-

0 items in quote

No products in the Quote Basket.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

ACCESSORIES

OPERATING MANUALS

DESCRIPTION

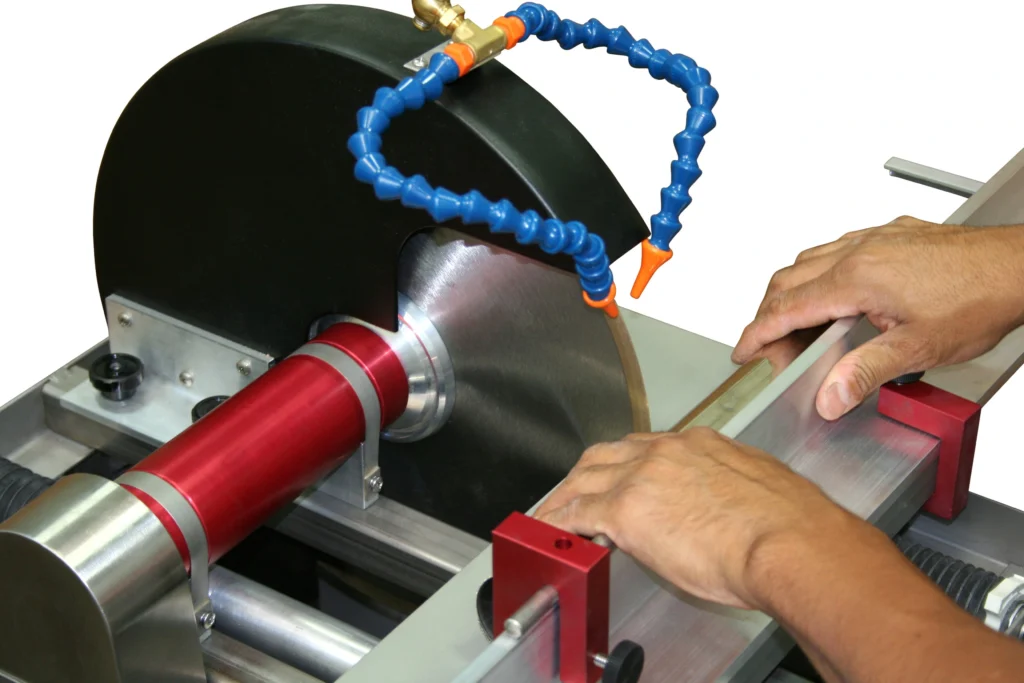

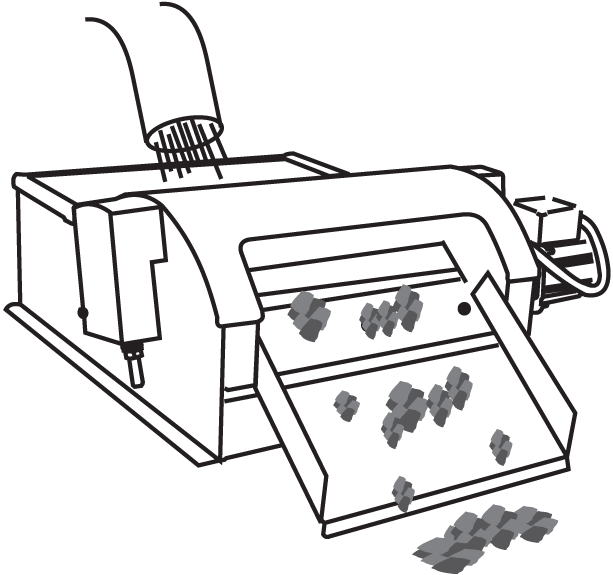

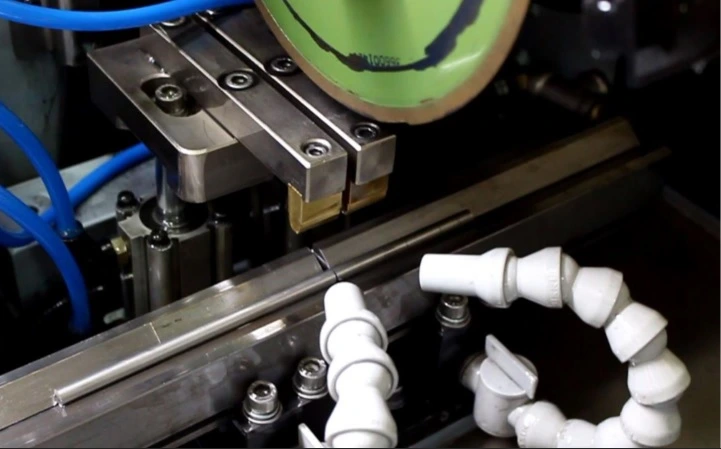

This machine is also well suited for cutting studied and planned to solve any cutting matter for hard metal bars manufacturers, tool grinders, and tools manufacturers (milling cutters for metal, cutters for wood, taps, reamers, carbide tips, punches,

dies, brazed tools, blades for planes, carbide components, etc..) and special tools manufacturers.

The main feature of such cutting machine is the cutting precision and the easy setup to adjust the shape. The cutting machine has been designed to carry out both automatic single cut and automatic production ones, with bar-loaders allowing autonomous cut management, without any operator. The cutting machine can automatically work various diameters and different lengths on the same bar, by optimizing the cutting quantity of each bar so that waste is very little or even nonexistent.

SPECIFICATIONS

- Cutting capacity up to 40 mm dia

- Powered by Motor 5 HP, 3 phase motor

- Diamond Cut off wheel dia 8″

- Spindle speed 50-2800 rpm ( variable)

- Machine size: 1600mm X 1000mm X 1200mm

- Tool makers need to cut carbide rods, Ejector pins on routine basis.

ADVANTAGES

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

ACCESSORIES

Magnetic Separator

Magnet filter for filtering Coolant Sludge and send clean Coolant Oil to the Recirculation tank

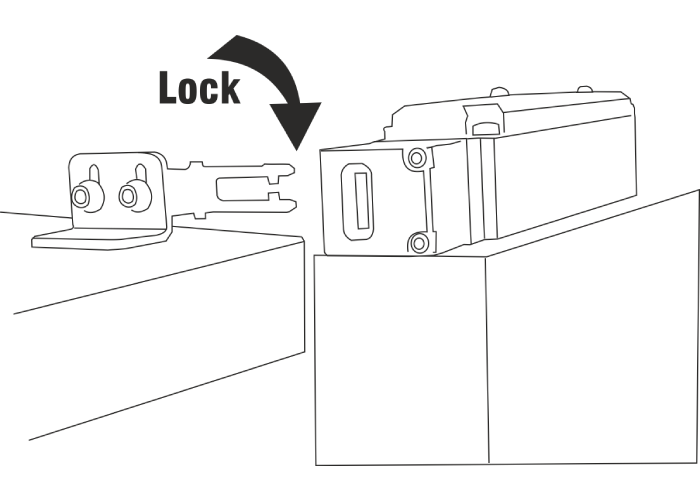

Door safety Interlock

Additional Safety Feature where the Door cannot be opened unless the Cutting process is stopped

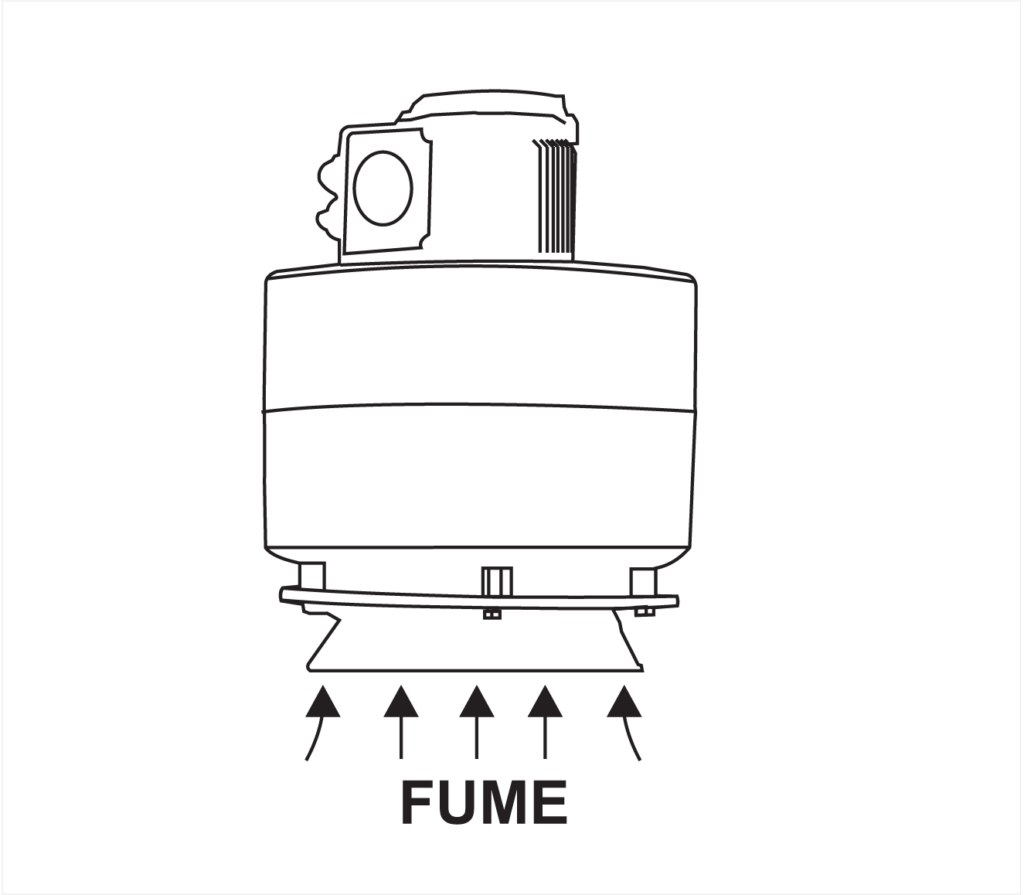

Fume digester

This helps to recirculate the fume caused while cutting into coolant. Gives clear vision on cutting process and also avoid human health hazards

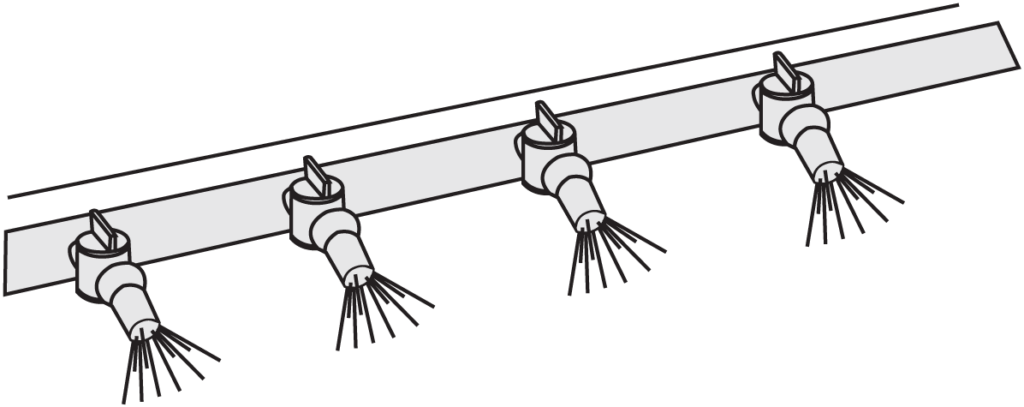

Bed wash

To clean the Bottom base bed Automatically while cutting and you can save operator Cleaning time

OPERATING MANUALS

Key Features

PLC Touch screen system

Advanc graphical touch screen display with pre set programming and data storage upto 25 programmes

Automatic carbide rod feeding

Automatic carbide rod loading with servo system

Sliding Door

Automatic individual pneumatic double clamping system

SMART CUT® COOLANTS

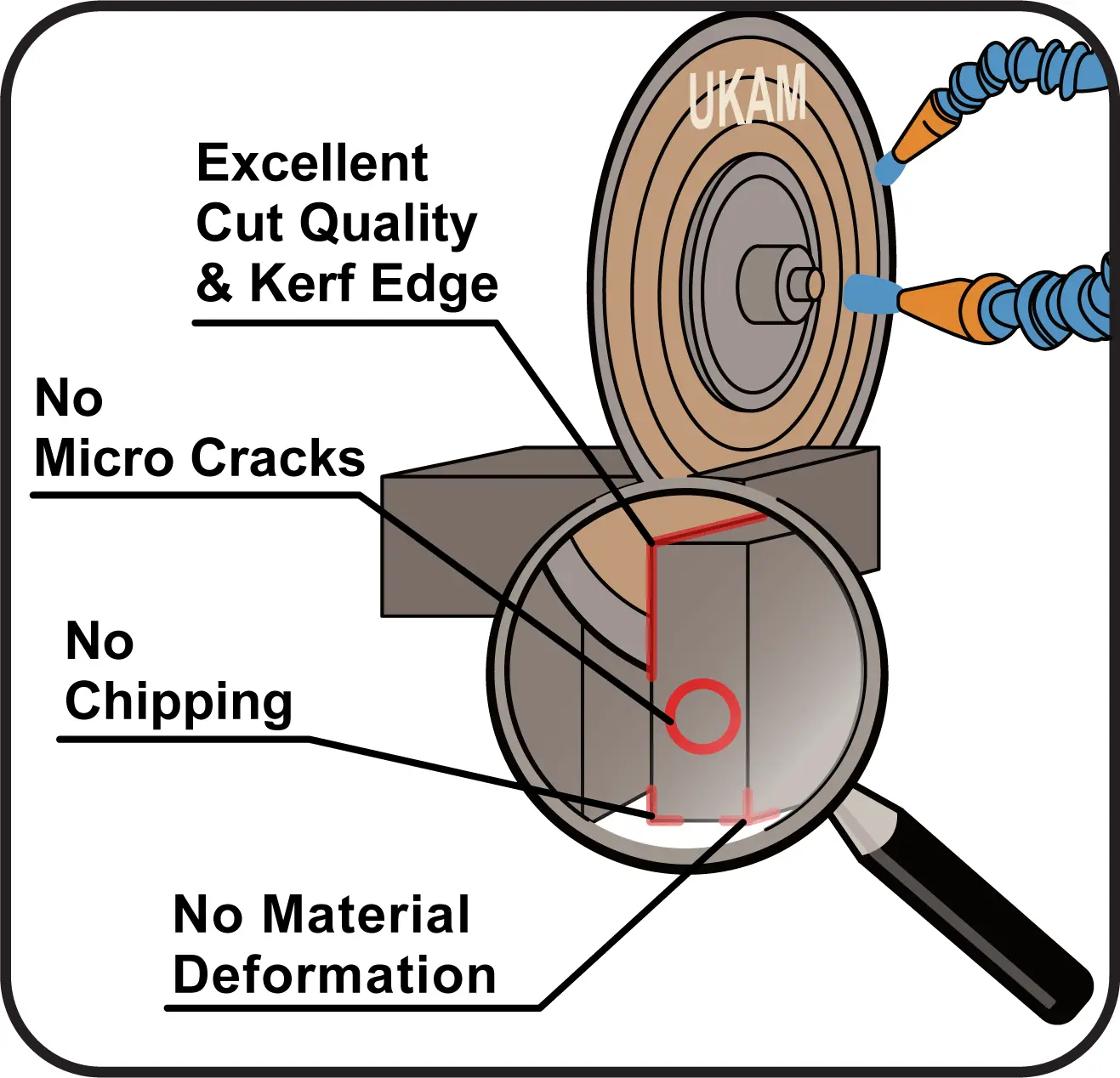

Your choice of one (1) quart of SMART CUT® Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT® Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

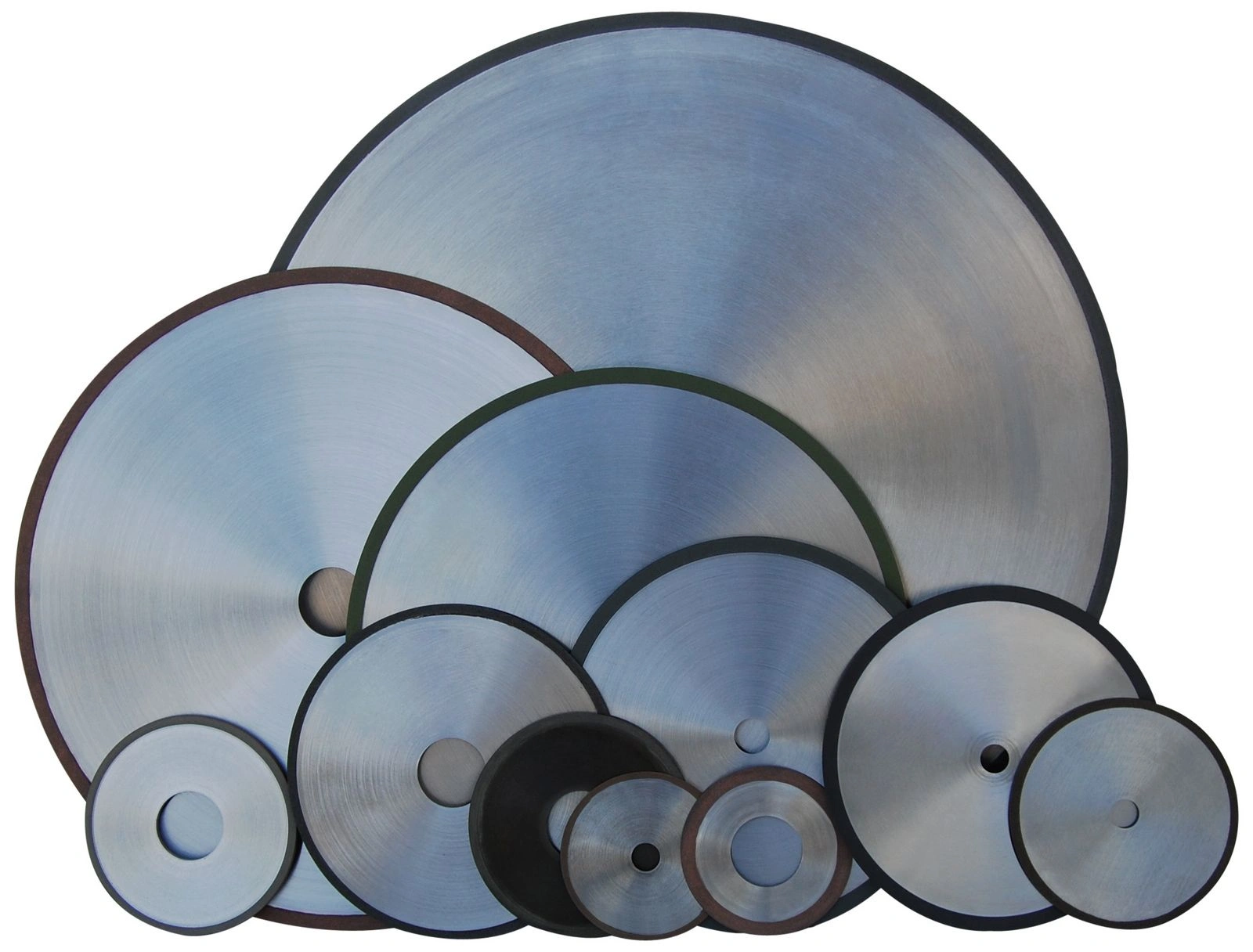

LARGEST SELECTING OF DIAMOND &

CBN WAFERING BLADES AVAIALBLE

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

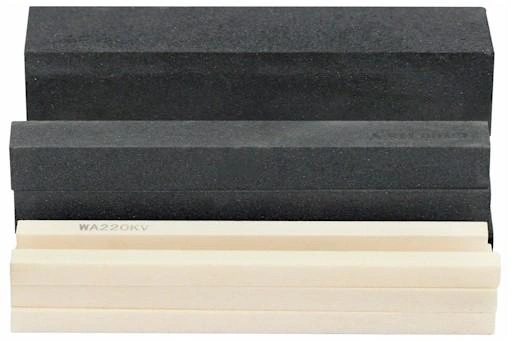

THE RIGHT DRESSING STICK FOR YOUR APPLICATION

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

Item # UKAMLS01-1 SMART CUT® 2001 – Precision Cut Off Saw

SMART CUT® 7001

SMART CUT® 7001 Heavy Duty Automatic Carbide Rod Cutting Machine is an advanced, fully automatic cutting solution engineered for mass production environments. Designed with precision, efficiency, and versatility in mind, this cutting-edge machine offers exceptional performance for the precise cutting of carbide rods and hollow tubes. Its robust design and intuitive features make it the ideal choice for industrial applications.

SMART CUT® 7005 Tube & Rod Cutting Machine

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Diamond & CBN Wafering Blade Case Studies

This study evaluates the cutting performance of SMART CUT® Diamond & CBN Wafering Blades compared to Conventional Wafering Blades under identical test conditions. The objective was to measure differences...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

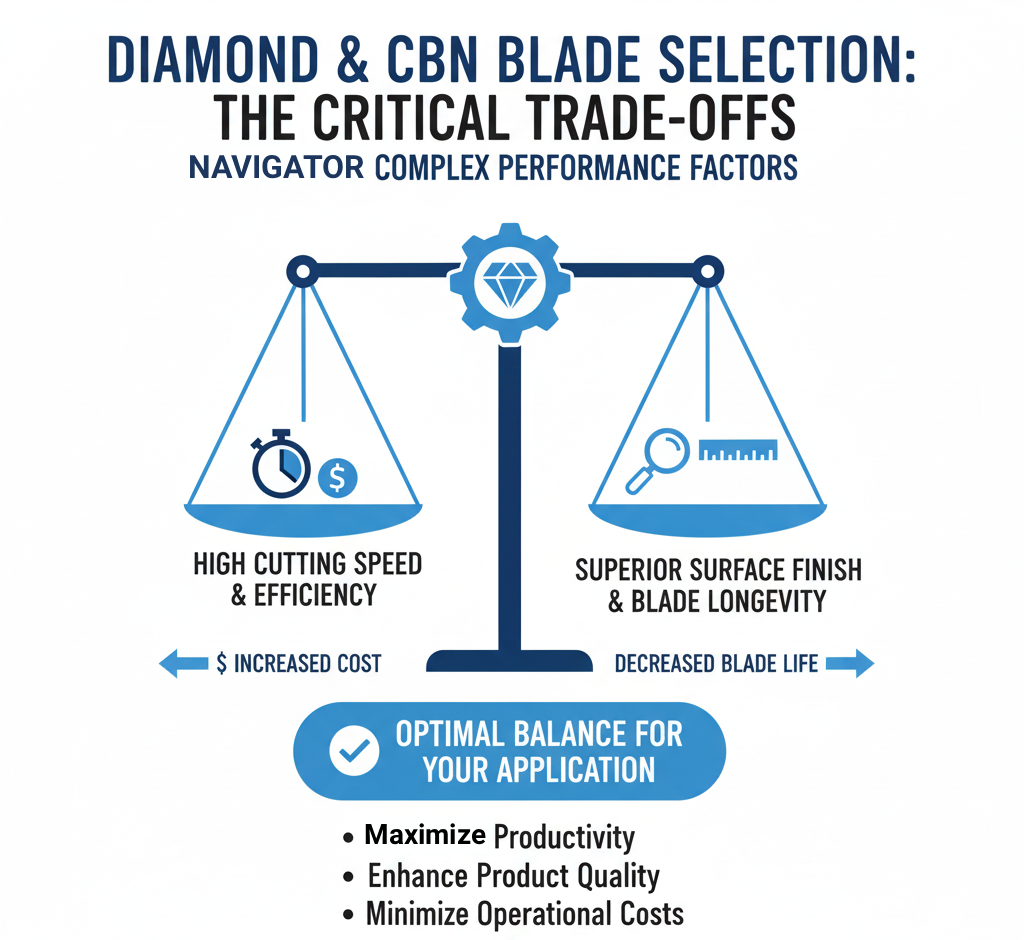

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

02

Nov

Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...