Selecting the Right Coolant Method for your Diamond & CBN Tools

-

Posted by

contactor6

Table of Contents

ToggleCoolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction and heat at the point of contact. If heat and friction are not controlled, serious problems can occur. Diamond can lose hardness through graphitization, CBN crystals can break, and the bond matrix that holds the abrasive particles can wear out too quickly. Using the correct coolant and applying it in the right way will greatly extend tool life, improve part quality, and keep machining consistent and efficient.

It is helpful to understand that coolant and lubricant are not the same thing, even though the terms are often used together. Coolant mainly works to control temperature, while lubricant works to reduce friction at the cutting edge. Both are equally important for diamond and CBN tools. Too much heat makes abrasives less effective, while too much friction wears out the tool faster, increases cutting forces, and lowers surface quality.

When coolant is applied properly, it prevents a number of issues. It stops overheating that leads to early abrasive breakdown or bond failure. It reduces the chance of thermal shock and cracking in fragile materials like glass and ceramics. It also prevents chip recutting, where chips are cut again instead of being cleared away, which can damage both the tool and the workpiece. Another benefit is that it lowers the risk of poor surface finish caused by tool loading and excess friction.

In addition to cooling and lubrication, coolant plays a major role in keeping machining stable. It helps remove chips from the cutting area, prevents clogging, and keeps cutting forces steady. This makes it easier to hold tight tolerances and dimensional accuracy in finished parts. For industries where precision is critical, such as semiconductors, optics, and advanced ceramics, the right coolant strategy can make the difference between success and failure.

Since this article is meant to focus only on coolant methods, it is important to expand on how coolant can be applied and delivered to the cutting zone. There are several methods available, and each one has its own advantages depending on the material being cut, the type of diamond or CBN tool, and the machining setup. Flood coolant is the most common and easiest to use, where a steady stream of fluid covers the cutting area to control temperature and wash away chips. High-pressure coolant delivery is more advanced, forcing fluid into deep or narrow cuts where standard flow cannot reach. This method is especially effective for drilling, slotting, and heavy grinding because it ensures that the abrasive stays cool and chips do not pack into the cut. Mist cooling systems combine coolant with compressed air to create a fine spray, which is useful for applications that cannot tolerate large amounts of fluid but still require temperature control and lubrication. Finally, through-tool coolant delivery pushes fluid directly through the blade or drill to the cutting edge, giving maximum efficiency in cooling and chip removal.

Air

Compressed air is the most basic form of coolant delivery in CNC machining. It is often used when liquid coolants cannot be applied or where cleanliness of the machining environment is a higher priority than aggressive cooling. For diamond and CBN tools, air plays a limited but sometimes important role.

Air is most effective for clearing chips and light dust generated during cutting or grinding. This is particularly valuable when machining brittle or porous materials such as advanced ceramics, composites, or plastics. These materials can absorb liquid or develop cracks if exposed to sudden temperature changes. In such cases, a directed air stream maintains process stability while avoiding contamination or thermal shock.

However, air offers no lubrication and only modest cooling. Diamond and CBN abrasives rely on stable temperatures to prevent premature wear, bond breakdown, and thermal degradation of the cutting edge. In heavy grinding or high-speed machining, compressed air cannot remove heat quickly enough. Excessive temperatures in these conditions cause rapid dulling of the abrasive surface, reduced tool life, and poor part finish.

Air is also less effective in chip-intensive operations. While it may blow loose chips away, it does not have the flushing power of liquid coolants. This can lead to wheel loading or chip recutting, both of which place unnecessary stress on the tool and the machine spindle.

In CNC applications, air is generally used in three scenarios:

- When machining delicate materials that cannot be exposed to liquid coolants.

- When working with very light grinding loads where heat generation is minimal.

- When paired with specialized diamond or CBN tools that have surface coatings designed to withstand higher operating temperatures.

Outside of these conditions, liquid-based coolants, whether flood or high-pressure are strongly preferred for diamond and CBN tooling because they provide the lubrication and thermal control needed for consistent results and extended tool life.

Mist

For diamond and CBN tools, mist is useful in very specific CNC applications. It is commonly applied with small-diameter drills, micro-drills, or tools performing shallow cuts, where excessive liquid from flood coolant could overwhelm the workpiece or risk dimensional instability. In these cases, mist provides enough lubrication to reduce friction at the cutting edge, which helps maintain sharpness of the abrasive particles and extends tool life. The light cooling effect also helps protect the bond from premature wear.

Another advantage of mist is that it reduces coolant consumption and lowers cleanup demands compared to flood systems. In shops where coolant management, recycling, or disposal is a concern, mist can be an attractive compromise between dry machining and full liquid cooling. It is also valuable for machining delicate or thin materials such as ceramics, composites, or certain plastics where oversaturation could cause warping, cracking, or contamination.

Despite these benefits, mist has serious limitations when applied to diamond and CBN tooling. The low fluid volume cannot dissipate the extreme heat generated in high-speed grinding, heavy stock removal, or deep drilling. Without enough cooling, diamond particles risk graphitization, and CBN grains may fracture under excessive thermal stress. Mist also lacks the flushing power to clear chips or swarf from the cutting zone. This often results in wheel loading or chip recutting, which quickly dulls the abrasive surface and reduces part quality.

Because of these constraints, mist should be reserved for light-duty machining, finishing passes, or situations where coolant use must be minimized due to cost, environmental, or material concerns. For more demanding CNC operations with diamond and CBN tools, flood or high-pressure coolant delivery is strongly preferred to ensure proper temperature control, lubrication, and chip evacuation.

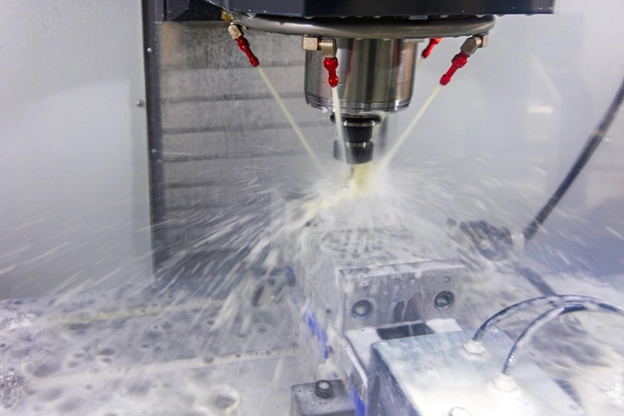

Flood Coolant

Flood coolant is one of the most widely used and effective methods for CNC machining with diamond and CBN tools. It involves delivering a steady, continuous flow of liquid directly into the tool workpiece interface. By covering the entire cutting zone, flood coolant performs three essential functions: it reduces friction, dissipates heat, and flushes chips and swarf away from the abrasive surface.

For diamond grinding wheels, flood coolant is critical because it prevents wheel loading, the condition where chips and debris clog the cutting surface. Loading reduces efficiency, increases cutting forces, and accelerates wear of the diamond grains. By keeping the tool surface clean, flood coolant ensures sharper cutting action, longer tool life, and more consistent results.

For CBN wheels machining hardened steels, flood coolant supports stable grinding conditions by reducing thermal stress on both the material and the abrasive particles. This is particularly important in CNC grinding operations where long contact times and high friction can rapidly increase temperature. By keeping the cutting zone cool, flood coolant minimizes risk of burns, cracking, or metallurgical damage in hardened materials.

Flood coolant is also the preferred option for ultra hard and brittle materials such as glass, sapphire, quartz, and ceramics. These materials are highly sensitive to rapid temperature changes. Without adequate cooling, they can develop micro-cracks or break catastrophically. A continuous liquid flow stabilizes temperatures and prevents thermal shock, making it possible to achieve clean cuts and smooth surface finishes.

Another key benefit of flood coolant is its ability to carry chips away from the cutting zone. This prevents chip recutting, which would otherwise dull the tool and damage the surface finish. In CNC operations requiring precision, such as dicing, slotting, or drilling, this chip evacuation is essential for achieving tight tolerances.

While flood coolant is highly effective, it comes with some challenges. Large fluid volumes must be properly filtered, monitored for concentration, and replaced to maintain consistent performance. If neglected, coolant can degrade, grow bacteria, or corrode machine components. Despite these maintenance demands, flood coolant remains the standard choice in CNC machining with diamond and CBN tools because it provides the best balance of cooling, lubrication, and cleaning action for most applications.

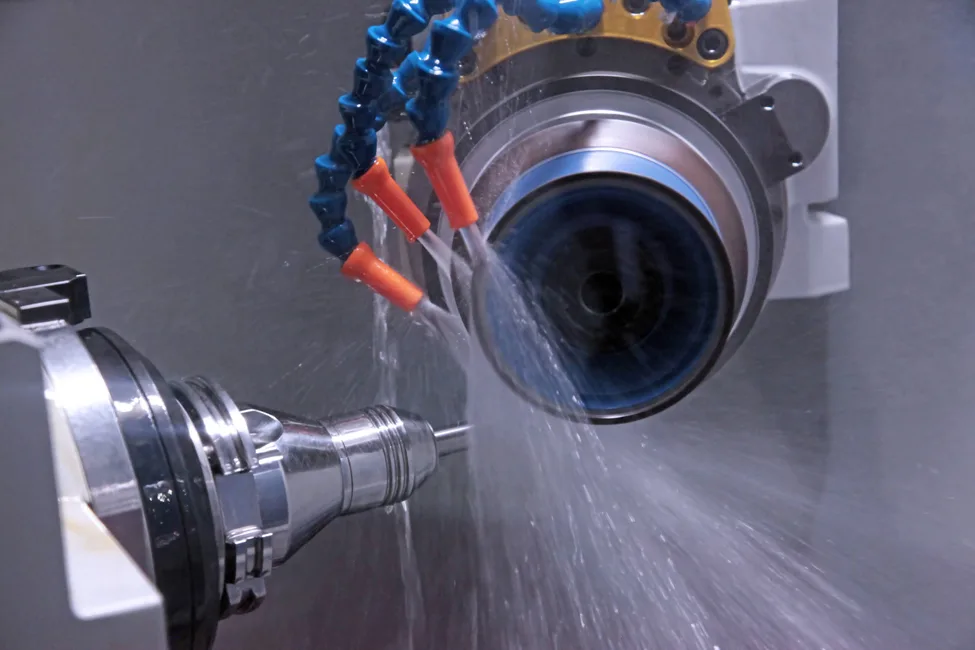

High-Pressure Coolant

High-pressure coolant systems deliver fluid at pressures typically above 1,000 psi, and in some cases, much higher. This method is highly effective for demanding CNC operations where standard flood coolant cannot provide sufficient penetration or chip evacuation. For diamond and CBN tools, high-pressure delivery is most valuable in deep hole drilling, slotting, and heavy grinding applications, where heat buildup and chip compaction are major challenges.

The greatest advantage of high-pressure coolant is its ability to force coolant directly into the cutting zone. In deep cavities, narrow slots, or holes where chips naturally pack and block coolant flow, high pressure ensures that both the abrasive tool and the workpiece remain cool. By maintaining a stable temperature at the cutting edge, high-pressure systems prevent thermal damage, abrasive breakdown, and bond softening.

Another major benefit is chip evacuation. In drilling or grooving operations, chips can compact inside the cut and cause tool jamming, wheel loading, or dimensional errors. High-pressure coolant blasts chips away from the contact zone, ensuring uninterrupted cutting action. This not only improves part quality but also reduces the risk of tool breakage and spindle overload.

High-pressure coolant works especially well when combined with diamond or CBN tools engineered with through coolant channels. These channels allow coolant to reach the cutting edge internally, delivering maximum cooling and flushing exactly where it is needed. Such designs are particularly common diamond core drills & diamond drills used for deep, precision holes in ultra hard ceramics, brittle materials, optics, glass, stone, and other related materials.

Despite its advantages, high-pressure coolant must be used carefully. Excessive force can damage small diameter tools, especially diamond micro-drills or thin cutting wheels. The sudden impact of high-pressure jets can cause microfractures in the abrasive layer, premature bond wear, or even catastrophic tool breakage. Therefore, pressure levels must be matched to tool size, geometry, and application requirements.

Another consideration is machine compatibility. Not all CNC machines are equipped to handle the demands of high-pressure coolant delivery. Systems must have adequate sealing, pumps, and filtration capacity to maintain continuous operation at high pressures. Poorly filtered high-pressure coolant can drive abrasive particles or chips back into the tool, leading to accelerated wear.

- The mist film reduces contact friction, lowering cutting forces.

- Because the fluid quantity is small, cooling relies mostly on reducing heat generation rather than removing heat by volume.

- The lubricant also helps prevent built-up edge formation and improves chip flow.

Minimum Quantity Lubricant (MQL)

Minimum Quantity Lubricant (MQL) is a coolant delivery method that uses a very small amount of fluid, applied directly to the cutting edge in the form of a fine aerosol or mist. Instead of flooding the machining zone with large volumes of coolant, MQL delivers only enough lubricant to reduce friction and provide a light cooling effect. This method dramatically reduces fluid consumption, disposal costs, and environmental impact, making it attractive for shops looking to minimize operating expenses and waste.

For diamond and CBN tools, MQL can be effective in light-load CNC operations where heat generation and chip volume are relatively low. Examples include finishing passes, shallow cuts, micro-drilling, and precision slotting where lubrication is more important than deep cooling. By applying a thin film of lubricant at the contact zone, MQL reduces abrasive-to-workpiece friction, helping to maintain sharp cutting edges and improve surface finish.

MQL is also valuable in situations where liquid flood coolant is impractical or undesirable. This may include machining porous materials (such as certain ceramics or composites) that can absorb coolant, or when working in environments where fluid containment is difficult. Because MQL produces little excess liquid, it helps keep CNC machines cleaner, reduces maintenance, and lowers the need for fluid recycling systems.

However, MQL has significant limitations when applied to diamond and CBN tools. The small fluid volume is not sufficient to remove the extreme heat generated during aggressive grinding, high-speed cutting, or deep drilling. Without enough cooling, diamond grains risk graphitization at high temperatures, while CBN grains may suffer thermal cracking or bond degradation. Additionally, because MQL does not flush chips effectively, wheel loading and chip recutting can occur, leading to poor part quality and shortened tool life.

For these reasons, MQL should be considered a special-purpose coolant strategy rather than a universal solution. It works best in precision finishing operations, light-duty machining, or applications where coolant reduction is a priority. For heavy grinding, large material removal, or deep-hole drilling with diamond and CBN tools, flood or high-pressure coolant delivery remains essential for protecting both the tool and the workpiece.

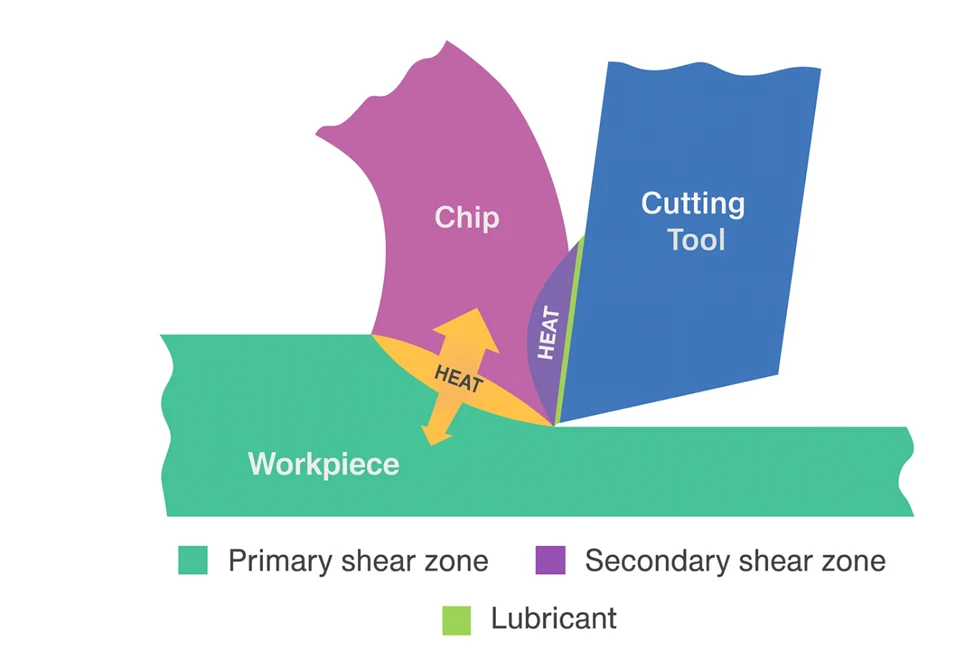

This illustration shows how Minimum Quantity Lubrication (MQL) works in a machining operation by focusing on the tool–chip–workpiece interaction zones.

- Primary Shear Zone (orange/blue/green area in different versions of the illustration)

This is where the material first begins to deform plastically under the cutting force. Heat is generated as the workpiece material shears and flows into a chip. - Secondary Shear Zone (red/purple area)

This is the interface between the cutting tool and the chip as the chip slides along the rake face of the tool. This zone produces the most frictional heat in machining. - Heat Flow (arrows)

Both the primary and secondary shear zones generate high temperatures. If uncontrolled, this heat can lead to tool wear, loss of cutting edge sharpness, and poor surface finish on the workpiece. - Lubricant Application (green line)

In MQL, a very fine aerosol mist of lubricant is applied directly to the cutting edge. Instead of flooding the entire zone with large amounts of coolant, MQL delivers just enough lubricant to reduce friction in the secondary shear zone where the chip slides over the tool.

- The mist film reduces contact friction, lowering cutting forces.

- Because the fluid quantity is small, cooling relies mostly on reducing heat generation rather than removing heat by volume.

- The lubricant also helps prevent built-up edge formation and improves chip flow.

5. How MQL Differs from Flood Coolant

- In flooding, large amounts of liquid absorb and carry away heat.

- In MQL, the focus is on minimizing friction at the interface, using only microliters of lubricant delivered with compressed air. This makes MQL cleaner, more environmentally friendly, and lower in cost, but it is less effective in high-heat operations such as deep grinding with diamond or CBN tools.

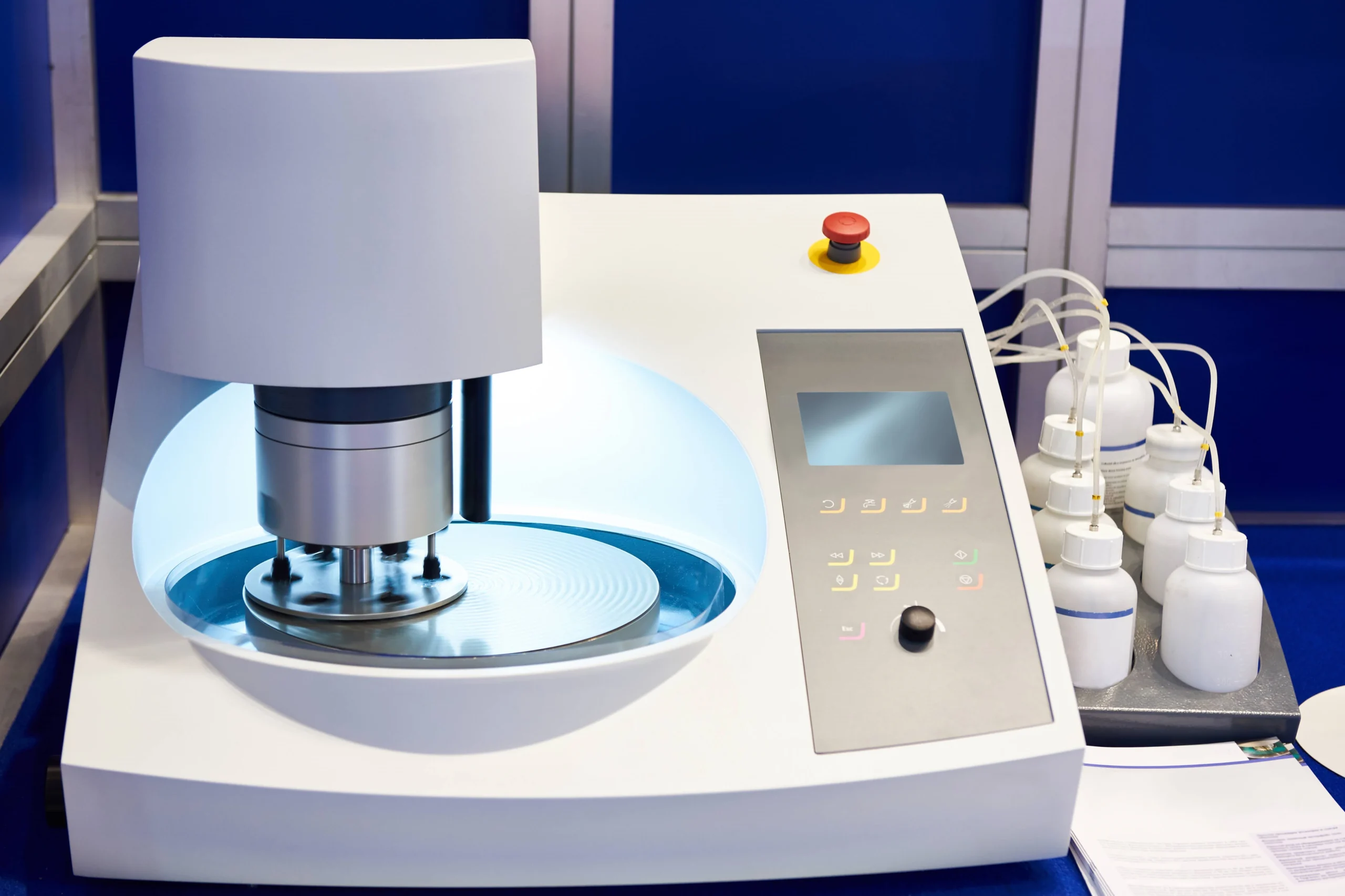

Coolant Through the Center of the Spindle

Coolant-through-the-spindle (CTS) technology delivers coolant directly from the machine spindle through the tool and into the cutting zone. Instead of spraying fluid externally, the coolant flows through internal channels in the tool or arbor, exiting at the exact point of contact between the diamond or CBN tool and the workpiece.

For CNC machining with diamond and CBN tools, CTS offers several important advantages. By delivering coolant internally, it ensures precise cooling and lubrication at the cutting edge, where it is most needed. This direct flow helps maintain stable temperatures, protecting diamond abrasives from graphitization and CBN crystals from thermal fracture. It also reduces friction on the bond matrix, extending tool life.

Another major benefit is chip evacuation in deep or narrow cuts. In operations such as deep-hole drilling, slotting, or grinding tight cavities, external flood or mist coolant often cannot penetrate far enough to clear chips. CTS uses pressure to push coolant and flush debris out of the cutting zone, preventing chip packing, tool jamming, or wheel loading. This leads to more reliable machining, higher accuracy, and improved surface finishes.

CTS also enables higher spindle speeds and feed rates, since the tool remains consistently cooled and lubricated. For diamond drills, micro-drills, or CBN reamers, this allows operators to achieve greater productivity without sacrificing tool life.

However, there are some considerations. Small-diameter tools with internal coolant channels can be fragile, and improper pressure levels may cause cracking or premature failure. The CNC machine must also be equipped with a high-quality filtration system, since contaminants or abrasive particles in the coolant can be forced directly into the tool, damaging the coolant channels or cutting edges. Maintenance of the coolant concentration and cleanliness is therefore critical for consistent CTS performance.

Coolant Delivery Method Comparison for Diamond & CBN Tools in CNC Machining

|

Method |

Strengths |

Limitations |

Best Applications |

|---|---|---|---|

|

Minimum Quantity Lubricant (MQL) |

|

|

Light finishing passes, shallow cuts, small diamond drills where flood coolant is impractical |

|

Air |

|

|

lastics, composites, ceramics, delicate parts where liquid may cause cracking or contamination |

|

Mist |

|

|

Small diamond drills, micro-drills, finishing of composites or ceramics |

|

Flood Coolant |

|

|

CNC grinding of hardened steels with CBN wheels, cutting brittle materials (glass, sapphire, quartz, ceramics) |

|

High-Pressure Coolant |

|

|

Deep hole drilling, slotting, heavy grinding with coolant-through diamond/CBN tools |

|

Coolant-Through-Spindle (CTS) |

|

|

• Requires specially designed tools with coolant channels • Demands very clean coolant to avoid clogging • Higher tool and machine cost |

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990