Diamond & Abrasive Consumables &

Machines For Grinding, Lapping, & Polishing

For Grinding, Lapping, & Polishing

Diamond & Abrasive Consumables & Machines

UKAM industrial manufactures and offers diamond & abrasive grinding, polishing and lapping solutions for many industries and applications for clients in Industry, R & D, and hobby/craft applications. Available from stock and custom manufactured for your needs.

Industries Used In:

- Automotive / Diesel

- Aerospace

- Compressor & Valve

- Pumps

- Precision Optics

- Precious & Semi Precious Stone

- Technical Ceramics

- Data Storage

- Specially Materials / Products

- Mechanical Seals

- Composites

- Glass

- Tool & Die

- Bearings

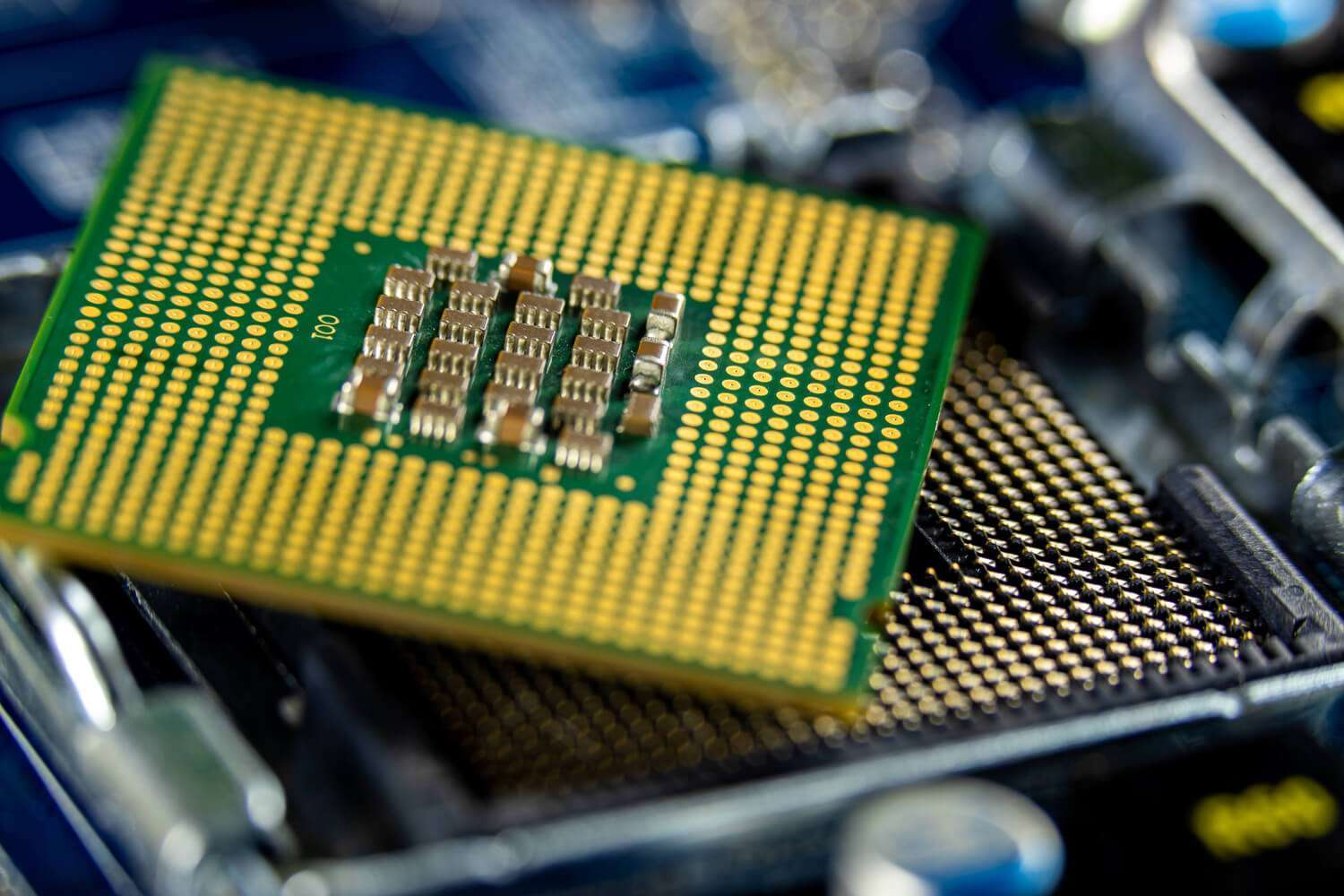

- Semiconductor

- Medical Devices

- Stone

- Metallography

