Diamond Blades For Stone Industry

Stone industry

Diamond Blades

Leading Manufacturer of High Precision & Ultra Thin Diamond Blades 0.5" (12.7mm) to 48 (1219mm) in Outside Diameter, starting from 004 (0.1mm) Thick.

We manufacture and offer a wide range of high-quality standard and custom tools for contractors. Our tools provide higher level of performance compared to what is typically available in the market. That's where we excel. Whan your standard tools fail to meet the cutting requirements, we have the solution you need. As a small American diamond tool manufacturer, we distinguish ourselves through our commitment to quality, high-performance capabilities, excellent value, and the ability to deliver unique and customized solutions.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

Established in 1990

Miniature Diamond Cutting Wheels Sintered (Metal Bond)

Handle materials ranging from 4.0 to 9.0 on the Mohs hardness scale, making them ideal for cutting diverse materials like ultra hard porcelain, stone of various hardness's and glass in one go.

Small Diameter, Continuous Rim (plated)

Continuous rim diamond catting blades are used for dry cutting of larger variety of composite materials, fiberglass, plastics and other soft and

Small Diameter, Slotted (plated)

Slotted, plated diamond cutting blades are used for dry cutting of larger variety of composite materials, fiberglass, plastics and other soft and gummy...

Miniature Slitting Blades (plated) with Straight Shank

Available from stock from 8mm to 22mm Diameter. These multi layered plated wheels come mounted on shank 3mm diameter. Kerf thickness .026" to...

Diamond Mounted Saws Continous Rim & Slotted

Mounted electroplated diamond trimming blades. These blades are used where it is necessary to cut close into a corner. The diamond blade and spindl...

Small Diameter, Mounted Blades (Braised Bond)

Braised bond diamond trimming blades, can be mounted on one of our arbors. These blades are used where it is necessary to cut close into a...

Slitting Blades Continuous Rim (plated)

SMART CUT Miniature Electroplated Diamond Wheels are precision-engineered tools, perfect for detailed cutting and slotting tasks. These wheels are specifically designed for enthusiasts and professionals who demand accuracy and efficiency in their work. 20 to 22mm in diameter kerf thickness.022" to .030" with small mandrel use for cutting, slotting large variety of materials used on dremel, foredom, other hand piece grinders, die grinders.

Slitting Blades, Sloted (Plated)

SMART CUT Minature Slotted Eelectroplated Diamond Wheels are desgiend for cutting and slotting large variety of materials. The slotted design helps cut faster and freer specially for softer and gummy materials. These are available from 20mm to 30mm diameter. Used on equipment such as dremel, foredom, and other hand piece grinders.

Slitting Blades, Slotted (Plated)

Electroplated Diamond Miniature Slotted Slitting Blades are precision-engineered tools designed for high-performance cutting and slitting applications. Ranging in diameter from 50mm to 100mm, these blades are ideal for detailed and intricate work. Slotted design helps cut faster and freer specially on softer and gummy materials.

Small Diameter Turbo Type Diamond Wheels with Mandrel

SMART CUT Miniature sintered turbo type diamond wheels mounted on a mandrel are used for cutting, engraving, and carving of large variety of materials. Available from 30mm to 75mm Diameter, with various kerf thicknesses, and shank/mandrel diameters.

Small Diameter Notching & Groving Blades

SMART CUT Electroplated Diamond Wheels are engineered with a unique design, featuring a core that is thicker than the diamond section. This innovative construction ensures enhanced durability and superior performance for a range of applications. Ideal for various tasks such as cutting, slotting, grooving, and scribing.

Minature Diamond Wheels, Sintered (Metal bond) with Mandrel

SMART CUT Sintered (Metal Bond) diamond & CBN slitting blades have diamond or cbn abrasive all the way through the slitter so you can use the edge for making thin, precise cuts through various materials or the top for grinding down edges. All of these blades can be mounted on various shafts such as 3/32" (2.35mm) or 1/8" (3.2mm) for use in a Dremel or Foredom Flexible shaft type grinder.

Sintered (Metal Bond) Mounted Diamond Slitting Wheels

diamond wheels for cutting, grinding, shaping larget veriety of materials are mounted to precision arbors usually with 5/8-11" female thread or other thread sizes to be used on different equipment such as high speed air grinders, angle grinders, cnc machines, etc available from 50mm to 150mm diameter.

Fully sintered (metal bond) mounted diamond slitting

wheels these wheels are made to order can be made of almost any diameter, any shank diameter any height, radius/angle, & specification.

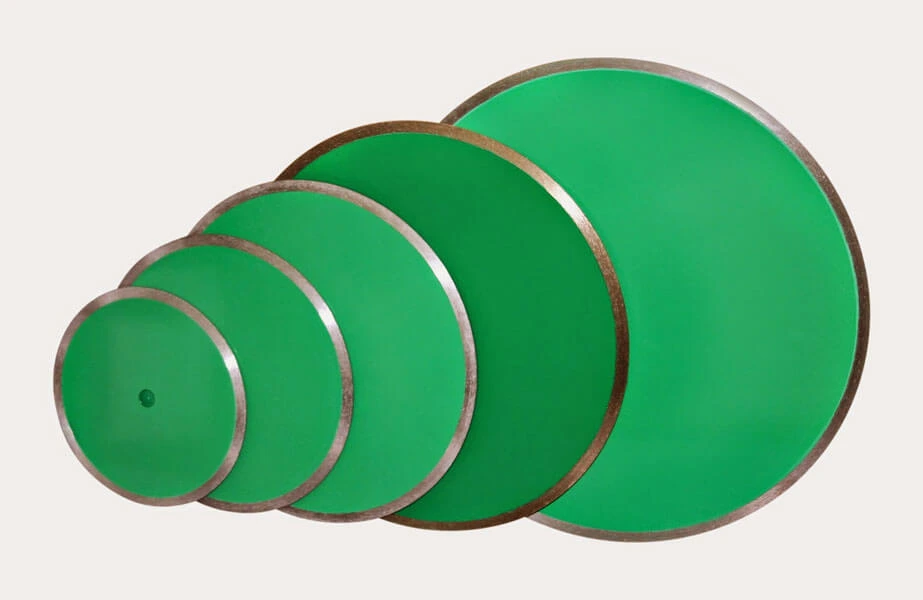

SMART CUT® Precision

Diamond Blades (Universal Application)

Handle materials ranging from 4.0 to 9.0 on the Mohs hardness scale, making them ideal for cutting diverse materials like ultra hard porcelain, stone of various hardness's and glass in one go.

SMART CUT® 305M

Lapidary Blades

Available 4" to 36" Diameter. Series 305M provide unmatched performance on a very wide variety of ultra hard to soft lapidary materials. This sintered (metal bond) lapidary blade is known for their aggressive, fast, and rough cutting capability.

Minature Diamond Cutting Wheels

Use for cutting, slotting, grooving, grinding, & shaping a large spectrum of materials. Ranging from ultra hard & brittle materials (such as A1203, sapphire, etc), Ultra Hard Metals, Glass, Composites.

SMART CUT® 301M

Lapidary Blades

SMART CUT® SERIES 301M blades feature a cutting- edge turbo design that accelerates the cutting process, offering a faster and freer cutting speed, compared to notched diamond cutting blades.

SMART CUT® 315M

Lapidary Blades

SMART CUT® SERIES 315M sintered (metal bond) diamond lapidary blades are specially designed to efficiently cut a wide range of hard lapidary materials

SMART CUT® 405M

Lapidary Blades

SMART CUT® Series - 405M DIAMOND CUT OFF BLADES FOR VERY ABRASIVE MATERIALS SMART CUT® Series 405M are Designed for...

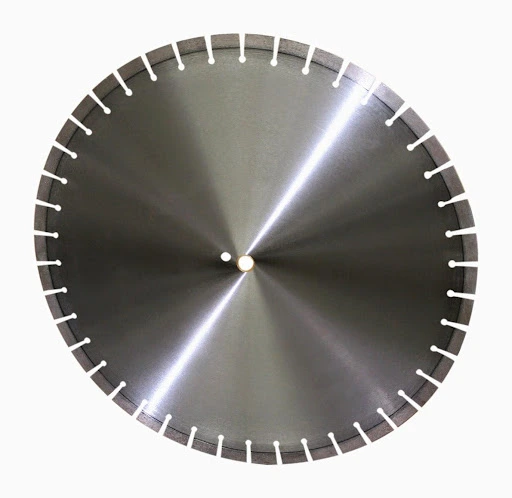

Lapidary Slabbing Blades 16"(406mm) to 48"(1,219)mm

SMART CUT® 330MS Segmented Lapidary Blade

Available 18" to 36" Diameter, Wide Slot Segment Design. spacing between segments. Designed for fast and more aggressive cutting, where chipping and very smooth cut loss is not essential.

SMART CUT® 325M Continuous Lapidary Blade

Available 18" (450mm) to 20" (500mm) Diameter Continuous rim, Sintered (Metal Bond) 325M blade is designed for delicate cutting and minimum chipping of wide variety of natural stone, semi precious stone, glass, and related materials.

Larger Diameter Slabbing Lapidary Blades

Large Diamond Diamond Lapidary Slabbing Blades larger then 36" (914mm) to 72" (1,828mm) are used for cutting large variety of materials on specialized cutting machines. These are typically made to order.

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superiror Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

- Custom Manufacturing

- Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

We understand that your success depends on select the right diamond & CBN blade, and optimizing your parameters to best fit your applications/needs.

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Diamond & CBN Cut Off Blades available in the USA. Diameters from 0.5” (12.7mm) to 48” (1,219mm), kerf thickness from 0.001” (0.025mm) to 0.5” (12.7mm), any arbor size, diamond mesh size, concentration, bond hardness, tolerances, Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary diamond & CBN Blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect diamond & cbn blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools