-

0 items in quote

No products in the Quote Basket.

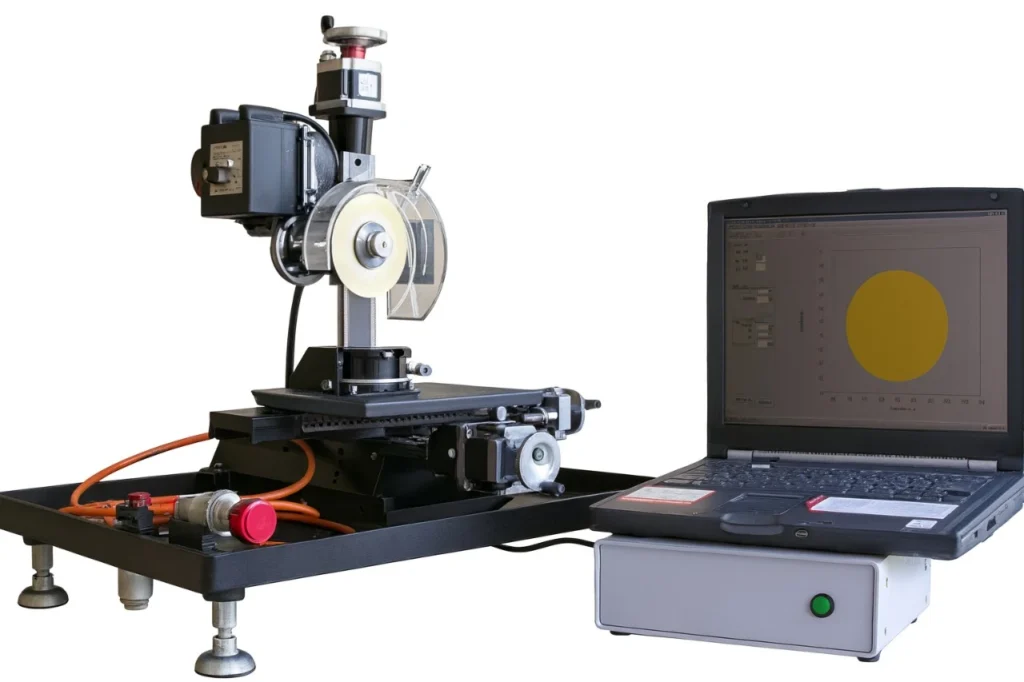

SMART CUT® 6035 diamond wire saw

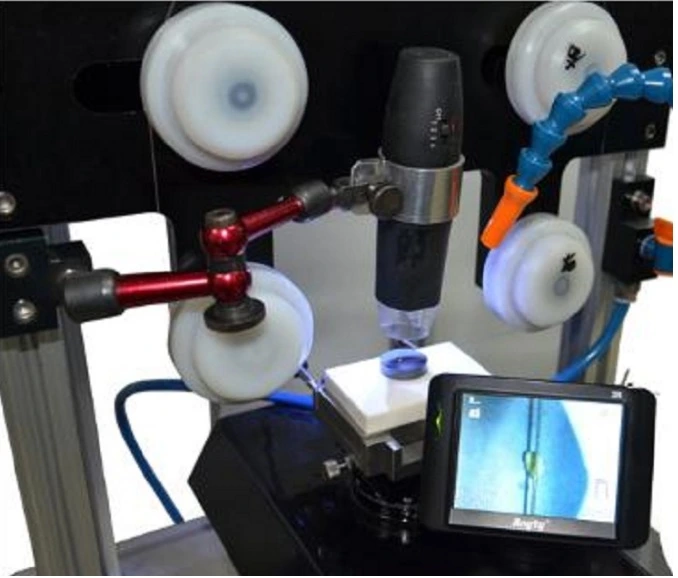

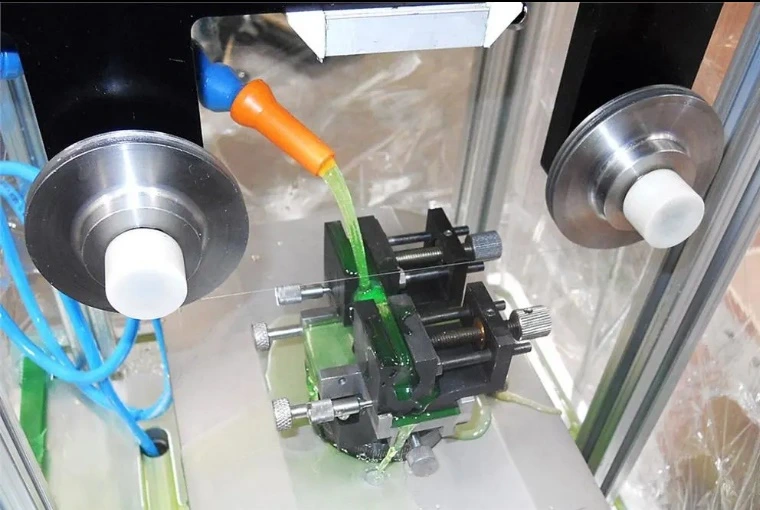

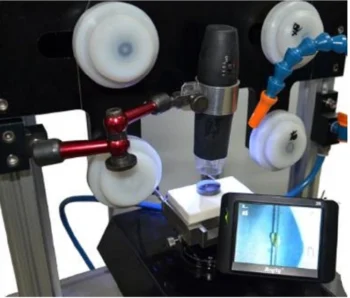

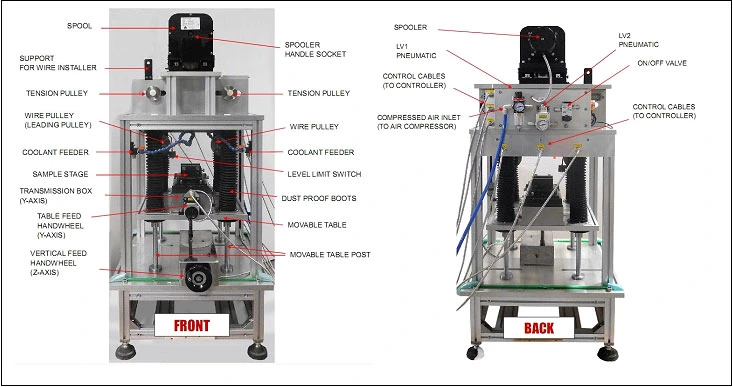

SMART CUT® 6035 diamond wire saw with advanced digital control offers the precise performance and durability essential for today’s leading laboratories and research institutions. Engineered with a three-dimensional digital control system, this saw is user-friendly and designed to deliver precision cutting at a highly competitive price point. Optimized for intricate cutting, dicing, and slicing of materials up to 50 mm in thickness, the SMART CUT® 6035 is ideal for handling fragile materials, such as delicate crystals, ceramic samples, and TEM or IC samples, ensuring exceptionally thin sections with minimal surface modification.

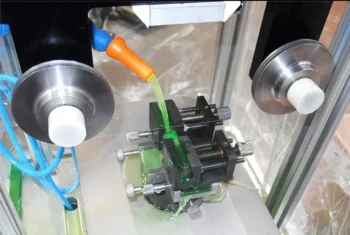

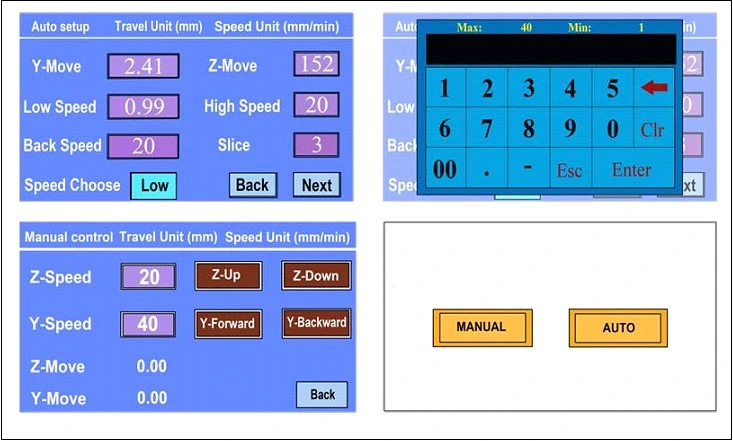

SMART CUT® 6035 is designed to support a wide range of cutting requirements, making it suitable for material research, TEM sample preparation, and IC failure analysis. The saw allows precise control over feed speeds, adjustable between 0.01 mm/min to 20 mm/min, enabling versatility for diverse material hardness and thickness. Both X and Y axes are digitally controlled via an intuitive touch panel, providing seamless, automated positioning and maximizing operational precision. Additionally, the saw includes a built-in water recirculating pump to cool the diamond wire during operation, ensuring smoother cuts and prolonging the wire’s lifespan.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

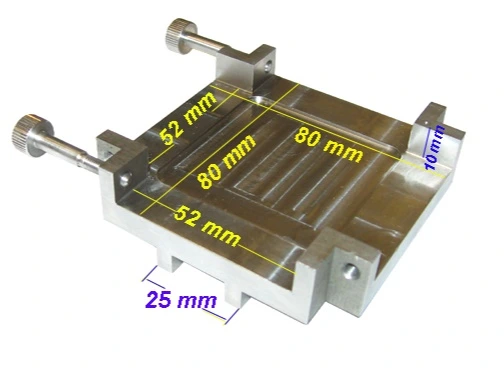

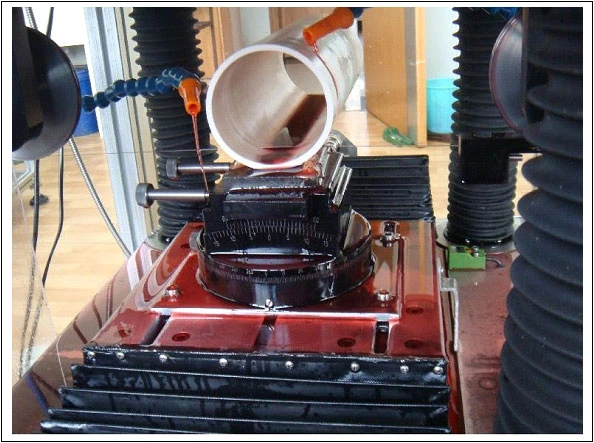

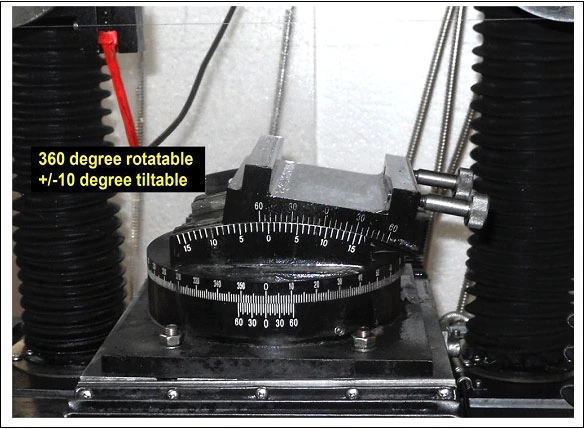

The saw’s heavy-duty aluminum alloy frame ensures durability and stability, while transparent protective panels prevent coolant splashing, enhancing safety during operation. The cutting mechanism employs a single swinging wire with an adjustable length ranging from 5 to 15 meters, which allows for reuse of broken wire sections, contributing to cost-efficiency. The sample stage offers 360° horizontal rotation and ±10° tilting, enabling flexible sample orientation for precise cutting and complex sample geometries. With a positioning accuracy of ±0.01 mm, users can confidently achieve highly detailed cuts.

For enhanced performance on brittle crystals, an optional 0.22 mm diamond wire can be ordered, which requires a reduced feed rate due to its delicate nature. For improved cooling and extended wire life, SMART CUT® Coolant is recommended. Users may also opt for a Fiber Optic Y-shape Dual Light Microscope Illuminator for enhanced lighting where necessary.

SPECIFICATIONS

Technical Data

|

General |

Designed for Bench top laboratory equipment |

|

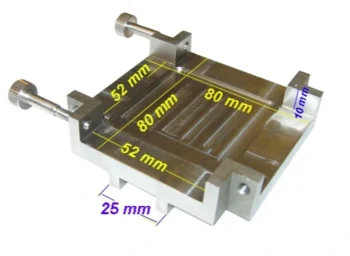

Stage travel |

Z axis: 50mm, automatically controlled by digital panel |

|

Sample stage |

Two dimension sample stage built in: 360°degree horizontal rotating and ±10° tilting |

|

Traveling position accuracy |

±0.01mm |

|

Controller & Touch Screen |

The saw wire moves along the Z-axis to implement cutting according to user defined program which specifying the cutting length, feed speed, back, speed, and spooler spinning speed. The feed speed is able to be set from 0.01mm/min to 20mm/min. |

|

Diamond wire |

≤15 meters used for each installation |

|

Wire traveling speed |

0-1.5m/s adjustable |

|

Cutting Depth & Thickness |

Max: 50mm in diameter or square |

|

Water Pump |

A small water recirculating pump is included for cooling diamond wire during cutting |

|

Power |

110 – 240V AC 50/60Hz, for universal power. 200W Max. |

|

Product dimensions |

Saw: 414mm(L) × 500mm(W) × 750mm(H) |

|

Warranty |

One year limited with lifetime support, not including cutting wire |

|

Certificate |

CE certified |

ADVANTAGES

Advantages:

