-

0 items in quote

No products in the Quote Basket.

Equipment Used on

Diamond Wire Loops

SMART CUT® Diamond Wire Loops are closed-loop precision tools mounted on pulleys and designed for high-accuracy cutting of wafers, optics, and crystals. Unlike spool-based systems, loop wires maintain stable and consistent tension across the entire loop, ensuring repeatable performance, minimal vibration, and extremely clean cuts. This makes them the preferred choice in laboratories, research facilities, and advanced production environments where tolerances are tight and surface quality is critical. They are manufactured with wire diameters ranging from 80 to 350 µm, using core materials such as high-tensile steel, tungsten, molybdenum, and NiTi alloys.

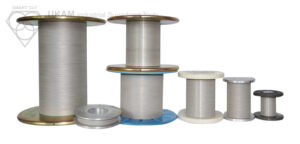

Diamond Wire Spools (Bobbin-Based)

SMART CUT® Diamond Wire Spools, also known as bobbin-based diamond wire, are specifically designed for extended, continuous cutting operations. They are ideal for processing large ingots, slabs, and blocks where long cutting paths are required. Unlike looped wire systems, spool-based wire is wound onto reels and fed continuously through the workpiece, meaning that fresh abrasive sections are always in contact with the material. This feature ensures steady cutting performance and consistent quality across very long cuts, making the method indispensable for heavy-duty production environments.

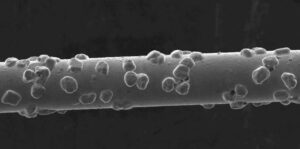

Diamond Wire

SMART CUT Diamond wire produces minimum kerf loss, less sub-surface damage, and contamination free coolant. Used for precision cutting of various types of artificial crystal, ceramic, quartz glass, monocrystalline silicon, polycrystalline silicon, sapphire and special metal materials. Diamond Wire cutting is an environmentally friendly cutting process as it eliminates slurry recycling and disposal issues.

It is widely used for slicing artificial crystals, ceramics, quartz glass, monocrystalline and polycrystalline silicon, sapphire, and specialty metals. The design provides high dimensional accuracy and smooth surfaces, often eliminating the need for extensive secondary processing.