-

0 items in quote

No products in the Quote Basket.

Lapidary

Diamond Grinding Wheels (Electroplated) – Concave

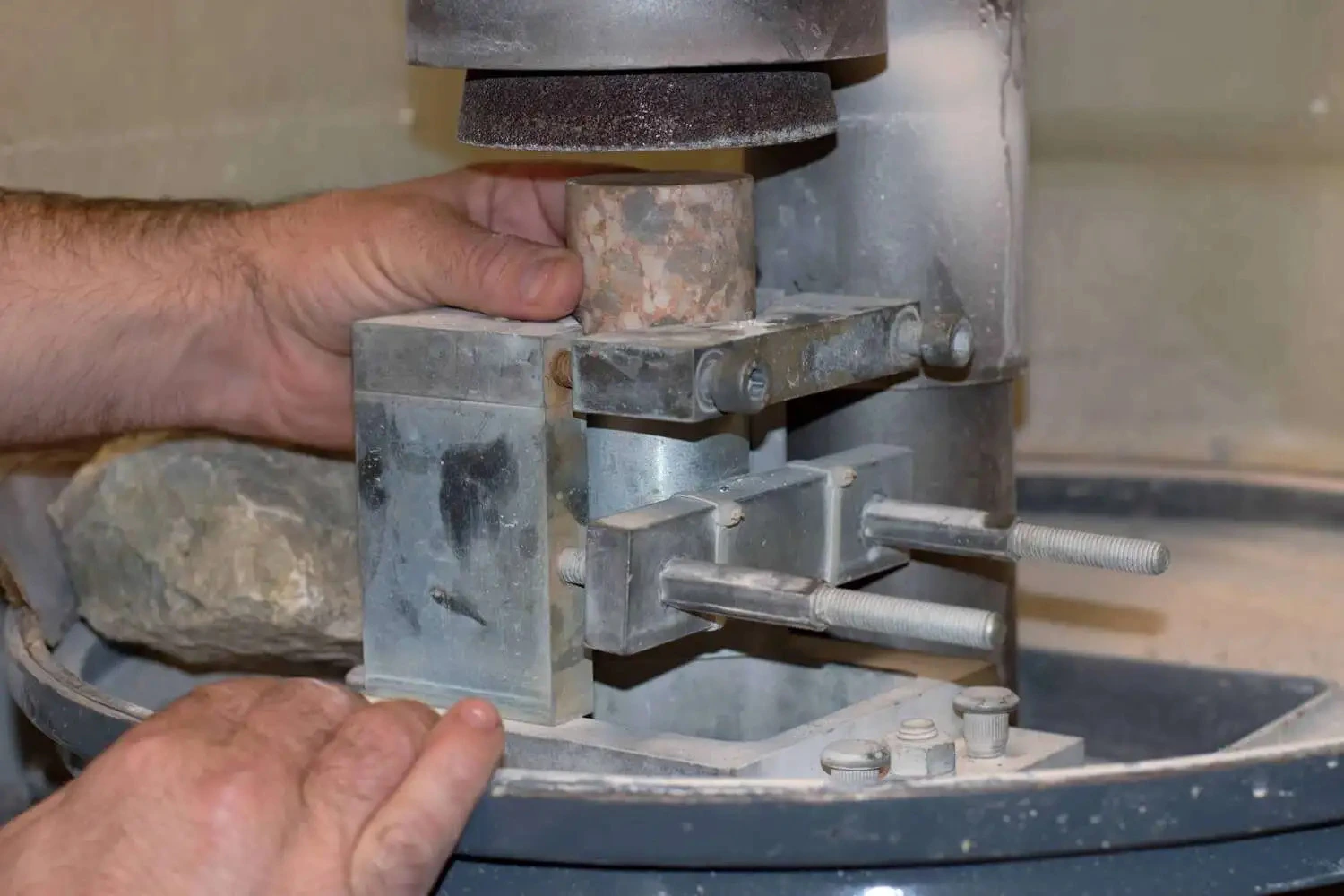

SMART CUT® Electroplated Diamond Cabbing Grinding Wheels – Concave are precision-engineered tools designed specifically for carving, shaping, and grinding concave surfaces in a variety of hard, brittle, and delicate materials such as stone, glass, ceramics, quartz, and advanced composites. The unique curved grinding surface enables users to achieve smooth, even contours and recessed forms that are difficult to accomplish with flat or standard profile wheels.

DIAMOND GRINDING WHEELS (Electroplated) – Non Textured PLASTIC HUB

SMART CUT® Electroplated (nickel bonded) diamond grinding wheels, with plastic center core. Made with the highest quality diamonds for longer grinding life, clean and faster cutting. Can be used on all conventional grinders made today. Such as Diamond Pacific, Barranca, Maxant, Graves, as well as other cabbing machines. All wheels have a 1in. Diameter and include bushing to accommodate 3/4in., 5/8in. and 1/2in. arbors. Individually boxed. The plastic hubs are lighter and can be used on less powerful grinding machines. We do not offer re-plating of the wheels, it is more cost effective to re-cycle the wheels.

DIAMOND GRINDING WHEELS (Electroplated) – Non Textured Steel Hub

SMART CUT® Electroplated (Nickel Bonded) Diamond Grinding Wheels with non-textured solid steel hubs are engineered for users who demand precision, durability, and high-performance results in their grinding operations. These wheels are manufactured using premium-grade synthetic diamonds and a precision-controlled electroplating process that exposes each diamond crystal at its optimal cutting point, delivering maximum grinding efficiency, faster cutting action, and a superior surface finish with minimal loading.

DIAMOND LAPS

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond laps & polishing discs. Below you will find information, specifications & prices on all laps & polishing discs we offer for this application. Contact us for volume pricing. We can also produce any custom diamond wheel per your specification. Contact us Today for Free Quote!

SMART CUT® RESIN BOND DIAMOND WHEELS

SMART CUT® Resin Bond Diamond Wheels offer a superior alternative to conventional Nova and Flex wheels, engineered specifically for cabbing, contour grinding, and precision finishing applications. These wheels are manufactured using a proprietary high-performance resin bond matrix combined with premium-grade synthetic diamond particles, delivering exceptional grinding efficiency, surface quality, and extended tool longevity.

One of the most notable advantages of SMART CUT® Resin Diamond Wheels is their immediate usability—no break-in period is required. Unlike traditional wheels that demand conditioning or dressing prior to use, these wheels are ready to perform straight out of the box, saving time and eliminating unnecessary preparation.