-

0 items in quote

No products in the Quote Basket.

Nickel Bond

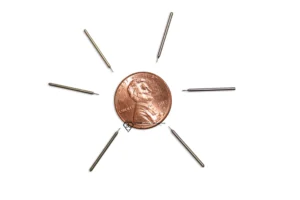

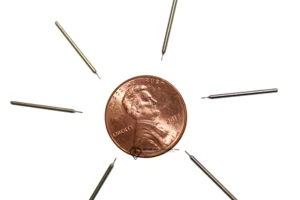

SMART CUT® 005DME MCDU

SMART CUT® 005DME Diamond Micro Drills represent a major advancement in precision micro-machining technology, specifically engineered to meet the challenges of drilling hard, brittle, and high-tech materials used across industries such as semiconductor, optics, advanced ceramics, aerospace, and medical device manufacturing.

These drills are widely used in electronics and semiconductor manufacturing for creating microscopic precision holes in wafers, essential for thermal management, electrical connectivity, and overall chip reliability. In optical engineering, they enable accurate hole placement in the assembly of lenses, mirrors, and optical components. In the medical field, they deliver consistent hole geometry and size control, which is vital for implant safety and precision assembly.

They are equally valuable in the aerospace and automotive industries, where components demand extremely tight tolerances and involve materials that are difficult to machine. The accuracy, stability, and repeatability of the SMART CUT® 005DME drills ensure defect-free holes in these critical applications, preventing system failures due to dimensional deviations.