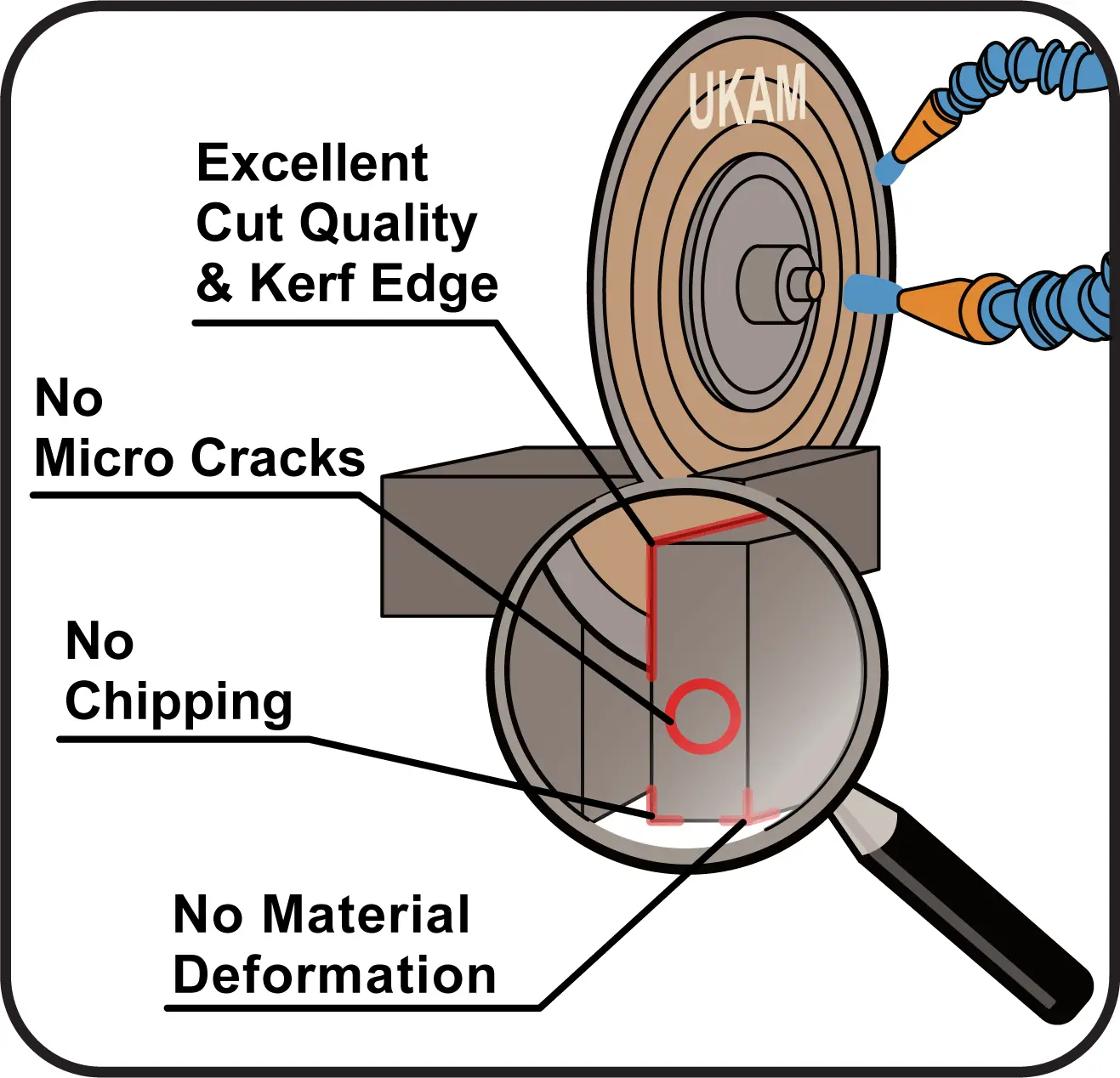

- High precision and accuracy

- Customizable digital control

- Versatile material compatibility

- Enhanced sample stage mobility

- Thin slicing with minimal structural modification

- Adjustable feed speed for controlled cutting

- Extended diamond wire life and reusability

- Integrated water recirculation and cooling system

- Robust and durable construction

- CE certified for safety compliance

- Compact bench-top design

- Universal power compatibility

- Universal power compatibility

- Optional upgrades for enhanced functionality

INDUSTRIES USED IN

Tab Content

FAQ

Tab Content

OPERATING MANUALS

Download Operating Manuals

ACCESSORIES

Tab Content

Features

- Sample up to 50mm thickness

- Designed to provide a smooth and precise cutting for many kinds of materials. Ideal cutting tool for material research, TEM sample preparation, and IC failure analysis

- Feed speed possible to be set from 0.01mm/min to 20mm/min

- X and Y axes automatically controlled by touch panel

- Water recirculating pump is included for cooling diamond wire during cutting

- CE certified

Optional Orders

- For slicing or dicing very brittle crystal, you may order 0.22mm dia. Diamond Wire. Note that 0.22mm dia. Wire is very easy to broken, please reduce feeding rate to minimum.

- For longer wire life, please use SMART CUT® Coolant

- Where improved lighting is required, please consider a Fibre Optic Y-shape Dual Light Microscope Illuminator

