Menu

No products in the Quote Basket.

Sign Up to recieve exclusive usage recommendations, illustrated trouble Shooting Guides & sales

9 am to 6 pm PST time

No products in the Quote Basket.

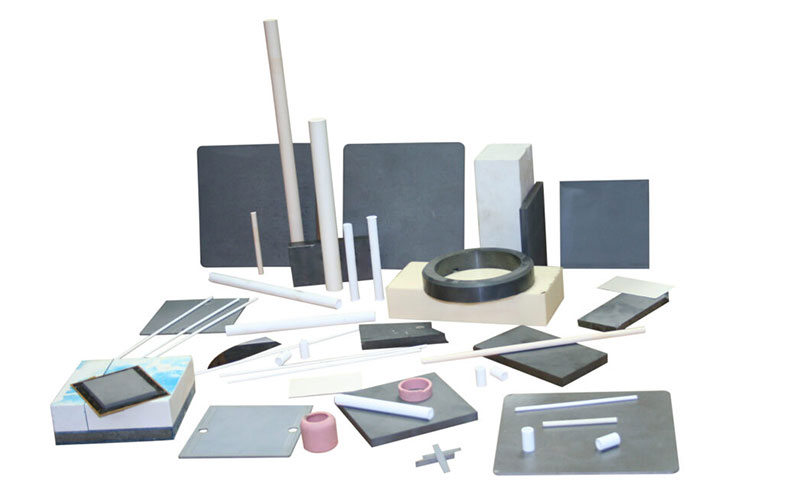

SMART CUT™ Series 330MS Continuous rim, Sintered (Metal Bond) blade is designed for delicate cutting and minimum chipping of wide variety of natural stone, semi precious stone, glass, and related materials. Continuous rim diamond blades produce the best surface finish and minimum amount of chipping possible.

SMART CUT Series – 325M Continuous Rim – Diamond Depth (Height): 8mm SMART CUT™ Series 330MS Continuous rim, Sintered (Metal Bond) blade is designed for delicate cutting and minimum chipping of wide variety of natural stone, semi precious stone, glass, and related materials. Continuous rim diamond blades produce the best surface finish and minimum amount of chipping possible.

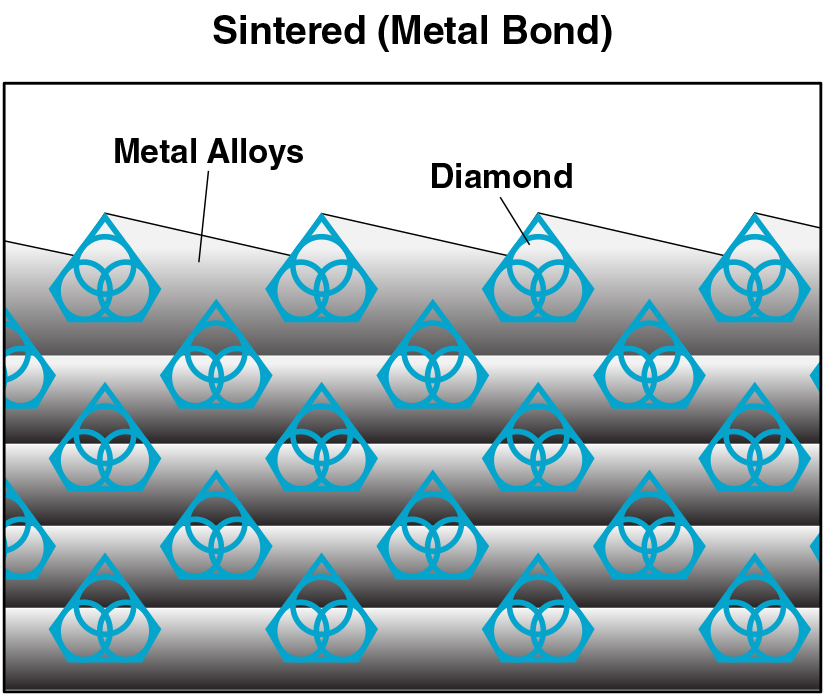

Bond Type: Sintered (Metal bond)

Edge Type: Segmented (Narrow Spacing Between Segments)

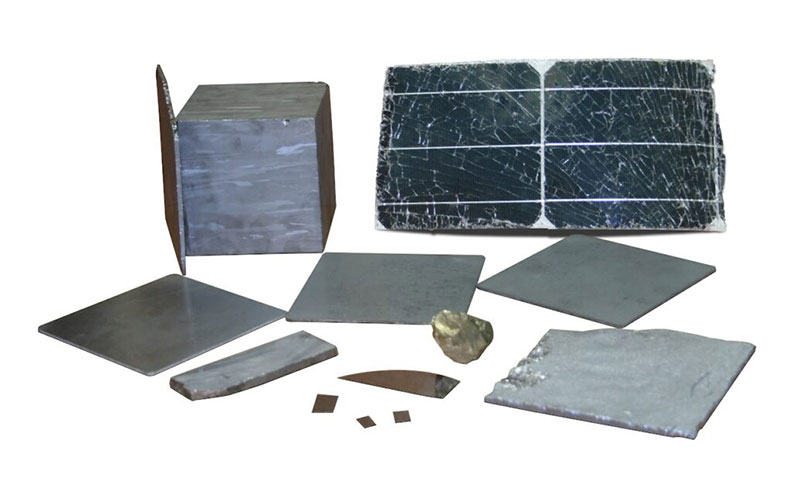

Application: Lapidary, Glass, Natural Stone, Advanced Ceramics, Composites

Diamond Grit Size: Coarse

Diamond Concentration: Low

Bond Hardness: Medium Soft

Diamond Type: Synthetic

Diamond depth: 5mm

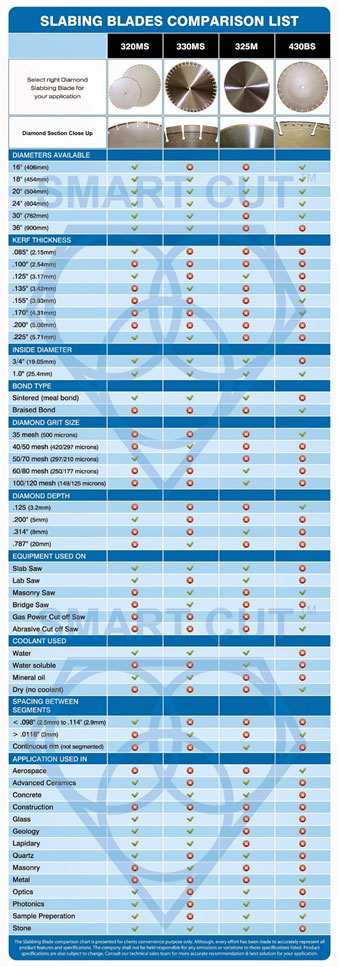

Blade Outside Diameters: 16″ (406.4mm) to 36″ (900mm)

Kerf Thickness: .085″ (2.16mm) to .200″ (5.08mm)

Inside Diameter: 1″ (25.4mm) or 3/4″ standard (other arbor sizes can be made same day)

Recommended Coolant: Water Soluble coolant such as SMART CUT or mineral oil

Saws Used On:

+ Slab Saws

+ Large Cut off Saws

+ Abrasive & Laboratory Saws

Tab Content

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

UKAMDRST4 | $15.39 | Max: Min: 1 Step: 1 | |||

UKAMDRST7 | $15.99 | Max: Min: 1 Step: 1 | |||

SMARTC1G | $34.81 | Max: Min: 1 Step: 1 | |||

UKAMDRST5 | $39.47 | Max: Min: 1 Step: 1 | |||

UKAMDRST8 | $39.47 | Max: Min: 1 Step: 1 | |||

SMARTC2G | $99.81 | Max: Min: 1 Step: 1 | |||

SMARTC4A | $317.41 | Max: Min: 1 Step: 1 | |||

SMARTC7A | $1,745.00 | Max: Min: 1 Step: 1 |

Image | Name | Diameter | Inside Diameter | Description | Price | Quantity | Add to cart | |

|---|---|---|---|---|---|---|---|---|

30mm | 1/2″ | Flanges for Accessories | $70.00 | Max: Min: 1 Step: 1 | ||||

30mm | 5/8″ | Flanges for Accessories | $70.00 | Max: Min: 1 Step: 1 | ||||

40mm | 1/2″ | Flanges for Accessories | $75.00 | Max: Min: 1 Step: 1 | ||||

40mm | 5/8″ | Flanges for Accessories | $75.00 | Max: Min: 1 Step: 1 | ||||

45mm | 1/2″ | Flanges for Accessories | $80.00 | Max: Min: 1 Step: 1 | ||||

45mm | 5/8″ | Flanges for Accessories | $80.00 | Max: Min: 1 Step: 1 |

| Blade Diameter | Recommended RPM | Blade Diameter | Recommended RPM |

|---|---|---|---|

| 4″ (100mm) | 4,000 | 16″ (400mm) | 1,000 |

| 5″ (125mm) | 3,438 | 18″ (450mm) | 1,000 |

| 6″ (150mm) | 2,675 | 20″ (500mm) | 900 |

| 8″ (200mm) | 2,000 | 22″ (550mm) | 825 |

| 10″ (250mm) | 1,600 | 24″ (600mm) | 700 |

| 12″ (300mm) | 1,325 | 30″ (762mm) | 550 |

| 14″ (350mm) | 1,140 | 36″ (914mm) | 500 |

Image | Item No. | Old Item No. | Outside Diameter | Rim Width (Diamond Thickness) | Rim Depth (Diamond Thickness) | Arbor Size (Inside Diameter) | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|

3181211 | 23-5018S | 18" (454mm) | .125" (3.17mm) | .315" (8mm) | 1" | $450.00$495.00 | Max: Min: 1 Step: 1 | ||

3201212 | 23-5020S | 18" (454mm) | .125" (3.17mm) | .315" (8mm) | 1" | $525.00$600.00 | Max: Min: 1 Step: 1 |

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT ® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Diamond & CBN tools with SMART CUT technology require minimum dressing, the bond renews itself.

SMART CUT series 330MS blades made utilizing SMART CUT technology are much more aggressive then conventionally blades. They can cut faster, while still leaving behind a smooth surface finish.

SMART CUT Series 330MS blades will outlast almost all other blades on the market today. The longer life can be attributed not only the higher diamond depth, but to higher diamond quality used. Advanced diamond distribution an orientation techniques, and proprietary bond chemistry. Combined with our competitive prices you re sure to obtain the best value and return on investment possible

SMART CUT Series 330MS Sintered (Metal Bond) Diamond Blades have hundreds of diamond layers impregnated inside the metal matrix. Unlike Many Other Blade Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

SMART CUT Series 330MS Sintered (metal bond) blades are the best investment you can make! Although they may cost more than other sintered (metal bond), electroplated (nickel bond), hot or cold rolled or some notched lapidary blades. Designed for users that understand and appreciate quality. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

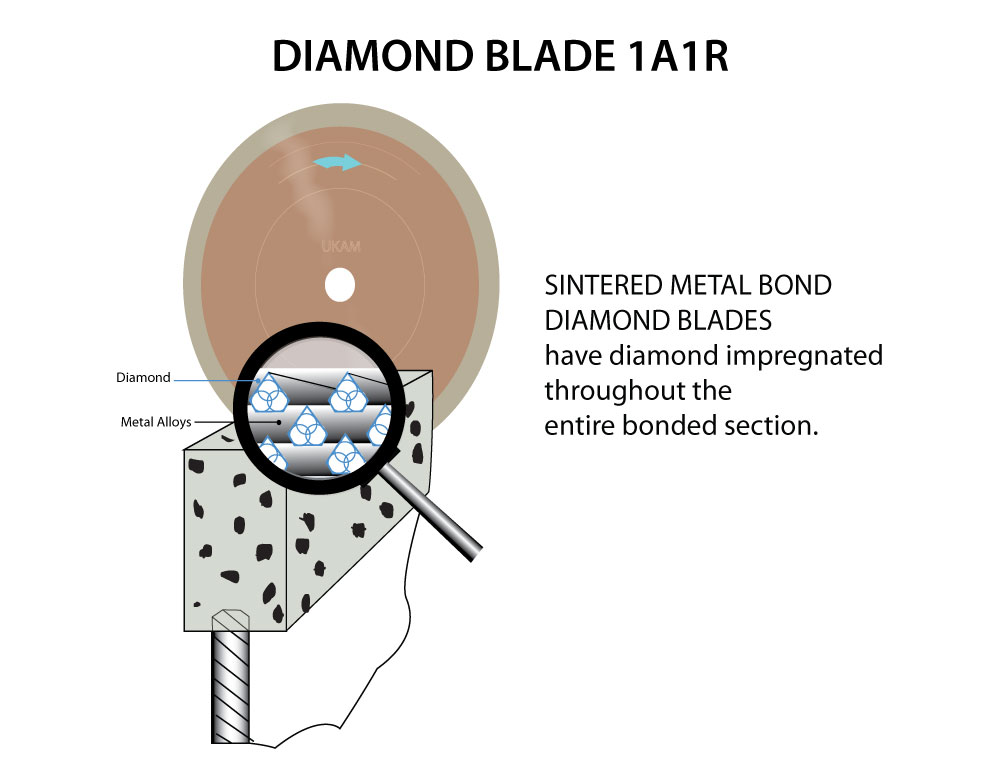

Sintered (Metal bonded) diamond blades are "impregnated" with diamonds. Diamonds sintered and multiple (hundreds) layers of diamonds impregnated inside the metal matrix. Electroplated and other types of diamond blades for lapidary application have only one layer of diamond that stays on the surface. Diamonds in a sintered (metal bond) diamond blade are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. The compacted materials are then hot pressed or sintered to full density. Heating rate, applied pressure, sintering temperature and holding time, are all controlled according to the matrix composition. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, agate, emerald, ruby, opal, petrified wood, glass, and etc.

The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting.

Sintered (metal bonded) diamond tools are recommended for cutting hard materials from 45 to 75 on Rockwell Scale (5 to 9.5 on mohs scale of hardness). It is more wear resistant and holds diamond well in place, usually producing the highest yield/cutting & best price per cut ratio.

They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

They wear evenly, and are known for their long life & consistency. Sintered (metal bonded) diamond blades are the latest technology available in Diamond Blades. And represent the BEST VALUE & PERFORMANCE PER CUT.

They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

Sintered (metal bonded) blades are the best investment you can make! Although they may cost more than electroplated (nickel bond), hot or colled rolled or some notched lapidary blades, sintered (metal bond) blades will more than pay for themselves in terms of:

Other Bond type blades may cost less, and at first glance may seem like the most cost effective alternative. However, they will cost you more in the long run. Depending on material and application, sintered (metal bonded) blades may last as much as 50 to 100 other diamond lapidary blade types put together. You can't get more life out of any other blade !!! Instead of constantly putting blades on and off the saw, you will save money by using one blade. This means cost per cut, sintered (metal bond) blades are the best choice

Other Blade Types have only one layer of diamond coated on metal core. Diamonds sit only on the surface. When this diamond portion is peeled off, the blade will slow down, cut on the side (not cut straight) or stop working (cutting) altogether. While other blade types may provide acceptable level of performance softer lapidary materials such as topaz, turquoise, amethyst, and etc. They will immediately burn out on harder materials such as agates, petrified wood, sapphire and etc. Metal bonded blades are sintered and impregnated inside the metal matrix. Multiple (hundreds) layers of diamonds are impregnated inside the metal matrix. Unlike Blade Types, metal bond blades wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance from sintered (metal bonded) blades.

Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is slower cutting speed. Low diamond concentration is recommended and widely used for cutting harder materials

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in chipping and surface finish. If you are cutting fragile, more delicate materials then we have available from stock finer mesh size diamond blades. If you need to cut as fast as possible and surface finish is not a concern we also offer much coarser cutting blades for this application

Blade thickness typically ranges from .014” (0.35mm) to .085” (2.0mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material due to the thickness of blade passing though the material. Blade thickness is important for users requiring most minimal amount of material loss cutting specially when cutting very valuable materials such as gemstones or meteorites There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker blades are more stiff and can whistand higher/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as students and beginning users.

Typically lapidary blade diameters range form 4” (100mm) to 8” (200mm) for trimming and 10” (254mm) and up are usually used for slabbing. The diameter should be selected based on material diameter and thickness being cut. Smaller diameter blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and pieces of material at higher loads and speeds than smaller blades Blade Inside Diameter - Most trim saws and tile saws has 5/8” arbor these are for blades 4” to 10” OD. Larger cutting machines such as 12” to 18” OD usually have 1” arbor. We can provide bushings to smaller arbor. We can also expand the current arbor size to anything you want same day

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness. Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Metal bonding offers long life and durability, and is the best bond type to use for lapidary applications

Feed rate is amount of force applied to the blade to go through material being cut. This will typically vary depending on blade diameter, kerf thickness & material being cut. Generally, harder materials are cut at higher feed rates and speeds (such a precious and semi precious stones) and more softer and brittle materials are cut at lower loads and speeds (such as glass, quartz). The Speeds/RPM’s you are using, shape/geometry of the material, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Most lapidary blades are used between 4,000 to 1,000 RPM’s Typically harder and more denser materials such as Sapphire, are cut at higher RPM’s/speeds Where more brittle materials such as as glass are cutting at lower RPM’s. Most rim saws RPM’s are typically limited from 1,000 to 4,000 RPM’s. Slabbing saws 500 to 1000 rpm’s. And trim saws from 3,000 to 6,000 rpm’s.

SMART CUTTM Series - 330MS Wide Slot Segment Design - Diamond Depth (Height): 8mm SMART CUT Series 330MS Wide spacing between segments. Designed for fast and more aggressive cutting, where chipping and very smooth cut loss is not essential. And loss of material is not critical. Perfect for medium to hard lapidary materials, and less experienced blade users.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales