blade with minimal side clearance and a high concentration of fine-grit diamond to prevent warping and edge chipping. In contrast, cutting a thick, heavy block of material may demand a thicker blade body, coarser grit, and more aggressive bond to maintain blade stiffness and cutting power.

Material density impacts the force needed to penetrate the workpiece and the amount of heat generated during the cut. High-density materials generate more resistance and require blades with better heat dissipation, often achieved through specific bond formulations and increased coolant flow. Lower-density materials, especially when abrasive, may cause premature wear and require harder bond blades to ensure longer tool life.

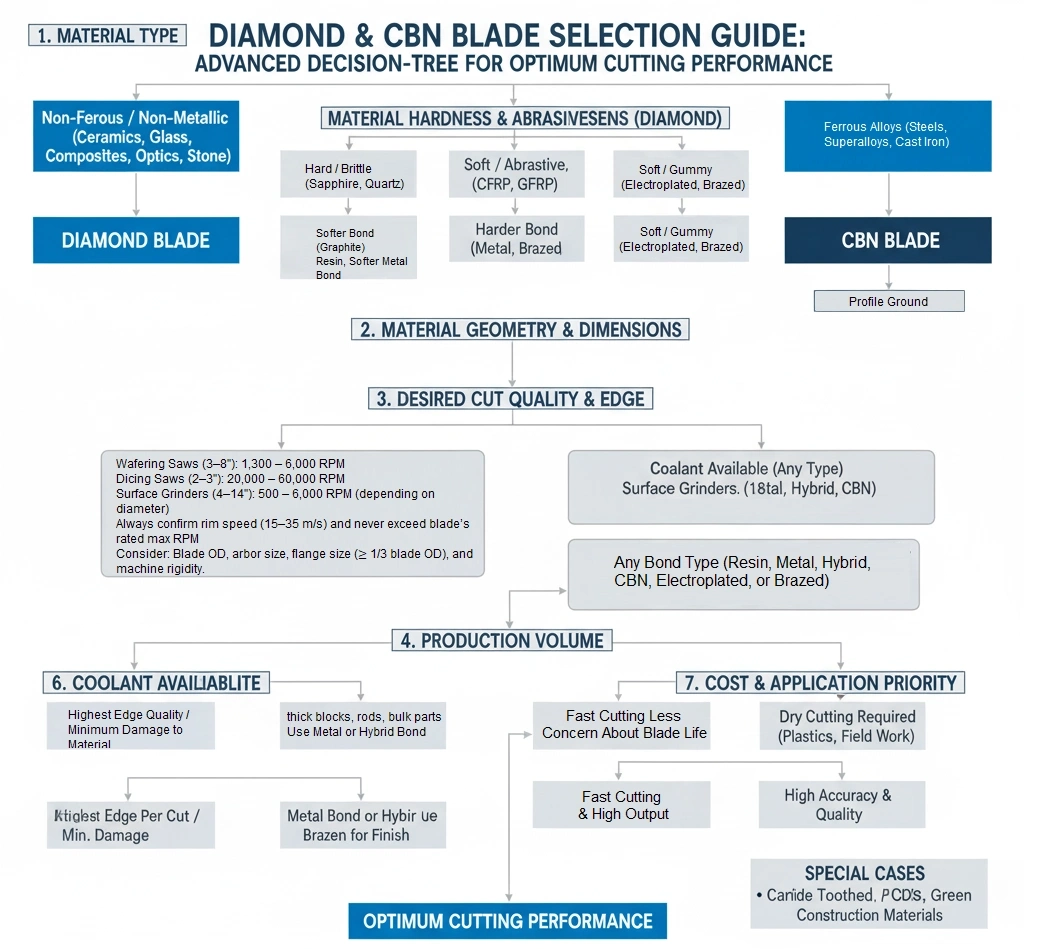

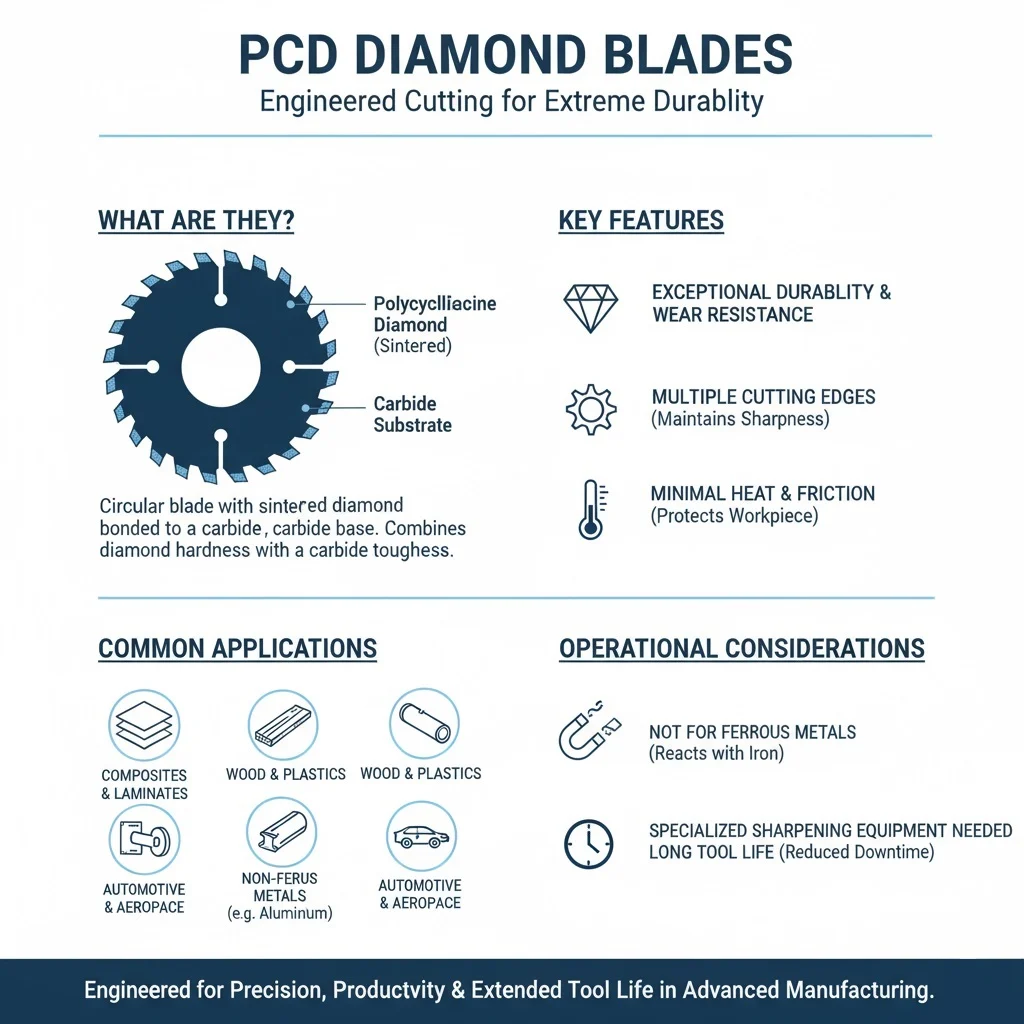

DIAMOND & CBN ABRASIVE SELECTION

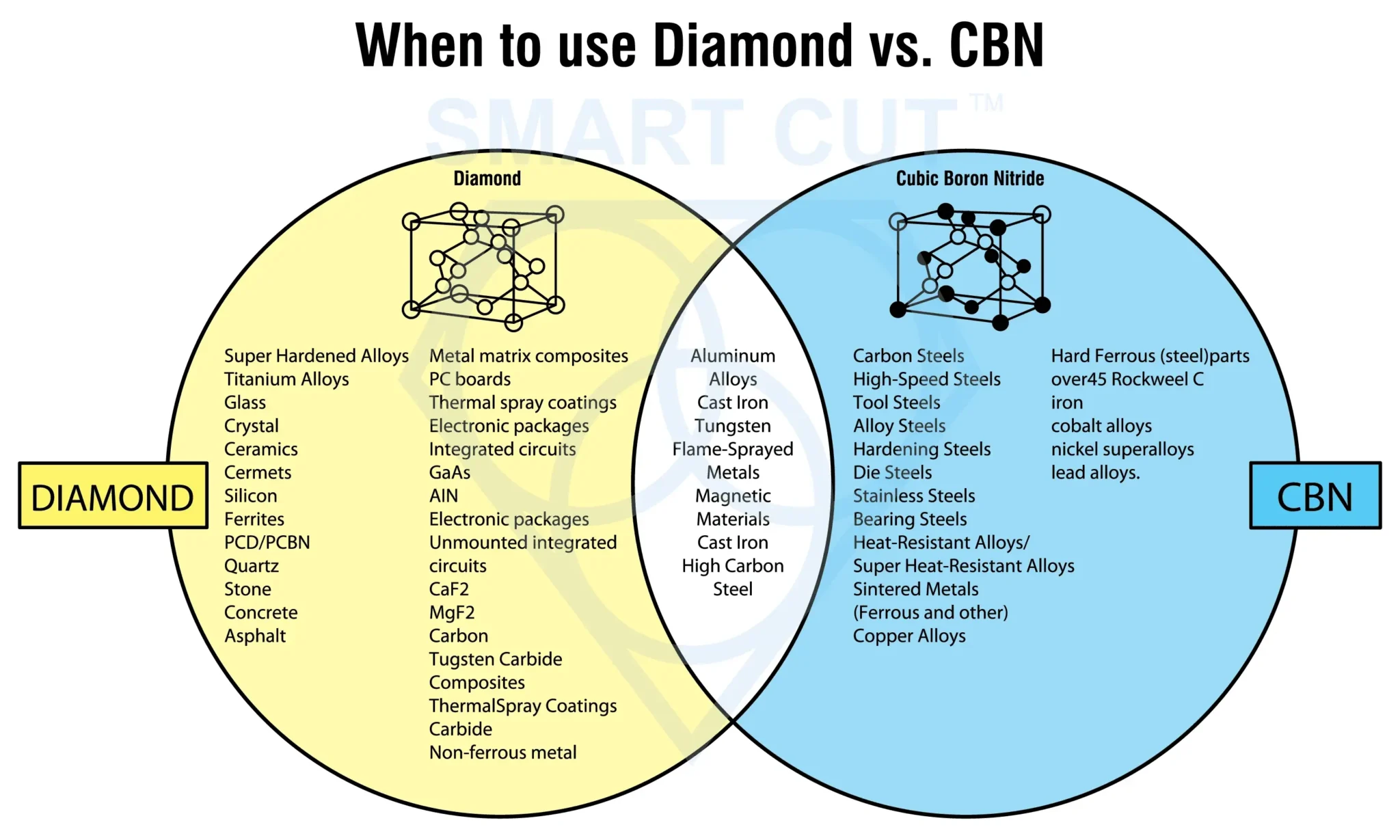

Choosing between diamond and cubic boron nitride (CBN) abrasives is the first step in selecting the right cutting blade for your application. The abrasive type determines how effectively the blade interacts with your material and directly impacts cut quality, tool life, and cost efficiency.

Diamond is the hardest known material and is recommended for hard and brittle materials such as optics, semiconductor packages, advanced ceramics, composites, glass, and non-ferrous metals. Diamond is also used on ferrous materials above 40 on the Rockwell scale, provided chemical reactivity at high temperatures is not a concern. Synthetic diamond is used almost exclusively in precision blades today because it offers consistent particle size, shape, and toughness. It can be engineered for specific cutting requirements, making it suitable for metal bond, resin bond, and electroplated (nickel bond) blades. By choosing the correct synthetic diamond grit size and concentration, users can balance surface finish, blade life, and cutting speed for their application.

Cubic Boron Nitride (CBN) is selected for ferrous alloys, hardened steels, tool steels, superalloys, and other materials with high metallic content. Unlike diamond, which chemically reacts with iron at elevated temperatures, CBN maintains its stability, making it the preferred abrasive for these applications. CBN blades can be manufactured in similar bond types to diamond, with the choice depending on whether the priority is long life, edge quality, or aggressive cutting performance.

In practice, the decision between diamond and CBN depends on the hardness, brittleness, and metallic composition of the material being cut. Diamond provides unmatched performance on brittle, non-metallic, and ultra-hard materials, while CBN ensures stable, reliable cutting of ferrous alloys. Understanding this distinction is essential to selecting the right blade for precision cutting.

Synthetic (Man Made) Diamonds – Most frequently used for most diamond blade manufacturing including sintered (metal bond), resin bond, electroplating (nickel bond). Synthetic diamond is more consistent in particle shape, hardness, and density. Synthetic diamond has replaced natural diamond in most applications because of this ability to tailor-make the diamond for the specific application.

Cubic Boron Nitride (CBN) – often used for machining materials with high metallic content.

The ability of a diamond to withstand an impact load is typically referred to as diamond impact strength. Other diamond-related factors, such as crystal shape, size, inclusions and the distribution of these crystal properties, play a role in the impact strength as well. Impact strength can be measured and is commonly referred to as Toughness Index (TI). In addition, crystals are also subjected to very high temperatures during manufacturing and sometimes during the cutting process. Thermal Toughness Index (TTI) is the measure of the ability of a diamond crystal to withstand thermal cycling. Subjecting the diamond crystals to high temperature, allowing them to return to room temperature, and then measuring the change in toughness makes this measurement useful to a diamond tool manufacturer.

The manufacturer must select the right diamond based on previous experience or input from the operator in the field. This decision is based, in part, on the tool’s design, bond properties, material to be cut and machine power. These factors must be balanced by the selection of diamond grade and concentration that will provide the operator with optimum performance at a suitable cost.

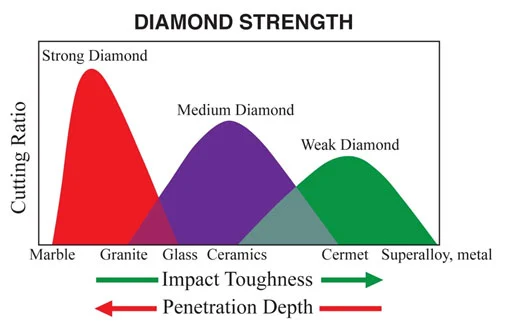

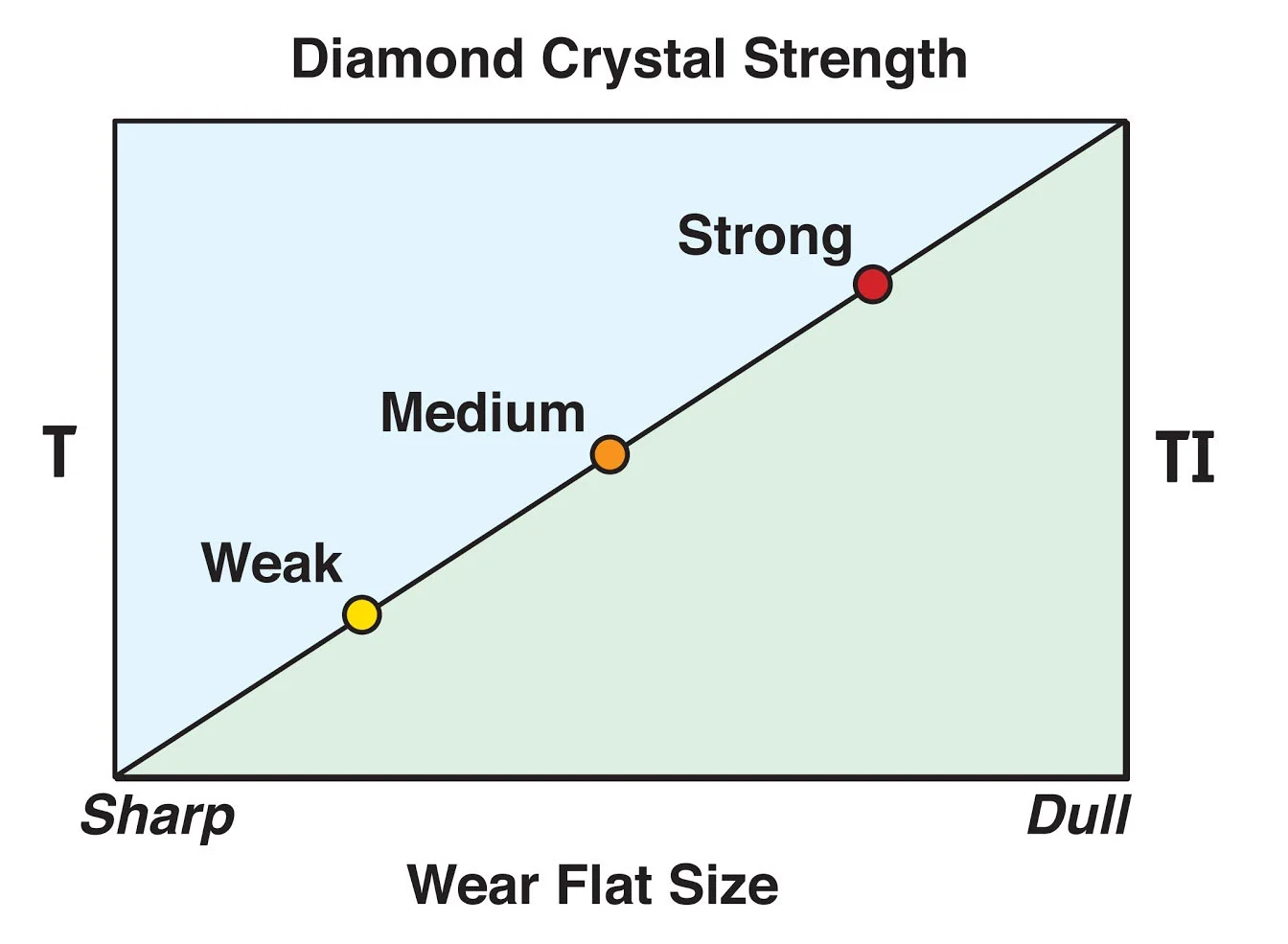

DIAMOND STRENGTH

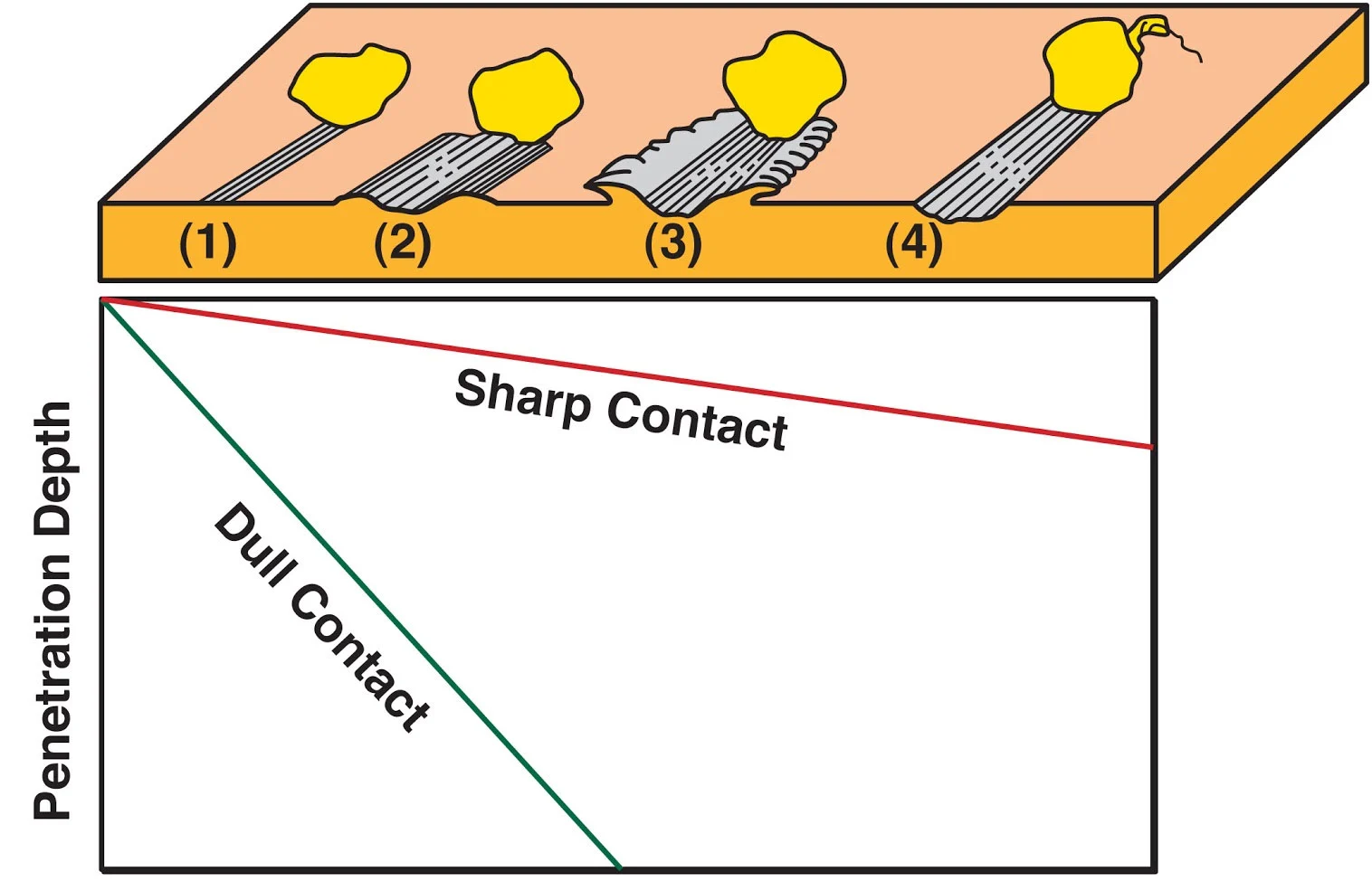

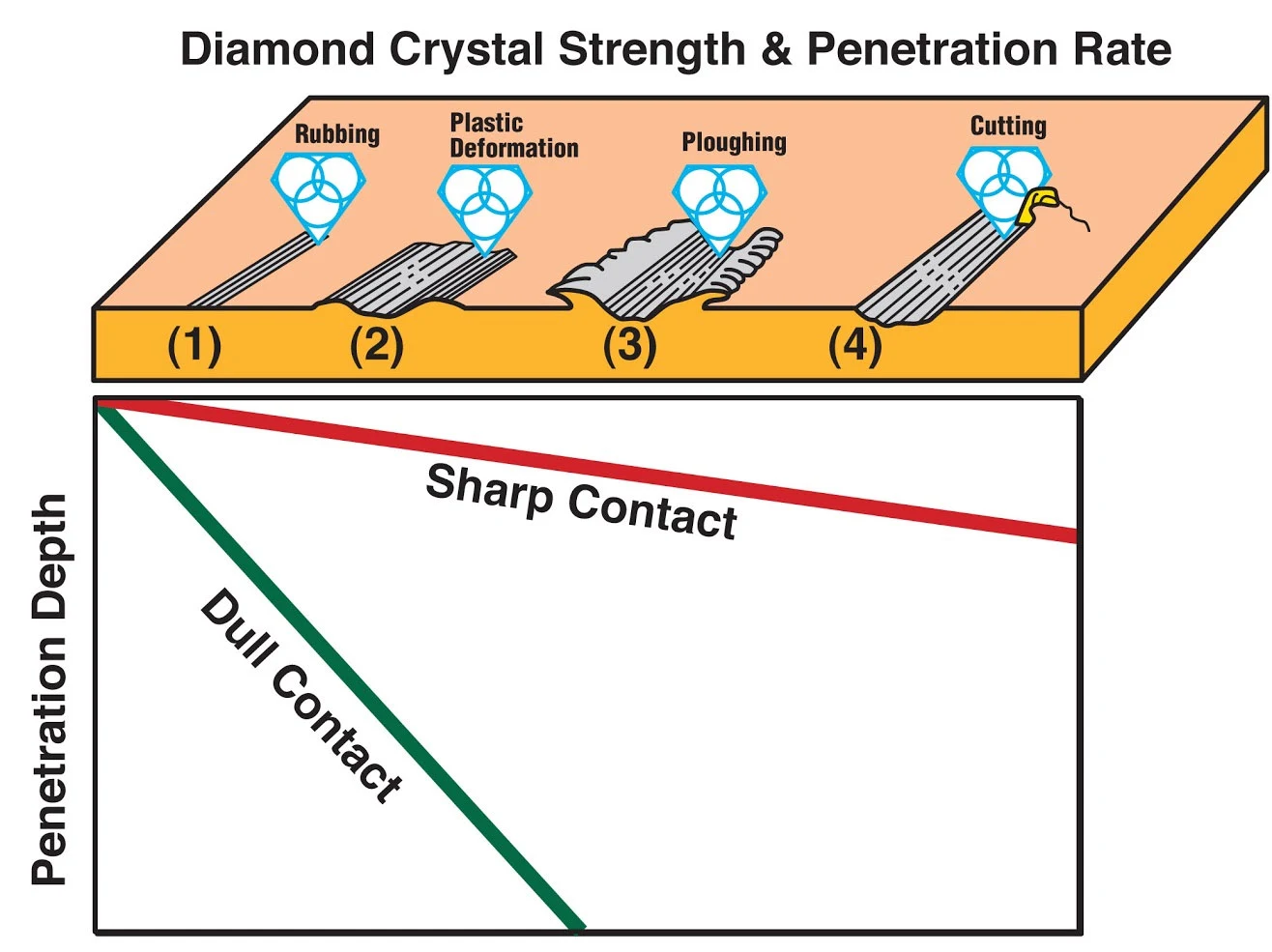

An overly strong diamond crystal will either be broken or lost, but an overly wear diamond crystal will be disintegrated too fast. For this reason diamond crystal strength must be adjusted to suit the impart force in such a way that micro chipping is the dominant mode of wear and occurs more slowly

Diamond crystal wear mechanism is dependent on diamond strength. In order to optimize the cutting performance in both cutting ration and cutting speed, diamond crystal loss must be turned to micro chipping at the expensive of smashing and pullout/micro fracture

If a tough diamond crystal is used to cut hard material will either be broken or it will be knocked off the bond matrix, depending on bond matrix hardness in comparison to diamond crystal. IF a diamond that is friable is embedded in a cushion

like a resin bond matrix and used to cut very hard material. Friable diamond will provide best level of performance at smaller cutting depth.

With deeper cutting depth the diamond crystal will be smashed quickly, yet with smaller cutting depth this diamond will stay sharp by forming microchips gradually. In this matter the shaper diamond crystals can penetrate the hard material and cut it in most efficient mater, by utilizing electrical energy. Diamond friability will increase with increasing toughness of the material. Here is each diamond crystal can cover a certain range of toughness. Diamond crystal will develop a wear flat and become too dull to penetrate.

Find more information about diamond specifications>>>

Cubic Boron Nitride (CBN)

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to diamond. CBN is the second hardest material known after diamond and exhibits similar properties to diamond in terms of wear resistance and thermal conductivity.

Share this Article with Friend or Colleague

CBN is primarily used in industrial applications, particularly for machining ferrous materials such as hardened steels, cast iron, and superalloys. Its hardness and thermal stability make it highly effective in high-speed machining operations, where it can withstand the heat and pressures generated during cutting and grinding processes. CBN tools, such as inserts, grinding wheels, and drills, are engineered to deliver superior performance, extended tool life, and high precision in demanding machining applications.

The exceptional properties of CBN have made it a valuable material in various industries, including automotive, aerospace, and manufacturing. Its ability to machine hardened materials with precision and efficiency has revolutionized the productivity and quality of metalworking CBN continues to be a subject of ongoing research and development to further enhance its properties and expand its applications in the field of cutting and abrasive tools. operations.

CBN is recommended for working with metals, specially iron and steel. Since carbon in steel reacts with carbon in diamond, quickly dulling the diamond crystal and slowing the material removal. CBN tools provide significantly reduced cutting times for tough, gummy materials, such as lead and titanium. However, CBN are not recommended for ceramics and other non metallic materials. CBN will provide optimal performance on difficult to cut materials. These CBN tools will significantly reduce your cutting time on ferrous materials compared to diamond tools.

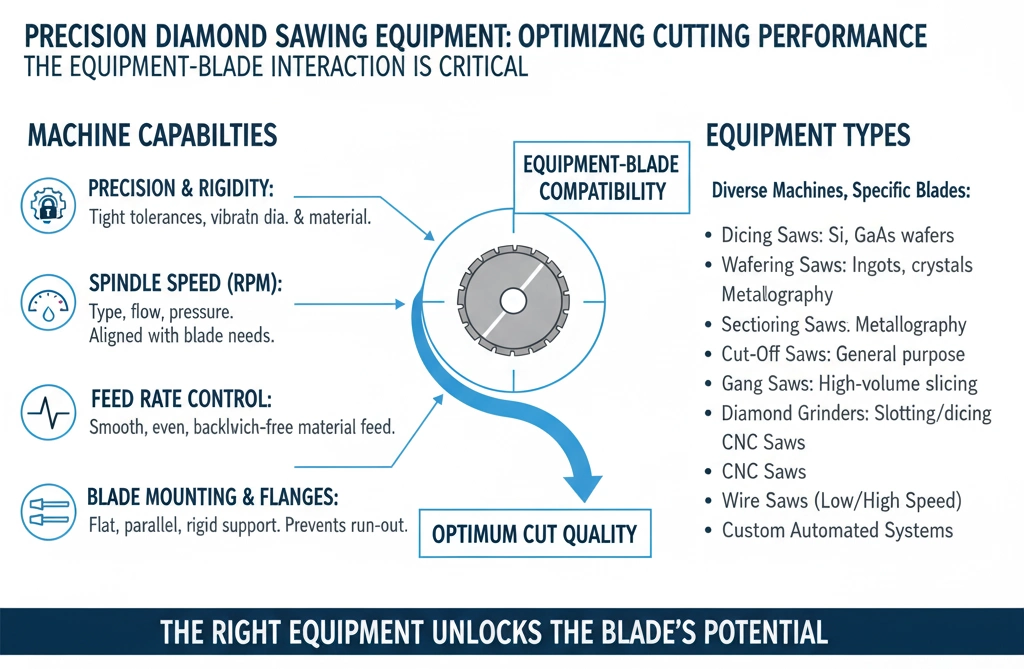

EQUIPMENT TO BE USED

The equipment you use and its overall condition plays a critical role in determining which diamond & cbn blade is best suited for your application. It directly affects your choice of blade specifications, operating parameters, and ultimately, the quality and consistency of your results.

Precision Diamond Sawing Equipment

Different cutting machines vary significantly in terms of precision, RPM range, feed rate control, coolant delivery, and rigidity. These variables will either expand or limit your options when selecting a blade. For example, a high-precision dicing saw allows the use of ultra-thin blades with micron-level tolerances and high RPM, while a basic tile saw may only support thicker, more general-purpose blades with limited accuracy.

The physical condition of your machine also matters. A well-maintained machine with tight mechanical tolerances and vibration control will deliver better results and allow for more advanced blade configurations. In contrast, worn-out spindles, misaligned tables, or inconsistent coolant flow can lead to premature blade wear, blade run-out, edge chipping, thermal damage, or poor cut accuracy no matter how high-quality the blade may be.

Additionally, your machine’s spindle speed (RPM) will define the peripheral speed at which the blade operates. Different blade diameters perform optimally at different RPM ranges. If your equipment cannot achieve or maintain the correct RPM for your selected blade, cutting performance will be compromised. Similarly, coolant compatibility must be considered. Some machines allow for pressurized or recirculated coolant systems, while others may only support gravity-fed or open-loop cooling. The type, flow rate, and pressure of the coolant system must align with the blade’s cooling and lubrication requirements.

The tolerances and repeatability of your equipment will also influence the level of precision and surface finish that can be achieved. This directly affects not only blade selection, but also feed rate settings, depth of cut, and fixturing requirements. If your machine lacks sufficient control or rigidity, you may need to compensate with a more robust blade design, slower cutting speeds, or modified tooling strategies.

Diamond blades are commonly used on a wide range of equipment types, including:

- Dicing saws

- Wafering saws

- Sectioning saws

- Precision cut-off saws

- Gang saws

- Surface grinders(adapted with thin-kerf blades/wheels)

- Diamond band saws

- Wire saws(in hybrid configurations or with blade attachments)

- CNC cutting saws and routers

- Laboratory low-speed saws

- High-speed automatic saws

- Metallographic saws

- Optical component saws(for glass, quartz, sapphire)

- Semiconductor package singulation saws

- Custom tube and rod cutting saws

- Panel saws for composites and laminates

- Slabbing saws(for geological and gemstone materials)

- Petrographic saws(for thin section preparation)

- Research and development sample prep saws

- Industrial production saws(custom automated systems)

Each equipment category supports a specific range of blade diameters, thicknesses, arbor sizes, tolerances, and bond types. Therefore, when selecting a diamond blade, you must ensure full compatibility with your machine’s specifications and operational capabilities.

In many cases, equipment limitations will influence not only what blade you can use, but how you use it. Even the most advanced diamond or cbn blade will underperform if used on equipment that lacks stability, cooling capacity, or speed control. That is why selecting the right blade must always be done in the context of the equipment it will run on.

To achieve consistent, high-quality results with Precision and Ultra-Thin Diamond Blades, your cutting equipment must meet specific mechanical and performance criteria. A diamond blade is only as effective as the saw or machine it operates on. Without the right equipment support, even the most advanced blade will underperform, wear prematurely, or produce poor results. For this reason, it is essential to ensure that your saw or cutting system is fully compatible with the blade specifications and cutting requirements of your application.

An adequate diamond cutting saw must be capable of providing sufficient cutting power, typically delivered through a motor with stable torque output across the required RPM range. Blade RPM (rotational speed) must be compatible with the blade diameter and material being cut. Running the blade too fast or too slow for its design can lead to overheating, blade warping, glazing, or excessive wear. You must ensure the machine supports stable and precise speed control, especially when working with ultra-thin blades or sensitive materials.

The saw must be equipped with a rigid, true-running spindle supported by high-quality bearings. Any spindle wobble, vibration, or axial play will be transferred to the blade, resulting in run-out, chipping, inconsistent kerf width, and loss of dimensional control. The blade mounting system must maintain proper alignment, ensuring that the blade remains centered and balanced after installation. Poor alignment causes uneven wear, side loading, and inconsistent cut quality.

Flanges play a critical role in blade stability. They must be flat, parallel, and ideally equal to at least one-third the diameter of the blade. Proper flange support helps prevent blade deflection, absorbs vibration, and maintains cut accuracy during extended cutting operations. Improper or undersized flanges are one of the leading causes of blade wobble and early blade failure in high-precision applications.

The work table or stage must feed the material smoothly, evenly, and without lateral play. Side-to-side movement during feeding can cause severe edge chipping, inconsistent depth of cut, and uneven wear on both the blade and the machine. Precision cutting applications demand tight mechanical tolerances and smooth, backlash-free movement.

Most Precision and Ultra-Thin Diamond Blades are designed for use with CNC or computer-controlled precision cutting equipment, where parameters such as feed rate, spindle speed, depth of cut, and coolant flow are closely monitored and controlled. In manufacturing environments, equipment selection varies widely depending on industry, material type, material size, and production volume.

For example, semiconductor manufacturers use high-speed dicing saws equipped with air-bearing spindles capable of reaching 25,000 to 35,000 RPM, allowing for extremely fine, fast, and accurate cutting of silicon wafers, substrates, and microelectronic components. These machines offer tight control over blade exposure, index step, and alignment, which is critical in singulation and wafer dicing.

In high-volume production environments, precision gang saws are often used for simultaneous slicing of multiple parts. These saws are ideal for applications such as slicing sapphire, quartz, and ceramics, where maximizing throughput without sacrificing cut quality is essential. Gang saws are also widely used in optics, semiconductor package singulation, and the production of glass tubes and rods.

Smaller operations or those involved in optics, materials science, or advanced ceramics may use manual or semi-automatic surface grinders for slotting, grooving, or slicing a wide variety of ultra-hard, brittle materials. While not as fast as dicing saws or gang saws, surface grinders offer versatility and are often well-suited to short-run, high-precision applications, especially when paired with specially formulated diamond blades.

Ultimately, your equipment must be matched not just to the blade, but to the specific needs of your material and cutting objective. Factors such as machine rigidity, speed capability, fixturing method, coolant delivery system, and automation level will all affect the performance of the diamond blade and the overall success of your cutting process.

COMMON PRECISION DIAMOND SAWING OPERATIONS FOR INDUSTRY AND R & D

Diamond sawing is a core process used across a wide range of industries and research applications for cutting, shaping, sectioning, and slicing ultra-hard, brittle, and exotic materials. These processes support both high-volume production and analytical investigations, depending on the application and material requirements. Selecting the appropriate sawing method is essential to achieving tight tolerances, clean edges, minimal material loss, and stable process repeatability.

Below are some of the most commonly used precision diamond sawing operations, along with their advantages and typical applications.

Diamond Slicing / Cut-Off Sawing

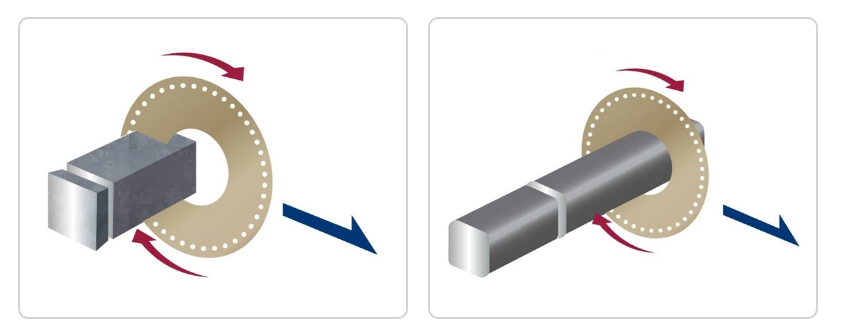

Diamond slicing refers to any operation in which a rotating blade is used to part or section material. This includes general cut-off as well as specialized forms like contour cutting or cropping. The most common slicing methods include:

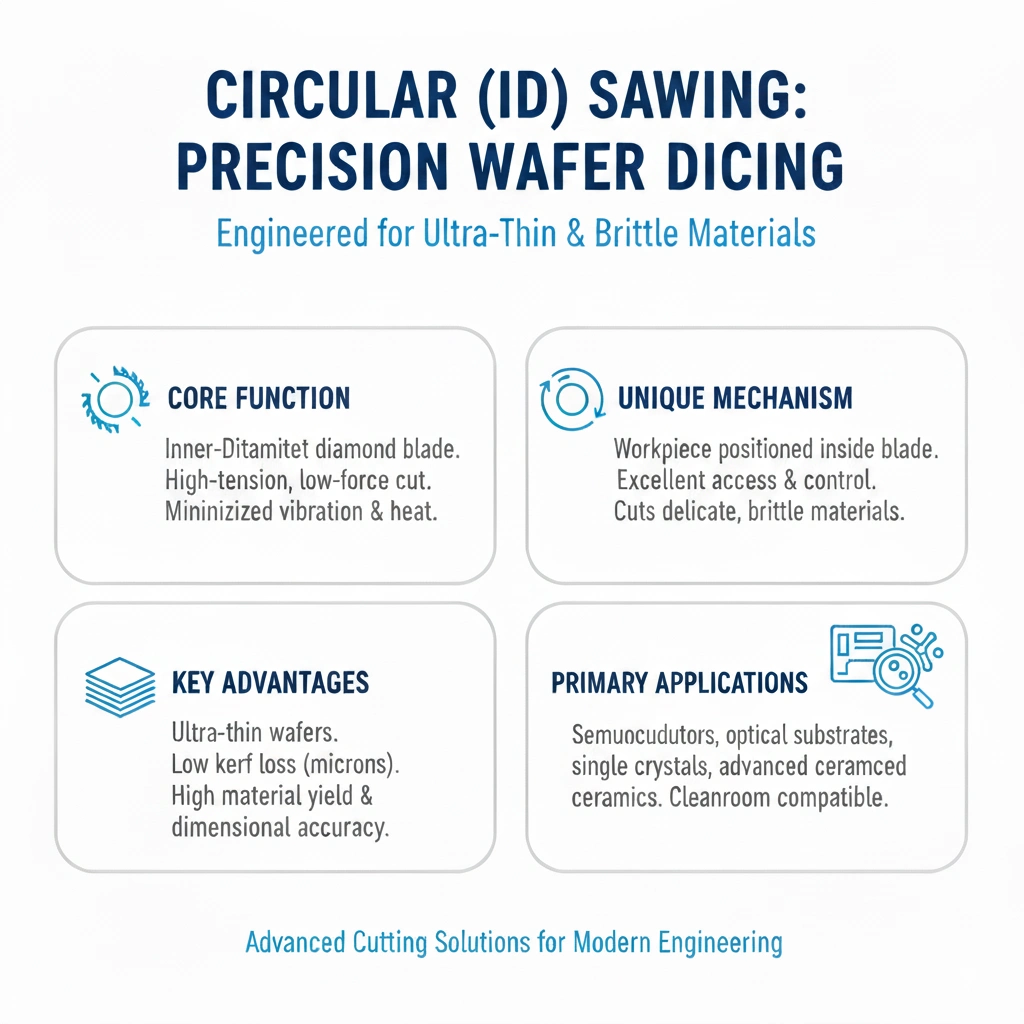

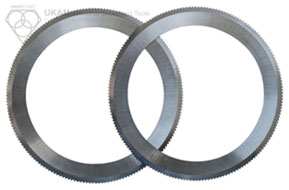

Circular or Annular (ID) Sawing

Circular or Annular (ID) sawing is a high-precision cutting process that uses a ID Diamond Cutting (Cropping Blade) ring-shaped diamond blade with the cutting edge located on the inner diameter of the blade. The blade is mounted under high tension within a rigid frame and driven by a high-precision spindle or chuck, allowing it to rotate at controlled speeds while maintaining concentricity and stability.

Unlike conventional saws that cut with their outer edge, ID saws allow the workpiece to be positioned inside the blade, providing excellent access and control during cutting. This configuration enables extremely fine, low-force cuts through delicate or brittle materials while maintaining exceptional dimensional accuracy and repeatability.

The cutting action is smooth and efficient, with minimal vibration, low heat generation, and reduced stress on the workpiece, making this method ideal for ultra-thin wafers, optical substrates, semiconductor materials, single crystals, and advanced ceramics. Kerf loss is very low, typically in the range of microns, allowing for maximum material yield, especially important when working with expensive or limited materials.

Because of their design, ID saws are commonly used in cleanroom environments, R&D labs, and precision manufacturing facilities where surface finish, edge integrity, and tolerance control are critical. With the proper blade selection and cutting parameters, this process delivers mirror-like surfaces, minimal subsurface damage, and eliminates the need for extensive post-processing.

Dicing Saws

Dicing is one of the most advanced precision cutting processes, designed to meet the extreme accuracy and reliability standards of the microelectronics and semiconductor industries. Beyond simple separation, dicing is about producing repeatable, damage-free cuts at the micron level, ensuring that every die or chip maintains its functional integrity throughout downstream processes.

This operation is performed on thin substrates such as silicon wafers, ceramics, gallium arsenide (GaAs), gallium nitride (GaN), indium phosphide (InP), and other compound semiconductors, which are often brittle, fragile, and costly. The use of Diamond dicing blades available in resin, metal, or hybrid bonds is essential to meet the dual requirements of narrow kerf widths and minimal chipping, while controlling cut depth with high precision. These blades are engineered in thicknesses often less than 100 microns, allowing maximum material yield and minimal waste.

Modern Dicing saws are highly sophisticated, equipped with CNC control systems, high-speed air-bearing spindles capable of 25,000 to 35,000 RPM, and precision motion stages. This combination enables operators to perform both full cut-through and partial depth cuts, depending on the design of the device or substrate. Multi-pass cutting strategies and programmable parameters allow optimization for each material’s hardness, thickness, and brittleness.

Applications of dicing extend across the singulation of integrated circuits, MEMS devices, photonic chips, optical sensors, LEDs, microfluidic devices, and sensor arrays. In each case, the priority is to produce clean edges, minimal burrs, and precise geometries that allow components to be assembled and packaged without reliability concerns. The superior edge quality and low mechanical stress delivered by this process are particularly important for mission-critical electronics, aerospace systems, medical devices, and high-performance photonics.

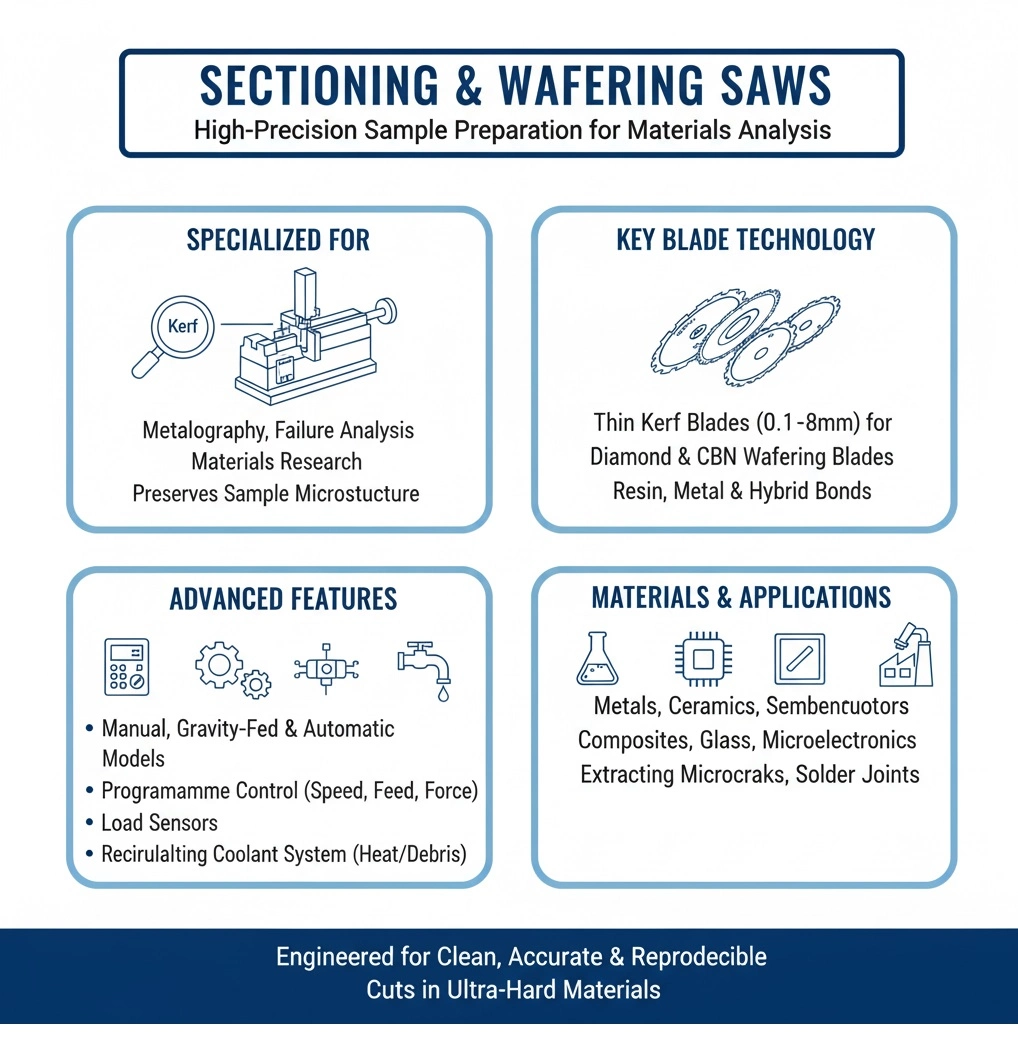

Sectioning / Wafering Saws

Sectioning and wafering saws are high-precision cutting systems used in metallography, failure analysis, and materials research to produce clean, accurate cross-sections of materials while preserving the sample’s microstructure. These saws are critical for isolating representative areas from a component with minimal thermal damage, deformation, or surface alteration, ensuring reliable downstream analysis.

They use diamond & cbn wafering blades or thin kerf abrasive blades, typically 0.1 mm to 0.8 mm thick, to achieve narrow kerf cuts and reduce material loss. These blades available in resin, metal, or hybrid bonds are suitable for cutting a wide range of materials including metals, ceramics, semiconductors, composites, glass, and microelectronic components. Wafering is ideal for extracting small features such as microcracks, solder joints, or defects without damaging surrounding areas.

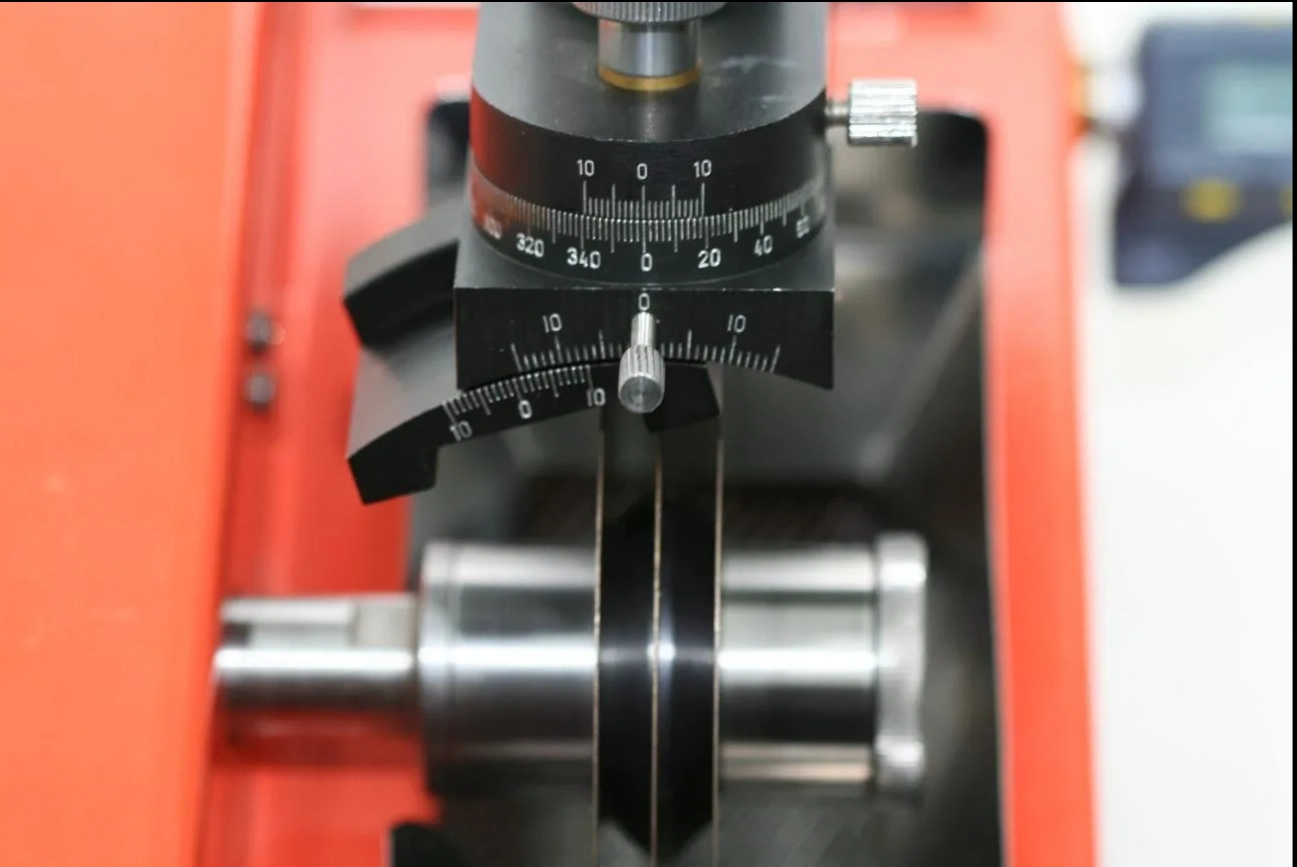

These saws are available in manual, gravity-fed, and fully automatic models. Fully automatic systems offer programmable control over key parameters such as spindle speed, feed rate, cutting depth, and force, and are ideal for high-throughput or repetitive tasks. Many models include digital micrometers, load sensors, and servo-driven feed mechanisms for enhanced precision and repeatability.

A key feature of these machines is the recirculating coolant system, which keeps both the blade and sample cool, reducing friction and flushing debris from the cut zone. This extends blade life and protects the sample from heat-related damage.

Whether used in an R&D lab or a production environment, sectioning and wafering saws are essential for producing clean, precise, and reproducible cuts in ultra-hard or brittle materials, forming the foundation for accurate material characterization and analysis.

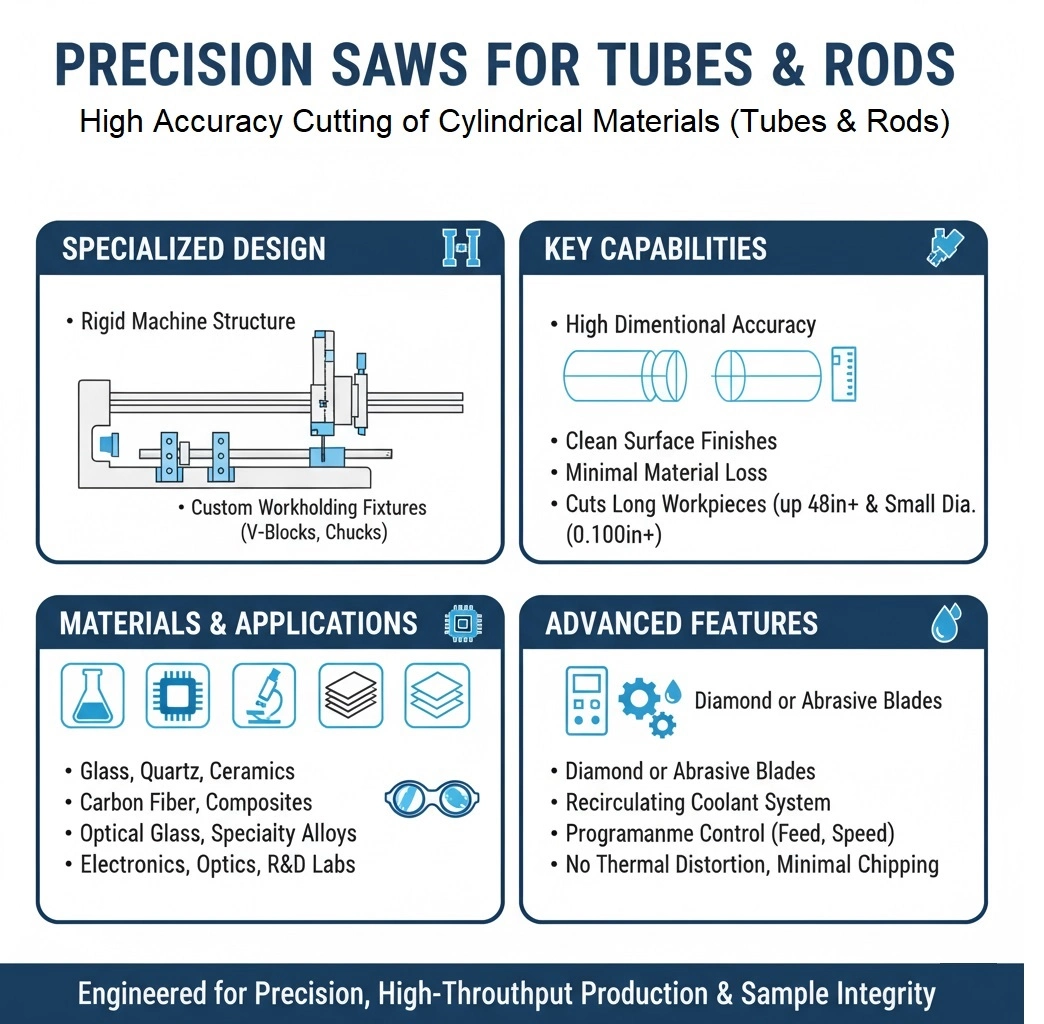

Cutting saws for tubes and rods

Cutting saws for tubes and rods are precision-engineered machines specifically designed to section cylindrical and tubular materials with high dimensional accuracy, clean surface finishes, and minimal material loss. These saws are essential for applications involving hard, brittle, or fragile materials, including glass, quartz, ceramics, carbon fiber, composites, optical glass, technical ceramics, non-ferrous metals, and specialty alloys.

Standard cutting equipment is often not suitable for these types of materials or geometries. Tubes and rods present unique challenges, such as vibration sensitivity, material deformation, and difficulty in securing the part during cutting. Tube and rod saws are specifically designed to overcome these challenges by offering rigid machine structures, precision-guided cutting heads, and customizable workholding fixtures that prevent part movement and ensure parallel, perpendicular, and repeatable cuts.

These saws are available in a range of configurations, from manual and semi-automatic units used in laboratories and R&D environments to fully automatic production-grade systems capable of high-throughput operation. Automatic versions offer programmable control over feed rate, cutting speed, blade position, and cutting depth, allowing for consistent and unattended operation with tight tolerances. These systems are ideal for high-volume production of electronic substrates, optical components, fused silica tubes, alumina rods, and machinable ceramics.

A key advantage of these machines is their ability to cut long workpieces often up to 48 inches or more while also accommodating small-diameter stock, including items as thin as 0.100 inches. This makes them suitable for cutting everything from microfluidic tubing and optical fibers to large diameter composite pipes.

The cutting process is performed using diamond or abrasive blades, selected based on the hardness and abrasiveness of the material. To maintain cutting quality and prevent heat damage, the saws are equipped with recirculating coolant systems that flush out debris, reduce friction, and keep both the blade and material cool. This results in minimal chipping, clean edges, and no thermal distortion, which is particularly important for samples that require further processing or analysis.

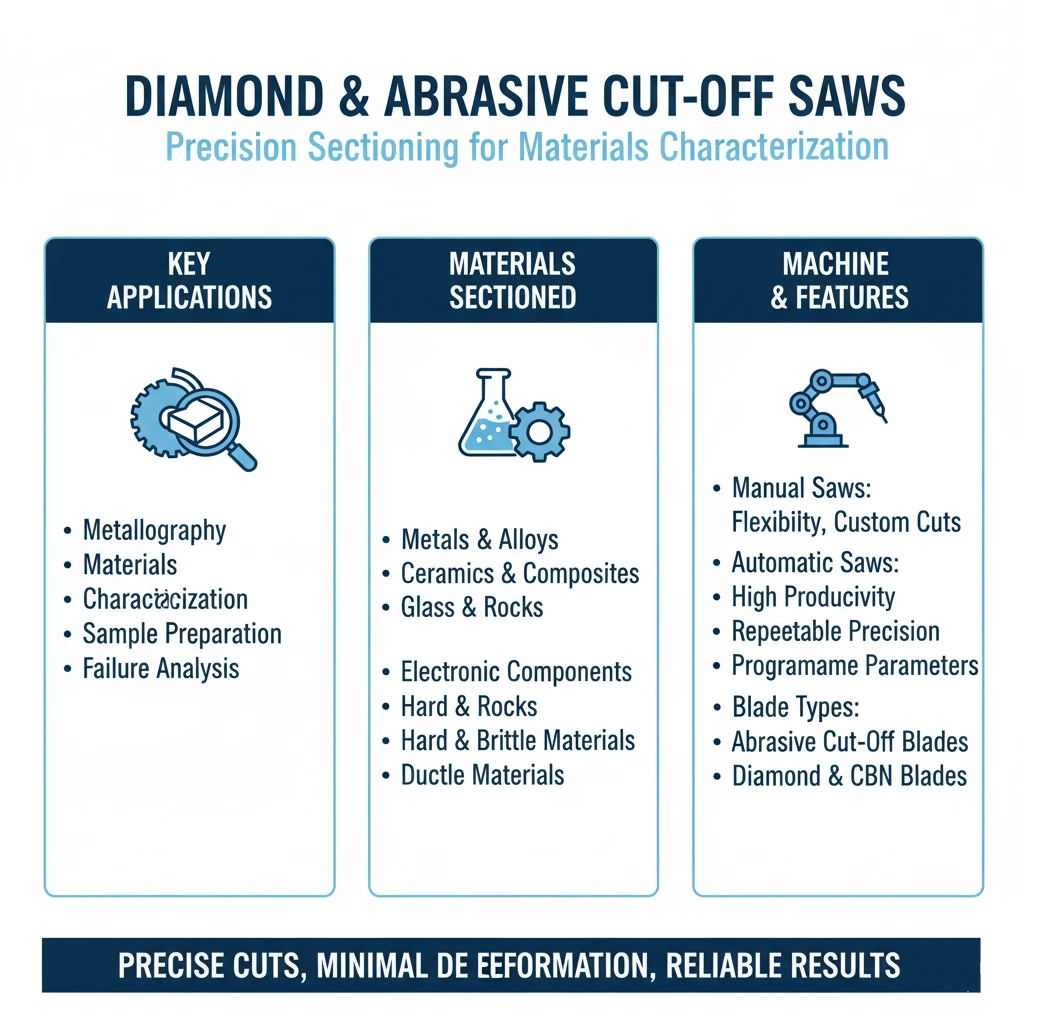

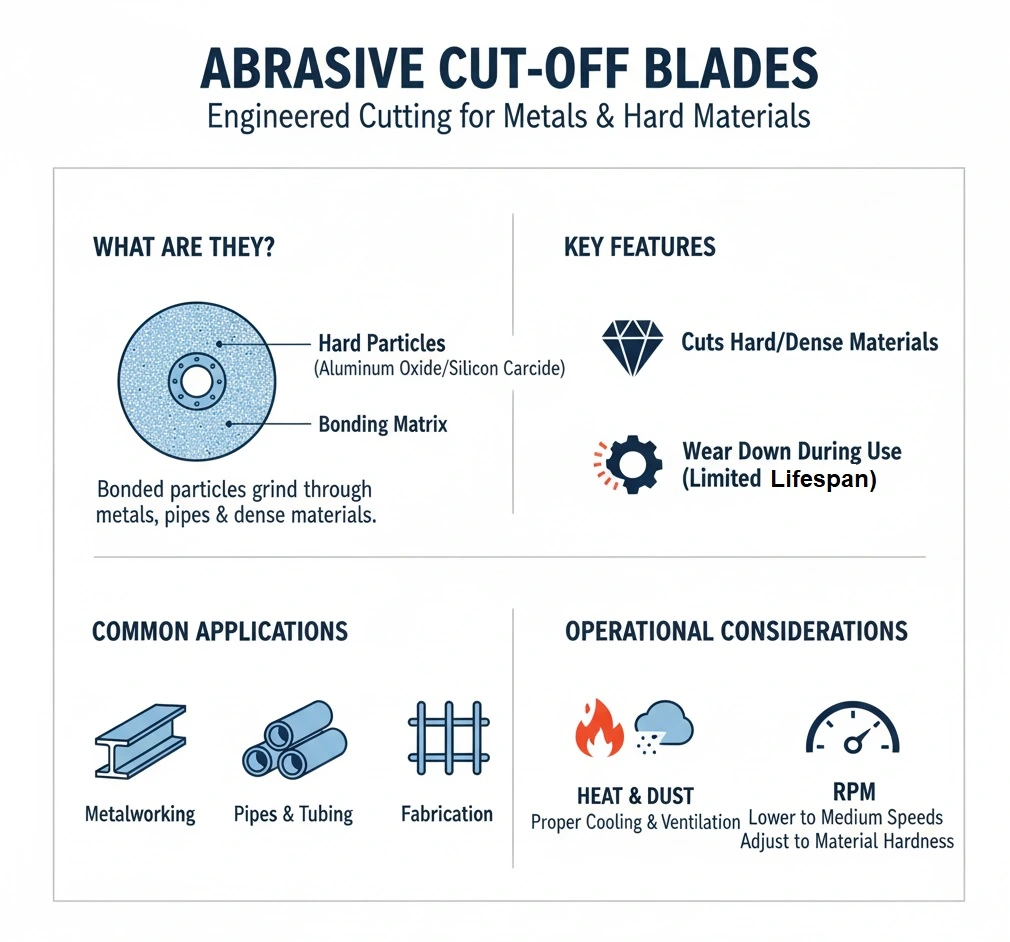

Diamond and abrasive cut-off saws

Diamond and abrasive cut-off saws are essential tools in metallography, materials characterization, and sample preparation, offering precise sectioning of a wide range of materials while preserving their structural integrity. These saws are specifically designed to produce clean, accurate cuts with minimal deformation, making them ideal for applications that require further analysis under microscopes or other inspection methods.

These machines are commonly used to section metals, ceramics, composites, glass, rocks, electronic components, and other materials found in manufacturing quality control labs, research and development, and failure analysis facilities. Whether you’re working with hard, brittle, or ductile materials, a properly selected diamond or abrasive blade combined with the right machine configuration can help achieve consistent and reproducible results.

These machines use both abrasive cut off blades and diamond & cbn cut off blades. Both manual and automatic models are available to meet varying throughput and precision needs. Manual saws provide flexibility and direct operator control for custom cuts and irregular-shaped samples, while automatic saws are designed for repetitive sectioning, enabling high productivity, operator safety, and repeatable precision. Automatic models often feature programmable parameters such as cut depth, feed rate, and spindle speed, allowing for optimal settings based on the material being sectioned.

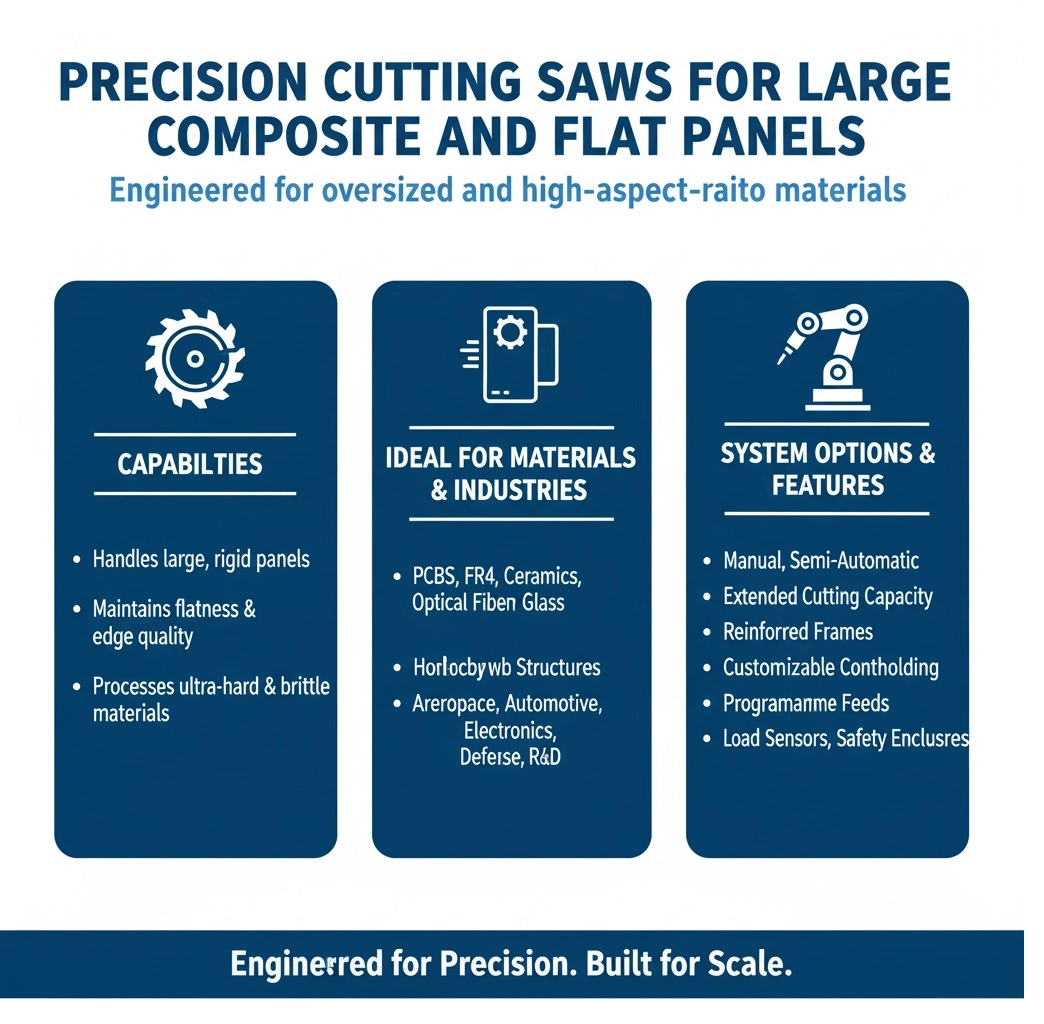

Precision Cutting Saws for Large Composite and Flat Panels

Precision Cutting Saws for Large Composite and Flat Panels are specifically engineered to handle materials that exceed the size or rigidity limitations of conventional high-precision cutting equipment. These saws are essential for applications where flatness, edge quality, and dimensional control must be preserved while processing oversized or irregularly shaped panels.

These machines are ideal for cutting sample coupons, test sections, or production parts from materials such as printed circuit boards (PCBs), FR4, ceramic substrates, electronic packaging, optical glass, flat panels, laminates, carbon fiber composites, fiberglass, honeycomb structures, and other ultra-hard or brittle materials. Many of these materials are used in aerospace, automotive, electronics, defense, and advanced research laboratories, where maintaining structural integrity and precision is critical.

Standard precision sectioning machines often cannot accommodate large-format samples or high-aspect-ratio materials without compromising cut quality or risking damage. In contrast, these specialized saws are designed with extended cutting capacity, reinforced frames, and customizable workholding systems to process parts that are too large or wide for traditional equipment.

Depending on the application, you can choose between manual, semi-automatic, or fully automatic systems, each offering varying levels of control, throughput, and automation. Our machines can be equipped with programmable controllers, servo-driven feed systems, load sensors, and safety enclosures to meet the demands of both production environments and materials R&D labs.

Cutting Saws for Petrographic Sample Preparation

Precision cutting saws for petrographic sample preparation are specially designed to meet the demanding requirements of geology, mineralogy, materials science, and petrography labs. These saws allow researchers and technicians to accurately section rocks, ores, fossils, ceramics, and other geological materials to produce high-quality samples for thin sectioning, grinding, polishing, and microscopic examination.

The goal of these machines is to cut samples while minimizing structural damage, heat generation, and surface deformation, which can interfere with petrographic analysis. These saws are typically used as the first step in thin section preparation, where flatness, parallelism, and preservation of original microstructure are critical. These machines use specialized diamond cutting blades for thin section and petrographic samples.

Available in manual, semi-automatic, and fully automatic configurations, these machines support a wide range of cutting tasks, from small delicate samples to large or irregularly shaped specimens. Some units combine both cutting and grinding capabilities in a single compact system, streamlining the sample preparation process and saving lab space. Others are heavy-duty models built for processing larger specimens, or tabletop systems ideal for routine use in teaching labs or research facilities.

These machines accept a wide range of diamond blades, optimized for cutting igneous, sedimentary, and metamorphic rocks, as well as technical ceramics and sintered materials. Integrated coolant systems help control temperature, reduce dust, and improve blade life while producing clean, flat surfaces.

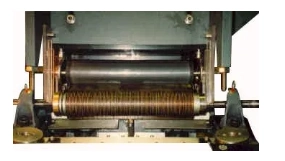

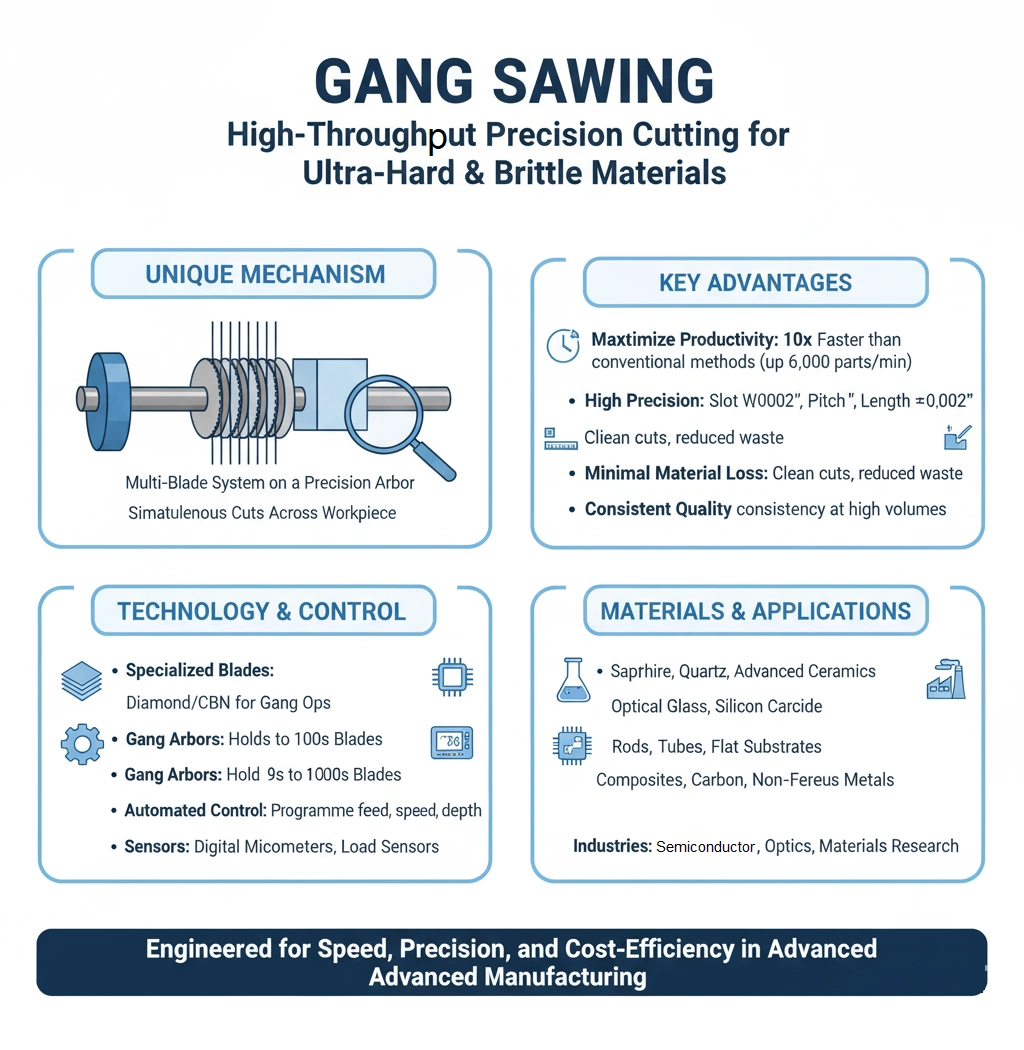

Gang Sawing

Gang sawing uses a multi-blade system mounted on a precision arbor to make simultaneous cuts across a single workpiece. This method is highly effective for high-throughput production of ultra-hard and brittle materials, such as sapphire, quartz, advanced ceramics, optical glass, and silicon carbide.

Because feed rates are typically very slow when cutting such hard materials, the multi-blade configuration allows all parts to be cut in one or two passes, dramatically increasing productivity. Precision gang saws maintain slot width tolerances within ±0.0002 in (±5.08 µm) and pitch tolerance of ±0.0002 in, ensuring dimensional consistency even at high volumes. These machines use specialized diamond / cbn cutting blades specially for gang operations.

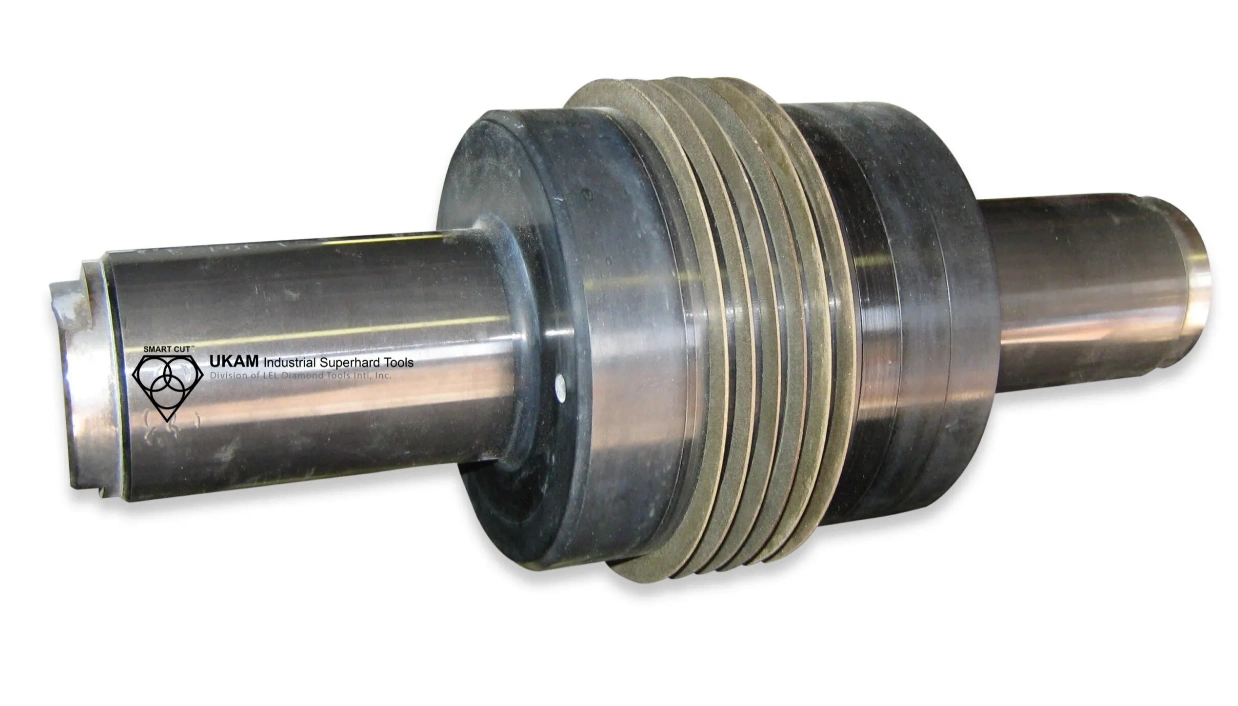

These use specialized gang arbors that can hold from several to over a hundred blades. Modern gang saws are capable of cutting rods, tubes, and flat substrates across a wide material spectrum, including glass, quartz, ceramics, fiber-reinforced plastics, carbon materials, and non-ferrous metals. These systems deliver production speeds 10 times faster than conventional methods, processing up to 6,000 parts per minute depending on part size. Normal length tolerances are ±0.002″, and squareness is within ±1.0 degrees, offering speed, precision, and cost-efficiency for industries that demand high output with strict quality standards.

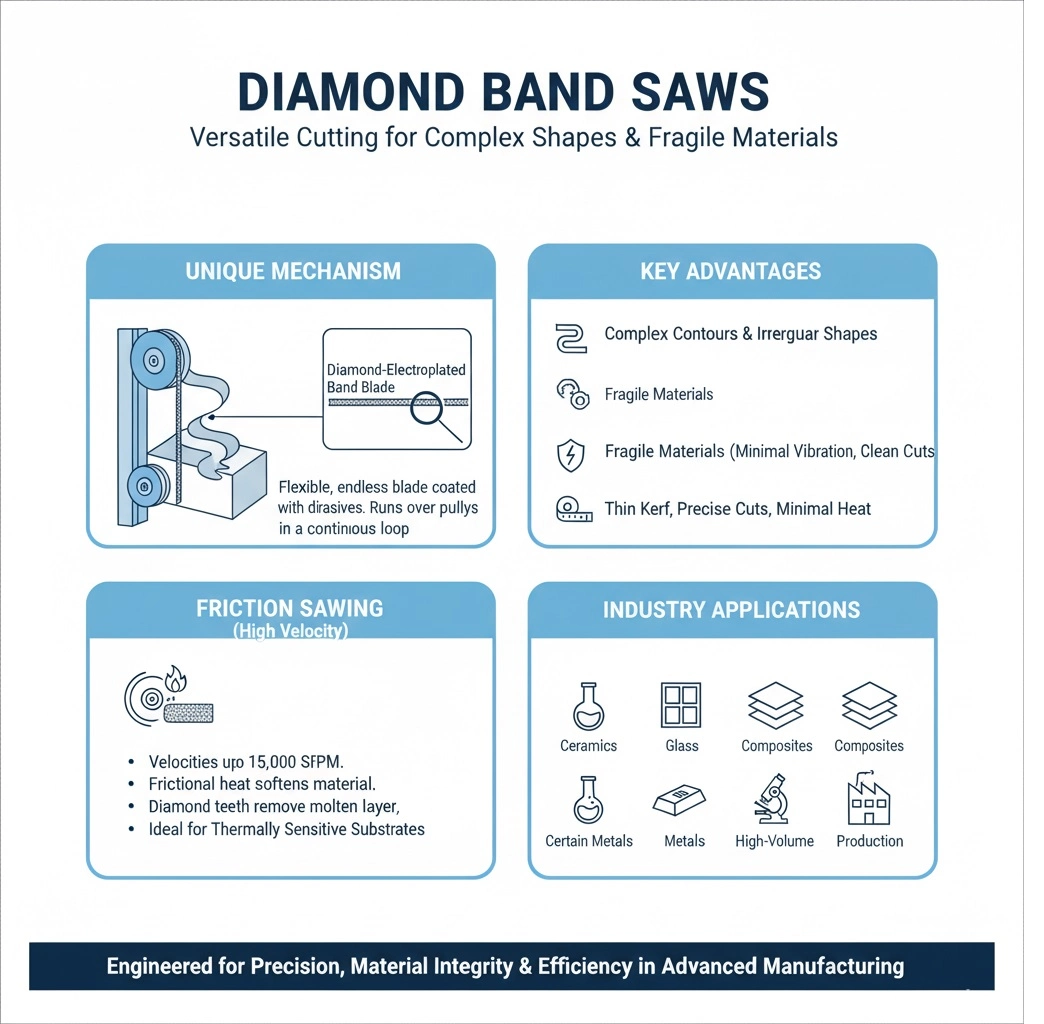

Diamond Band Sawing

Diamond band sawing uses a flexible, diamond band saw blades which is endless band blade coated with diamond grit, typically by electroplating. The blade runs over two pulleys and passes through the workpiece in a continuous loop. This method is excellent for cutting complex contours, irregular shapes, and fragile materials where vibration must be minimized.

Band saws are commonly used to cut ceramics, glass, composites, and certain metals. The electroplated diamond layer is embedded in a nickel matrix, which provides strong diamond retention and ensures clean, precise cuts with minimal heat generation. Friction saws, a variation of diamond band saws, can reach velocities of 15,000 surface feet per minute (sfpm), where frictional heat softens the material and the diamond teeth remove the molten layer. This method is particularly effective for hard, thermally sensitive substrates, where conventional cutting would cause cracking or distortion.

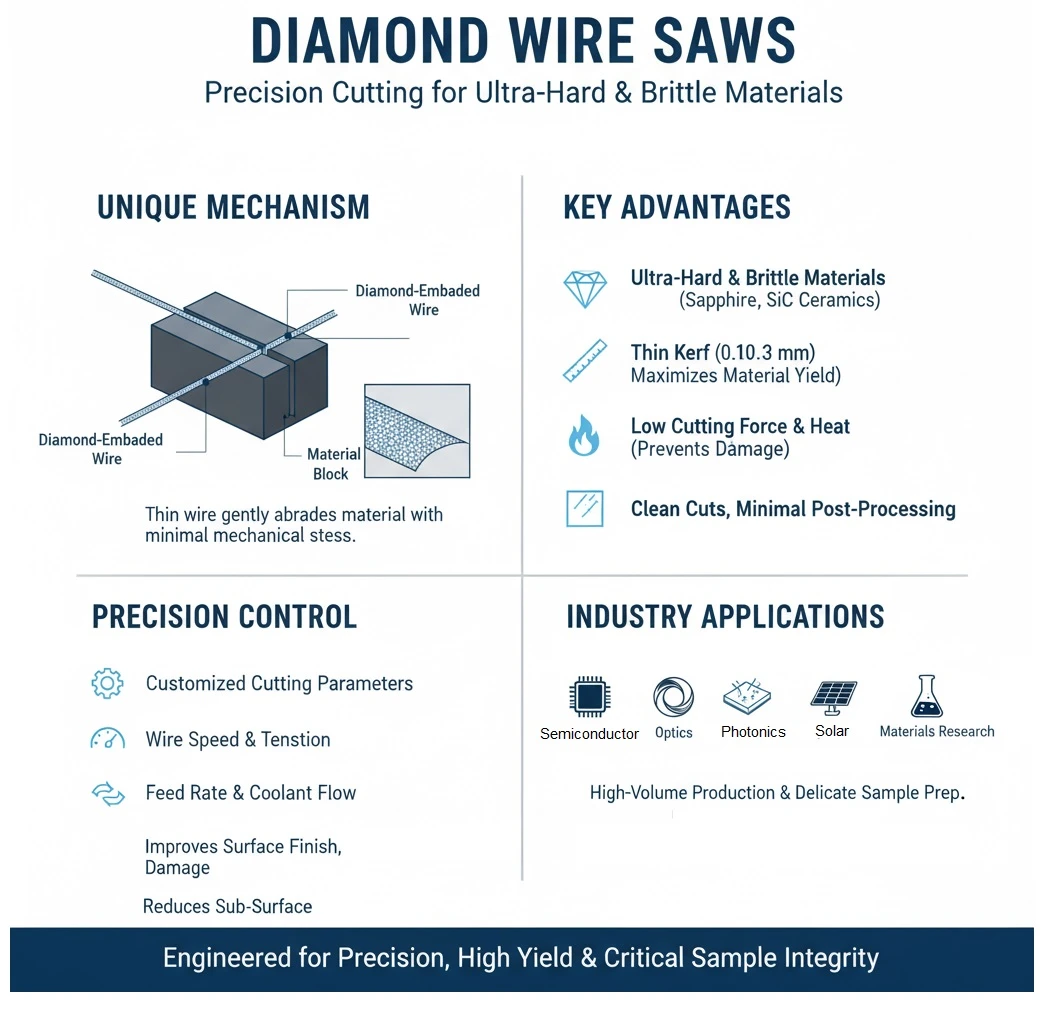

Diamond wire saws

Diamond wire saws are highly effective for cutting ultra-hard and brittle materials such as sapphire, silicon carbide, fused quartz, ceramics, optical glass, and other advanced substrates. Unlike conventional blades, diamond wire saws use a diamond wire which is thin wire embedded with diamond abrasives to gently abrade the material with minimal mechanical stress.

This method is ideal for materials that are prone to cracking, chipping, or thermal damage, as the wire produces low cutting forces and generates minimal heat. The process delivers exceptionally clean cuts, often eliminating the need for extensive post-processing.

One of the most important advantages of diamond wire sawing is its ability to achieve a very thin kerf, typically in the range of 0.1 to 0.3 mm, which helps to maximize material yield—especially critical when working with expensive or limited materials. The thin kerf also contributes to higher precision and less waste.

Cutting parameters such as wire speed, tension, feed rate, and coolant flow can be precisely controlled to match the material and application. This enables customized cutting strategies that improve surface finish, reduce sub-surface damage, and extend tool life.

Diamond wire saws are used across semiconductor, optics, photovoltaics, and materials research industries for both high-volume production and delicate sample preparation. Their ability to cut difficult materials with precision, low force, and minimal loss makes them a critical tool in advanced material processing.

Diamond Grinding

Diamond grinding is a material removal operation where abrasive diamond particles, held in a resin, metal, or vitrified bond, remove material through mechanical abrasion. It supports a broad range of grinding formats:

- Precision surface grindingfor flatness and squareness

- Cylindrical and centerless grindingfor external shapes and profiles

- Chamfering and form grindingfor edge finishing and grooves

- Offhand grindingfor manual operations

- Tool and cutter grindingfor carbide, PCD, or ceramic tools

- Lapping and polishingfor mirror-finish surfaces in optics and electronics

- Honing and disc grindingfor ultra-flat surfaces and internal diameters

Diamond grinding is especially critical for achieving sub-micron finishes, tight dimensional control, and edge quality on ceramics, sapphire, hard metals, and composites. It is often the final step in component fabrication or preparation for inspection and bonding processes.

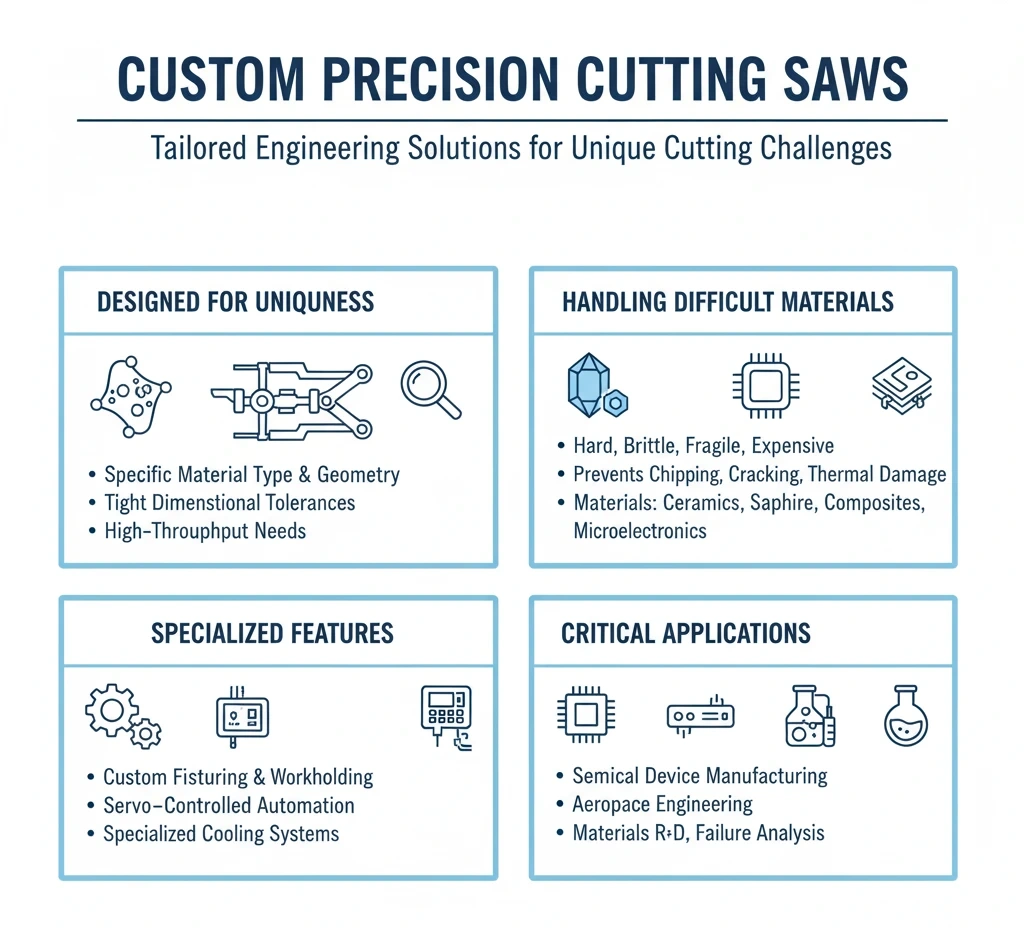

Custom precision cutting saws

Custom precision cutting saws are specialized machines engineered to meet unique cutting requirements that cannot be effectively addressed with standard or off-the-shelf equipment. These saws are tailored to a customer’s specific material type, part geometry, dimensional tolerances, throughput needs, and application environment. They are used in situations where high precision, specialized tooling, or complex automation is required to consistently produce accurate and repeatable cuts.

Unlike general-purpose machines, custom saws are designed around the exact challenges of the user’s process. This may include handling very hard, brittle, fragile, abrasive, or expensive materials such as ceramics, quartz, sapphire, optical glass, advanced composites, aerospace alloys, or microelectronic substrates. In many cases, these materials require highly controlled cutting conditions to prevent chipping, microcracking, thermal damage, or dimensional distortion.

Custom saws are also used when the part being cut is non-standard in shape or size, such as tubes, rods, irregular geometries, large panels, or miniature components. These machines can include custom fixturing, servo-controlled automation, programmable logic, and specialized cooling systems to meet both technical and production demands.

Applications span across semiconductor fabrication, medical device manufacturing, aerospace engineering, optics and photonics, geology, materials research, and failure analysis labs, where cutting accuracy, repeatability, and surface integrity are mission critical.

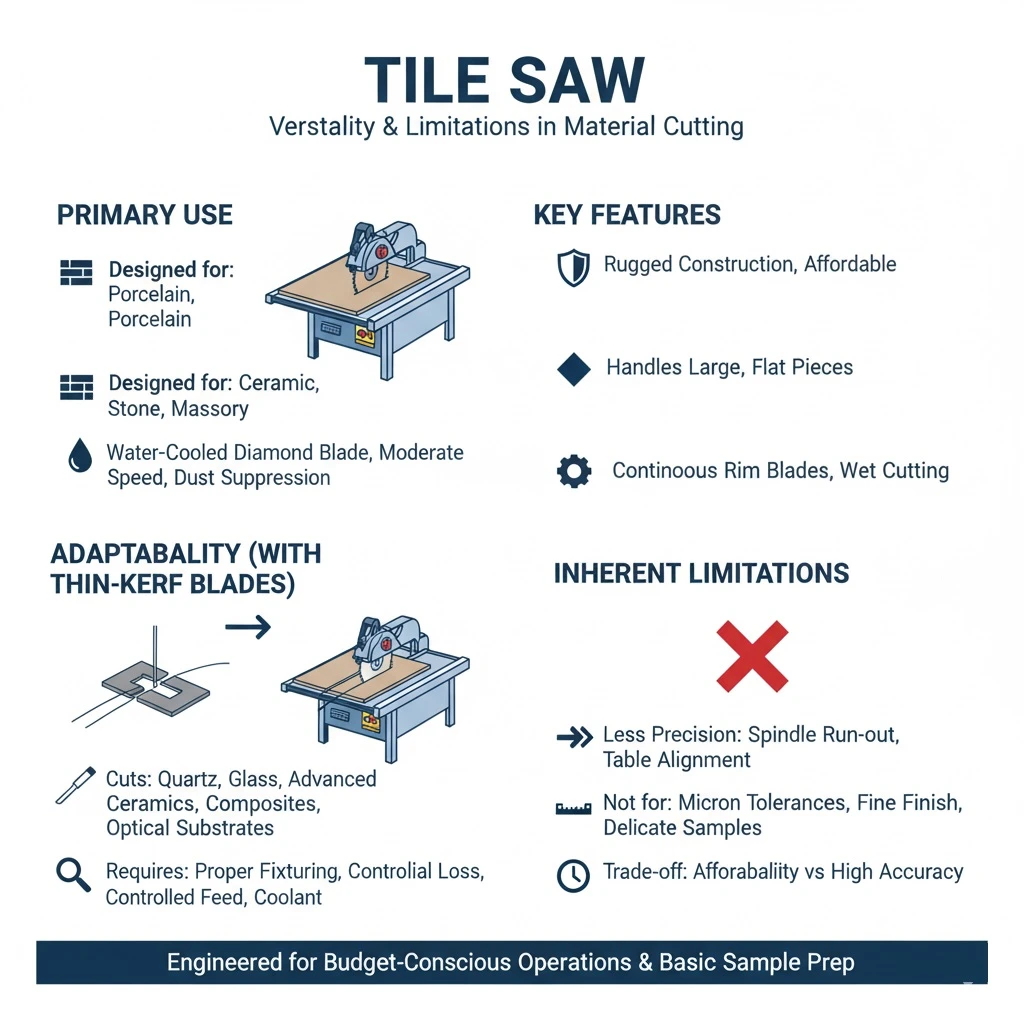

Tile Saw

A tile saw is a general-purpose cutting machine originally designed for use in the construction and stone industries to cut ceramic tiles, porcelain, masonry, and natural stone. These saws typically use a water-cooled diamond blade, supported by a sliding table or rail system, to provide straight, clean cuts in materials that are relatively hard but not as demanding as advanced technical substrates.

Tile saws are valued for their rugged construction, affordability, and ability to handle larger, flat pieces. Most models are equipped with continuous rim diamond blades and operate at moderate spindle speeds, with water delivered to the blade to suppress dust and cool the cutting zone. While they are not designed with the same tolerances or spindle accuracy as laboratory-grade precision saws, tile saws can still be adapted for more demanding applications when paired with the correct blade technology and careful setup.

By equipping a tile saw with thinner, high-precision diamond blades, it is possible to extend its capabilities to cut a wider range of ultra-hard and brittle materials such as quartz, glass, advanced ceramics, composites, and even some optical substrates. These thinner blades reduce the kerf width, which lowers cutting forces, minimizes chipping, and decreases material loss. When combined with proper fixturing, controlled feed rates, and adequate coolant delivery, a tile saw can perform reasonably well on materials far outside its intended use.

It is important to note that while a tile saw can be adapted for these purposes, it does have limitations. The machine’s spindle run-out, table alignment, and feed stability are generally less precise compared to dedicated precision sectioning or wafering saws. This means that while tile saws can produce functional cuts in a broad range of hard materials, they are not suitable for applications requiring micron-level tolerances, delicate sample preparation, or extremely fine surface finishes.

For labs, small-scale workshops, or budget-conscious operations, a tile saw equipped with the right thin-kerf diamond blade offers a practical entry-level solution for cutting difficult materials. While not a substitute for true precision equipment, it can bridge the gap between affordability and capability, making it a useful option when cutting larger samples or when ultra-high accuracy is not the primary requirement.

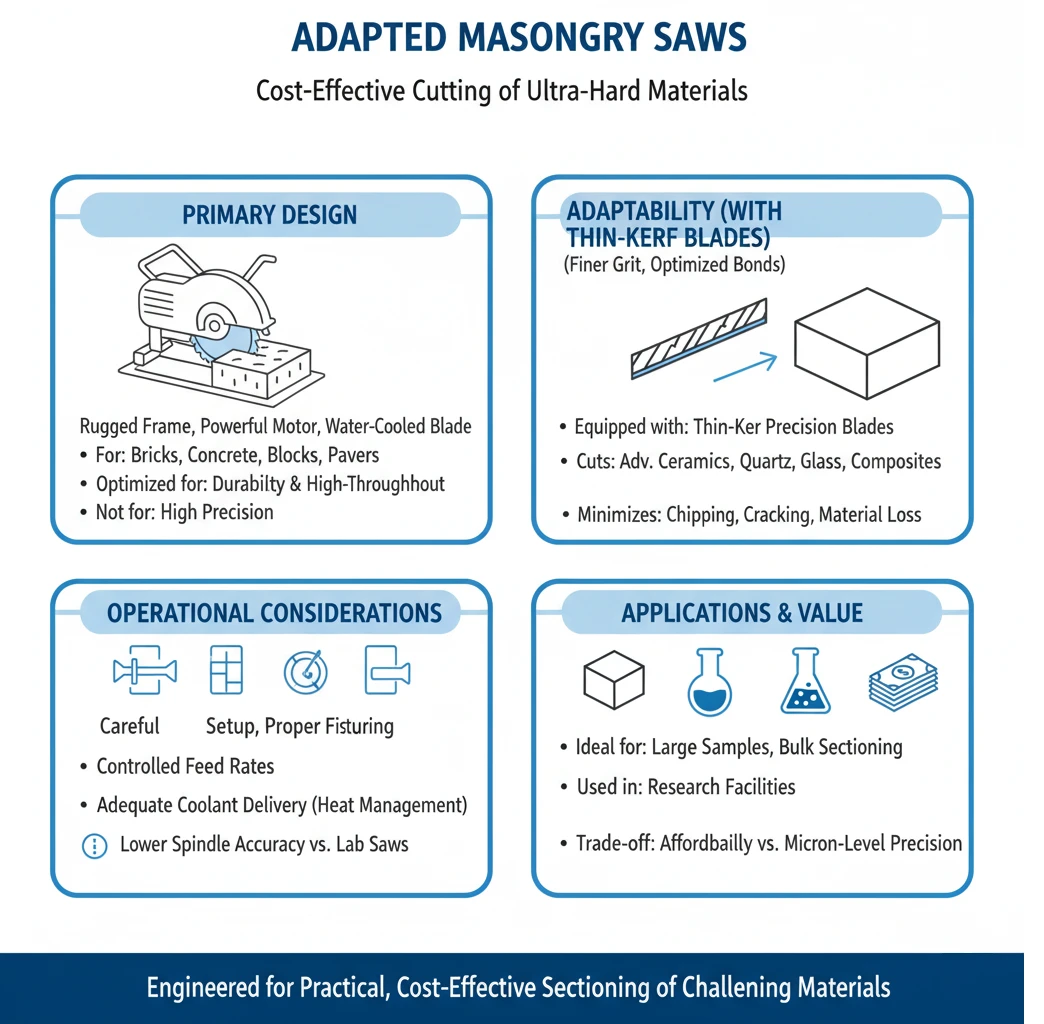

Masonry Saw

A masonry saw is a heavy-duty cutting machine originally designed for the construction industry, where it is used to cut bricks, concrete, blocks, pavers, stone, and similar building materials. These machines are built with a rigid frame, powerful motors, and water-cooled diamond blades to handle large, dense, and abrasive materials. Masonry saws are optimized for durability and throughput rather than high precision, making them reliable tools for construction sites and fabrication shops.

While their intended purpose is rough cutting in construction, a masonry saw can be adapted for use on a wider range of ultra-hard and brittle materials when equipped with thin-kerf, high-precision diamond blades. Using specialized blades with finer grit sizes and optimized bond structures allows the saw to cut advanced ceramics, quartz, glass, composites, and technical stones with greater accuracy than its standard configuration. The thinner blades help minimize kerf width, reduce cutting forces, and lower the risk of chipping or cracking, which is particularly important when working with brittle or valuable materials.

Masonry saws typically operate at lower spindle accuracy compared to precision laboratory saws, and their feed systems and tables are not designed for micron-level alignment. However, with careful setup, proper fixturing, and controlled feed rates, they can produce functional cuts suitable for applications where absolute precision and fine surface finish are not critical. Adequate coolant delivery is essential, as it helps manage the additional heat generated when cutting dense, brittle, or high-value materials not originally intended for this equipment.

For workshops, research facilities, or production environments where large sample sizes or bulk sectioning of hard materials is required, masonry saws offer a practical, cost-effective solution.

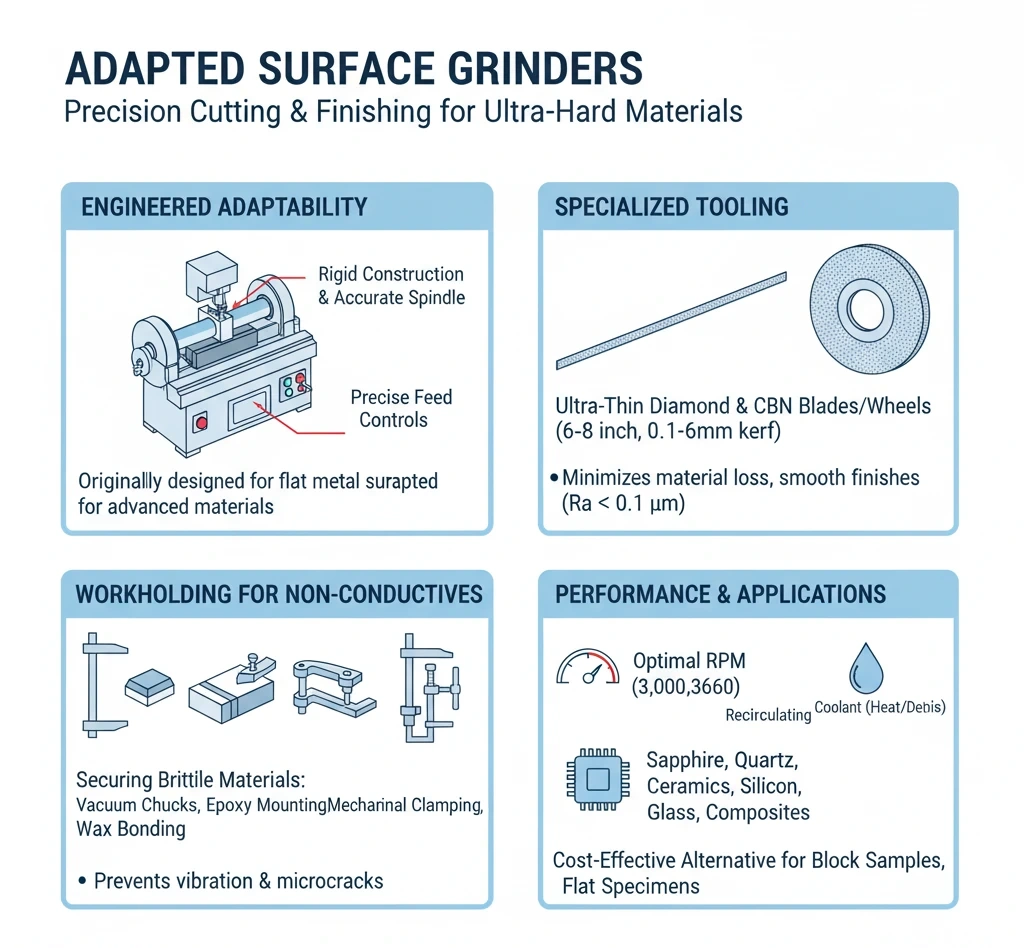

Surface Grinder

A surface grinder, when adapted with ultra-thin diamond or CBN blades and wheels, is a reliable platform for cutting and finishing ultra-hard and brittle materials. While these machines were originally designed for producing flat surfaces on metals, their rigid construction, accurate spindles, and precise feed controls make them suitable for sectioning, slotting, and grinding advanced materials such as sapphire, quartz, ceramics, silicon wafers, glass, and composites.