LARGEST SELECTING OF DIAMOND WIRE

BLADES AVAILABLE

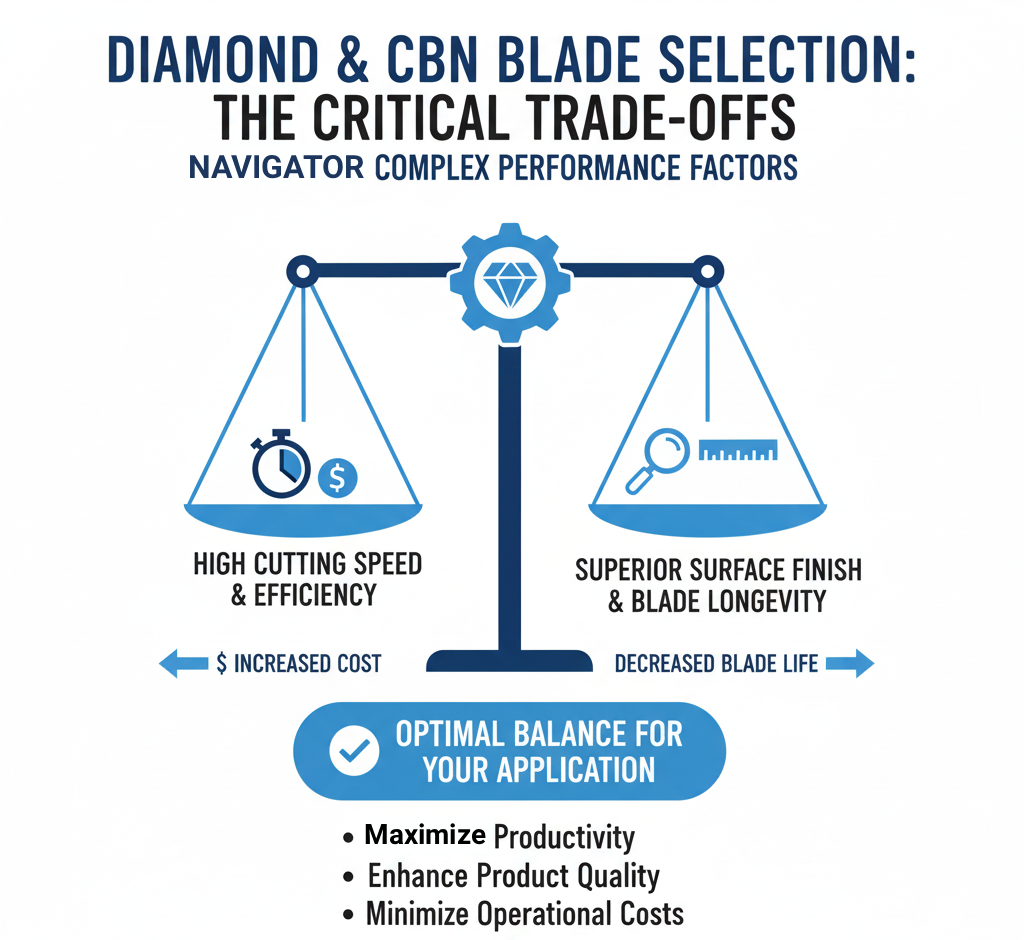

SMART CUT® Diamond Wire is available in loops and spools multiple configurations to meet different cutting requirements and fit almost any type of wire saw. Fine wires are used for semiconductor wafers, sapphire, and optics where precision and surface quality are critical. Medium wires are suited for solar wafers, glass, and ceramics, providing a balance of efficiency and finish. Larger wires are designed for stone, silicon ingots, and composites where durability and throughput are essential. Core materials include steel, stainless steel, tungsten, molybdenum, and specialty alloys such as NiTi, offering options for strength, flexibility, and corrosion resistance. Bond types include electroplated, resin bond, multi-layer, spiral, continuous, and segmented, allowing users to choose the best combination of cutting speed, tool life, and surface finish for their application.

Related Products

Item # 1001 SMART CUT® – DIAMOND DICING / SLICING SAW

Item # 8000011 SMART CUT® 6012 – Diamond Wire Saw (Lab)

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Diamond & CBN Wafering Blade Case Studies

This study evaluates the cutting performance of SMART CUT® Diamond & CBN Wafering Blades compared to Conventional Wafering Blades under identical test conditions. The objective was to measure differences...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

02

Nov

Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...