-

0 items in quote

No products in the Quote Basket.

SMART CUT® 7005

Tube & Rod Cutting Machine

SMART CUT® 7005 is Designed for high-performance and precision, our Tube & Rod Cutting Machine is the ultimate solution for industries demanding exact cuts and efficient material handling. This machine is engineered to slice through large variety of tube and rod rod materials such as: carbide and high-speed steel rods, ceramic, glass, composites, and many others with high degree of accuracy and speed, making it an indispensable tool for manufacturers in aerospace, automotive, metal fabrication, and tool-making sectors.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

SMART CUT® 7005 is Floor Model machine designed for robust engineering for professional and high-volume industrial applications. Constructed from rust-proof steel with a corrosion-resistant cutting chamber, this machine is designed for longevity and reliability in demanding environments. It features a sliding door for ease of access and a manual cutting action for the ‘Z’ movement, controlled by a sturdy handle.

This model is equipped with a powerful 3 HP (2.2 kW) motor that operates on a three-phase connection, delivering a spindle speed of 2800 rpm. It accepts a spindle diameter of 31.75mm, with an optional 25.4mm, and utilizes diamond wheels of 8 inches (200 mm) or 10 inches (250 mm) in diameter. The machine’s advanced control system includes an intuitive user interface with straightforward controls that enhance operational efficiency.

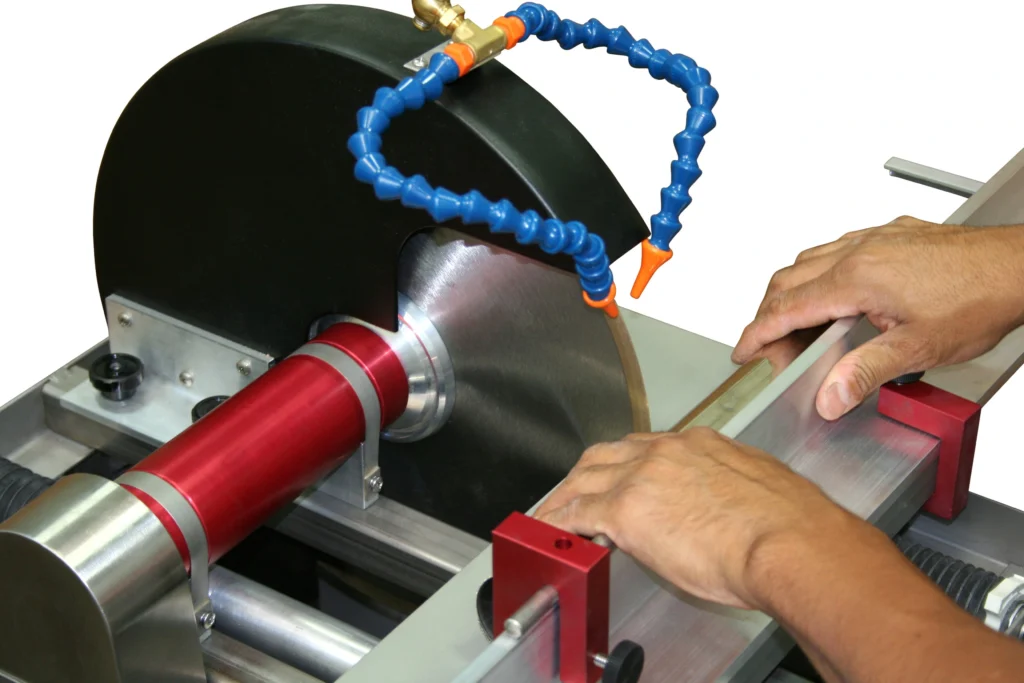

The cutting chamber is designed for easy flow and includes a special floor coating, complemented by a splash-proof, corrosion-resistant see-through hood. It features a work-holding V-block with a brass insert and pneumatic clamping with an adjustable pressure system. A manual adjustable measurement stopper system accommodates carbide rods from 20 mm to 300 mm in length.

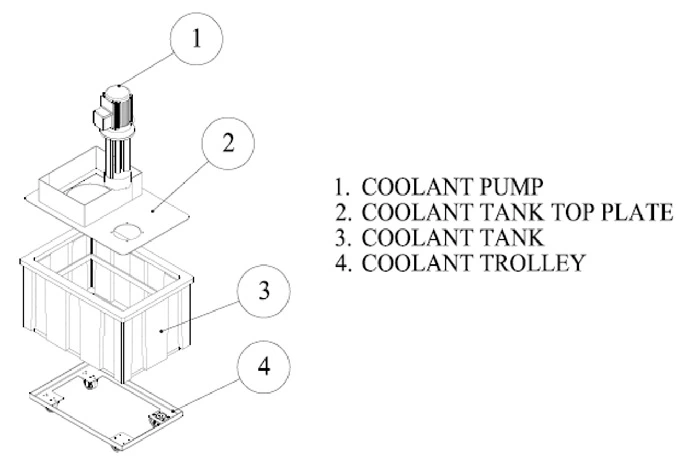

Cooling is efficiently managed by two high-flow coolant systems dedicated to the cutting zone and additional coolant jets for the cut-off wheel. The inbuilt movable recirculation coolant tank has a 50-liter capacity and features a two-stage filtration system with 100 and 50-micron filter bags. A manual wash cleaning attachment with a hanging hook and a powerful LED light ensures the work area is well-illuminated for precision tasks.

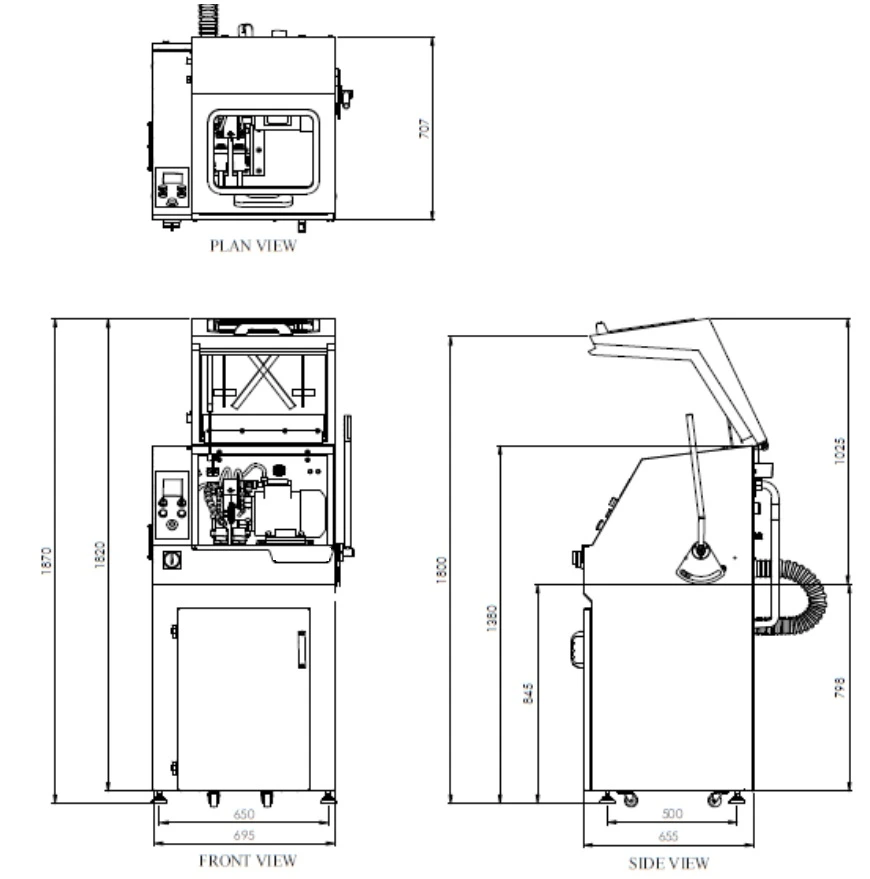

The machine operates on a standard voltage of 415V/50Hz (R+Y+B+N+E) with an optional setting of 220V/60Hz/3 Phase (R+Y+B+PE). Its dimensions are 800mm x 850mm x 1400mm (LxDxH), and it weighs approximately 220 kg. The enclosure is painted in RAL 7040, while the base and stand are in RAL 7016, aligning with CE compliance for safety systems.

Designed for adaptability in production levels, optional accessories include a variable speed system allowing adjustments between 1000 and 3000 RPM, an electronic braking system for enhanced safety, an automatic wash system to save cleaning time, a fume digester for water-based coolant oils, and a fire suppression system.

SMART CUT® 7005 is an affordable precision cutting machine for manufacturing facilities that require robust solution for cutting variety rod & tube materials on a budget.

SPECIFICATIONS

- Cutting Capacity: Up to 25 mm in diameter for carbide rods and up to 40 mm for HSS rods.

- Motor Power: 5.5 kW high-efficiency motor.

- Electrical Requirements: 220V/380V, 50/60Hz.

- Dimensions: 1500 mm x 800 mm x 1400 mm (L x W x H).

- Weight: Approximately 750 kg

ADVANTAGES

- Increased Productivity: Streamline the cutting process with high-speed operations and minimal manual intervention.

- Reduced Operating Costs: Lower energy consumption and reduced material waste contribute to significant cost savings over time.

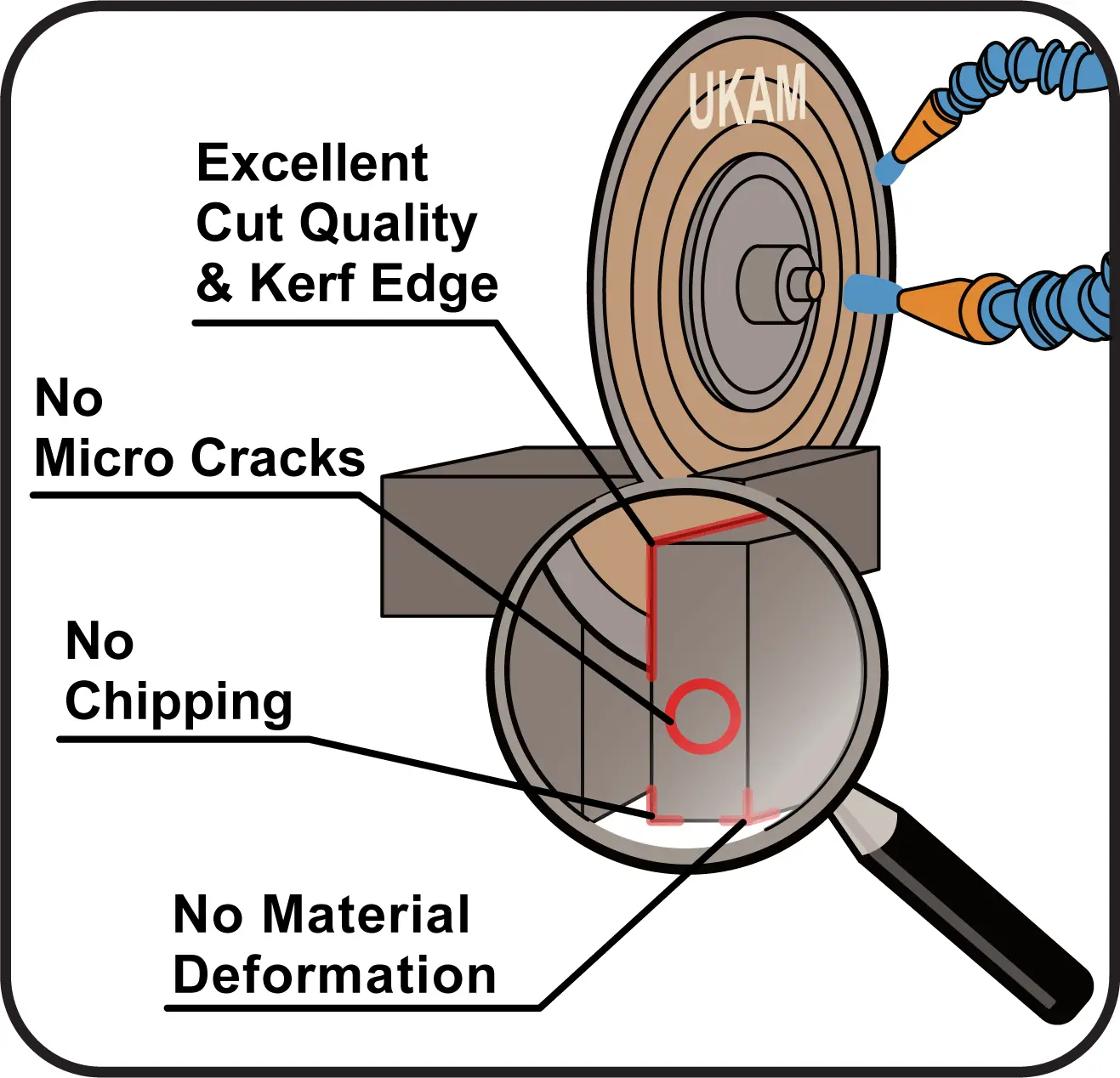

- Superior Cut Quality: Achieve smooth, clean cuts consistently, enhancing the quality of the end products.

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

Tab Content

OPERATING MANUALS

Tab Content

ACCESSORIES

Tab Content

Features

- Robust Construction: Built with industrial-grade materials, our machine ensures durability and longevity under rigorous operational conditions.

- Advanced Cutting Technology: Equipped with a high-torque motor and precision-engineered blades, the machine offers clean cuts with minimal burr formation, reducing the need for secondary finishing processes.

- Adjustable Speed Settings: Customize cutting speeds with variable speed controls to handle different diameters and materials of carbide and HSS rods, optimizing the cutting process for efficiency and precision.

- Automated Feeding System: An automated rod feeding system allows for continuous operation, increasing throughput and reducing labor costs. The feed mechanism is designed to minimize material waste and ensure consistent cutting performance.

- Safety Features: Comprehensive safety features, including emergency stop buttons, protective guards around cutting blades, and automatic shutoff sensors, provide a safe working environment for operators.

- Ease of Maintenance: Designed with accessibility in mind, routine maintenance tasks such as blade replacement and system diagnostics are straightforward and fast, minimizing downtime.

Related Products

Item # UKAMLS01-1 SMART CUT® 2001 – Precision Cut Off Saw

SMART CUT® 7001

SMART CUT® 7001 Heavy Duty Automatic Carbide Rod Cutting Machine is an advanced, fully automatic cutting solution engineered for mass production environments. Designed with precision, efficiency, and versatility in mind, this cutting-edge machine offers exceptional performance for the precise cutting of carbide rods and hollow tubes. Its robust design and intuitive features make it the ideal choice for industrial applications.

SMART CUT® 7002 Heavy Duty Automatic Rod & Tubbing Cutting Machine.

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Diamond & CBN Wafering Blade Case Studies

This study evaluates the cutting performance of SMART CUT® Diamond & CBN Wafering Blades compared to Conventional Wafering Blades under identical test conditions. The objective was to measure differences...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

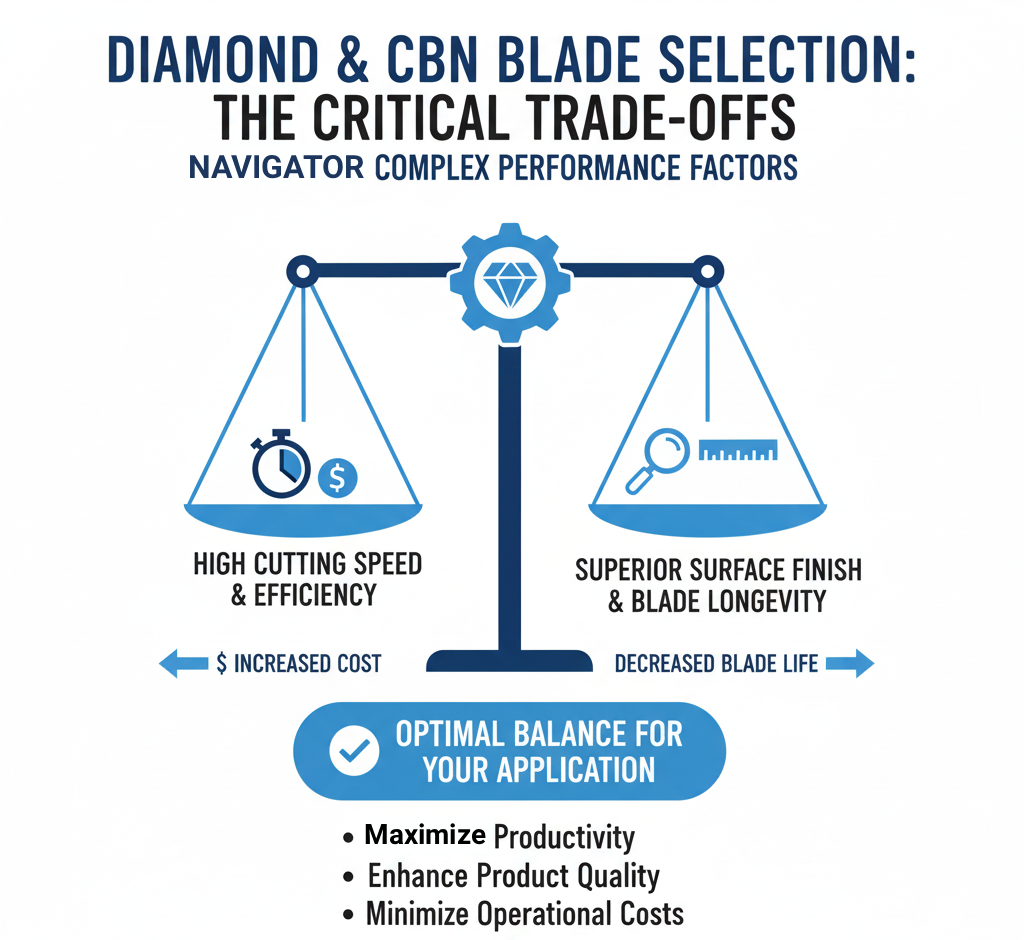

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

02

Nov

Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...