Most surface grinders used in laboratory and precision applications operate with 6 to 8 inch (150 mm to 200 mm) blades or wheels. This size range offers the best balance between stability, surface speed, and compatibility with thin-kerf tooling. With spindle speeds typically in the 3,000 to 3,600 RPM range, these grinders generate the correct surface feet per minute (SFPM) to allow diamond and CBN blades to cut efficiently without glazing or overheating. Variable-speed models extend this range, enabling more flexibility across different materials.

When paired with ultra-thin blades in the 0.1 mm to 0.6 mm kerf range, surface grinders can achieve minimal material loss, smooth surface finishes, and tight dimensional tolerances. This is especially valuable when cutting expensive or fragile samples where yield and integrity are critical. For grinding applications, precision diamond and CBN wheels in the same 6–8 inch range provide the ability to produce flat, damage-free surfaces with finishes often reaching Ra < 0.1 µm.

Fixturing is an important consideration. Since magnetic chucks are ineffective for non-conductive materials like ceramics or glass, alternative workholding methods are required. Common solutions include vacuum chucks, epoxy mounting, mechanical clamping, or wax bonding to glass carriers. These hold parts securely, minimize vibration, and prevent microcracks or fractures during cutting.

In practice, a surface grinder with 6–8 inch ultra-thin blades or wheels provides a flexible, cost-effective alternative to specialized wafering saws. While not capable of the micron-level tolerances achieved by dedicated sectioning systems, they are highly effective for flat specimens, block samples, and bulk material preparation. With proper tooling, speed control, coolant flow, and fixturing, they deliver clean cuts, reduced chipping, and excellent repeatability across a wide variety of brittle and ultra-hard materials.

Usage Volume

Your diamond blade requirements will greatly vary with your frequency of use and the number of cuts you need to make. Diamond Blades are generally used for:

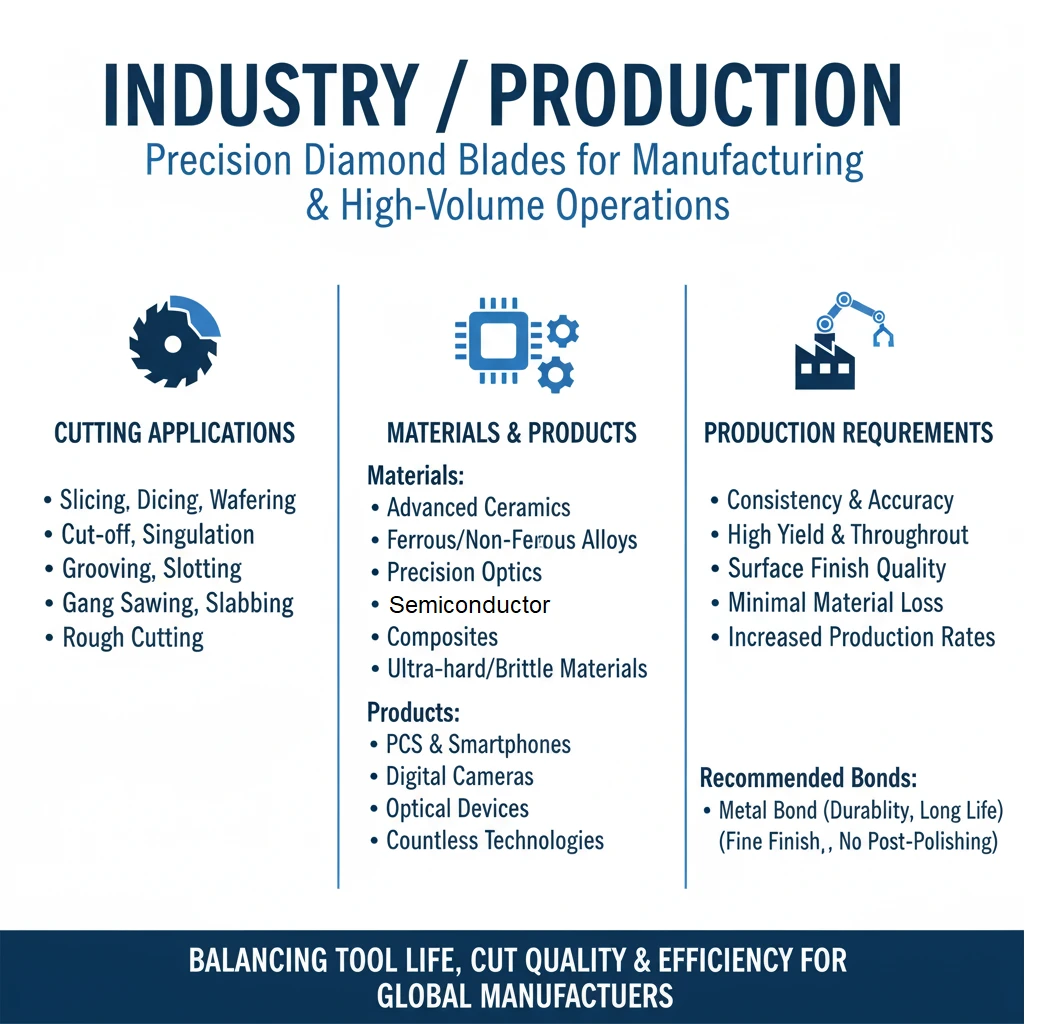

INDUSTRY / PRODUCTION

Ultra-thin and high-precision diamond blades are used daily across hundreds of industries and production operations to manufacture the components and devices that define modern life. These blades are applied in slicing, dicing, wafering, cut-off, singulation, grooving, slotting, gang sawing, slabbing, and rough cutting of a wide range of materials, including advanced ceramics, non-ferrous and ferrous alloys, precision optics, semiconductors, composites, and other ultra-hard or brittle materials.

The products created with the help of these blades are found in PCs, smartphones, digital cameras, video game systems, optical devices, and countless other technologies. Each cutting operation demands blades that deliver consistency, accuracy, high yield, surface finish quality, and minimal material loss while supporting increased production rates.

In production environments, diamond blades are often used continuously throughout the day, cutting thousands of parts until the blade wears out and is replaced. For this type of heavy-duty, high-volume use, metal bond (sintered) diamond blades are typically recommended because of their durability and long life. However, when an application requires an extremely fine finish without post-polishing, hybrid bond or resin bond diamond blades may provide the best results.

The technical requirements are as diverse as the industries themselves. Manufacturers, engineers, and technicians rely on the right blade choice to balance tool life, cut quality, and production efficiency. With decades of experience, we provide the expertise and solutions to address even the most complex manufacturing challenges. That is why advanced material, semiconductor, optics, composite, glass, stone, and jewelry producers worldwide depend on precision diamond blades to achieve the highest levels of productivity and performance in their sawing and machining operations.

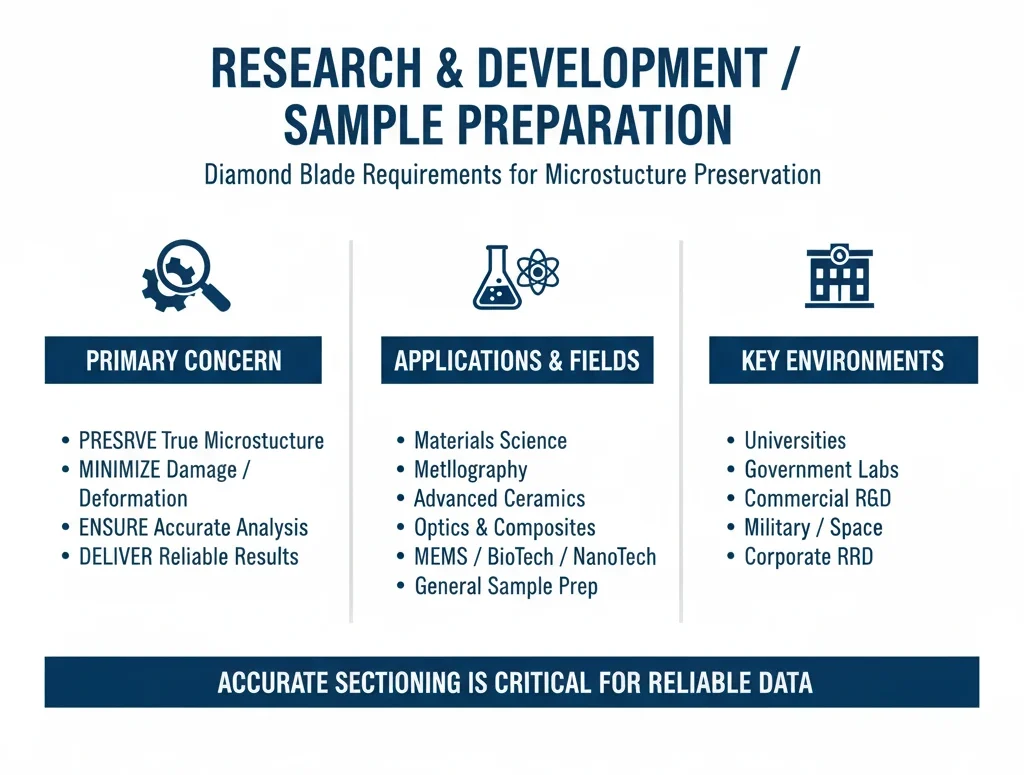

RESEARCH & DEVELOPMENT / SAMPLE PREPARATION

The requirements for diamond blades in research and sample preparation are as varied as the fields that rely on them. In these environments, the primary concern is to preserve the true microstructure of the material while introducing the least possible amount of damage or deformation. Achieving this balance is essential for accurate analysis and reliable results.

Research applications span a wide spectrum, including materials science, metallography, advanced and technical ceramics, optics, composites, and general sample preparation, as well as newer fields such as MEMS, biotechnology, and nanotechnology. Diamond blades are widely used in universities, government laboratories, commercial labs, military research facilities, space programs, and corporate R&D departments.

Most laboratories today work with a broad variety of materials, often requiring different sectioning methods and preparation techniques for each one. Selecting the right blade, equipment, consumables, and process parameters for a given application directly impacts the accuracy, efficiency, and reliability of the sectioning process.

With decades of experience, we understand the unique challenges faced by research and development organizations. Our diamond blades, precision equipment, and accessories are designed specifically to address the needs of R&D and sample preparation. Beyond supplying products, we continuously invest in our own R&D and process development, ensuring that our solutions keep pace with the demands of an increasingly complex and advanced materials community.

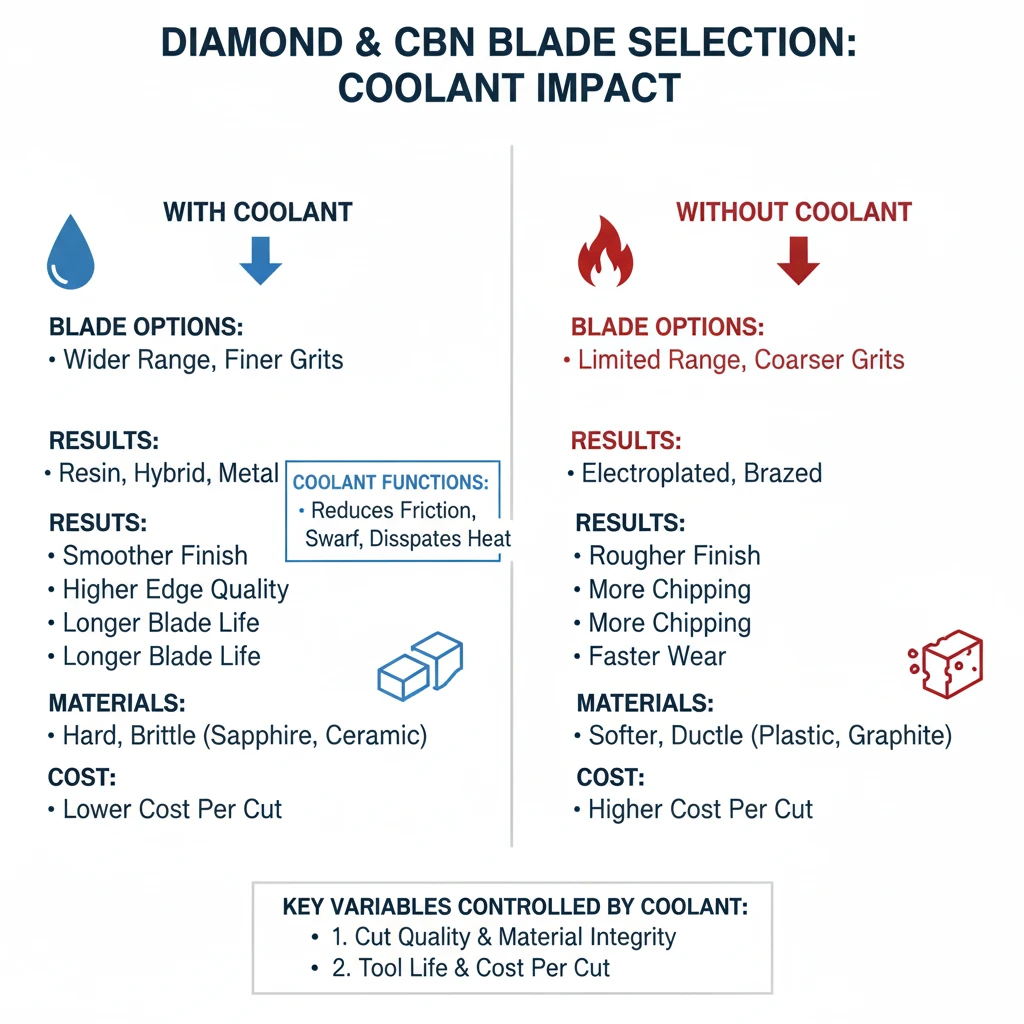

Effect of Coolant Availability on Diamond and CBN Blade Selection

Coolant is one of the most important variables in precision cutting with diamond and CBN blades. It does far more than just keep the blade cool. It controls friction at the cutting edge, reduces thermal stress on both the blade and material, removes swarf from the cutting zone, and stabilizes cutting forces. Whether coolant is used or not has a direct impact on which blade should be selected, the grit size that will perform best, and the overall cost per cut.

When coolant is available, the range of blade options is much wider. Resin bond blades operate best with coolant because the coolant prevents glazing and premature bond breakdown. Hybrid bonds also benefit significantly, as the coolant keeps their softer resin-metal mixture from loading up while preserving form and geometry. Metal bonds are even more effective with coolant, since coolant reduces the higher heat generated by their slower cutting action and extends life dramatically. With coolant flushing the cutting zone, finer grit sizes can be selected without risk of loading, allowing smoother surfaces, tighter tolerances, and minimal edge chipping. In these conditions, operators achieve the highest edge quality and longest blade life, since heat damage and microcracks are prevented.

In contrast, when coolant is not available or cannot be used, blade choice becomes more limited. Electroplated and brazed blades are best suited for dry cutting because their open structure allows freer cutting, faster chip evacuation, and reduced heat buildup. The diamonds are fully exposed and do not rely on bond wear to stay sharp, making them effective in dry environments. Resin and hybrid bonds are poor choices without coolant, since they heat up quickly, load with debris, and lose form, leading to rapid wear and poor cut quality. Metal bonds also struggle without coolant, as they hold diamonds too tightly and generate significant heat. In dry applications, coarser grit sizes are necessary, because the larger cutting points reduce friction and create space for swarf removal. However, the tradeoff is a rougher surface finish and shorter blade life compared to wet cutting.

The nature of the material being cut is also tied to coolant availability. For hard, brittle, and heat-sensitive materials such as sapphire, quartz, silicon, and advanced ceramics, coolant is essential. Without it, thermal cracking, microfractures, and excessive chipping will occur, making dry cutting unsuitable. On the other hand, softer, ductile, or fibrous materials such as plastics, composites, and graphite can sometimes be cut dry, but the operator must accept faster blade wear and less consistent results. In these cases, dry-capable bonds like electroplated or brazed can be useful.

The geometry and size of the workpiece add another layer. Thicker blocks, rods, or bulk materials always require coolant because the contact time and cutting forces are higher, increasing the risk of overheating and blade failure. Smaller parts, thin sections, or delicate cuts may sometimes be done dry, but this is only advisable with the right bond and machine setup.

Machine design also matters. Dedicated wet cutting machines with integrated coolant systems, pumps, and enclosures are designed for stability, precision, and blade safety. Attempting to run these blades dry not only shortens tool life but may also void safety margins. Conversely, in field work, in-situ sectioning, or when contamination must be avoided, dry operation with electroplated or brazed bonds may be the only option, but it should be limited to shallow cuts and softer materials.

From a cost standpoint, coolant almost always reduces the true cost per cut. With coolant, blades last longer, cut quality improves, and rework is minimized. Without coolant, tool consumption is higher, edges are rougher, and productivity drops, even if initial cutting speed feels faster. For production environments, the economic advantage of using coolant and resin, hybrid, or metal bonds is overwhelming. Dry cutting is better reserved for short runs, prototyping, or unique situations where liquids cannot be used.

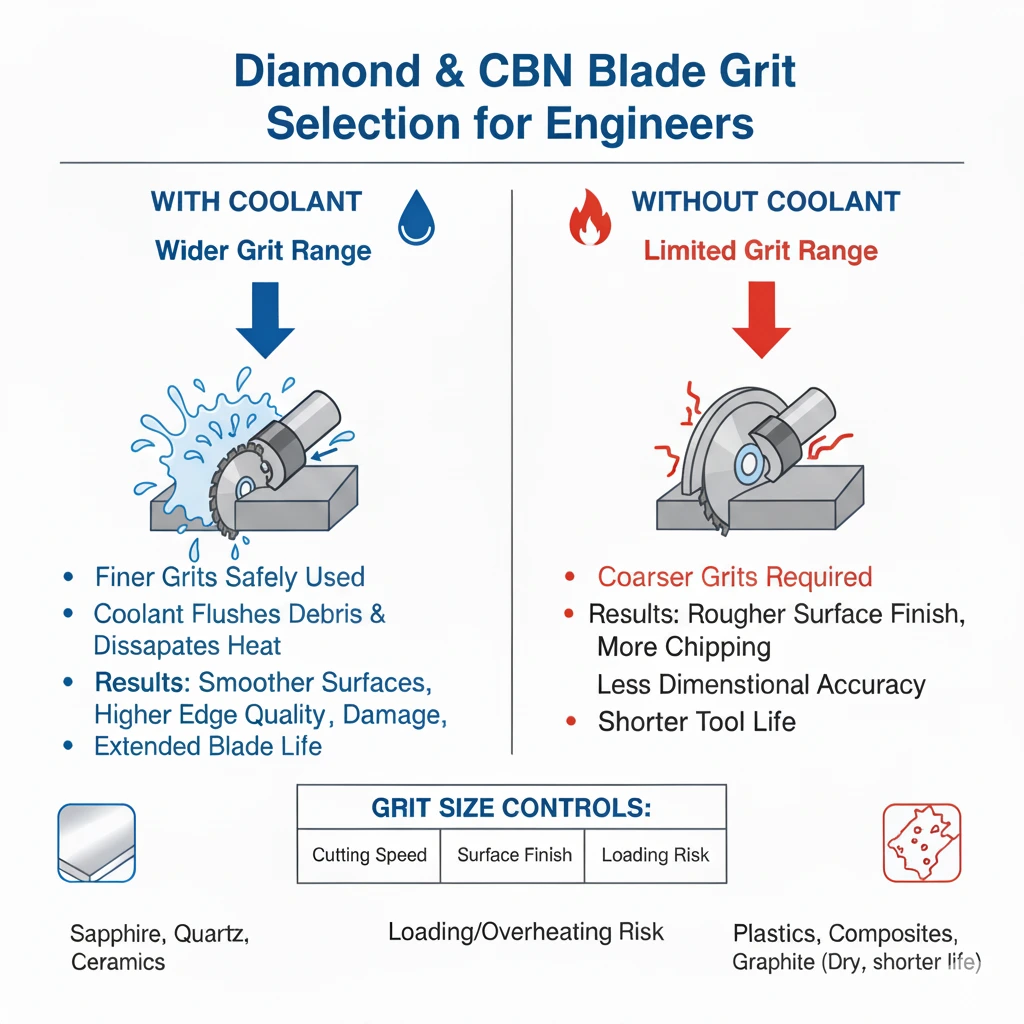

Grit Size and Coolant: How They Work Together

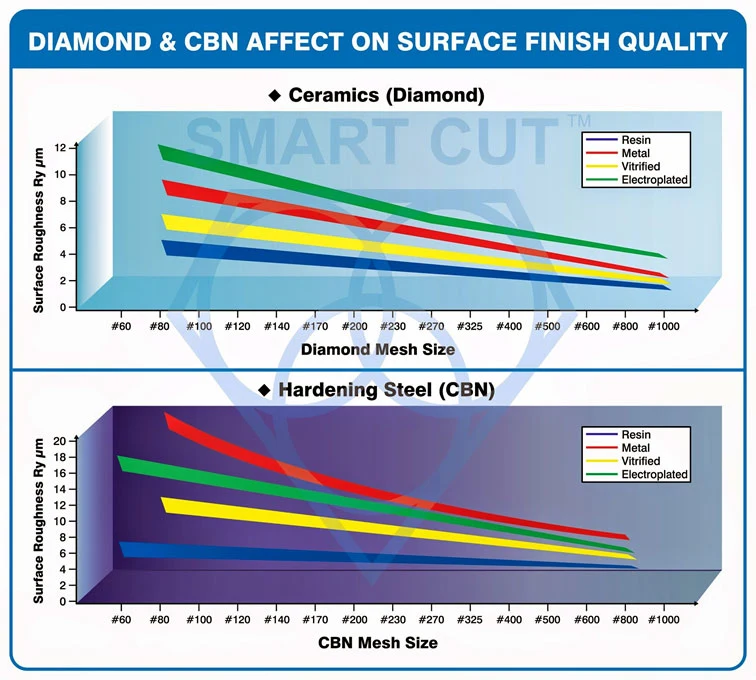

The choice of grit size in diamond and CBN blades is closely tied to whether coolant is available or if the process must be done dry. Grit size directly controls cutting speed, surface finish, and the risk of loading or overheating. When coolant is present, the range of usable grit sizes expands significantly, but without coolant the options become limited and compromises must be made.

With coolant, finer grit sizes can be safely used. The coolant flushes debris from the cutting zone, prevents swarf from clogging the blade, and dissipates heat that would otherwise build up at the contact point. This allows the blade to produce smoother surfaces, higher edge quality, and minimal subsurface damage even on brittle materials such as sapphire, quartz, silicon, or ceramics. The use of fine grit under wet conditions also extends blade life, since the diamonds are not overheated or prematurely fractured. Operators can run slower feed rates with fine grit blades and achieve precision cuts that preserve the integrity of delicate samples.

When coolant is not available, the situation changes. Fine grit sizes are generally unsuitable for dry cutting because the small cutting edges generate high friction and trap debris. This causes rapid heat buildup, glazing, and even thermal damage to both blade and material. Without coolant to carry away swarf, the blade loads quickly and stops cutting efficiently. Instead, coarser grit sizes are required for dry operation. The larger diamond particles create wider chip spaces that allow some debris evacuation even without coolant, reducing friction and helping the blade “breathe.” Coarse grit also cuts more aggressively, which lowers the time of contact and decreases heat accumulation. However, the tradeoff is a rougher surface finish, more chipping, and less dimensional accuracy.

In brittle materials, dry cutting with coarse grit often leads to edge damage and cracks. In softer or more ductile materials such as plastics, composites, or graphite, coarse grit electroplated or brazed blades can be used dry, but tool life will still be shorter than under wet conditions. For bulk sections, rods, or thick blocks, coarse grit without coolant is prone to overheating and wear, making coolant highly recommended.

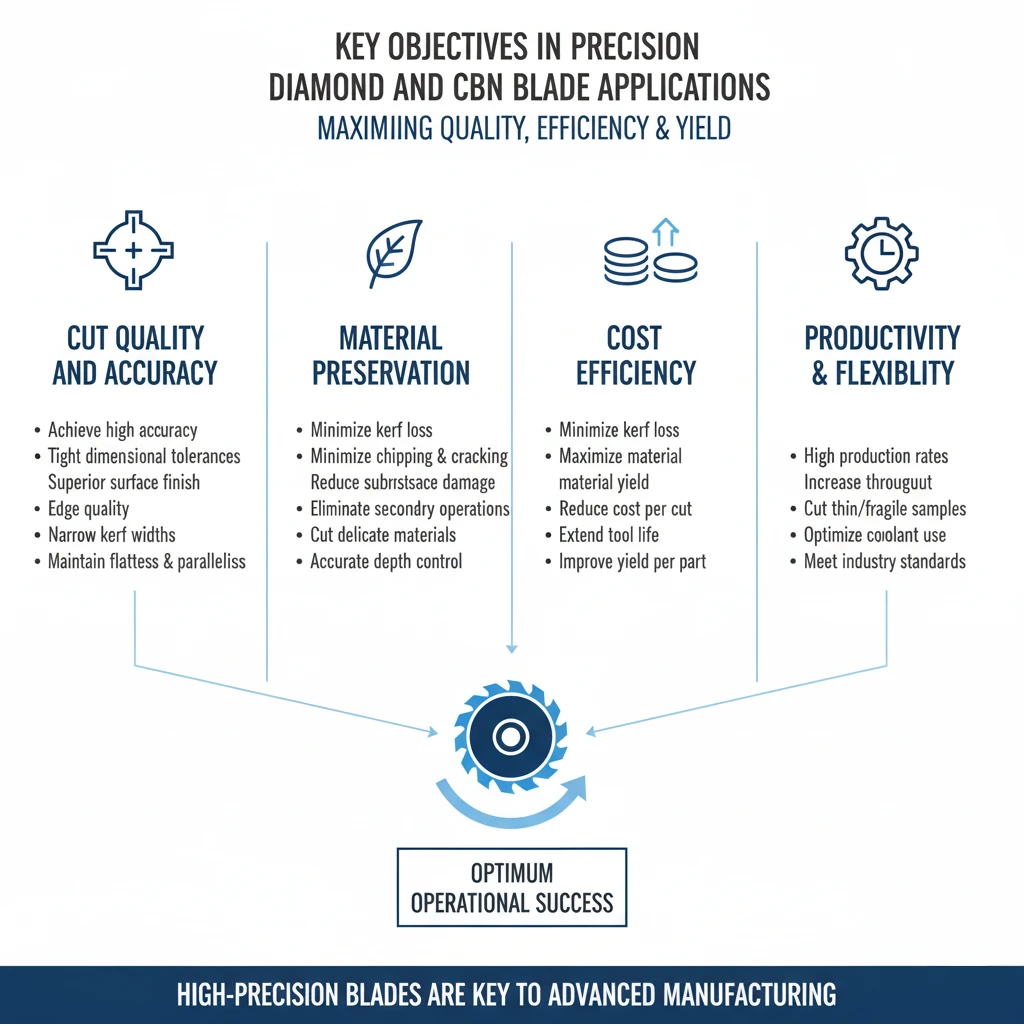

Key Objectives in Precision Diamond and CBN Blade Applications

The effectiveness of ultra-thin and high-precision diamond and CBN blades is defined by measurable performance metrics. Clients in semiconductors, optics, advanced ceramics, composites, and research evaluate blades by cut accuracy, dimensional tolerances, surface finish, edge quality, kerf width, repeatability, material preservation, productivity, and cost per cut.

Selecting the right blade means balancing these metrics to match the requirements of each application. A blade that scores well in accuracy and finish may not maximize productivity, while one designed for long life may sacrifice edge quality. Understanding these tradeoffs is essential to choosing the blade that provides the best overall performance.

The following sections highlight the key performance metrics used to assess and select ultra-thin and high-precision blades.

Cut Quality and Accuracy

- Achieve high accuracy and tight dimensional tolerances

- Maintain consistent and repeatable cut quality

- Achieve superior surface finish and edge quality

- Enable narrow kerf widths for precision applications

- Maintain flatness, squareness, and parallelism

Material Preservation

- Preserve material integrity and true microstructure

- Minimize chipping, cracking, and subsurface damage

- Reduce or eliminate secondary operations (grinding, lapping, polishing)

- Cut delicate, brittle, or high-value materials without damage

- Control cutting depth with high accuracy (partial or full cut-through)

Cost Efficiency

- Minimize kerf loss and maximize material yield

- Reduce overall cost per cut

- Extend tool life and reduce blade changeovers

- Improve yield per wafer, rod, or panel

Productivity and Flexibility

- Support high production rates without sacrificing quality

- Increase throughput and efficiency in production

- Provide flexibility for diverse applications and materials

- Allow safe, stable cutting of very thin or fragile samples

- Optimize coolant use for heat control and debris removal

- Meet specific industry standards (semiconductor, aerospace, medical, defense, R&D)

Why Key Objective is Important

Selecting the right diamond or CBN blade is defined by its ability to deliver precise, consistent results. Performance is measured by accuracy, repeatability, surface finish, kerf width, and dimensional control. Each of these factors determines whether a cut meets the required standards for quality and efficiency. The following points outline the core aspects of cut quality and accuracy and how different bond types and blade characteristics contribute to achieving them.

Achieve High Accuracy and Tight Dimensional Tolerances

High accuracy in cutting is achieved when the blade maintains a precise cutting path without deflection or drift. Metal bond blades provide the most stability, making them ideal for long cuts in dense or abrasive materials where tolerances must be held. Resin and hybrid bonds excel in delicate materials, where tighter tolerances are required at the micron level, such as in optics, semiconductors, and ceramics. The right bond, combined with proper machine rigidity and flange size, ensures the blade cuts exactly where intended, even in demanding applications.

Maintain Consistent and Repeatable Cut Quality

Consistency means every cut looks and measures the same, regardless of batch size. Sintered metal bond blades wear evenly, which makes them the best choice for repeatable cuts over long production runs. Hybrid bonds balance consistency with smooth surface quality, particularly in applications where both repeatability and edge integrity matter. By matching bond hardness and grit size to the material, users can achieve predictable, stable results from one cut to the next, minimizing variability and waste.

Achieve Superior Surface Finish and Edge Quality

When surface finish and edge integrity are priorities, fine grit resin or hybrid blades used with coolant are preferred. These blades self-sharpen, exposing new diamonds that produce clean edges and smooth surfaces with minimal subsurface damage. This is especially important when cutting fragile materials like sapphire, quartz, or ceramics, where even microscopic chipping can cause failure. Coolant is essential here, as it flushes debris, reduces friction, and preserves edge quality throughout the cut.

Enable Narrow Kerf Widths for Precision Applications

For applications where material conservation and precision are critical, such as wafering, dicing, or micro-sectioning, ultra-thin blades are essential. Resin and hybrid bond blades are often manufactured with very narrow kerfs, allowing operators to remove the least amount of material while achieving high accuracy. Narrow kerf widths reduce material waste, improve throughput, and allow smaller, more delicate samples to be sectioned without excessive force or stress on the workpiece.

Maintain Flatness, Squareness, and Parallelism

True accuracy goes beyond edge quality — it also means the cut surface must remain flat, square, and parallel to reference planes. Achieving this requires a blade with minimal run-out, tight side tolerance, and the correct flange support. Metal bonds provide rigidity for flatness, while resin and hybrid bonds are better for fine edges that remain square and parallel. Proper machine alignment, arbor size, and clamping methods are equally important. A well-matched blade and setup will ensure parts remain dimensionally true and free from angular deviations.

Preserve Material Integrity and True Microstructure

When preparing samples for materials research, quality control, or failure analysis, the goal is not only to section the part but also to keep the material’s original structure unchanged. Even minor thermal or mechanical deformation can alter test results. Using resin or hybrid bond blades with fine grit and proper coolant flow helps preserve the true microstructure. These blades cut with less force and generate less heat, preventing artifacts that could misrepresent the material’s actual properties.

Minimize Chipping, Cracking, and Subsurface Damage

Brittle materials such as sapphire, ceramics, or quartz are vulnerable to chipping and hidden cracking beneath the surface. This damage reduces performance and can render a sample unsuitable for analysis. Choosing fine grit resin or hybrid blades with controlled feed rates and adequate coolant flushing lowers cutting stress, prevents debris buildup, and minimizes thermal loading. Under these conditions, the blade produces smooth edges with far less subsurface damage, leaving samples intact and usable.

Reduce or Eliminate Secondary Operations

If a blade delivers clean, smooth cuts, the need for post-cut finishing steps such as grinding, lapping, or polishing is greatly reduced. This saves both time and consumables, especially in high-volume labs and production environments. Resin and hybrid bond blades with fine grit sizes can often produce surfaces that are flat and damage-free enough to skip or shorten secondary operations. The right blade choice directly lowers operating costs by producing ready-to-use surfaces on the first cut.

Cut Delicate, Brittle, or High-Value Materials Without Damage

Materials such as silicon wafers, sapphire, optical crystals, or advanced ceramics are both costly and fragile. Damaging even a small piece can mean significant losses. For these cases, softer bonds with fine grit and abundant coolant are the most reliable. They cut with lower pressure, reduce heat buildup, and protect valuable yield. In dry cutting situations where coolant is not possible, electroplated or brazed blades can sometimes be used, provided feed rates are carefully controlled and the material can tolerate more aggressive cutting.

Control Cutting Depth with High Accuracy

In microelectronics, optics, and composites, many applications require partial cuts rather than full cut-through. These processes demand blades with tight thickness tolerances, minimal run-out, and stable bonding systems. Resin or hybrid blades are especially effective here, as they allow controlled depth cutting without over-penetration. With the right setup, these blades provide accurate, repeatable results while preserving the integrity of the remaining material.

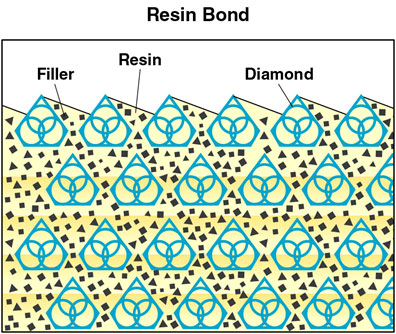

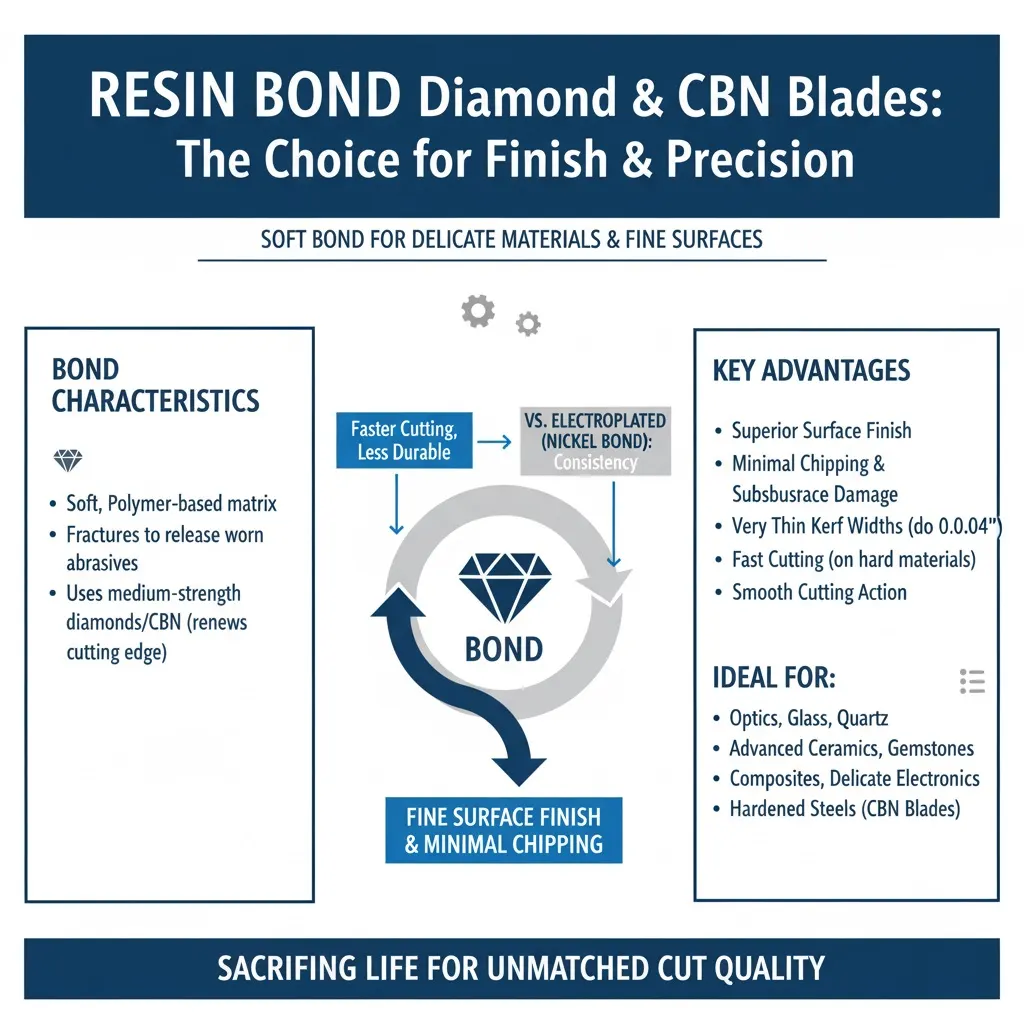

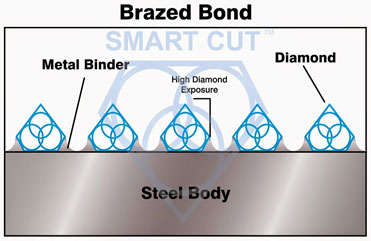

Understanding Diamond and CBN Bond Types

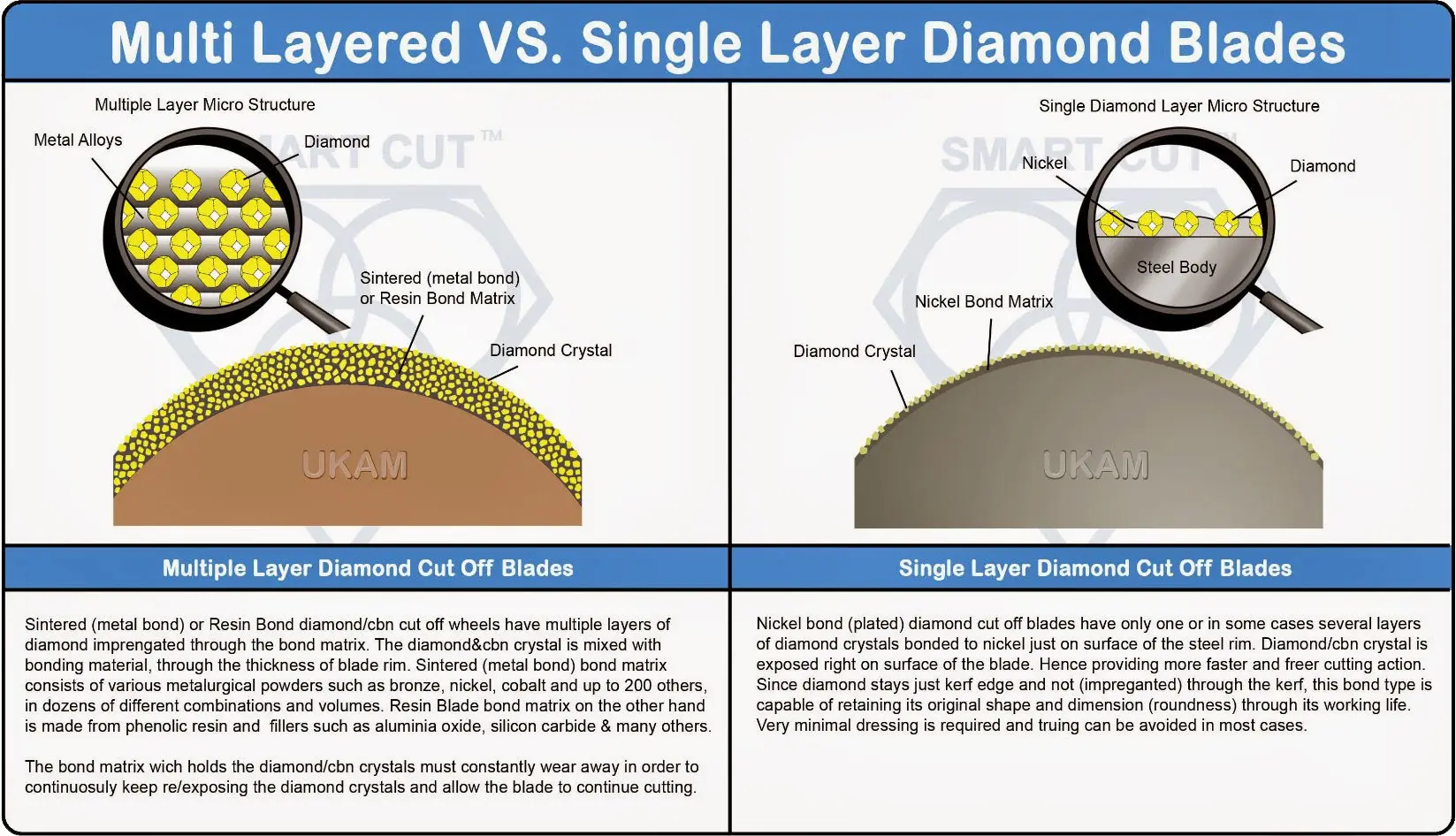

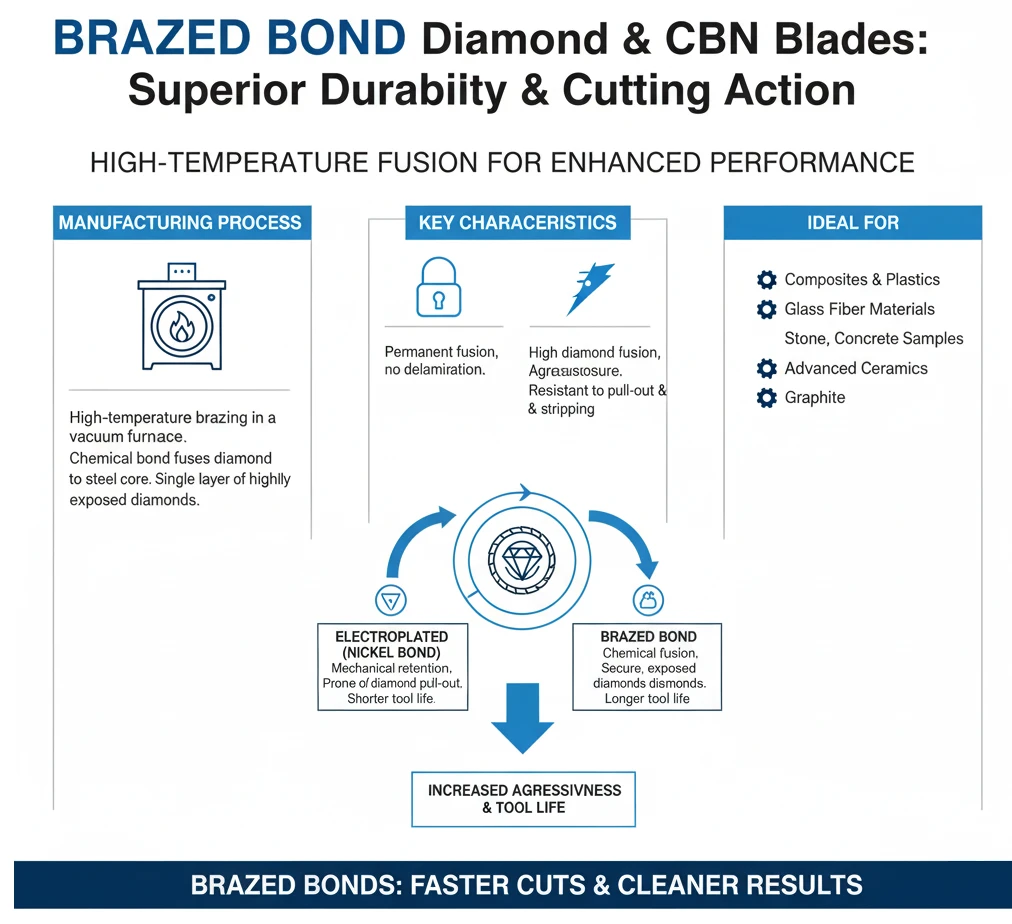

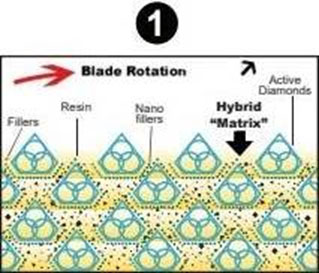

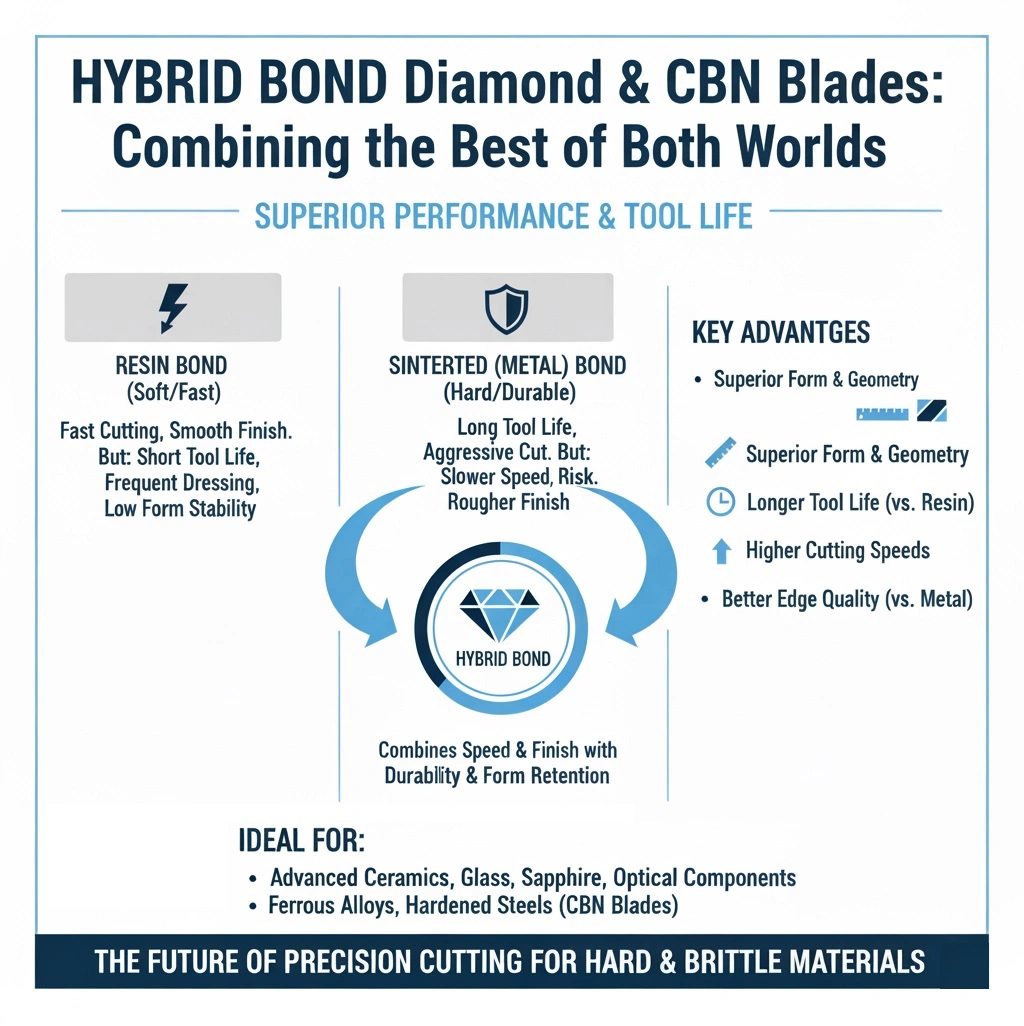

Diamond and CBN blades are manufactured with several types of bonding systems, each designed for specific materials and cutting needs. Sintered (metal bond) blades contain multiple abrasive layers and provide the longest life and most consistent performance on hard and brittle materials. Resin bond blades cut faster and produce smooth surfaces with minimal chipping, but wear more quickly and require frequent dressing. Electroplated (nickel bond) blades have a single abrasive layer that cuts aggressively and at low cost, making them suitable for short runs or delicate applications. Brazed bond blades chemically fuse a single diamond layer to the core for strong retention, aggressive cutting, and longer life than electroplated types. Hybrid bond blades combine the durability of metal bonds with the smooth finish of resin bonds, offering a balance of precision, speed, and tool life.

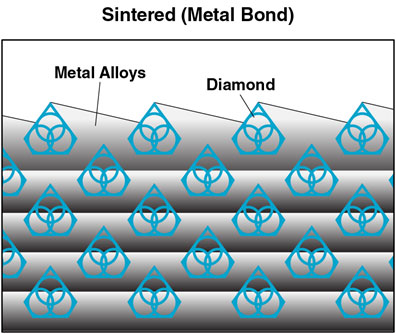

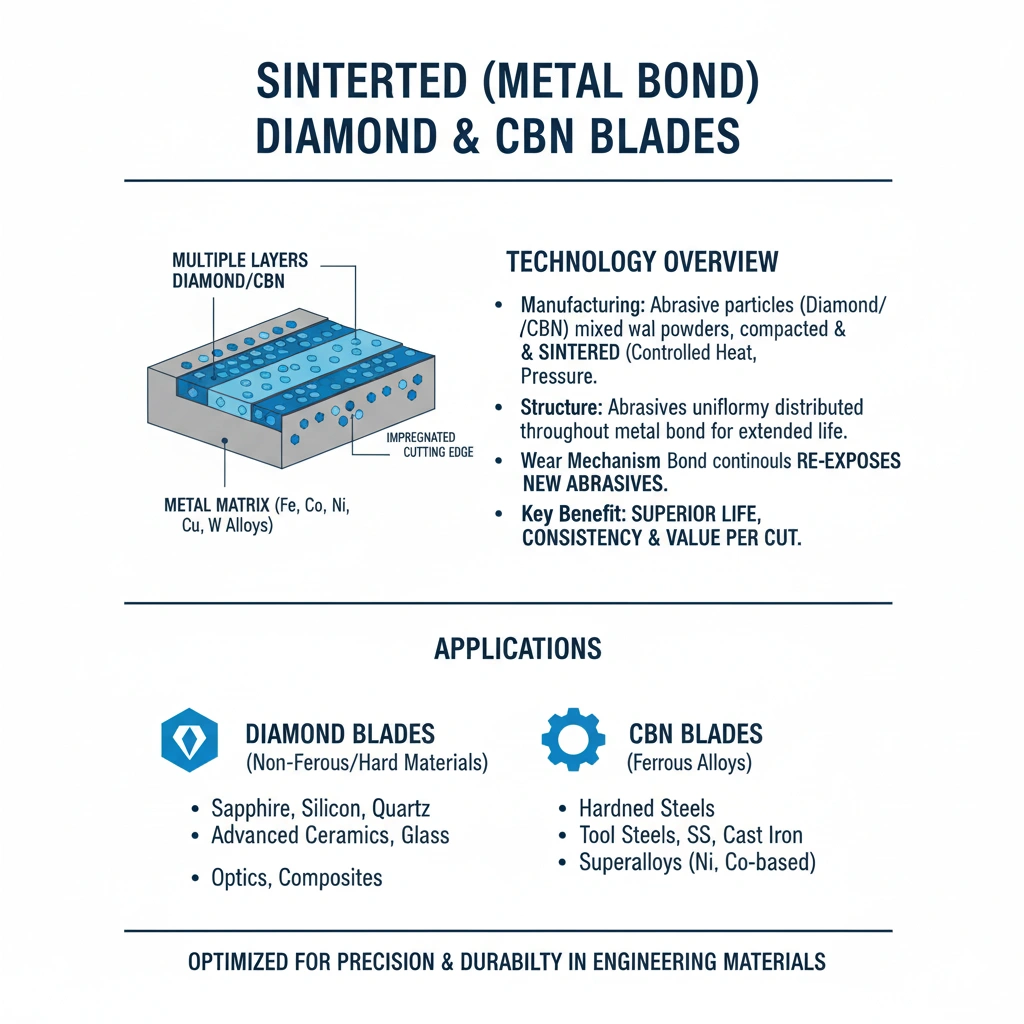

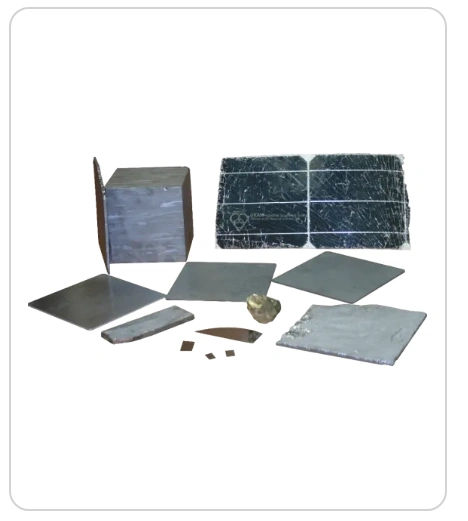

SINTERED (MEAL BOND) DIAMOND & CBN BLADES

Sintered (Metal bonded) diamond blades diamonds sintered and multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal Bonded Diamond Tools are “impregnated” with diamonds. The compacted materials are then hot pressed or sintered to full density. Heating rate, applied pressure, sintering temperature and holding time, are all controlled according to the matrix composition.

This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, advanced ceramics, optics, glass, granite, tile and etc. The metal bond surrounding the diamonds must wear away to diamond blades longer than other diamond bond blades such as resin bond and electroplated (nickel bond) blades. They wear evenly, and are known for their long life & consistency. Sintered (metal bonded) diamond blades are the latest technology available in Diamond Blades. And represent the best value and performance per cut. Metal bond matrix does not protrude diamonds very high and hence usually requires lower cutting speeds than electroplated (nickel bond) and resin bond blades. continuously keep re-exposing the diamonds for the diamond tool to continue cutting. Sintered (metal bonded) diamond tools are recommended for machining hard materials from 45 to 75 on Rockwell Scale (5 to 9.5 on mohs scale of hardness). It is more wear resistant and holds diamond well in place, usually producing the highest yield/cutting ratio. As a general rule of thumb, Metal Bond (sintered)

The letter M designates metal as the type bonding used. Through research in metal powder metallurgy, metal bond has become the most universal bonding material for diamond products. No other bonding utilizes so well the extreme durability of diamonds as an abrasive. It is possible to vary and control the toughness of metal to a great degree while maintaining maximum blade life.

Sintered (metal bonded) diamond and CBN blades are produced by embedding multiple layers of abrasive particles into a dense metal matrix made from iron, cobalt, nickel, bronze, copper, tungsten, or alloys of these powders. The powders are compacted and then furnace sintered under controlled heating rates, pressures, and temperatures to create a strong bond that securely holds the cutting crystals. Metal Bonded Diamond Tools are the most common blades and tools used across many applications. Unlike electroplated blades, which contain only a single abrasive layer, sintered blades contain diamonds or CBN distributed throughout the entire bond depth, allowing them to deliver much longer life and consistent cutting performance.

In use, the metal bond must wear away gradually to re-expose new sharp crystals. This controlled wear mechanism ensures stable and efficient cutting over extended use. Diamond sintered blades are best suited for non-ferrous, hard, and brittle materials such as sapphire, silicon, quartz, advanced ceramics, optics, composites, and glass. CBN sintered blades are recommended for ferrous alloys, including hardened steels, tool steels, stainless steels, cast irons, and nickel- or cobalt-based superalloys, where diamond would chemically react with iron at elevated temperatures.

Because the diamond or CBN protrusion is shallower, metal bond blades typically run at slower cutting speeds than resin or electroplated types, but they provide greater accuracy, stability, and longer service life. The toughness of the metal bond can be adjusted through powder metallurgy to achieve different results, such as faster cutting on extremely hard materials with softer bonds or greater wear resistance on abrasive composites with harder bonds.

Overall, sintered (metal bonded) diamond and CBN blades represent the most universal, durable, and reliable bonding system for precision cutting. By combining long life, high consistency, and superior yield per cut, they provide the best overall value and performance across both industrial production and research applications.

SINTERED METAL BOND TYPES

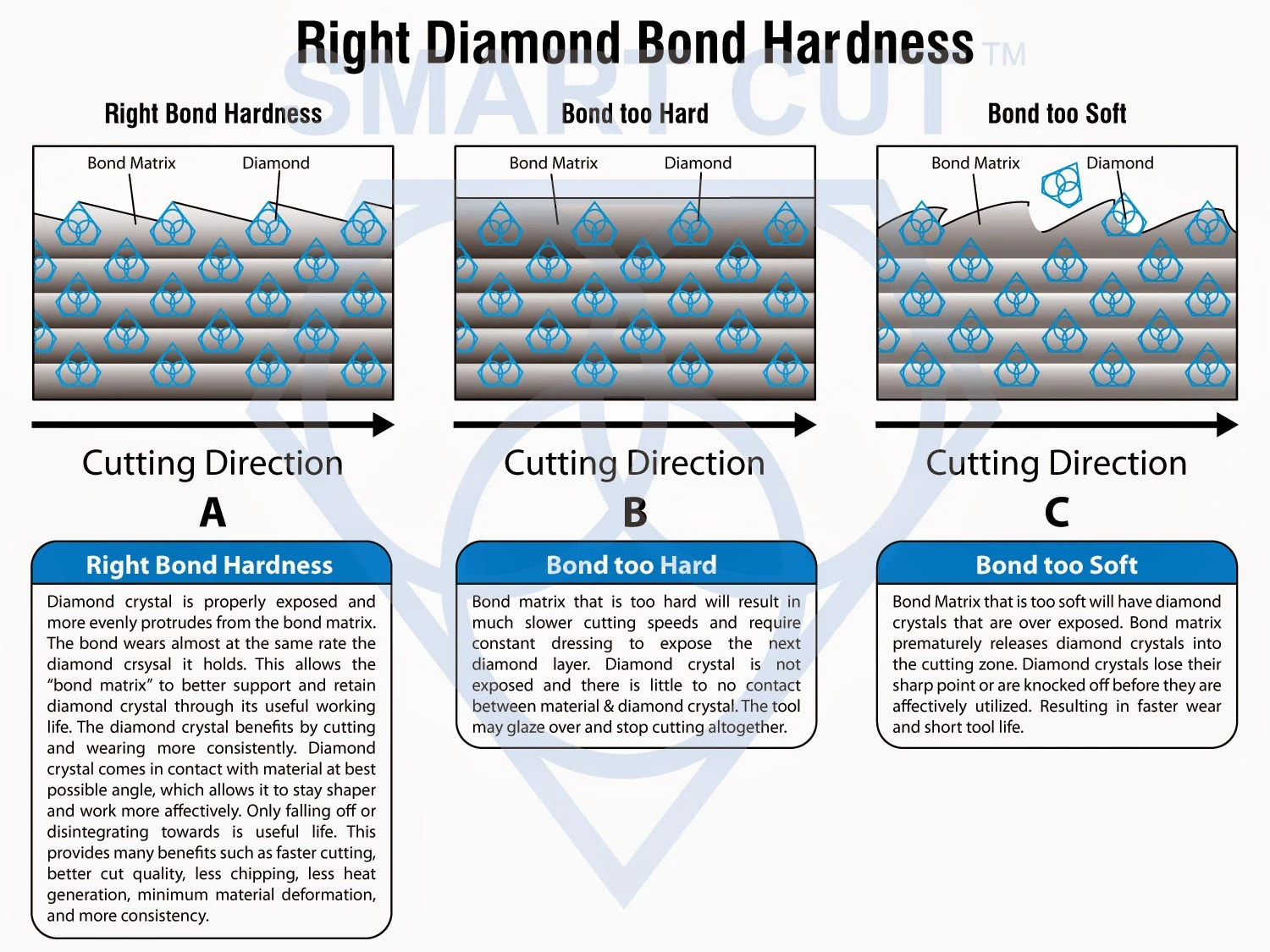

Sintered Metal Bond Types represent one of the most critical factors in selecting the correct diamond or CBN blade specification for your application. The bond determines how effectively the abrasive particles are held, how quickly they are released, and ultimately how the blade performs on your material. The proper bond will hold the cutting crystals until they reach their full capability, then release them so new sharp particles can take their place. Without this controlled wear, the blade would either dull prematurely or wear away too quickly.

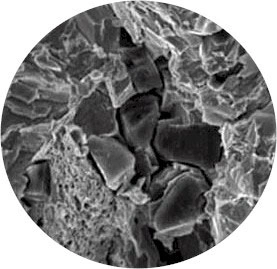

SEM Image of Sintered (metal bond) diamond cut off blade

Examples of most common sintered (metal bonds) used for cutting application

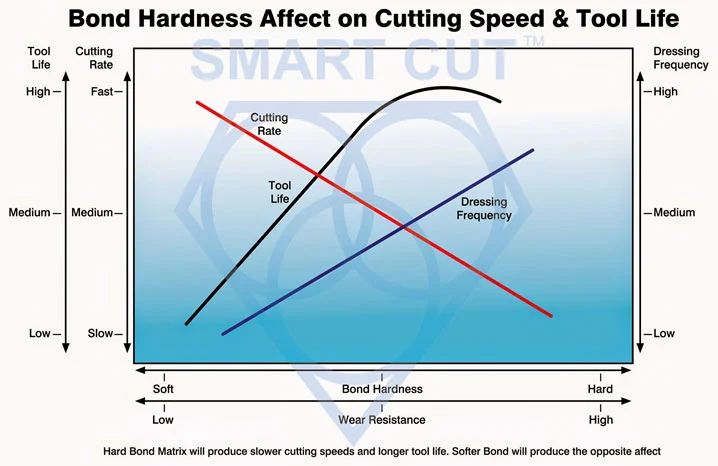

Diamond and CBN blades must have a defined wear factor. If the bond is too hard, diamonds remain trapped and stop cutting efficiently, causing glazing, burning, or cracking of the material. If the bond is too soft, the blade wears too fast and loses life. The correct wear factor ensures maximum blade life while maintaining sharpness, smooth cutting action, and high productivity.

Bond hardness is expressed through bond grading, which indicates the relative strength or holding power of the bond. Selecting the right grade requires careful consideration of the material’s hardness, density, abrasiveness, and geometry.

Examples of common sintered metal bond types include: