-

0 items in quote

No products in the Quote Basket.

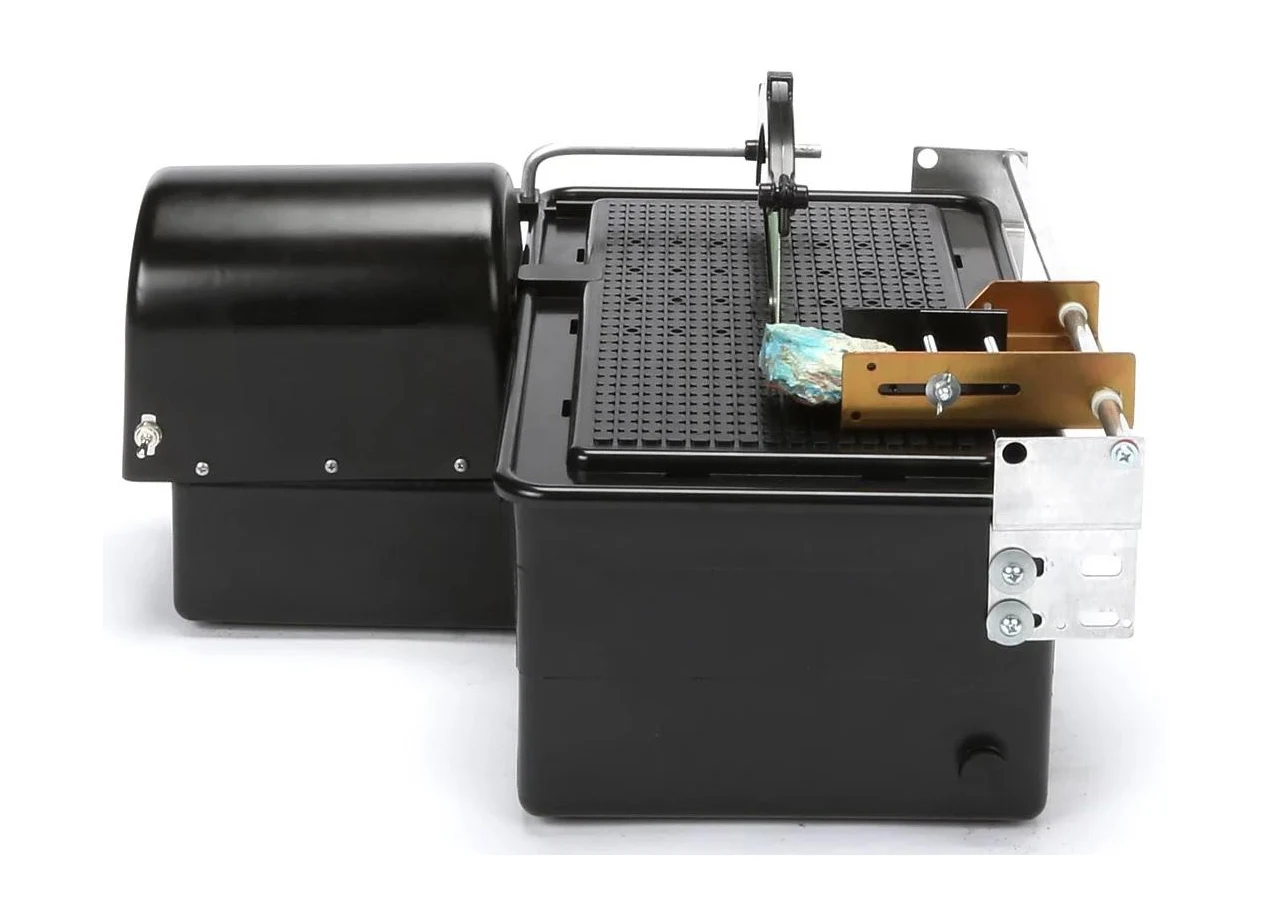

SMART CUT® 1010

Cut Off Saw

SMART CUT® 1010 are entry level laboratory cutting saw that are very affordably priced, Fast & Minimum Material Deformation sectioning of large variety materials. Coolant is stored below and applied to sample by rotating the blade. Saw table has a large working area and no inhibiting lip. The optional vise holds mot material shapes and swings back out of the way for hand sectioning. Coolant can be easily drained through small opening at the bottom. Optional Rip Fence attachment allows to align material for easier sectioning

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

ACCESSORIES

OPERATING MANUALS

DESCRIPTION

This machine will accept any 10″ blade that has a 5/8″ arbor. The large saw table gives you plenty of room for oversize materials, measuring 19-3/4″ L X 12″ W. The housing is made of unbreakable, cross-linked polyethylene that makes it rustproof and easy to clean. Installed in each slab saw is a 1/3 hp motor to provide plenty of strength for large cuts, delivering a speed of 1,725 rpm. The coolant reservoir is built right into the base of the machine and can hold up to 32 ounces of coolant. The removable saw table that covers the reservoir makes cleanup easy. The splash guard that comes with the machine keeps coolant off you and on your material, making it easier for you to cut.. Made in U.S.A.

SPECIFICATIONS

- Cutting Action: Linear blade feeds into work piece. Material is slowly feed into the rotating blade.

- Motor Power: 1/3 HP

- RPM’s (Single Speed) 1,725 rpm’s

- Blades can accommodate: 10” OD

- Blade Thickness: .020” to .070”

- Can be used with: any type of blade 10” OD

- Coolant Capacity: 32 oz

- Arbor: 5/8″ (15.8mm)

- Shipping Weight: 35 lb

- Shipping Dimensions: 19″ L X 21″ W X 12″ H

ADVANTAGES

- Affordable & Simple Entry Level Lab Cutting Saw Reduce Consumables Cost by up to 300%

- Equal or Cut Quality on most Applications to more complex cutting machines, at small Fraction of cost.

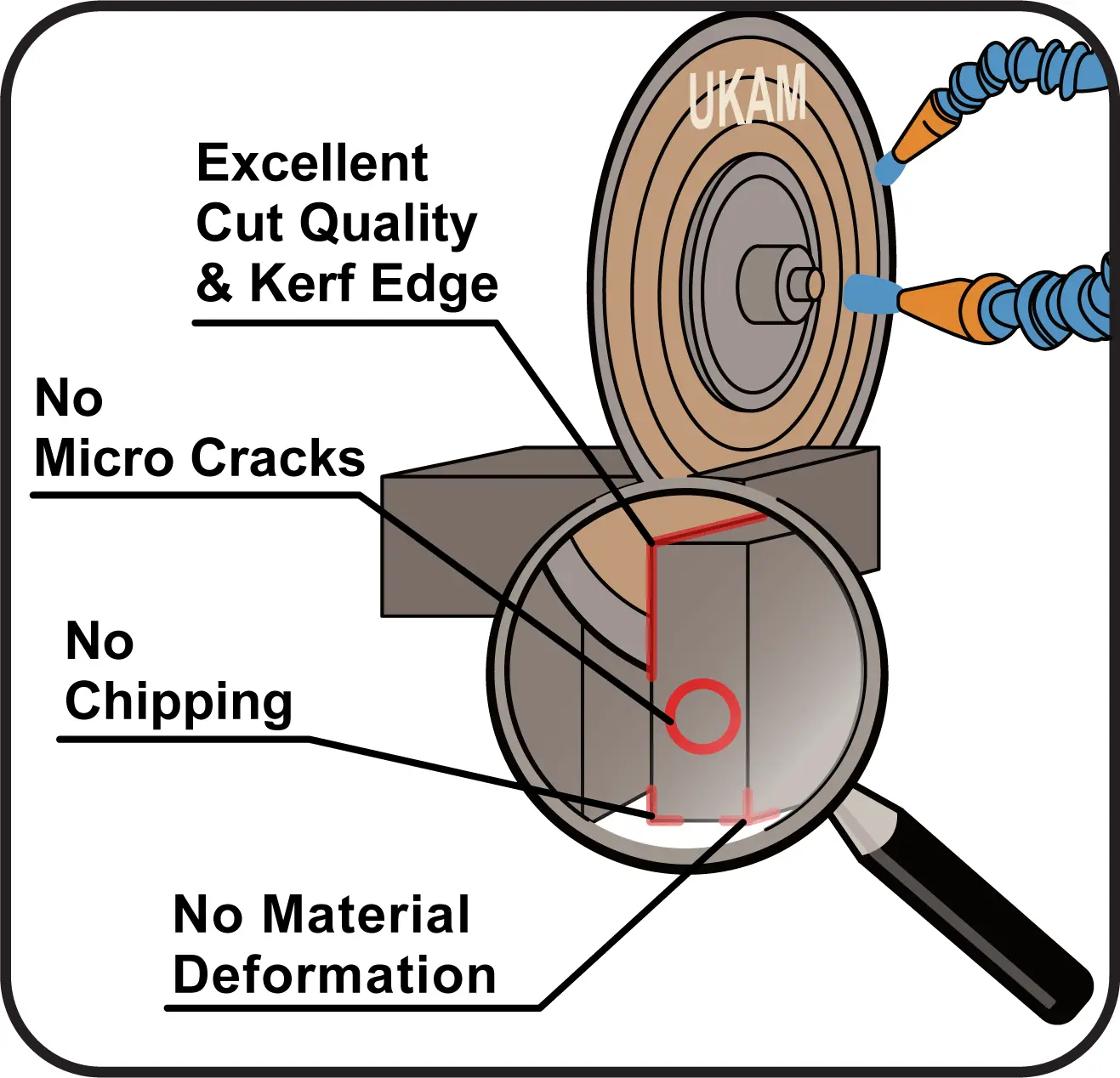

- No Material Deformation

- Can withstand more exploitation that conventional sectioning saws

- Very Easy to use (reduce operator error & training)

- Can be used for just about any material or application

- Very compact, requires minimum space

- Powerful motor designed for cutting very hard to soft materials

- Straight forward design allows the operator to concentrate on sectioning samples, not operating the machine

- Perfect for Manufacturing and R & D Organizations on a Budget

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

The SMART CUT® 1010 is an entry-level laboratory cutting saw designed for fast and minimal material deformation sectioning of a wide variety of materials.

This saw is ideal for laboratories and users looking for an affordable yet efficient cutting solution.

The coolant is stored below and applied to the sample by the rotating blade.

The saw table measures 19-3/4″ L X 12″ W, providing ample working space for oversize materials.

Yes, an optional vise is available that can hold most material shapes and can be swung back out of the way for hand sectioning.

The coolant can be easily drained through a small opening located at the bottom of the machine.

The Rip Fence attachment allows users to align materials for easier and more precise sectioning.

The machine can accept any 10″ blade with a 5/8″ arbor.

The SMART CUT® 1010 is equipped with a 1/3 HP motor that delivers a speed of 1,725 rpm.

The coolant reservoir can hold up to 32 ounces of coolant.

The housing is made of unbreakable, cross-linked polyethylene, making it rustproof and easy to clean.

The machine employs a linear blade feed into the workpiece, where the material is slowly fed into the rotating blade.

Yes, it can be used with any type of blade that has a 10” OD.

The machine can accommodate blades with a thickness ranging from .020” to .070”.

The shipping weight of the machine is 35 lb.

The shipping dimensions are 19″ L X 21″ W X 12″ H.

The SMART CUT® 1010 is made in the U.S.A.

Yes, the machine comes with a splash guard to keep the coolant on the material and prevent splashing onto the user.

The machine features a removable saw table that covers the reservoir, making cleanup straightforward and efficient.

The saw is designed for fast sectioning with a precise blade feed mechanism, ensuring minimal deformation of the material being cut.

Yes, the SMART CUT® 1010 is versatile and can handle a wide variety of materials, from soft to hard, given the right blade selection.

The machine’s design includes a splash guard to prevent coolant splashes, and its rustproof housing ensures long-term durability without corrosion risks.

The frequency of coolant replacement depends on usage. It’s advisable to check the coolant regularly for debris and replace it when it appears dirty or its performance diminishes.

While the SMART CUT® 1010 is designed primarily for laboratory use, its robust design and features make it suitable for small-scale commercial production.

The machine is designed for ease of setup, but it’s always advisable to refer to the user manual for any assembly or setup instructions.

Yes, replacement parts for the SMART CUT® 1010 are typically available through the manufacturer or authorized distributors.

Specific inclusions might vary based on the package or distributor. It’s best to check with the seller regarding any included accessories.

Cross-linked polyethylene is a durable material that is resistant to chemicals, ensuring the machine remains rustproof and maintains its appearance over time.

The optional vise provides a secure grip on various material shapes, ensuring precise cuts. When not needed, it can be swung out of the way for hand sectioning.

Yes, the SMART CUT® 1010 typically comes with a user manual that provides detailed instructions on setup, operation, and maintenance.

The built-in coolant system helps dissipate heat generated during cutting, ensuring the material and blade remain cool and reducing the risk of heat-induced deformities.

Users should always wear appropriate safety gear, ensure the work area is clean, and follow the guidelines provided in the user manual to ensure safe operation.

Warranty and after-sales support details would be provided by the manufacturer or distributor. It’s advisable to check with them directly for specific terms and conditions.

The SMART CUT® 1010 stands out due to its affordability, versatility, and design features, making it a preferred choice for many laboratory applications.

The machine is built with durable materials and is designed to withstand regular use. Proper maintenance and regular checks can further ensure its longevity.

With proper maintenance and care, the SMART CUT® 1010 is designed for long-term use. The exact lifespan can vary based on usage frequency and the materials being cut.

Yes, given its user-friendly design and safety features, the SMART CUT® 1010 is ideal for educational settings such as universities and training institutes.

While the machine can accommodate any 10″ blade with a 5/8″ arbor, the specific blade type should be chosen based on the material being cut.

The machine features a removable saw table for easy cleaning. Additionally, the rustproof polyethylene housing can be wiped down with a damp cloth.

The machine is designed to operate smoothly, but it’s always advisable to place it on a stable surface to minimize vibrations.

The saw is designed for fast sectioning with a precise blade feed mechanism, ensuring minimal deformation of the material being cut.

Yes, the SMART CUT® 1010 is versatile and can handle a wide variety of materials, from soft to hard, given the right blade selection.

The machine’s design includes a splash guard to prevent coolant splashes, and its rustproof housing ensures long-term durability without corrosion risks.

The frequency of coolant replacement depends on usage. It’s advisable to check the coolant regularly for debris and replace it when it appears dirty or its performance diminishes.

While the SMART CUT® 1010 is designed primarily for laboratory use, its robust design and features make it suitable for small-scale commercial production.

The machine is designed for ease of setup, but it’s always advisable to refer to the user manual for any assembly or setup instructions.

Yes, replacement parts for the SMART CUT® 1010 are typically available through the manufacturer or authorized distributors.

Specific inclusions might vary based on the package or distributor. It’s best to check with the seller regarding any included accessories.

Cross-linked polyethylene is a durable material that is resistant to chemicals, ensuring the machine remains rustproof and maintains its appearance over time.

The optional vise provides a secure grip on various material shapes, ensuring precise cuts. When not needed, it can be swung out of the way for hand sectioning.

Yes, the SMART CUT® 1010 typically comes with a user manual that provides detailed instructions on setup, operation, and maintenance.

The built-in coolant system helps dissipate heat generated during cutting, ensuring the material and blade remain cool and reducing the risk of heat-induced deformities.

Users should always wear appropriate safety gear, ensure the work area is clean, and follow the guidelines provided in the user manual to ensure safe operation.

ACCESSORIES

OPERATING MANUALS

Download Operating Manuals

Features:

- Affordable Entry-Level Laboratory Saw: Priced to provide an economical solution for precise cutting and sectioning.

- Fast & Minimal Material Deformation: Designed for fast cutting with minimal material deformation, ensuring clean and accurate cuts.

- Large Working Area: Saw table dimensions of 19-3/4" L x 12" W, providing ample space for large materials.

- Versatile Blade Compatibility: Accepts any 10" blade with a 5/8" arbor, offering flexibility in blade selection.

- Durable Construction: Housing made of unbreakable, cross-linked polyethylene that is rustproof and easy to clean.

- Powerful 1/3 HP Motor: Delivers strong cutting performance with a motor speed of 1,725 RPM for large cuts.

- Integrated Coolant Reservoir: Built-in coolant reservoir with a capacity of 32 ounces to keep materials cool during cutting.

- Splash Guard: Helps keep coolant contained and directs it onto the material, preventing mess and enhancing cutting efficiency.

- Removable Saw Table: Facilitates easy cleanup with a removable table that covers the coolant reservoir.

- Vise Assembly: Adjustable guide that allows precise material clamping, ensuring accurate cuts. Wing nuts secure materials, and the carriage feeds material evenly into the blade.

- Rip Fence Attachment (Optional): Adjustable table rip fence enables repeatable, guided sectioning for manual, freehand cutting, providing consistent slice dimensions.

- Easy Maintenance: Coolant can be easily drained through a small opening at the bottom of the machine.

- Versatile Material Handling: Capable of cutting a wide variety of materials with ease, including metals, composites, ceramics, plastics, and more, making it a versatile tool for diverse applications.

- User-Friendly Operation: Simple setup and operation, making it ideal for both novice users and experienced operators in laboratory settings.

- Quick Setup and Adjustment: The vise and rip fence attachments can be easily installed and adjusted, ensuring fast setup and accurate material positioning.

- Precise Cutting: The adjustable vise and rip fence enable precise material sectioning, ensuring consistent cutting results and repeatability.

- Compact Design: Despite its large working area, the saw has a compact footprint, making it suitable for labs with limited space.

- Efficient Coolant Management: The coolant system keeps the blade and material cool during cutting, extending blade life and improving cutting performance.

- Affordable Maintenance: The saw is designed for easy maintenance, with a simple coolant drainage system and removable parts for easy cleaning and upkeep.

- Lightweight Yet Sturdy: The polyethylene construction offers a balance between lightweight design and robust durability, ensuring long-lasting performance.

- Unmatched Selection of Diamond, CBN, & Abrasive Blades: Unmatched slection of diamond, cbn, abrasive and other wafering blade specifications (e.g., diameter, thickness, grit) to fit any specification. Best Prices & Performance in North America.

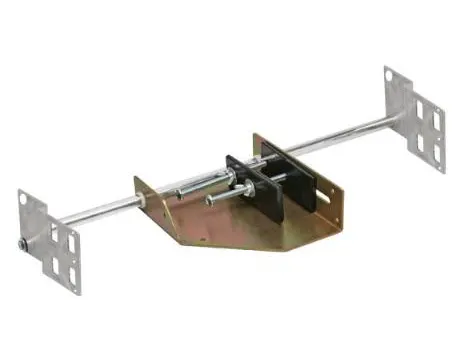

Vice Assembly

Vise Assembly is an adjustable guide that allows for accurate precision cuts. Wing nuts are tightened to clamp the work piece securely in place. The carriage advances slowly to feed material evenly into the blade. Easily installed by bolting into place. Samples can be accurately positioned in vice. Vise can be easily adjusted to accommodate a large variety of material sizes, thickness, shapes, and configurations.

Rip Fence Attachment

Adjustable table rip fence provides repeatable, guided sectioning of all types of materials in manual free hand cutting applications. Serves as a guide that runs parallel to the blade. One side of the material stays in contact with the rip fence as the other side of the piece passes through the blade. The distance between the rip fence and blade determines the dimension of the material section being cut. The position of the rip fence can be changed along the cutting table depending on your desired end product slice dimensions

SMART CUT® COOLANTS

Your choice of one (1) quart of SMART CUT™ Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT™ Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

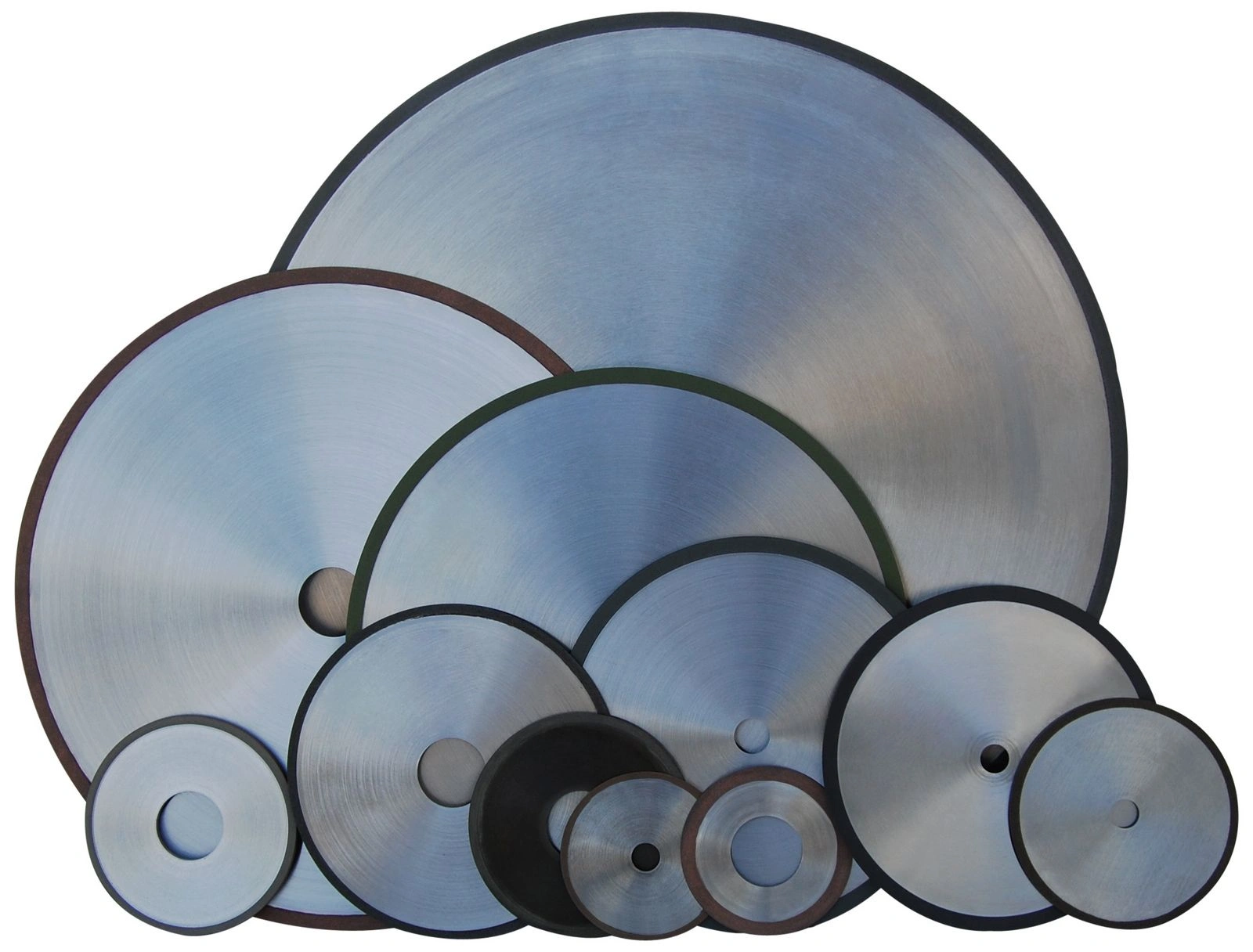

LARGEST SELECTING OF DIAMOND &

CBN WAFERING BLADES AVAIALBLE

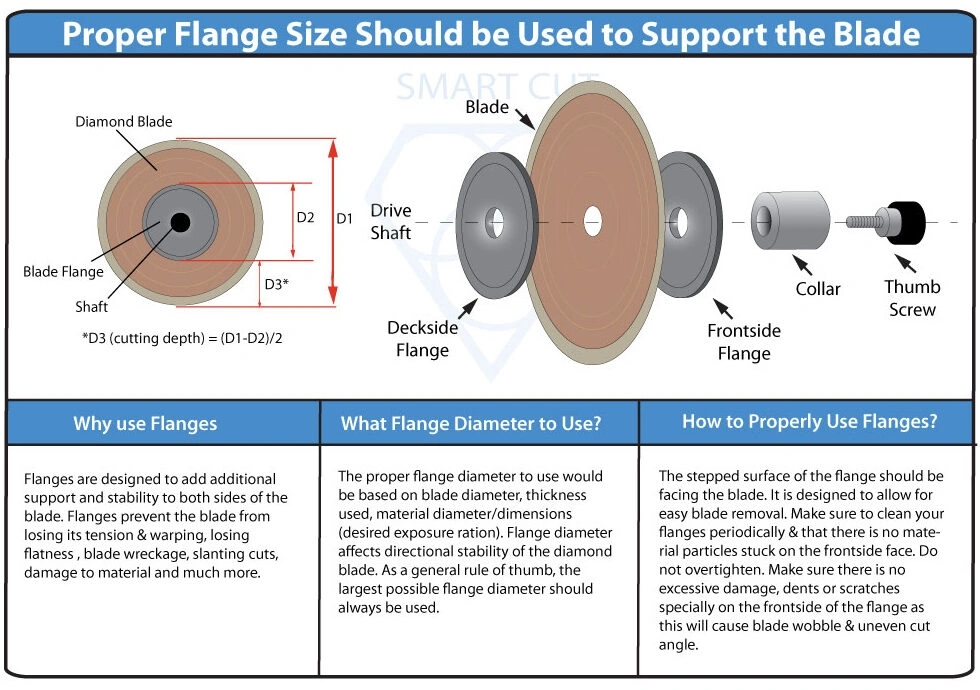

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

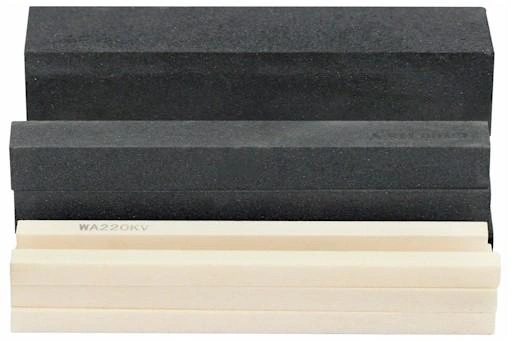

THE RIGHT DRESSING STICK FOR YOUR APPLICATION

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

Item # 8054245-1-2 SMART CUT® 12001 – Cut Off Saw

Item # 8054245-1 SMART CUT® 16001 – Cut Off Saw

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Diamond & CBN Wafering Blade Case Studies

This study evaluates the cutting performance of SMART CUT® Diamond & CBN Wafering Blades compared to Conventional Wafering Blades under identical test conditions. The objective was to measure differences...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

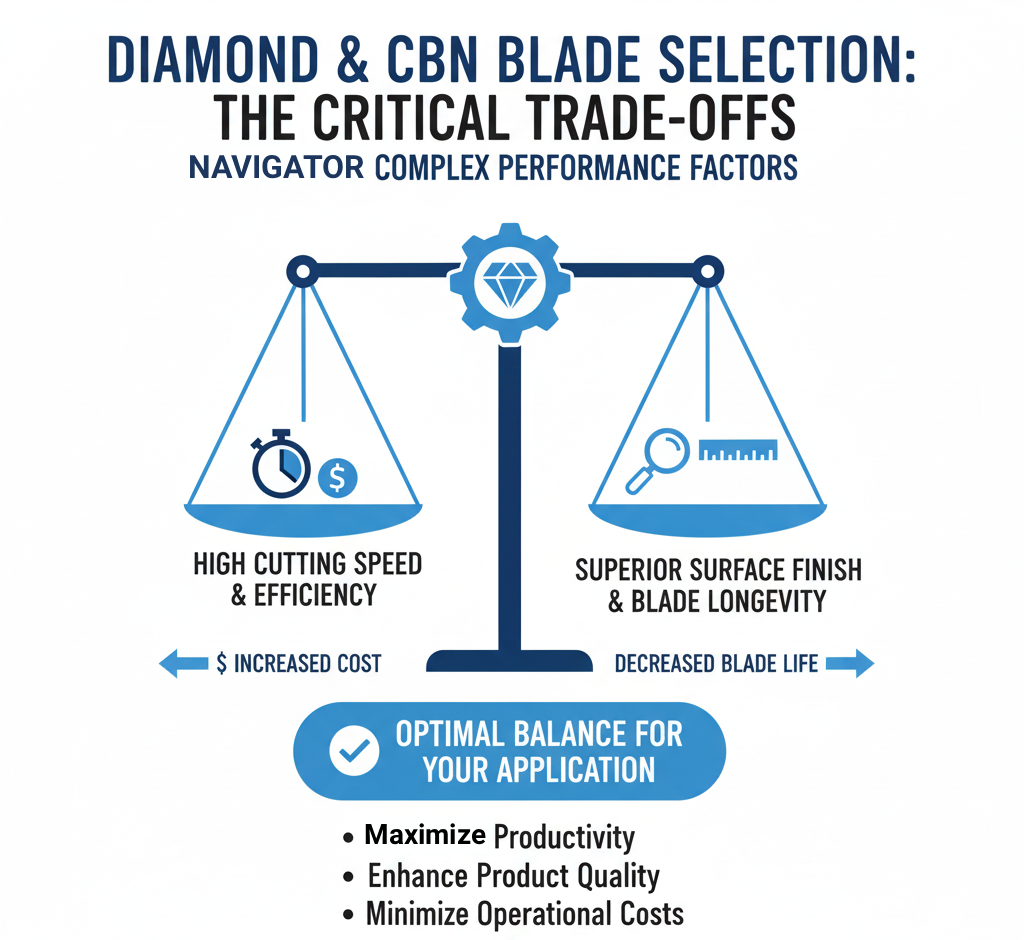

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

02

Nov

Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...