-

0 items in quote

No products in the Quote Basket.

Water Swivel Adapters

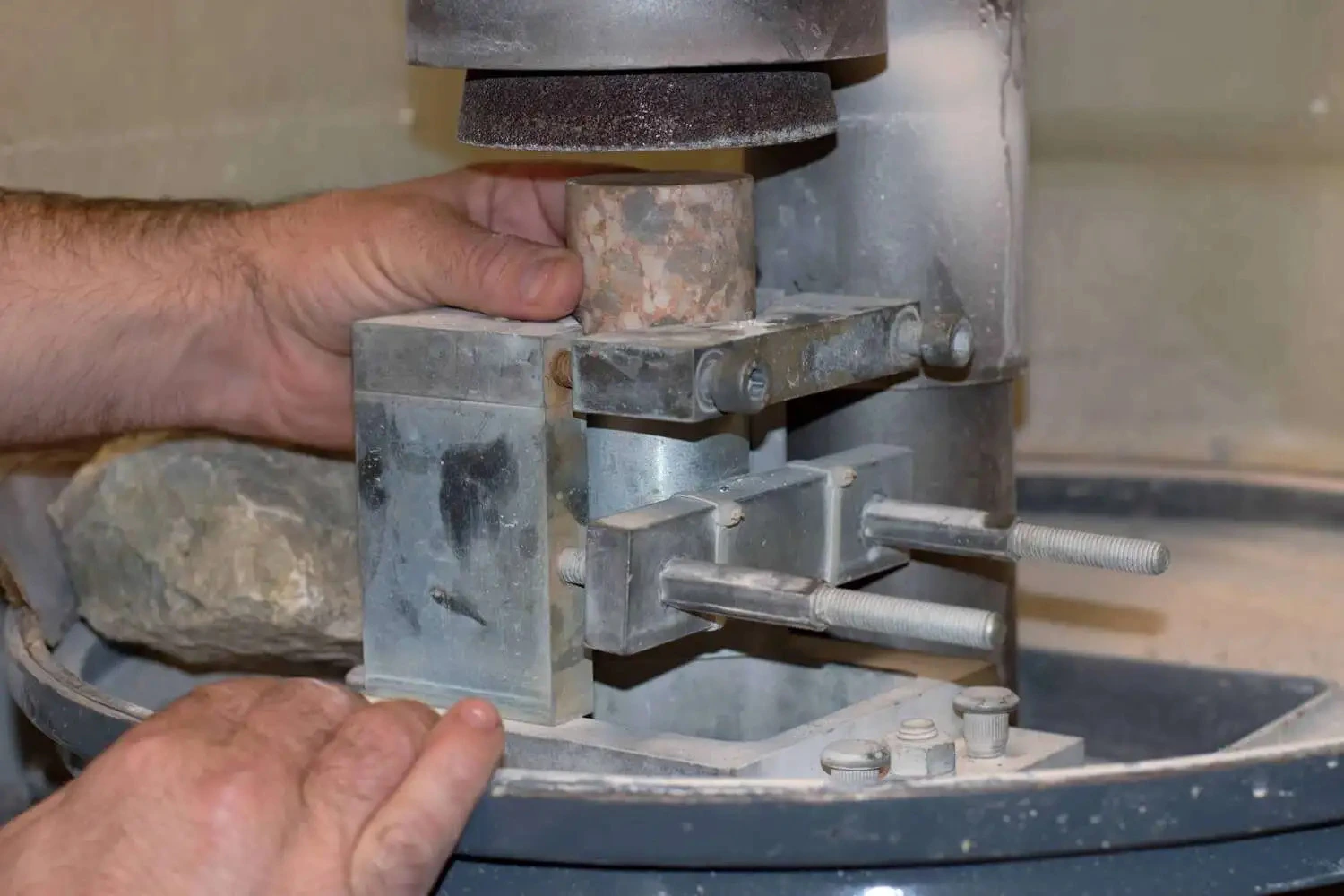

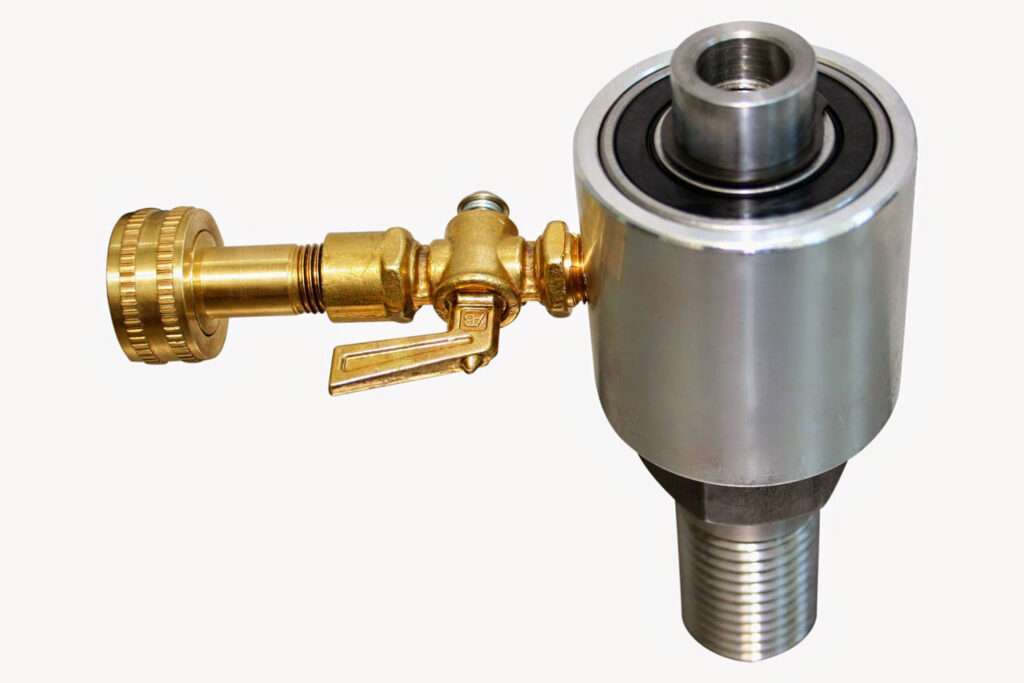

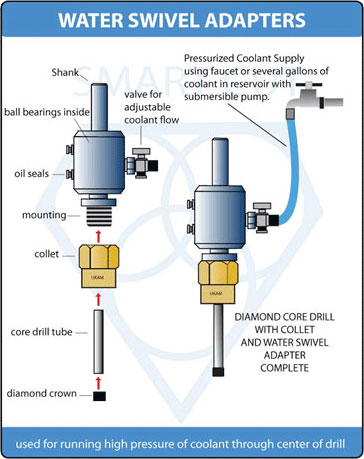

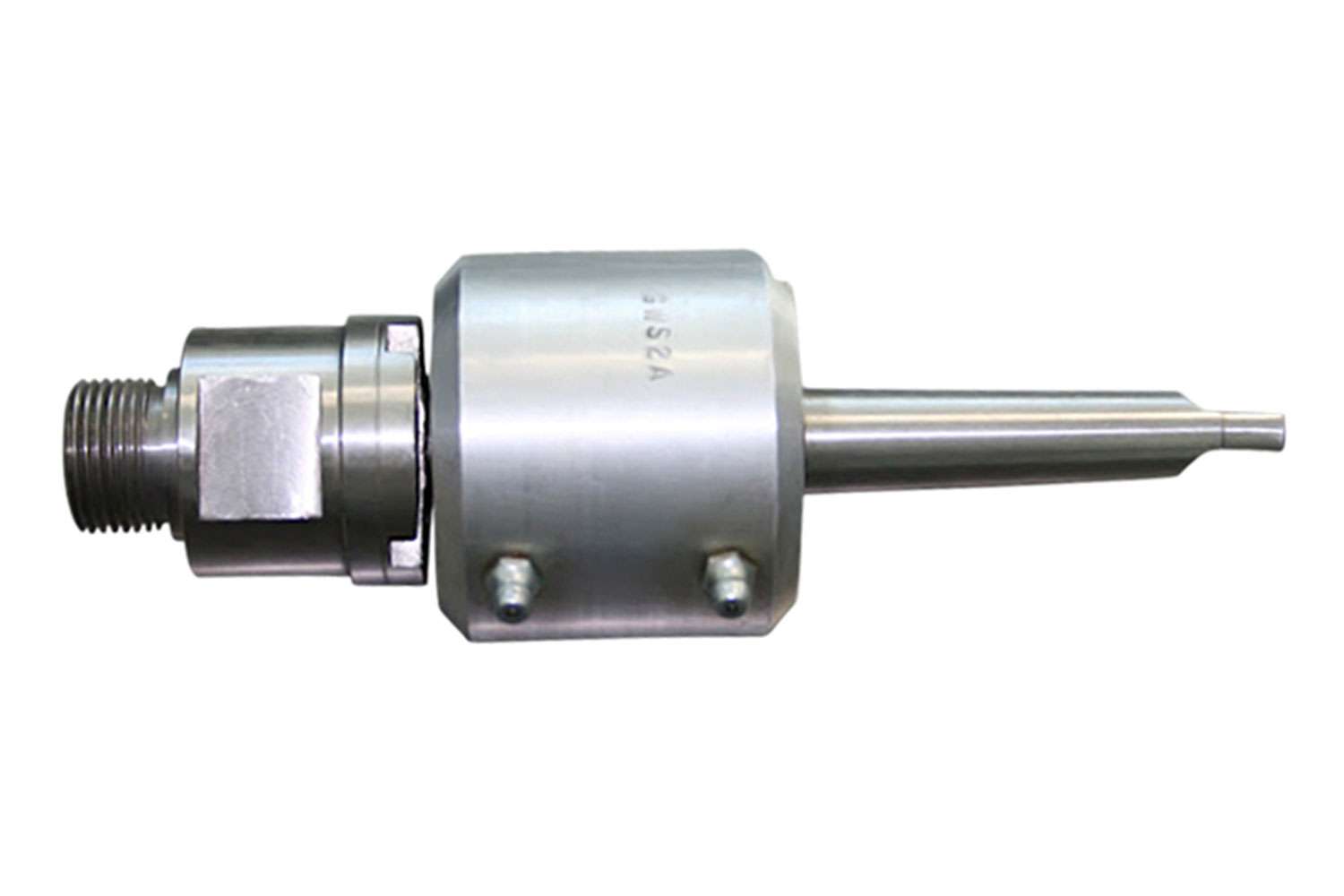

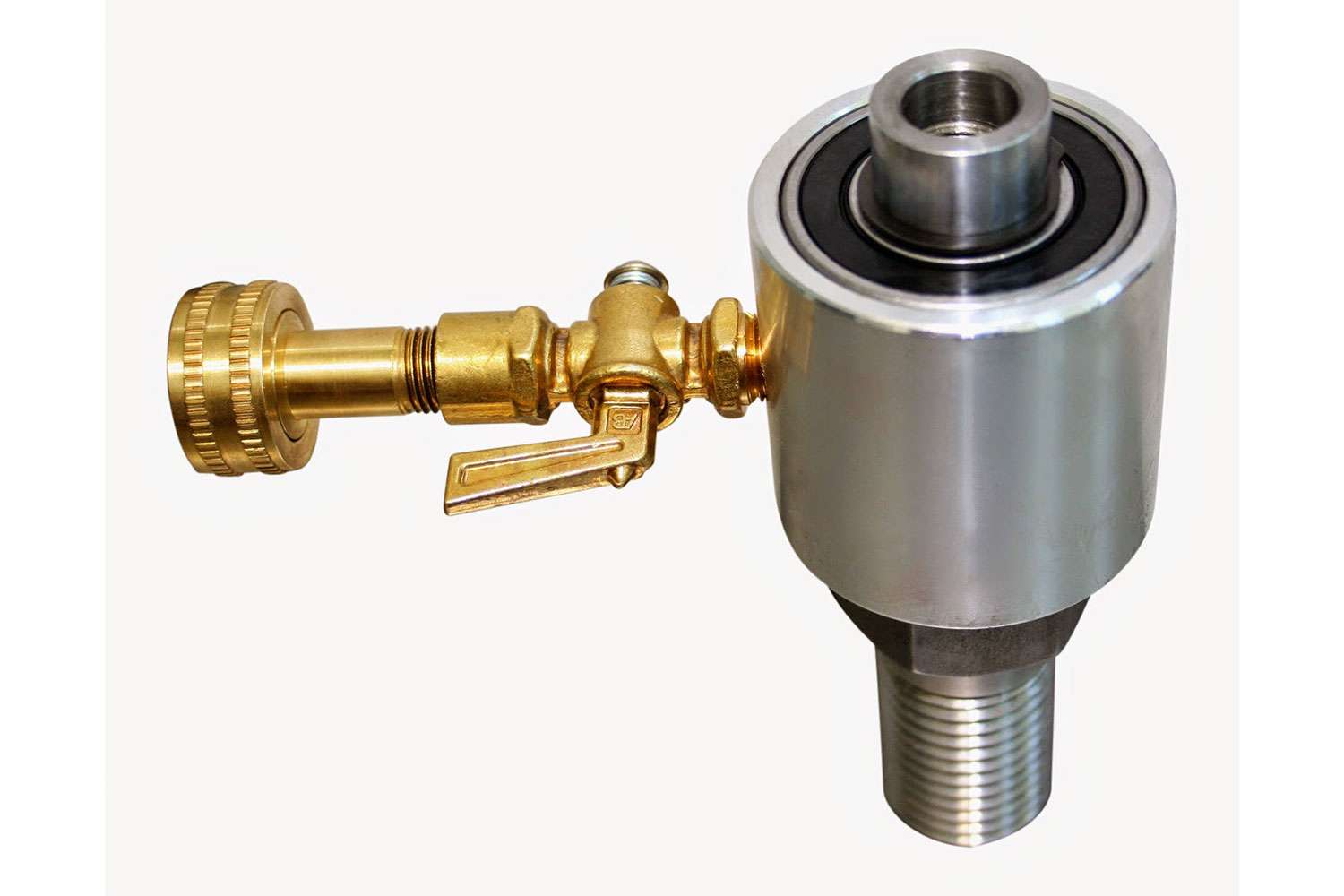

SMART CUT® Water Swivel Adapters, also known as drill head assemblies, are precision-engineered components essential for delivering a continuous, pressurized flow of water, coolant, or air directly through the center of your diamond core drills and other hollow-shaft rotary tools. This internal coolant delivery method provides direct lubrication at the cutting interface, ensuring the most effective heat dissipation and friction reduction where it matters most—at the point of contact between the tool and the material.

By channeling coolant through the core of the tool, these adapters help maintain stable cutting temperatures, reduce thermal expansion, and significantly minimize the risk of cracking, delamination, burning, and tool loading. This results in dramatically extended tool life—in some in many cases over 350% +—as well as faster drilling speeds, reduced downtime, and superior material finish and dimensional accuracy. The integration of SMART CUT® Water Swivel Adapters into your operation will substantially enhance process efficiency and consistency, particularly when working with heat-sensitive, brittle, or high-precision materials.

Universally compatible, these adapters are designed to seamlessly fit a wide range of drilling systems, CNC machines, manual drill presses, and automated drilling equipment. They are available in multiple shaft diameters, thread types, and mounting configurations, and are engineered to mate precisely with diamond drill collets and chuck systems.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Both male and female thread options are available to accommodate a broad range of tool and machine specifications.

While primarily used with diamond core drills, these adapters are also compatible with many other internally cooled or water-fed tools, including diamond reamers, rotary grinding tools, and air- or liquid-cooled spindles. This makes them a versatile and highly recommended accessory for most diamond drilling, grinding, and machining operations where wet cutting is preferred or dry cutting is not feasible.

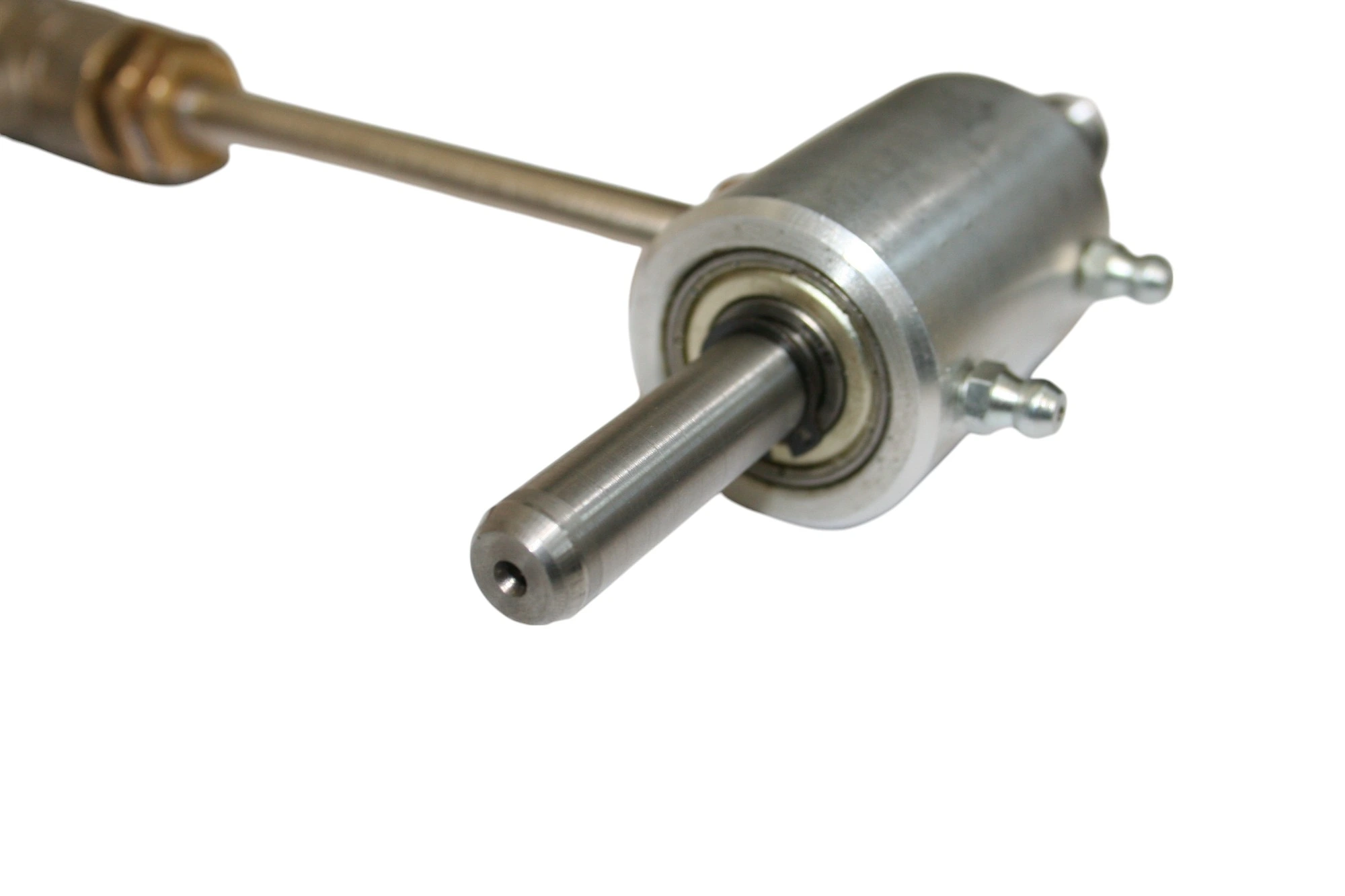

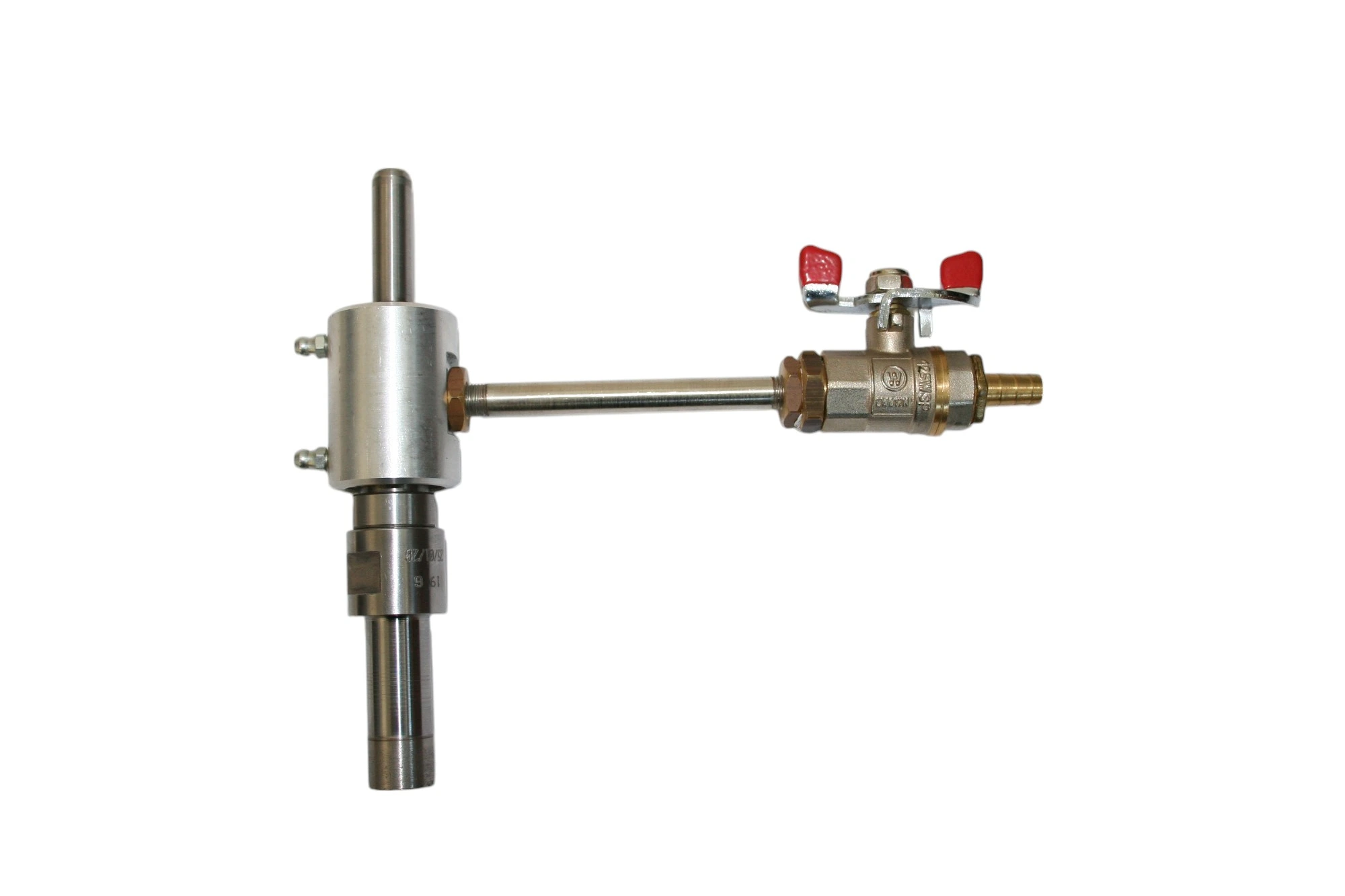

Each SMART CUT® Water Swivel Adapter is manufactured from high-grade stainless steel and built to last under demanding conditions. They feature precision ball bearings, grease fittings, and tight runout tolerances for exceptional stability, durability, and rotational accuracy.

These adapters are designed for long-term use, even in high-RPM or continuous-duty applications.

To meet the diverse needs of industries such as advanced ceramics, optics, aerospace, composites, geology, and materials research, we offer an extensive inventory of over a dozen standard models. For unique or specialized applications, we provide custom manufacturing services with lead times as short as 5 to 7 business days, and no minimum order quantity required.

Whether you’re upgrading your lab setup or enhancing industrial-scale drilling operations, SMART CUT® Water Swivel Adapters offer a measurable improvement in performance, productivity, and return on investment.

SPECIFICATIONS

Water Swivel Adapter Specifications Available:

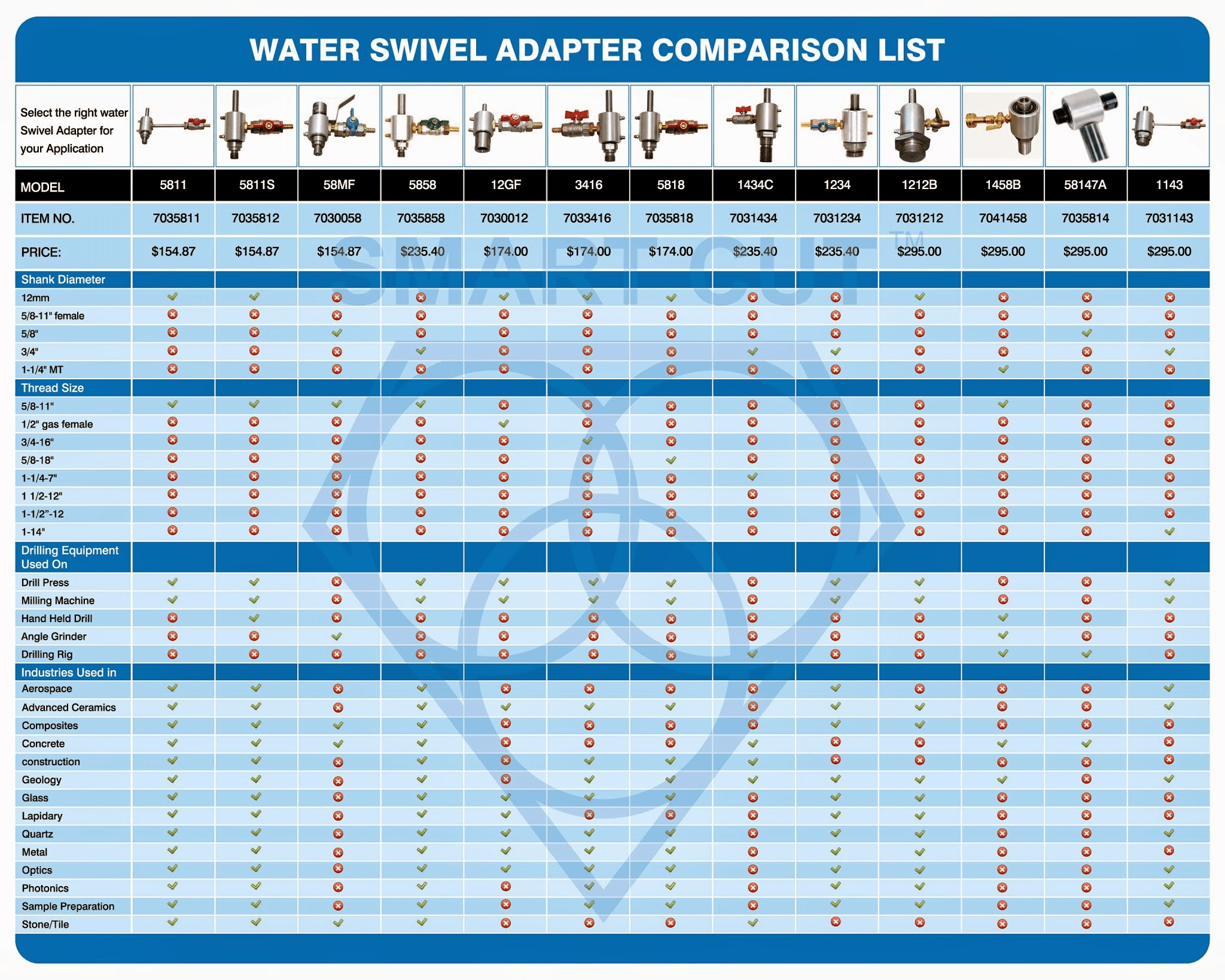

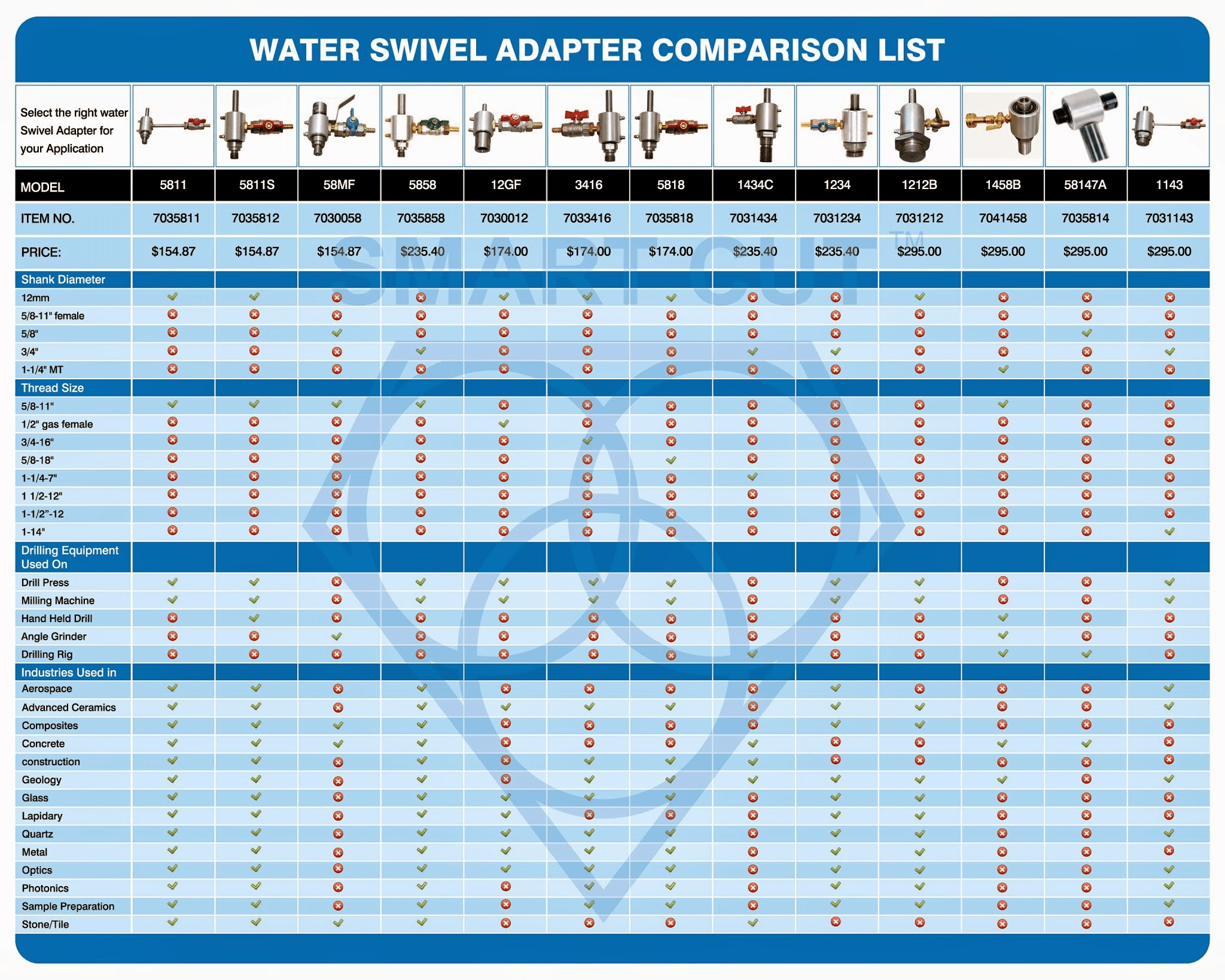

We manufacture and have in stock over 12 different models of water swivel adapter to fit most drilling equipment and popular diamond drills mounting types.

Shank/Shaft Diameters Available: 12mm, 5/8″, 3/4″, 5/8-11″ female, 1-1/4″ MT

Thread Sizes Available (Male Thread): 5/8-11″, 3/4-16″, 5/8-18″m 1-1/4-7″, 1-1/2-12″, 1-14″, & 1/2″ gas female

In additional to our standard product line we manufacture custom water swivel adapters to your specifications in as little as few days. To fit any drilling equipment, any RPM’s, Tool Types, & specifications

FREQUENTLY ASKED QUESTIONS

A water swivel adapter is a device that facilitates the flow of water to a diamond core drill or other drilling tool while it’s in operation. It helps in cooling and lubricating the drill bit, preventing overheating and reducing wear.

Water acts as a coolant and lubricant when drilling with diamond core drills. It helps in reducing heat, dust, and prevents the diamond segments from wearing out too quickly. Additionally, it helps in removing cut debris from the drilling site.

Water swivel adapters are designed to be compatible with a range of machines including drill presses, CNC machines, handheld machines, and angle grinders. However, it’s essential to choose the correct type of adapter suitable for your specific machine.

Installation methods may vary depending on the make and model of your equipment and the adapter. Typically, the adapter connects between the machine’s spindle and the diamond drill.

Yes. Periodic checks for leaks, wear, and damage are necessary. Some parts, like seals or bearings, may require occasional replacement due to wear.

Most water swivel adapters come with an inlet port where a water hose or line can be attached. It’s essential to ensure a secure connection to prevent leaks during operation.

It’s recommended to use clean, sediment-free water to prevent blockages and ensure efficient cooling. While tap water is commonly used, some professionals might use deionized or distilled water to prevent mineral buildup.

Yes. Water swivel adapters come in various sizes and configurations to match different drilling tools and machine types. Ensure you select an adapter that’s compatible with your equipment and intended application.

Water pressure requirements can vary based on the drilling material, depth, and drill bit size. However, it’s essential to maintain a consistent flow of water to ensure efficient cooling. Refer to your equipment’s guidelines for specific recommendations.

While technically possible, it’s not recommended. Drilling without water can lead to premature wear of your diamond drill bit and potential damage to the material you’re drilling.

While the basic function remains consistent, some adapters might be tailored for specific industries or applications. Always ensure that the adapter you select is suited for your intended use.

If you have further questions or need more information about water swivel adapters, consider reaching out to manufacturers or experts in the drilling tool industry.

While the adapter facilitates water flow, it’s the diamond core drill that does the actual cutting. Diamond drills can be used on a variety of materials such as concrete, stone, glass, ceramics, and more. The adapter ensures efficient cooling across all these materials.

The lifespan of a water swivel adapter varies based on usage frequency, maintenance, water quality, and the drilling conditions. With proper care, they can last for several years, but seals or bearings might need periodic replacement.

Common signs include inconsistent water flow, leakage from the adapter, or unusual noises during operation. If you notice these, it’s time to inspect, repair, or replace the adapter.

While water is the most common coolant used, some applications might benefit from specialized coolants or lubricants. Ensure they’re compatible with your adapter and won’t cause blockages or damage.

If the water swivel adapter is correctly installed and there are no leaks, the risk is minimal. However, it’s always good to check your workspace and ensure that sensitive areas or components are protected from potential water splash.

A well-designed and appropriately installed water swivel adapter should not impact drilling accuracy. Ensure the adapter is aligned correctly, and there’s no wobble or misalignment during operation.

After use, it’s advisable to flush the adapter with clean water to remove any debris. Dry it thoroughly and store it in a cool, dry place away from direct sunlight.

While they’re designed primarily for diamond core drills, many adapters can be used with other types of drill bits. However, ensure that the water flow and cooling provided are appropriate for the drill bit and material in question.

Always wear appropriate personal protective equipment, like safety goggles and gloves. Ensure there are no water leaks that could lead to slip hazards. Check the connections and setup before starting the drilling process, and make sure the work area is well-lit and free from obstructions.

Modifications might be possible, but they should be approached with caution. It’s essential to ensure that any changes don’t compromise the safety or efficiency of the drilling process. Consulting a professional or the equipment manufacturer is advisable before making modifications.

For any other concerns or queries about water swivel adapters, remember that manufacturers, suppliers, and industry experts can provide detailed information tailored to specific equipment and applications.

Monitor the drilling site. If you notice excessive heat or smoke, or the drill bit becoming too hot to touch, you might need to increase the water flow. Additionally, check manufacturer recommendations for specific flow rates for different materials and drill sizes.

The primary environmental concern is water wastage. It’s essential to use water judiciously and recycle or reuse when possible. Additionally, ensure that the water runoff, which might contain debris or sediment from the drilling process, is disposed of appropriately.

Some specialized water swivel adapters are designed for underwater applications, ensuring that the water used for cooling doesn’t mix with the surrounding water. If you’re considering underwater drilling, ensure you use equipment specifically designed for that purpose.

Not directly. However, the consistent cooling they provide can allow for more aggressive drilling speeds without overheating the bit, potentially increasing overall efficiency.

Common issues include leaks, blockages, and inconsistent water flow. Regularly inspect the adapter for visible damages, clean the inlet and outlet ports, and replace worn-out seals or bearings.

When used correctly and ensured that there are no leaks, the risk is minimal. However, always ensure that your equipment is grounded and avoid working in wet conditions without appropriate safety precautions.

Regular maintenance, using clean water, and ensuring the adapter isn’t subjected to undue stress or pressure can help extend its lifespan. Store in a safe location after use, and periodically check for wear and tear.

While water swivel adapters are the most common solution for bringing coolant to the drill bit, there are other cooling and lubrication methods, depending on the material and drilling conditions. Some operations might use air or specialized coolants, but these may require different adapters or systems.

If you’re working in freezing temperatures, the water can freeze, causing blockages or even damaging the adapter. Consider using antifreeze solutions or ensure the water is kept above freezing temperatures.

Quality water swivel adapters are built to handle a range of pressures. The adapter’s seals and construction are designed to manage the pressure from both the water supply and the drilling operation.

Yes, water swivel adapters can be used with abrasive materials. The primary purpose is to provide cooling; the kind of material being drilled doesn’t affect the adapter directly, though abrasive materials might wear out the drill bit faster.

Many water swivel adapters come with a valve or regulator to adjust the water flow. Ensure you consult the manual or guidelines to make accurate adjustments according to your drilling needs.

Yes, some water swivel adapters are designed for deep drilling operations, ensuring consistent water flow even at significant depths. If you’re engaging in deep drilling, you might need a specialized adapter or additional equipment.

Some parts of the adapter, like seals or bearings, can be replaced. However, if the adapter body or core components are damaged, it might be safer and more efficient to replace the entire unit. Please note you would need extensive knowledge and understanding and preferably fixture to replace different components and seal it properly.

Depending on your setup and the required water pressure, you might need an external water pump. Some machines have an integrated water supply system, while others require an external source.

Using distilled or deionized water can help prevent mineral buildup. If using tap water, periodically running a descaling solution or a mix of water and vinegar can help in reducing mineral deposits.

While the primary function of the adapter is to cool the drill bit, extremely high temperatures can potentially damage the adapter’s seals or other components.

While there are many standard adapters available, we can produce almost any water swivel adapter specification including any shank diameter or thread type, thread type, very high rpm’s and coolant pressure

While the adapter itself should operate quietly, the drilling process can produce noise. The adapter shouldn’t add significant noise, but always use appropriate hearing protection during drilling operations.

Yes, with the appropriate filtration and recycling system, water used in the drilling process can be recycled, reducing waste and environmental impact.

While they can technically handle both, saltwater can be corrosive and might reduce the lifespan of the adapter. If you intend to use saltwater, ensure the adapter is made of corrosion-resistant materials or rinse it with freshwater after use.

Yes, water swivel adapters are designed to function in both vertical and horizontal drilling scenarios, ensuring consistent water flow in either orientation.

High-pressure adapters are designed to handle higher water pressures without leakage or failure, often used in more demanding or deep drilling operations or for use on certain type of equipment.

Ensuring consistent water flow helps remove debris and reduces friction, which can prevent the bit from getting stuck. Additionally, regular checks and not forcing the drill can help.

Most adapters are designed for easy installation and removal with standard tools.

Ensure that the water source is always below the level of the adapter and that there are no leaks or gaps in the connection points. Some systems might also have air purge valves to remove trapped air.

Water swivel adapters introduce water to the drilling site, which can reduce the risk of ignition. However, always follow safety guidelines and be cautious when drilling near or through flammable materials.

The frequency depends on usage and the specific conditions of your drilling operations. Regularly inspect seals for wear or damage, and replace them if signs of deterioration are evident.

Yes, water swivel adapters can be used with ultrasonic drilling machines, ensuring that the drill bit remains cooled and lubricated during the drilling process.

While the adapter simply provides water, consider the diamond drill material compatibility. For example, some materials might be water-sensitive or could react adversely when exposed to moisture.

Although they’re designed to deliver water, if there’s a need for dry drilling, ensure the water source is turned off. The adapter itself won’t interfere with dry drilling, but its primary benefit might be redundant.

The ROI can vary based on the application. Such as material being drilled, diameter of the hole or core sample, drilling depth and volume of use. Using a water swivel adapter can prolong the life of diamond drills and tools, improve efficiency, and reduce downtime due to overheating, reduce chipping, material deformation, micro cracking and much more

Tolerance ensures that the adapter connects securely and provides consistent water flow. If outside of its tolerance, it may leak, not fit correctly, or malfunction.

This varies by manufacturer and design. Always refer to the manufacturer’s specifications for precise tolerance values.

Accuracy refers to how closely a measurement aligns with its true value. Tolerance, on the other hand, is about permissible variations. In drilling, accuracy might relate to how precisely the tool drills, while tolerance could relate to allowable variations in the adapter’s dimensions.

Maintaining accuracy ensures that the hole is drilled to the exact specifications required, avoiding potential issues like misalignment or structural weaknesses.

Yes, if the adapter is outside its tolerance and doesn’t provide consistent water flow, it can lead to uneven cooling, potentially affecting drilling accuracy.

Regular maintenance, inspection, and using the adapter within its specified limits will help maintain its accuracy. If parts wear out, replace them promptly.

Yes, factors like temperature, pressure, or corrosive environments can affect the adapter’s materials and performance, potentially pushing it outside its tolerance or affecting accuracy.

Using calipers or micrometers, you can measure the adapter’s dimensions such as shank diameter

There is no industry standard but usually you want the run out of the water swivel adapter to be a small as possible. Usually the run our on most of our water swivel adapter models are 15 microns or better

This depends on usage frequency and the required tolerances for your application. For critical applications and to insure high precision tolerances, regular checks before each use might be warranted.

While water quality might not directly impact tolerance, minerals or contaminants in the water can lead to blockages or wear, potentially affecting the adapter’s performance and drilling accuracy.

Yes, water swivel adapters can be designed to work with chuck systems. They can be integrated in a way that the water flows through the adapter to the drill while it’s held securely by the chuck.

Absolutely! Water swivel adapters can also be configured to be compatible with collet systems. Just ensure that the adapter and the collet’s size and design are complementary.

It depends on the specific design of your chuck or collet. Some standard adapters might fit seamlessly, while others might require specialized connectors or fittings.

Always check the seals and fittings. If using a specialized adapter, it should be designed to create a secure, leak-proof connection with the chuck or collet system.

No, the water swivel adapter is designed to provide water flow to the drill bit without interfering with the gripping mechanism of the chuck or collet.

As long as the adapter is compatible with your chuck or collet, there shouldn’t be significant limitations. However, always ensure that the water flow rate and pressure are suitable for the drilling operation at hand.

How do I choose the right adapter for my chuck or collet system?

Some adapters might be versatile enough to fit multiple sizes or types, especially with the use of additional fittings or connectors. However, always ensure a secure and leak-proof connection.

In a properly designed system, the water pressure delivered through the adapter should not impact the holding strength of the chuck or collet.

Regularly inspect for wear or damage, especially at the connection points. Clean any debris or mineral buildup to ensure smooth water flow and secure connections.

INDUSTRIES USED IN

INDUSTRIES USED IN:

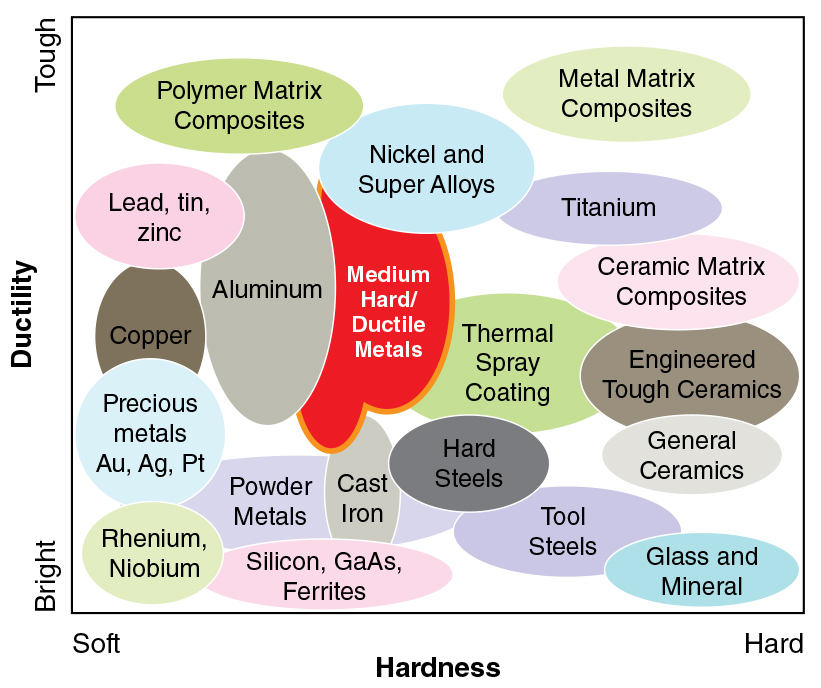

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

FERROUS & NON-FERROUS METALS:

- Plain Carbon Steels

- Electronic Packages

- stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

ACCESSORIES

Showing 1 – -1 of 13 results Showing all 13 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Name | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $15.39 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $15.99 | Max: Min: 1 Step: 1 | |||

5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads… | $22.46 | Max: Min: 1 Step: 1 | |||

5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads… | $26.72 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $39.47 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $39.47 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $154.87 | Max: Min: 1 Step: 1 | |||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $154.87 | Max: Min: 1 Step: 1 | |||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $235.00 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 |

USAGE RECOMMENDATION

02

Jun

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will…

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided…

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind…

02

Jun

Diamond Tools Guide – Selecting Right Drills & Tools for your application

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms,…

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency….

02

Jun

Micro Drilling Guide

Share this Article with Friend or Colleague

In order for you to get the most out of your diamond micro drill or carbide / high speed steel micro drill, we strongly urge you to read…

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide…

Preparation

- Safety First: Before starting, ensure you’re wearing appropriate safety equipment, such as gloves and safety glasses.

- Check Equipment: Make sure you have all the necessary tools and equipment at hand. This might include wrenches, Teflon tape, seals, lubricants, etc.

- Clean Work Area: Ensure the work area is clean and free from any debris.

- Before you begin, ensure the drill or milling machine is powered off and unplugged.

Inspect the Adapter

Examine the water swivel adapter for any visible defects, cracks, or damage.Check seals, gaskets, and threads to ensure they are in good condition. Make sure you have chosen the right water swivel adapter for your application to fit your equipment and requirements. Such as diamond core drill size, weight, required tolerances, run out, too length, rpm’s, coolant flow rate, coolant used and environment used in.

Prepare the Drill

Examine the chuck or collet for any signs of wear, damage, or debris. Clean if necessary.

Similarly, inspect the water swivel adapter, especially its shank or the portion that will be inserted into the chuck or collet. Clean the drill’s connection point where the adapter will be attached.

Use a clean cloth or brush to remove any dust, debris, or residues from the chuck/collet and the shank of the swivel adapter. If the swivel adapter requires lubrication for insertion, apply a minimal amount of appropriate lubricant.

For a chuck, use the chuck key to open the jaws wide enough to fit the shank of the water swivel adapter. For a collet, depending on the design, either loosen the drawbar or use a wrench to slightly loosen the collet from the collet holder.

Carefully insert the shank of the swivel adapter straight into the chuck or collet. Ensure it goes in evenly without forcing it. For collets, make sure the shank fits snugly without any wiggle room.

Secure the Adapter

- For a chuck, use the chuck key to tighten the jaws around the shank of the adapter. Ensure it’s evenly tightened for a secure grip. Do not overtighten, as this can cause damage.

- For a collet, tighten the drawbar or use a wrench to secure the collet, thus clamping down on the swivel adapter. Ensure the tightening is even and firm.

Connection

Apply Teflon tape or suitable thread sealant to the threaded ends of the swivel adapter to ensure a watertight connection. Connect the water swivel adapter to the drill, ensuring it’s hand-tightened initially. Using a wrench, finish tightening the connection, but avoid over-tightening, which could damage the threads or seals. Thread the diamond core drill or other tool on the water swivel adapter and make sure it threads all the way. Use wrench is necessary. Do not overtighten

Water Source Attachment

Connect the other end of the water swivel adapter to the water or coolant source. Such as faucet or coolant thank with submersible pump. Even a small pump will do for most water swivel adapters. Ensure the connection is secure to prevent any water leaks. Make sure the water pressure does not exceed the maximum recommended pressure the water swivel adapter is rated.

Check Alignment

Ensure the swivel adapter aligns correctly with the drill axis. Misalignment can lead to premature wear and inefficiencies during operation. Use dial indicator if available to check alignment and run out the diamond core drill or other tool. Manually rotate the drill or milling machine spindle to ensure the swivel adapter is centered and doesn’t wobble. Misalignment can lead to vibrations, premature wear, and inefficient drilling.

Initial Testing

With safety gear on, power on the drill or milling machine at a low speed initially. Ensure everything runs smoothly without excessive noise or vibration. Test water flow to ensure smooth and consistent flow through the adapter.

- Before full operation, test the system by running water through the adapter.

- Look for any leaks at the connection points.

- Ensure the water flows smoothly without any obstructions.

Safety Checks

- Ensure there are no loose parts or tools left in the work area.

- Double-check that all connections are secure and that there are no leaks.

Operational Testing

- Power on the drill at a low speed to test the rotation with the water flow.

- Gradually increase speed while monitoring the system for any issues.

- Look out for excessive vibrations or noise, which might indicate an installation problem.

Final Adjustments

Depending on the drilling requirements, adjust the water flow rate. Ensure you’re getting enough water to cool the drill bit and remove any cuttings. Especially during the initial usage after installation, check the swivel adapter and its connection to the chuck or collet to ensure it remains secure and doesn’t loosen from vibrations or use.

Documentation and Logging

- Note down the installation date, any observations, and other relevant details. This can be helpful for maintenance and troubleshooting in the future.

Regular Monitoring

- Especially during the initial stages of use, monitor the swivel adapter for any issues frequently. Regular checks will help detect and correct problems before they escalate. Make sure to remove the core drill from water swivel adapter when its not being used. If using recirculating coolant supply make sure to properly filter the coolant from material swarf to prevent it from clogging inside.

What Are Water Swivel Adapters?

Water Swivel Adapters are precision-engineered components designed to supply a continuous flow of water, coolant, or air through the center of hollow diamond core drills and other rotary tools. These adapters are typically mounted in the chuck or appropriate collet of virtually any standard or specialized drilling machine. By delivering coolant directly to the drilling zone, they help maintain low temperatures, reduce tool wear, and improve drilling efficiency and cut quality.

Water swivel adapters are not one-size-fits-all. They are available in a variety of designs tailored for specific industries and drilling applications. The primary distinctions between models include shaft (shank) diameter, thread type (male or female), and thread size, all of which must be matched carefully to the corresponding diamond drill or tool.

Each water swivel adapter is manufactured to properly mate with the mounting configuration of your diamond drill. Compatibility is essential: for instance, if the water swivel adapter features a male thread, the diamond drill should have a corresponding female thread—and vice versa.

At UKAM Industrial Superhard Tools, we stock and manufacture over 12 different standard models of water swivel adapters, ensuring compatibility with most commonly used drilling machines and mounting types of diamond drills. In addition, we offer custom-manufactured water swivel adapters built to your exact specifications, typically with a turnaround time of just a few days.

|

Available Shaft (Shank) Diameters: |

Available Thread Sizes (Male Thread): |

|---|---|

|

12 mm |

5/8″–11 |

|

5/8″ |

3/4″–16 |

|

3/4″ |

5/8″–18 |

|

5/8″–11 female |

1-1/4″–7 |

|

1-1/4″ Morse Taper (MT) |

1-1/2″–12 |

|

1″–14 |

|

|

1/2″ gas female (BSPP) |

Whether you are working with low-speed precision drilling machines or high-speed CNC rotary systems, we can provide a water swivel adapter built to meet your specific equipment, spindle speed (RPM), tool type, and operational requirements. If you are unsure which model fits your setup, please contact our technical support team for assistance in selecting the optimal adapter for your application. We also provide custom engineering support for OEMs and specialized tooling applications.

Why Use Adapters? |

How to Select the Right Water Swivel Adapter |

|---|---|

|

here are the variables to consider in selecting right water swivel adapter for your application:

|

Please See Our Water Swivel Adapter Comparison List

Standard Water Swivel Adapters Specifications Available From Stock

Showing 1 – -1 of 3 results Showing all 3 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Name | SHANK DIAMETER | Thread Size | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|

12mm | 5/8-11” male | $154.87 | Max: Min: 1 Step: 1 | ||||

12mm | 5/8-11” male | $154.87 | Max: Min: 1 Step: 1 | ||||

5/8” (15.87mm) | 5/8-11” male | $235.00 | Max: Min: 1 Step: 1 |

Water Swivel Adapters 5/8-11” female thread - Compatible with angle grinders

Showing 1 – -1 of 3 results Showing all 3 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Name | Shank Diameter | Thread Size | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|

5/8-11” female | 5/8-11” male | $154.87 | Max: Min: 1 Step: 1 | ||||

5/8-11” female | 1-1/4-7” Male | $295.00 | Max: Min: 1 Step: 1 | ||||

1 1/4" - 12" | $295.00 | Max: Min: 1 Step: 1 |

Precision Water Swivel Adapters – have more threads per inch to maintain high degree of precision tolerances

Showing 1 – -1 of 7 results Showing all 7 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Name | Shank Diameter | Thread Size | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|

12mm | ½” gas male | $174.00 | Max: Min: 1 Step: 1 | ||||

12mm | ¾-16” Male | $174.00 | Max: Min: 1 Step: 1 | ||||

12mm | 5/8-18” | $174.00 | Max: Min: 1 Step: 1 | ||||

¾” (19.05mm) | 1-1/4-7” Male | $235.40 | Max: Min: 1 Step: 1 | ||||

12mm | 5/8-18” | $235.40 | Max: Min: 1 Step: 1 | ||||

¾” (19.05mm) | 1-1/2-12" Male | $295.00 | Max: Min: 1 Step: 1 | ||||

12mm | $295.00 | Max: Min: 1 Step: 1 |

CUSTOM

Water Swivel Adapters

We can produce Water Swivel Adapter to fit virtually any drilling equipment - any type of mounting (any straight shank diameter, moris taper size, or female thread).

For any rpm’s – we use different bearing type of materials and specifications to whistand super high rpm’s or harsh environments

-

Thread Size

Thread Size

-

Connection Type

Connection Type

-

Material Composition

Material Composition

-

Pressure Rating

Pressure Rating

-

Flow Rate

Flow Rate

-

Seal Type

Seal Type

-

Bearings Type

Bearings Type

-

Drilling Equipment Used

Drilling Equipment Used

-

Tolerances

Tolerances

-

Run Out

Run Out

-

MAX RPM's Rating

MAX RPM's Rating

-

Weight

Weight

-

Equipment Used On

Equipment Used On

Why Use Water Swivel Adapters

Best and most efficient way of drilling ultra hard materials

Ultra Hard Materials are very hard and dense. Highly optimized drilling parameters (not just the diamond drill itself) is required to be affective on these more challenging applications. Running high pressure of coolant through center of the drill right into the drilling zone has proven to be most effective method

Best & most efficient way to obtain (extract) core samples and Remove Center Plugs

Whether you are drilling a hole or trying to obtain core sample. Running coolant through center of drill is the most effective way to automatically extract (dislodge) the core sample from the core drill tube/barrel fast and easy. No need to stop the drilling operation in order to manually extract the core. Painstaking process that can possibly ruin structural integrity of the sample, and or ruin the diamond core drill itself. Strong coolant pressure will wash out material debris (center plugs) stuck in center of your drill. Center plugs restrict coolant flow to center of drill and prevent coolant from reaching the diamond section. Your drill will start to drill dry, significantly reducing your drill life, material surface finish, and deteriorating overall performance. Center plugs preventing water reaching the diamond section, are behind 90% of all drill wreckage. Running Coolant through center becomes crucial specially for smaller diameter drills and longe depths.

Improve surface finish quality and reduce material chipping

Chipping and material blowout at hole exit usually occurs due

Increase Diamond Drill Life up to 350%, Improve Drilling Rates & Prevent Drill Breakage

You will find the more pressure you have on your coolant, usually the better your drilling results will be. Heat is the worse enemy for diamond crystal. Without high pressure of coolant to provide constant coolant and material swarf/chip removal at cutting zone, the diamond crystal will start to oxidize and glaze over. Loose its sharp point, crack or fall out. The bond matrix holding the diamond crystals in place will heat up in turn. The diamond drill may stop drilling altogether, develop burn marks on diamond edge, loose its form, or the diamond crown (tip) may separate from the steel tube/body. Running High Pressure of Coolant through center of drill is also the only most affective way of drilling holes beyond 1.0" (25.4mm) in depth. Submerging Material in coolant or applying coolant from an outside source is not able to affectively reach the drilling zone. Drilling speeds will taper off, and number of issues indicated above will arise.

Increase Drilling Speed & Feed Rate

Constant Coolant Pressure will reduce amount of heat generated and temperature found in the drilling zone. Insuring maximum effectiveness and working potentials of diamond crystals placed inside diamond drill bond matrix not overheated, will not loose its sharp points, maintain its firm shape, and kerf edge/form all the way through the life of the core drill. The drill will drill freely at consistent speed, requiring very minimal amount of dressing. This translates into faster drilling speeds, faster output, more consistency, and above all savings in money and time.

Prevent micro cracks & Preserve Material Micro Structure that arises from heat generated while drillings

-

Preserve material true micro structure

Preserve material true micro structure

-

Obtain More Consistent overall performance

Obtain More Consistent overall performance

-

Optimize your Diamond Drilling Operation to ultimate point of efficiency

Optimize your Diamond Drilling Operation to ultimate point of efficiency

Used on almost any Drilling Equipment

Water Swivel Adapters will fit into universal drilling machine chuck or proper collet of almost any drilling machine. Different water swivel adapters are designed for different applications and industries they are used in. Main differences include shank/shaft diameter, and male or female thread size. Each water swivel adapter is designed to mate with diamond drill collet. They should have compatible thread sizes. For example if water swivel adapter has male thread, the diamond drill should have female thread. And vice versa

Drilling Equipment Used On:

-

Drill Press

Drill Press

-

Hand Held Drills

Hand Held Drills

-

Angle/Hand Held Grinders

Angle/Hand Held Grinders

-

Electric Hand Held Drills

Electric Hand Held Drills

-

Milling Machines

Milling Machines

-

CNC Machines

CNC Machines

-

Other Equipment

Other Equipment

Minimize Drill & Material Overheating

Frictional heat produced at the working face of diamond crown (tip) must be disposed immediately. Otherwise the diamond crystal inside the diamond core drill tip will become rapidly damaged by oxidation and graphitization. Excessive heat generated while drilling will also damage the bond matrix holding the diamonds in place.

Insure More Consistent Drilling Performance

Material Debris (swarf particles) generated while drilling should be removed as soon as they are produced. When this material debris is not removed rapidly, diamond wear increases through abrasion caused by the presence of excessive coarse micro material fragments.

Water is the most common coolant used for many drilling applications. It is always a good idea to pump an adequate supply of water through the center of the drill. So that an uninterrupted flow is maintained flushing across the working surface of the drill diamond section. In this way diamond crystal and the bond matrix are both kept sufficiently cool. And material debris is removed as soon as it is generated.

Reduce Friction between material and drill

Coolant or Water also penetrates the micro-cracks witch are generated upon impact of material and diamond drill. Under ideal conditions, the material will absorb water/coolant, hence becoming completely saturated. In this state the material is weaker and more easily drillable.

The coolant surface tension also plays an important part in the drilling operation. Usually the lower the surface tension, the easier it is for the coolant to enter the micro cracks. Coolant with a lower surface tension also wets the diamonds more easily. Most users find that by lowering the surface tension of their coolant, resulted in better cooling (wetting) of their diamond, and more effective overall cooling. Lower surface tension also improves material debris lubrication, promoting efficient removal.

Related Products

SMART CUT® Water Soluble Coolant

(General Materials Formula)

High-Performance Fully Synthetic Coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

SMART CUT® Water Soluble Coolant (General Materials Formula) is a fully synthetic, non-oily, and non-foaming coolant and lubricant engineered to meet the rigorous demands of slicing, dicing, drilling, sectioning, wafering, grinding, and polishing operations involving hard and brittle materials. This advanced formula has been specifically developed for use with ceramics, precision optics, quartz, silicon, sapphire, and other materials commonly found in semiconductor, photonics, and materials research applications.Shank Adapters for Diamond Drills

used to create conical holes, expanding existing holes, breaking corners and chamfering holes and polishing existing holes in a large variety of materials. Available from stock in many specifications and we can also custom manufacture to fit almost any application/requirement.

Multi-Layered Electroplated Diamond Countersinks are designed for countersinking operation in materials such as Glass, Quartz, Composites, Graphite Epoxy, Carbon, Boron, Fiberglass, Marble, and many other materials.

Dressing Sticks For Precision Diamond & CBN Tools

Diamond Tools must be used with diamonds exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and heat cracks in the diamond tool as well as material being machined. Resulting in premature diamond tool wear, blade tensioning problems, and will eventually destroy the diamond tool. The more a diamond tool is dress the cooler it will drill or cut. Everything you wanted to know about dressing Diamond & CBN Tools

SMART CUT® Dressing Sticks are expertly designed to help you clean, sharpen, and condition your diamond blades, grinding wheels, and other diamond tooling, ensuring optimal performance and extended tool life. Available from stock in many different dimensions, abrasive types, grit size, and bond harnesses to fit most requirements. Manufactured in the USA with premium-grade materials, these dressing sticks are an essential accessory for any industry relying on precise cutting, drilling, grinding, & operations. Custom specifications can be produced upon request with fast lead times & small minimum order quantities.

Recently Viewed Products

ARE YOU USING RIGHT DIAMOND CORE DRILLS & TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND CORE DRILLS & TOOLS?

Knowledge Center

02

Jun

Select right Diamond Drill for your application

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will...

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind...

02

Jun

Diamond Tools Guide – Selecting Right Drills & Tools for your application

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms,...

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency....

02

Jun

Micro Drilling Guide

Share this Article with Friend or Colleague

In order for you to get the most out of your diamond micro drill or carbide / high speed steel micro drill, we strongly urge you to read...

02

Jun

Selecting Right Drilling Equipment for your Application. What you features & functionality you should look for?

Share this Article with Friend or Colleague

There are hundreds or even thousands of different drilling equipment options. Selecting the right equipment for a specific application involves carefully considering several variables and attributes of the...

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

https://ukam.com/wp-content/uploads/2024/07/diamond-drill-troublehsooting-guide.mp4

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide...

09

Sep

Understanding & Calculating Return on Investment for Diamond Core Drills & Other Tools

The term "ROI" (Return On Investment) is widely used across industries, often interpreted differently depending on the context. However, few truly understand what ROI represents and its specific implications, particularly in the context of diamond...

09

Sep

Understanding Tradeoffs – Searching for Perfect Diamond Drill & Tool

Choosing the right diamond drill or tool can significantly impact efficiency, cost, and quality. However, this is not a simple and clear-cut process. Selecting the optimal drill or tool involves navigating a complex landscape of...

19

Sep

Why Use Diamond Drills?

Diamond, known as the hardest material on Earth, enables diamond drills and tools to grind away material at a micro (nano) scale. This extreme hardness allows diamond tools to effectively work on materials with a...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use