- Sample preparation

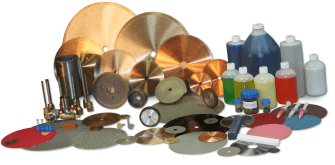

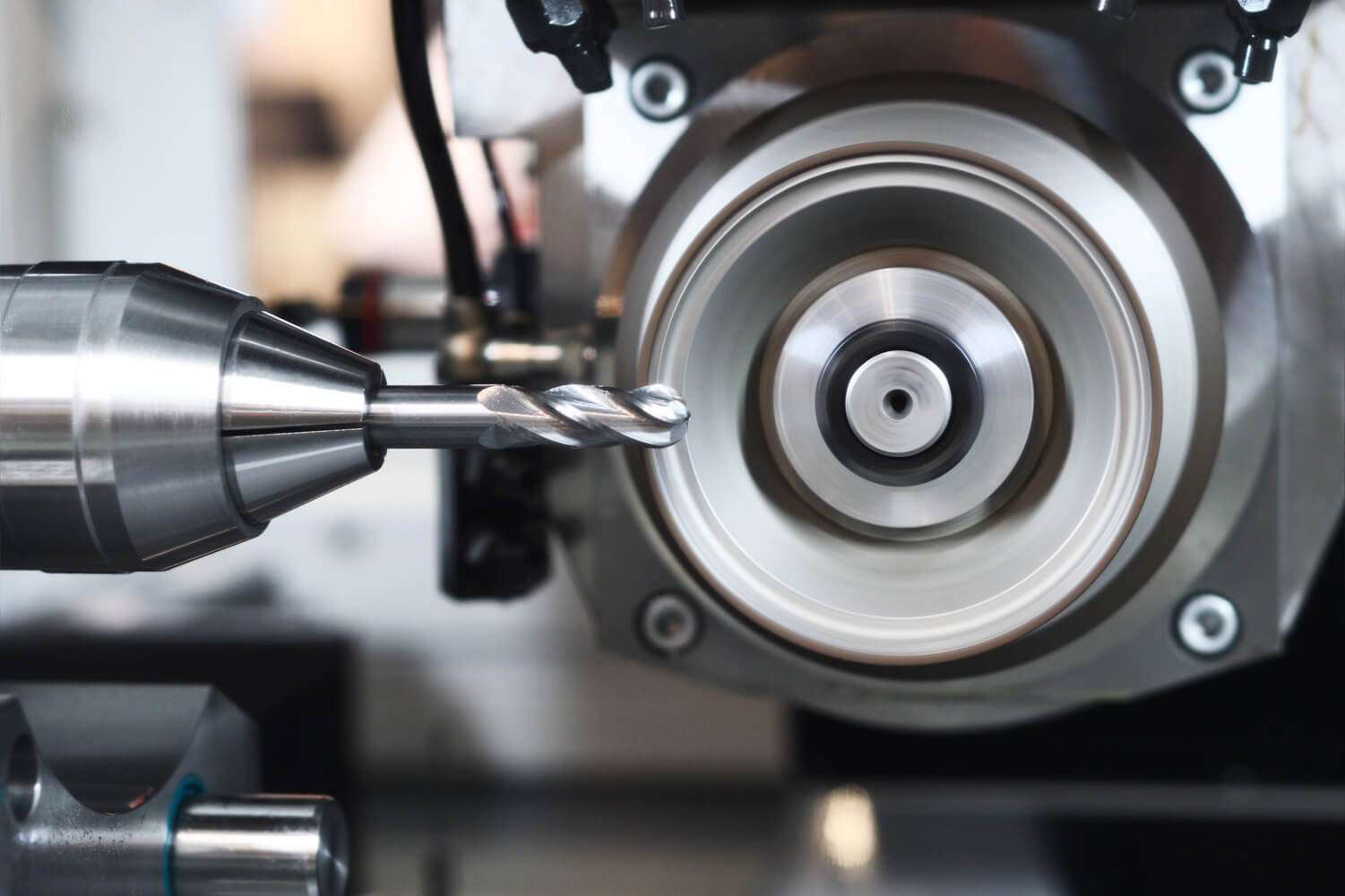

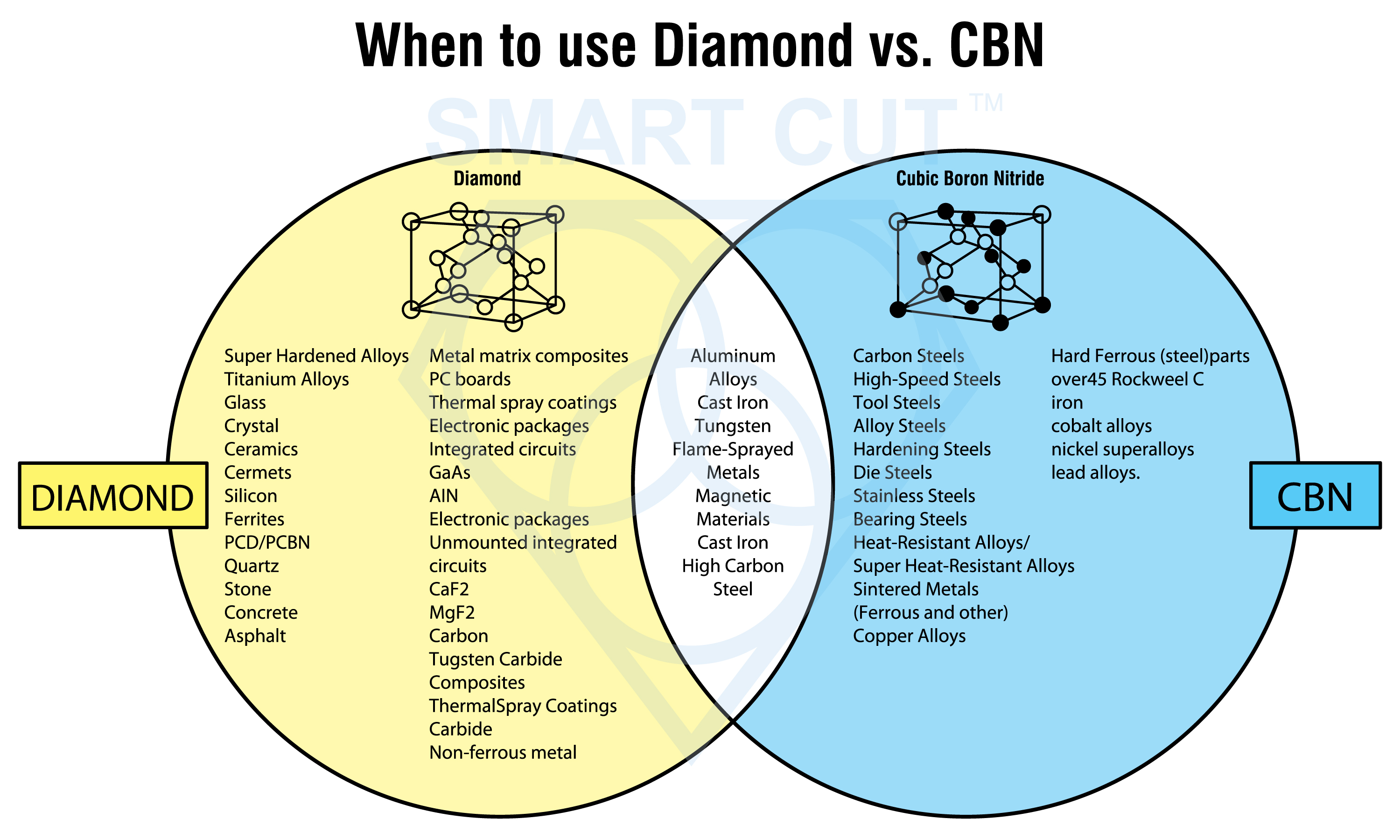

Diamond Abrasive Products (Fixed Diamond)

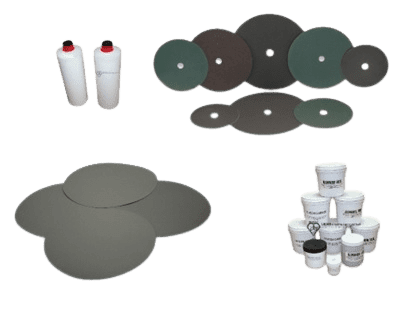

Fixed Abrasive diamond discs are used for grinding and polishing applications. They consist of flat circular discs with diamond particles embedded in resin or metal matrix

Metal Bond Diamond Discs for sample preparation

Our metal bond diamond discs can be used on all popular grinding & polishing machines designed for sample preparation. Such as Buehler, Struers, Leco & many others. Available in 8” (200mm), 10” (250mm) & 12” (300mm) OD with psa adhesive or magnetic backing or no backing. Diamond Sizes available from 250 to 6 microns

Resin Bond Diamond Discs

Our resin bond diamond discs can be used on all popular grinding & polishing machines designed for sample preparation. Such as Buehler, Struers, Leco & many others. Available in 8” (200mm), 10” (250mm) & 12” (300mm) OD with psa adhesive or magnetic backing or no backing. Diamond Sizes are available from 160 microns to 6 microns

Metal Bond Diamond Discs for glass, stone & ceramic

Diamond Laps also known as metal bond diamond discs, have diamond particles held firmly in place on a rigid backing by electroplated erosion resisting nickel for maximum bond strength and heat dissipation.

Resin Bond Diamond Polishing Discs for Large Machines

SMART CUT Resin Bond Diamond Discs are designed for fine and coarse grinding/polishing of high hardness materials such as metals, ceramics, refractories, cement, geological rocks, glass, optics, composites, and many other materials 35 and up Rockwell C scale of hardness

Diamond pellets

Diamond Pellets provide quick material removal with precision finishing. Diamond pellets are suited for superfine glass, sapphire, ceramics, semiconductor materials, ultra hard & brittle materials and other glass like materials.

Diamond Files

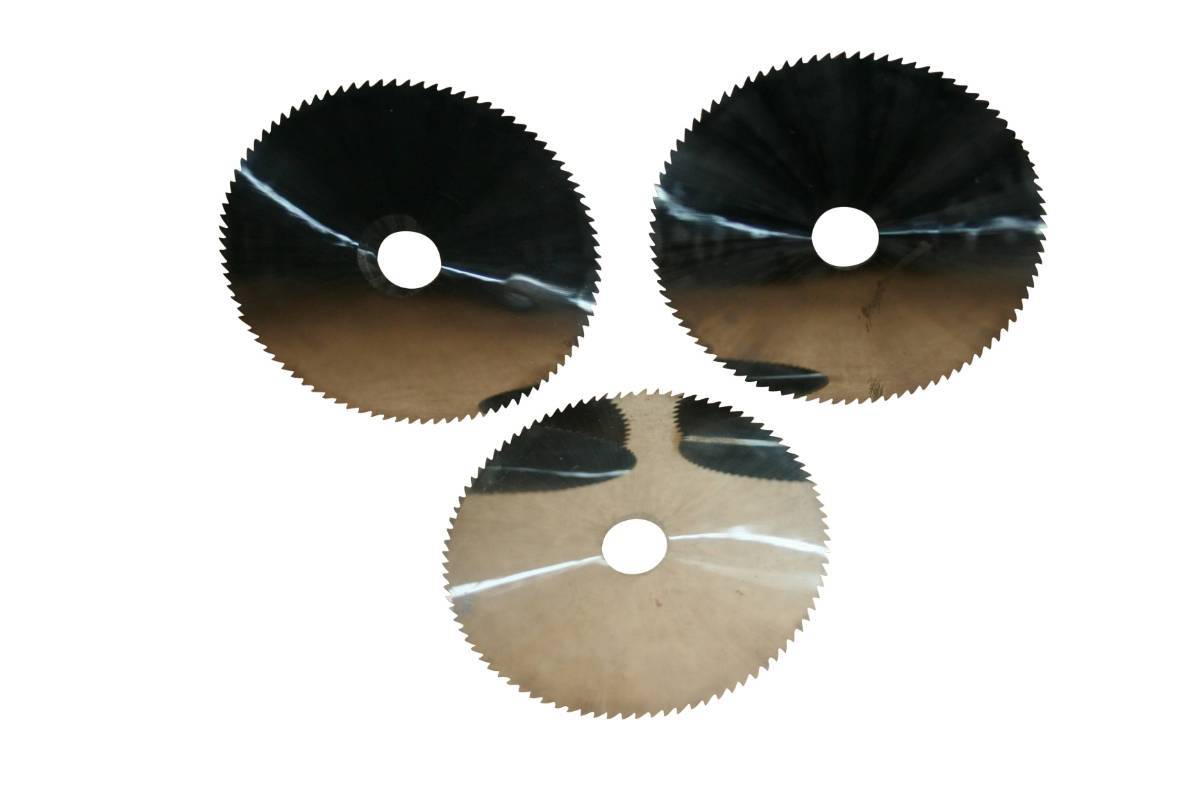

Diamond files are used for deburring, notching, dressing and honing hard, brittle materials such as hard steels, glass, and ceramic. This allows you to file in side to side motions, circular, and back and forth

Diamond Sheet

Diamond Sheet material can take many forms. It has been proven as a reliable dicing blade for precision dicing applications. It has also been used for lapidary operations, whether it be stationary or by hand. These superabrasives can range in size from a coarse "grit" to an ultra-fine micron. Thicknesses range from .040" down to .004".

Diamond Foil

Diamond flexible abrasive sheet is ideal for cutting and adhering to surfaces with which to make your own grinding, shaping, deburring, polishing and sharpening tools. make your own custom diamond abrasive tools cut the sheeting to size and required shape.

Diamond Cloth

Selected high quality diamonds are electroplated with a nickel matrix through a special flexible stainless steel mesh, or a very strong flexible backing cloth, which achieves a very strong fast grinding and finishing product

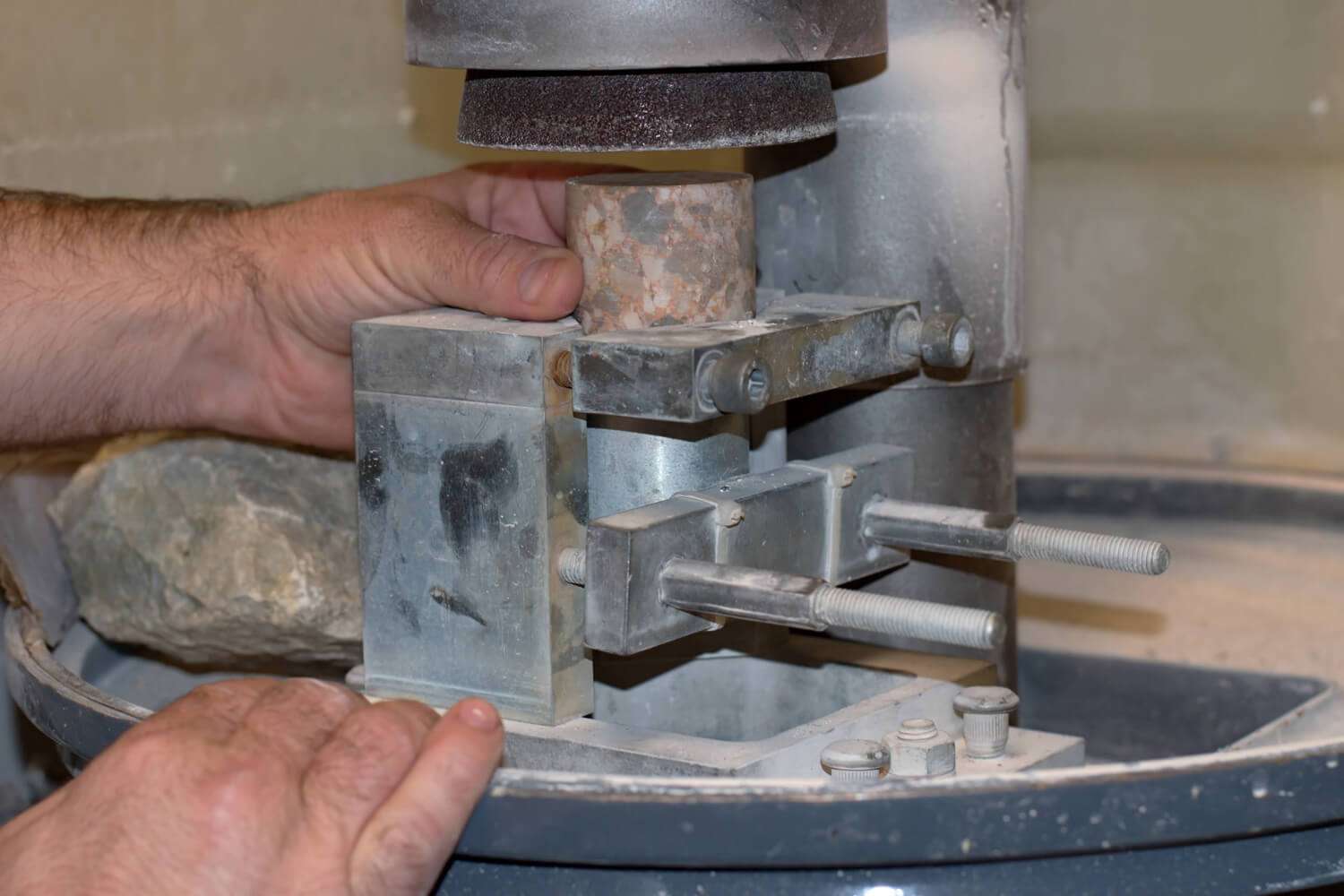

Diamond Laps for Gemstones/ Lapidary/Glass/Faceting

Electroplated & resin bond diamond discs provide a flat grinding surface for both rough and fine grinding on stone, gemstone, glass & other materials

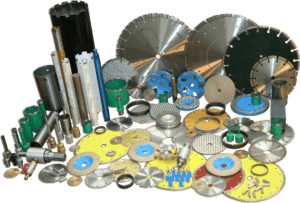

Diamond Backgrinding Discs

Used on backgrinding machines for thinning and flattening silicon wafers, glass products, ceramic products. Sizes range from 8” to 14” O.D. Used on machines manufactured by Disco, Okamoto, Strasbaugh, and many others.

Ceramic Lapping Plates

ceramic lapping plates are used for material is used for lapping, polishing, and sharpening of large variety of hard materials.

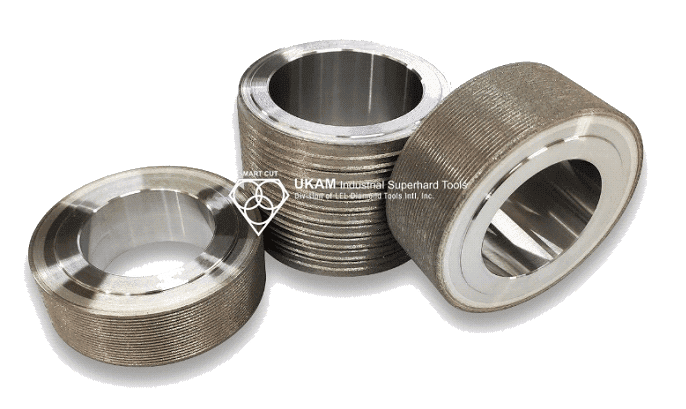

Curved Pellet Diamond Lapping Wheels

These wheels have pellets mounted on curved surface. The curvature of the pellets is a key characteristic, allowing for more effective engagement with the material being processed. This design enhances the wheel's ability to grind, smooth, or polish complex surfaces, including those with intricate geometries or hard-to-reach areas.

Flat Pellet Grinding Wheels

Fine grinding wheels produce material removal rates are up to 20 times faster than lapping. Pellet type wheels are available with spaces (grooves) between the pellets or with the inter-pellet spaces filled to provide a smooth surface. Segmented wheels which appear as a solid grinding surface are also available.

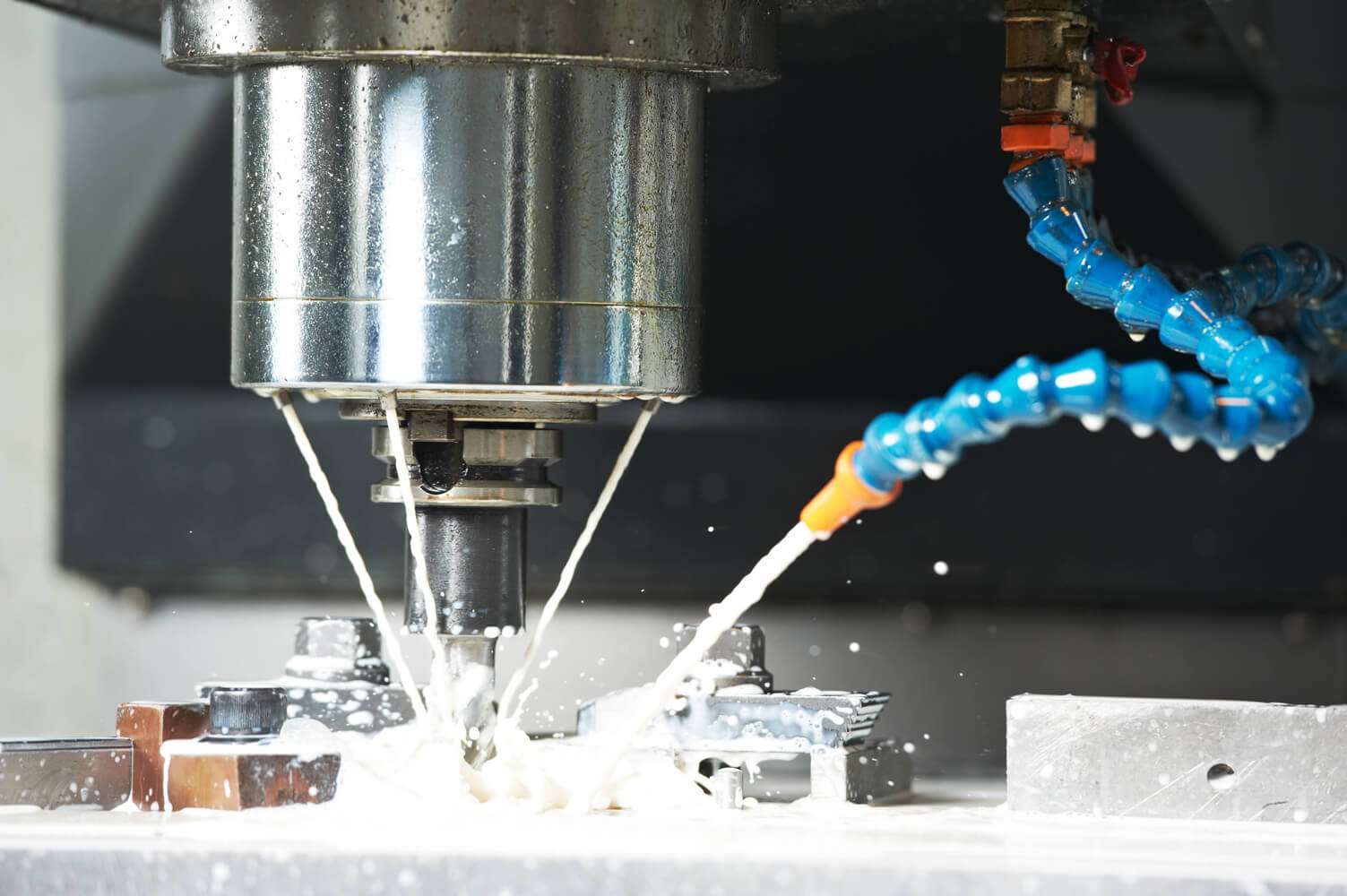

Fine Grinding Plates & Double Disc Grinding Wheels

SMART CUT Fine Grinding (Fixed Abrasive) Plates is the ultimate solution for achieving unparalleled precision and exceptional surface quality in your machining processes. These cutting-edge plates are designed to revolutionize your fine grinding operations by replacing traditional lapping processes, making them ideal for parts demanding impeccable parallelism and precise dimensional control.

Sintered (Metal Bond) Diamond Polising Plate

SMART CUT diamond discs are specialized tools designed for grinding and sculpting glass, jewelry, stones, ceramics, composites, optics, metals and other hard, dense and brittle materials. These discs are usually produced with metal bond and with diamonds impregnated inside.

Resin Bond Diamond Polishing Plate

SMART CUT diamond discs are specialized tools designed for grinding and sculpting glass, jewelry, stones, ceramics, composites, optics, metals and other hard, dense and brittle materials.

Diamond Belts

Flexible Diamond Resin Bonded Belts can be used for sanding and polishing of large variety of materials. Excellent alternative to abrasive belts. Belts can be made any size to fit almost any type of equipment

Lapping Plates

Radial Groove Pattern Lapping Plate. Most common default groove pattern. Used to generate enough surface interruption to optimize surface finish, most appropriate for Free-Abrasive Machine

Diamond Film

Lapping Films are ultra-fine, uniformly coated abrasive high performance films for use in lapping and polishing operations.

Fine Grinding (Flat Honing) Plates

Used on fine grinding machines as a replacement for lapping processes for parts that require high parallelism and close dimensional control.

Diameter of plates range from 450mm (17”) to over 1000mm (40”). Used on machines manufactured by Stahli, Peter Wolters, Speedfam, and others.

for Stone, Concrete & Construction

Diamond Grinding & Polishing Discs

Diamond Cup Wheels

We manufacture & offer a large variety of diamond cup wheels, and accessories for grinding and polishing all types of hard materials, stone, concrete, etc

Diamond Polishing Pads

Polishing discs for use with hand held grinders & polishers. Perfect for all types of ultra hard stone materials such as granite, porcelain, marble, and other materials.

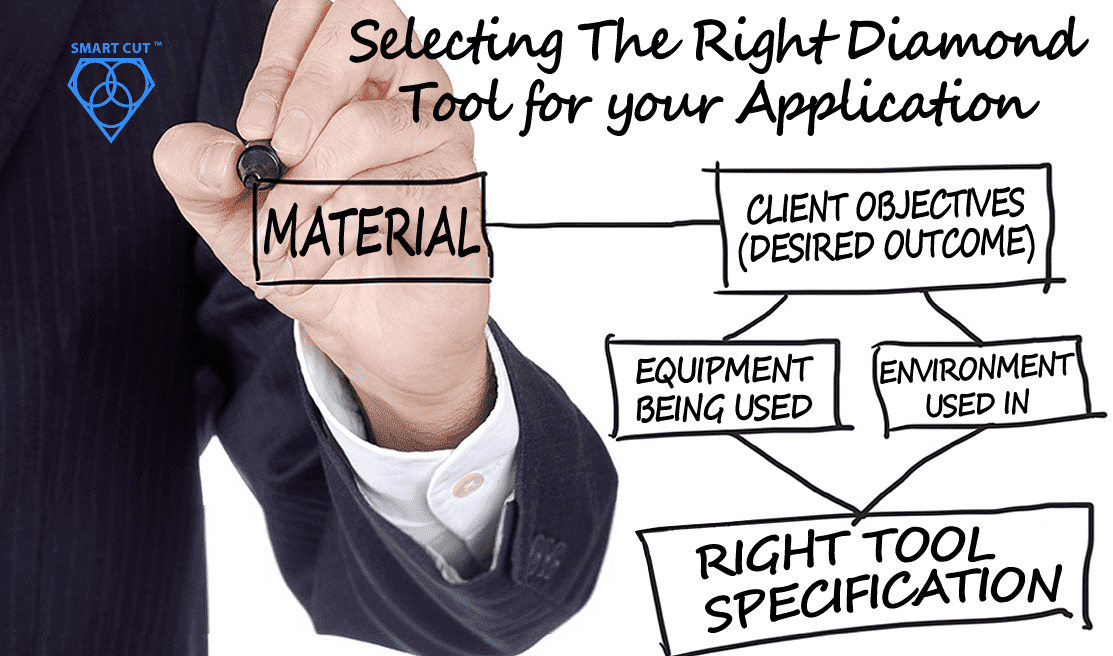

Let Us Help You:

- Improve Surface Finish Quality

- Increase Production Rate

- Improvce Productivity

- Preserve True Material Microstructure

- Improve Part Geometry, Straightness & Tolerances

- Increase Tool Life

- Reduce & Eliminate Material Deformation

- Improve Process Consistency

How SMART CUT® Bond Works?

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Why Work With Us?

Comprehensive Source Of Information On Diamond Tools

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting, drilling, grinding and polishing on the web. Find everything you ever wanted to know about diamond tools.

Large Inventory & Custom Manufacturing

We have the largest variety of diamond tools available in stock. we regularly produce custom diamond tools to better fit customers specific needs & specifications. Just about any diamond tool can be designed and manufactured per customer drawing or specifications.

Umatched Technical Support

We Are A Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality & Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

Experience Makes All The Difference

"One Of The Most Experienced Companies In The Industry"

With a team of highly knowledgeable and experienced engineers, we possess a deep understanding of the challenges you encounter when cutting, drilling, grinding and polishing. This expertise is gained from decades of experience manufacturing sophisticated and high precision tools and equipment for advanced industries and complex applications. Unlike other companies that exclusively focus on tools for the stone and construction industries, we offer unique solutions that surpass their capabilities and expertise.