Optimizing your Diamond Dicing Performance

-

Posted by

Ayan Sadyk

Ayan Sadyk

Table of Contents

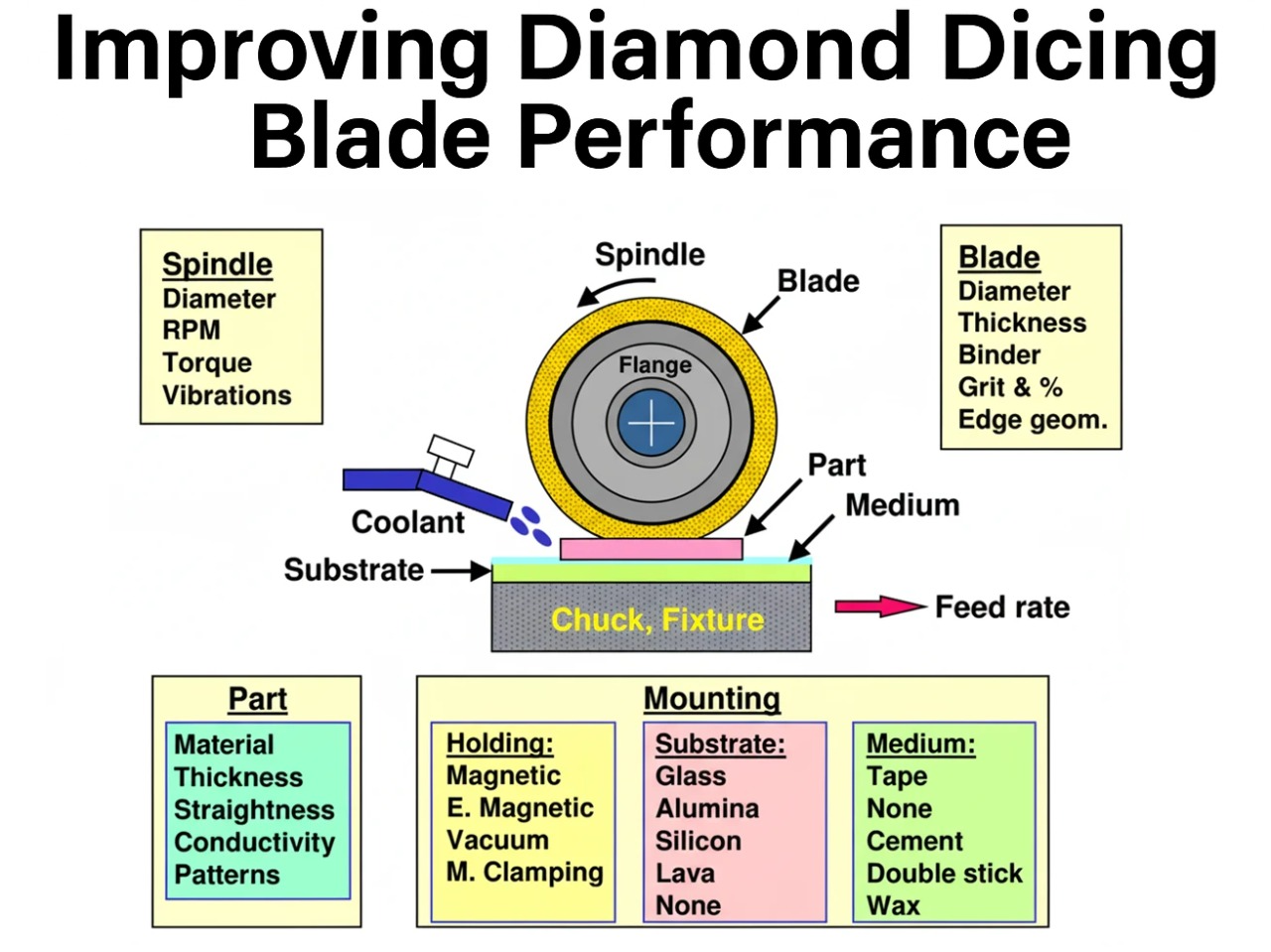

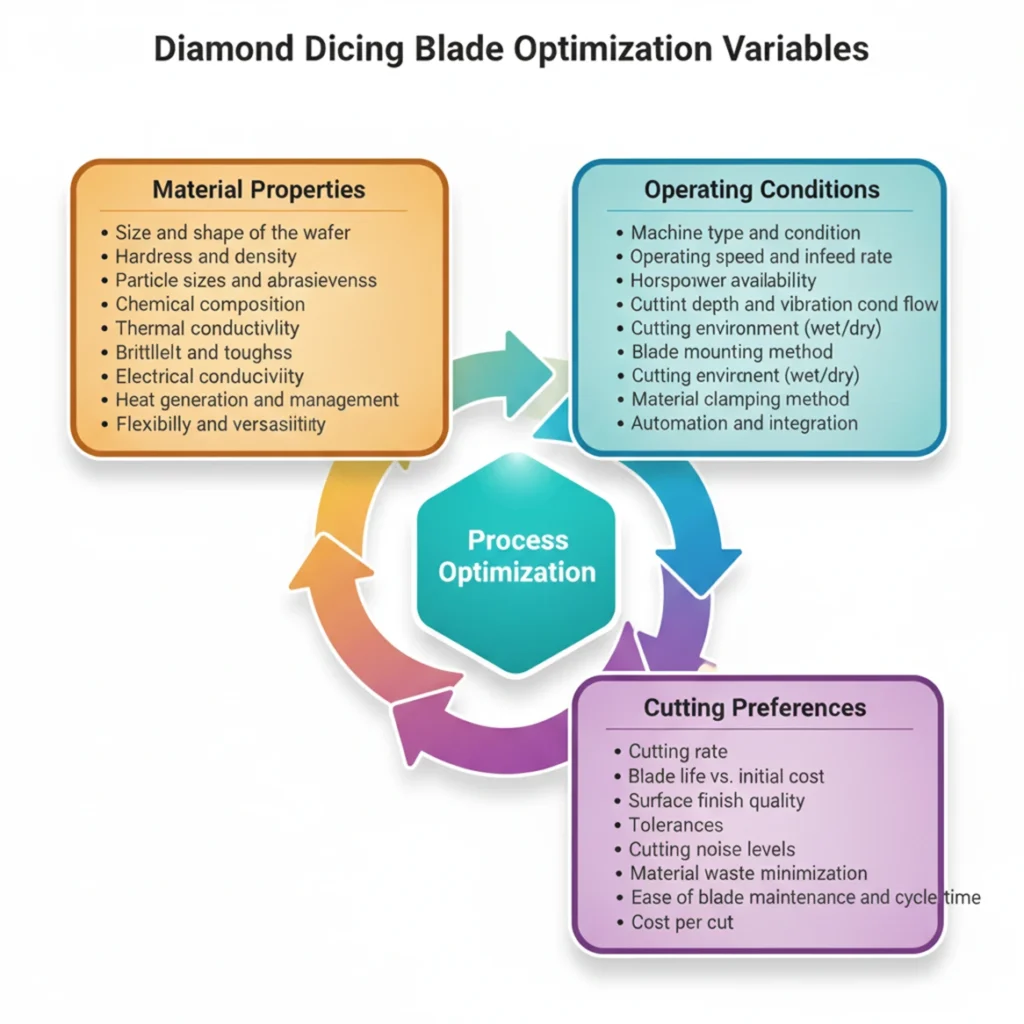

ToggleThe performance of diamond dicing blades is influenced by a wide range of interdependent variables, and understanding these factors is essential for selecting the correct blade specifications and optimizing the dicing process. Each parameter, whether related to the blade itself, the material being cut, or the operating conditions, is only one part of a larger system. Adjusting a single factor in isolation rarely produces efficiency. True optimization comes only when all parameters are properly balanced and work together as a system.

Even when blades are manufactured to the highest tolerances, process variation can still occur. Material hardness, bond strength, machine stability, coolant delivery, mounting accuracy, and operator technique all play critical roles. Just as in a mathematical equation, one incorrect variable can undermine otherwise well-selected factors, leaving the entire system inefficient. Many users approach dicing without complete knowledge of how these variables interact. This often results in setup mistakes, skipped steps, or misplaced blame directed at the blade itself when problems arise.

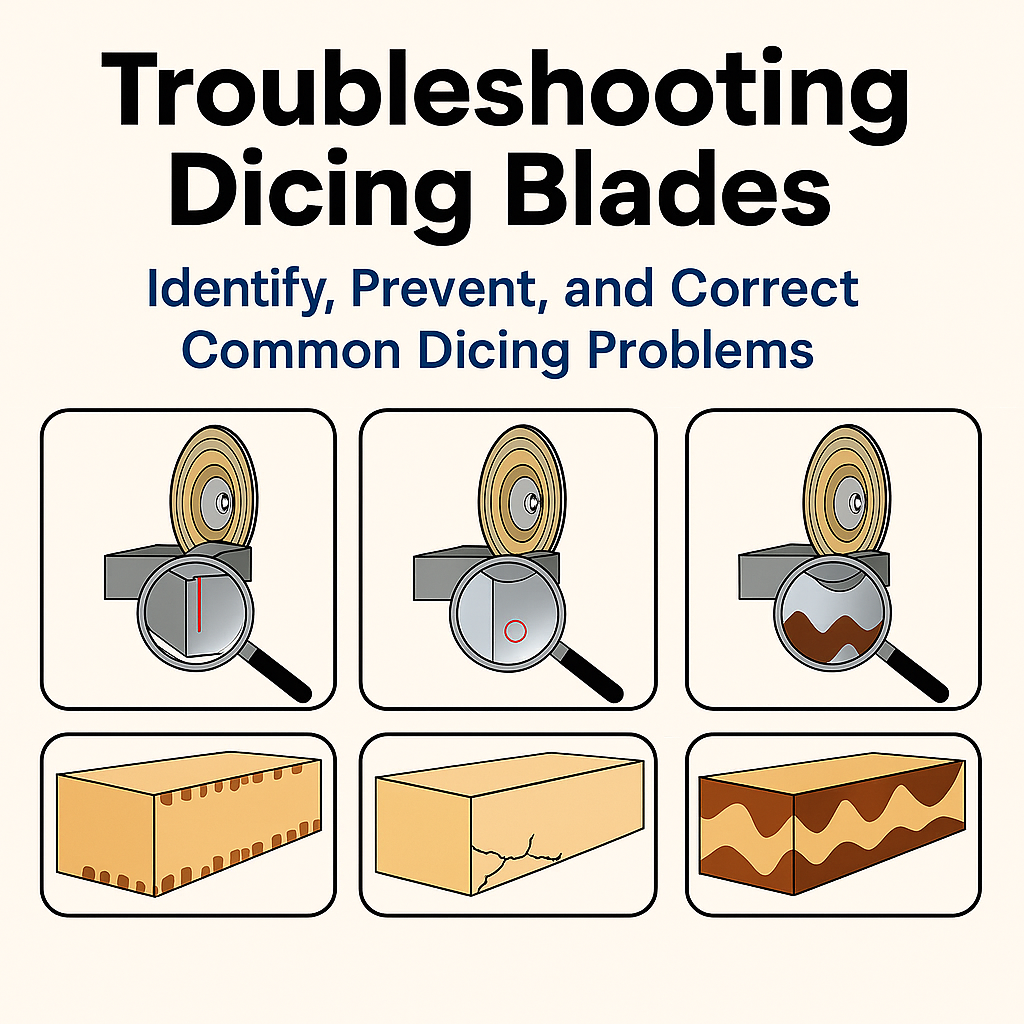

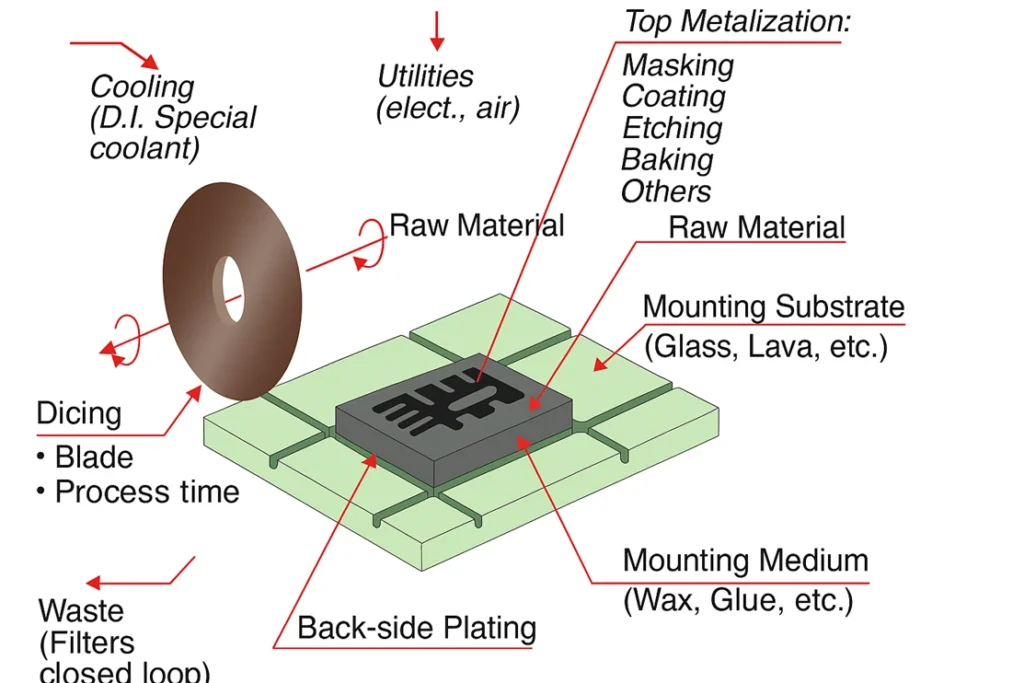

What may initially appear to be a serious blade defect can often be corrected by simple changes in the process. Examples include adjusting coolant flow direction or pressure, modifying mounting methods, changing spindle RPMs or feed rates, or ensuring that the blade is properly dressed. Recognizing that blade selection, machine setup, coolant delivery, and process control are interconnected is the key to achieving consistent and repeatable results.

Selecting the right combination of parameters for each material whether silicon, sapphire, ceramics, or glass is both a science and a skill that requires experience to master. Substrate hardness, brittleness, grain structure, and thermal conductivity determine the most effective combination of grit size, bond type, diamond concentration, and blade design. At the same time, machine horsepower, spindle speed, feed rate, coolant chemistry, and mounting stability define the operating window where the blade can perform reliably.

The challenge lies not only in choosing the right dicing blade specification but in creating a process environment where that dicing blade can operate at its full potential. Without proper coolant delivery, even the best dicing blade will generate heat, cause chipping, and fail prematurely. Without correct mounting, vibration and run-out will degrade accuracy. Without stable spindle speed and feed control, cut quality and die yield will be compromised. In every case, the solution is not to look at one variable in isolation but to consider the system as a whole.

The information presented in this article is based on both laboratory research and decades of field experience in diamond dicing applications. It reflects the reality that successful dicing is not about theory alone but about applying proven process optimization methods under real world production conditions. By focusing on process control, variation management, and feedback-driven optimization, manufacturers can achieve superior cut quality, higher throughput, longer blade life, and lower cost per cut.

The following sections highlight the most critical variables that govern diamond dicing blade performance and explain how each can be evaluated and adjusted for more stable, predictable, and profitable results.

Diamond Dicing Blade Process Optimization Variables

| Material Properties |

Operating Conditions |

Cutting Preferences |

|---|---|---|

|

Size and shape of the wafer influence street width selection and blade thickness. |

Machine type and condition determine indexing accuracy, vibration, and alignment stability. |

Cutting rate drives throughput but must be optimized against blade life and chipping risk. |

|

Hardness and density affect blade bond selection and grit size. |

Operating speed and infeed rate set throughput capacity but require torque monitoring to prevent BSC. |

Blade life vs. initial cost defines true cost per cut. Longer life blades often reduce total expenses. |

|

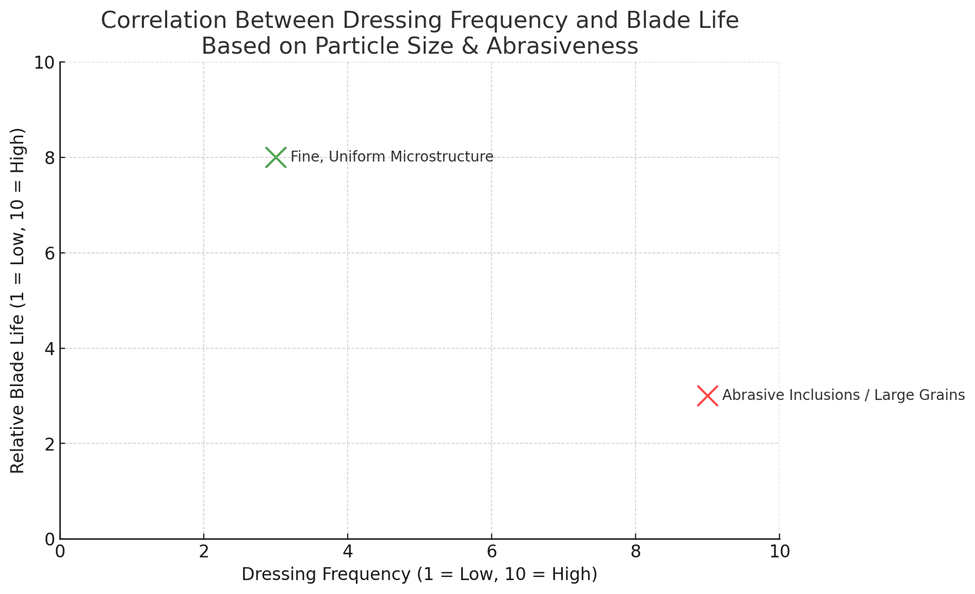

Particle sizes and abrasiveness influence diamond wear and dressing frequency. |

Horsepower availability impacts achievable feed rates and cut stability. |

Surface finish quality requirements dictate blade grit size and concentration. |

|

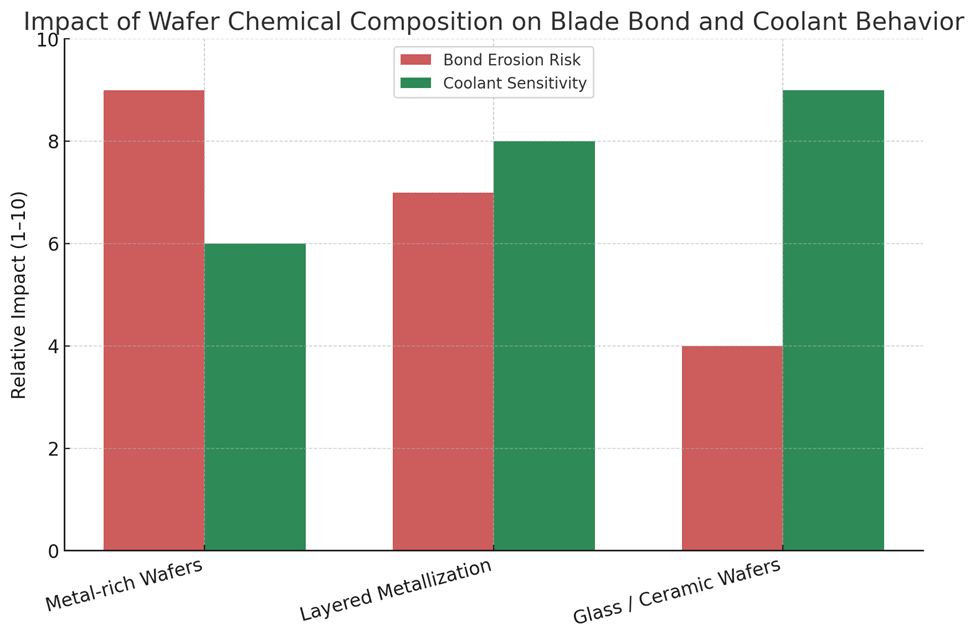

Chemical composition may interact with bond type or coolant chemistry. |

Coolant type, concentration, and flow manage heat, debris removal, and cleanliness. |

Tolerances and precision demand tighter alignment and blade control. |

|

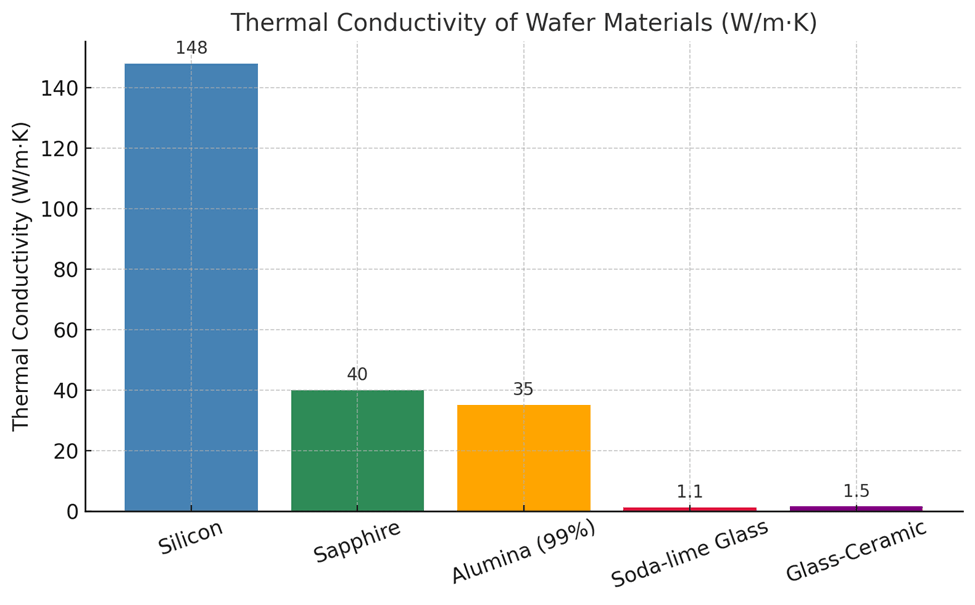

Thermal conductivity affects heat dissipation during cutting. |

Cutting depth and vibration control influence blade exposure and kerf stability. |

Cutting noise levels and environmental impact are reduced with optimized coolant and balanced setups. |

|

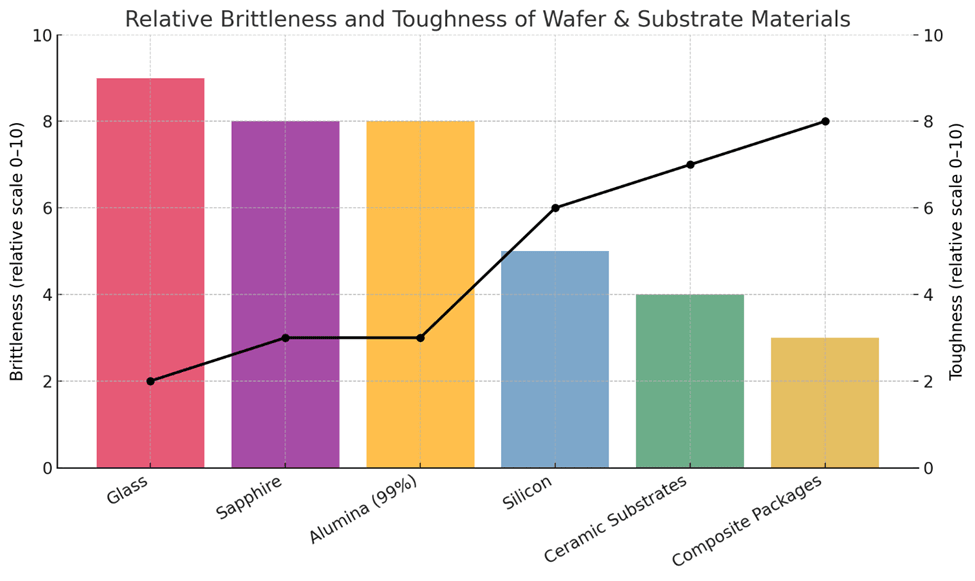

Brittleness and toughness determine chipping sensitivity and feed rate limits. |

Blade mounting method affects run-out, side wobble, and stability. |

Operator safety improves with stable coolant flow, minimal vibration, and automated handling. |

|

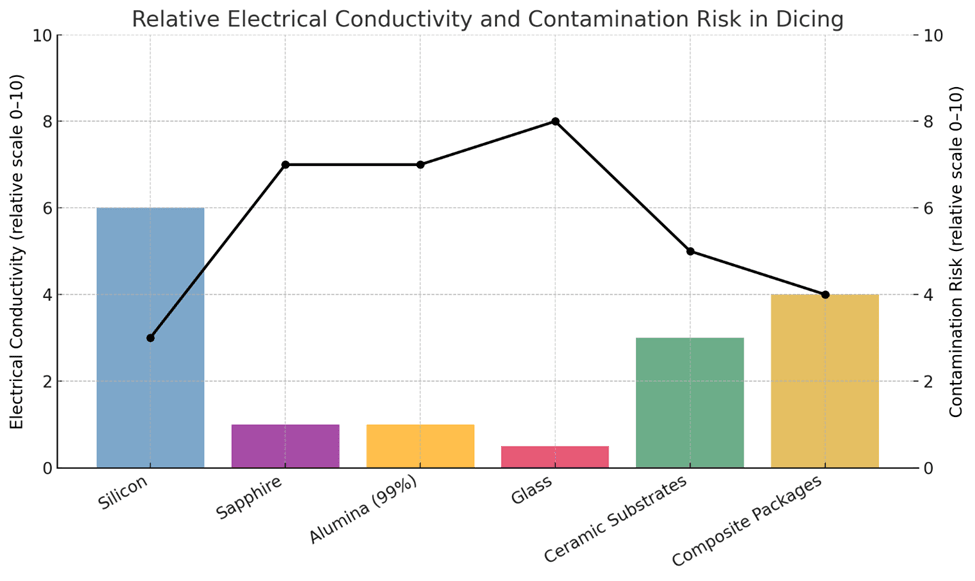

Electrical conductivity can affect downstream packaging needs. |

Cutting environment (wet/dry) influences cooling and contamination levels. |

Material waste minimization requires optimal kerf width and thin blades. |

|

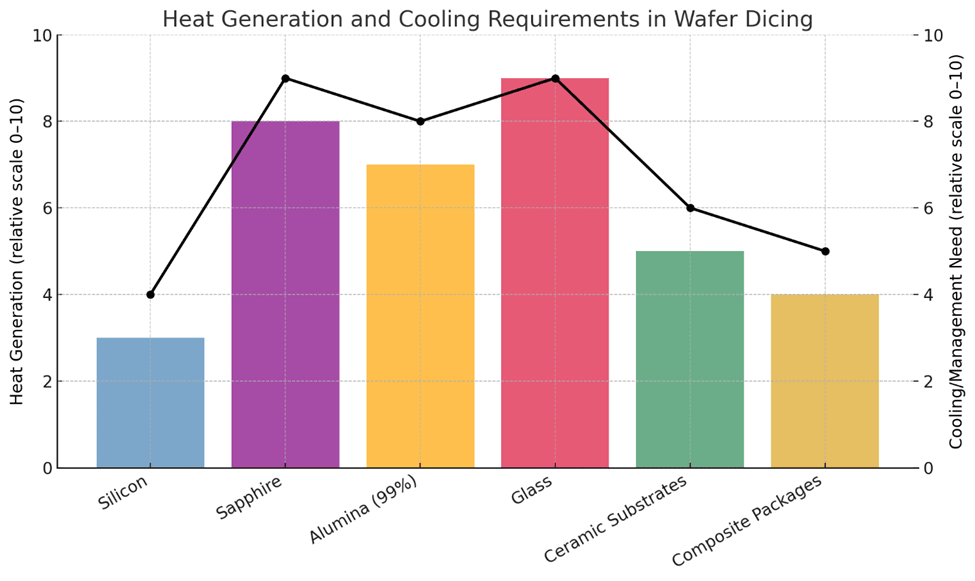

Heat generation and management influence both blade wear and wafer integrity. |

Material clamping method impacts vibration and placement accuracy. |

Ease of blade maintenance and cycle time affect overall throughput efficiency. |

|

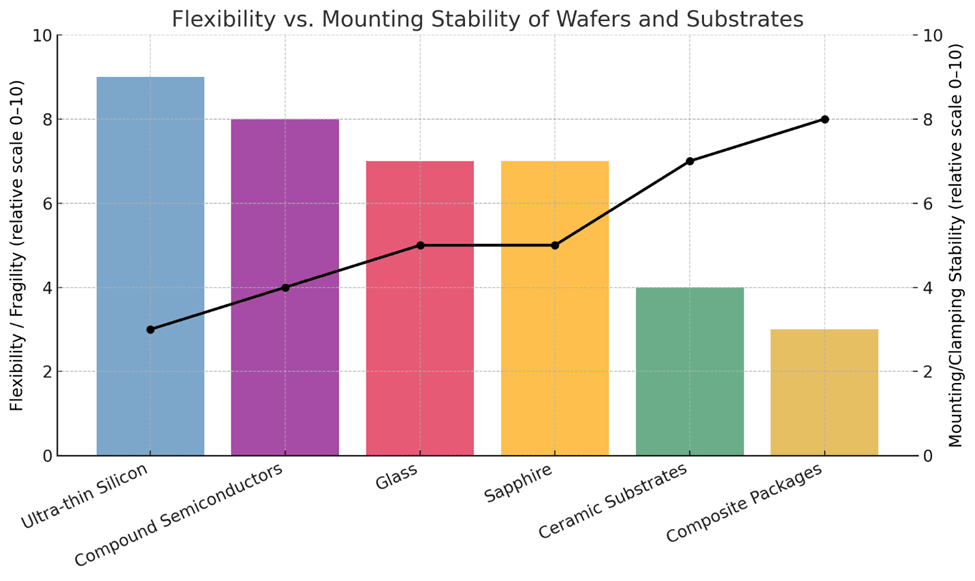

Flexibility and versatility of the substrate affect mounting and process repeatability. |

Automation and integration increase reproducibility and reduce operator errors. |

Cost per cut is the ultimate optimization metric combining blade, consumables, and yield. |

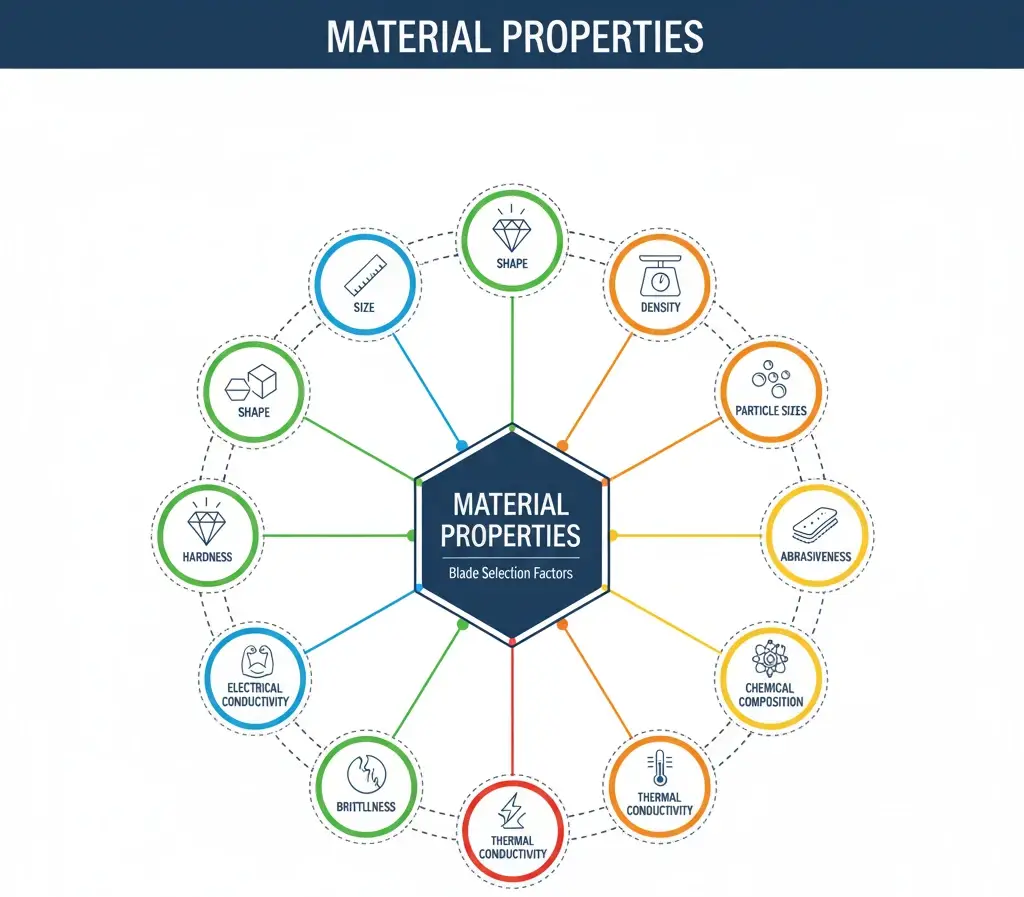

Material Properties and Their Role in Dicing Blade Optimization

Size & Shape of the Wafer or Substrate

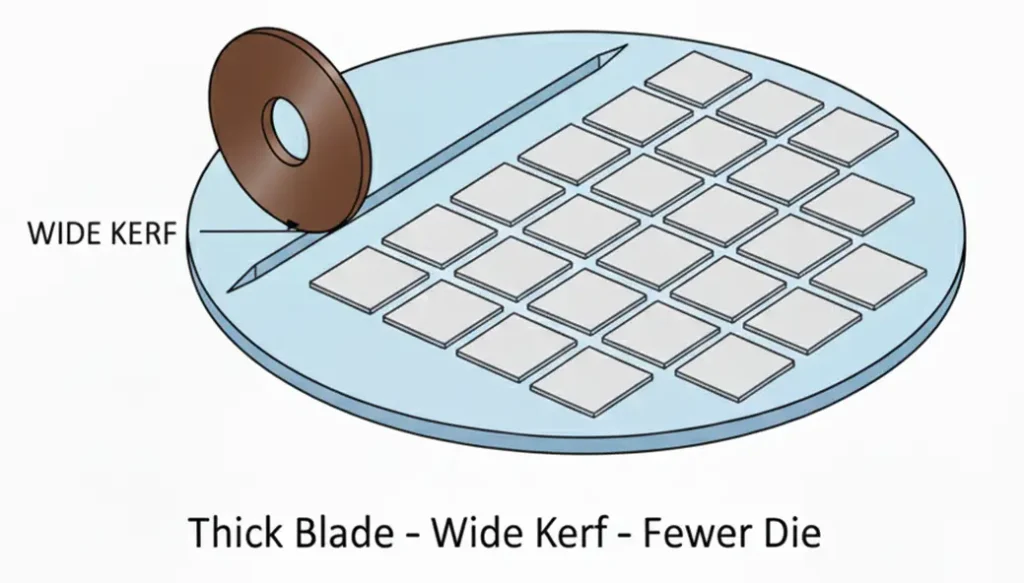

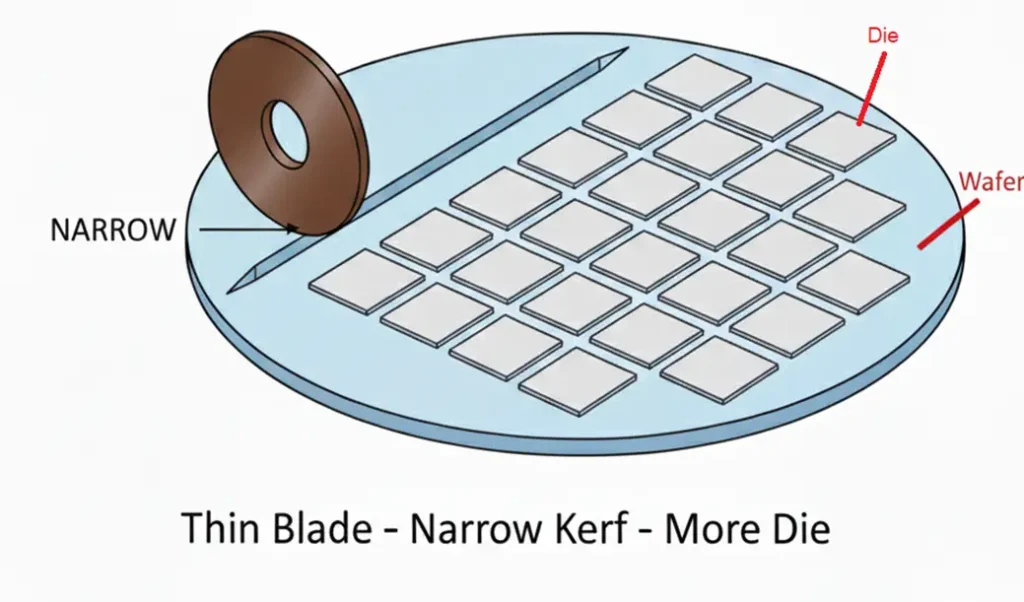

The size and shape of the wafer or substrate determine how narrow the dicing streets can be and directly influence the choice of blade thickness. Thinner blades reduce kerf width and increase the number of usable die per wafer, improving yield. However, they are less rigid and more sensitive to vibration, run-out, and feed rate changes. To maintain stability with ultra-thin blades, exposure must be minimized, flanges must be precise, and torque must be monitored closely.

Larger wafers add more cutting length and stress on the blade, increasing torque and wear. Irregular wafer shapes can cause uneven loading, requiring careful control of mounting and clamping to keep cuts stable. The optimization goal is to use the thinnest blade possible for the given street width, while still ensuring cut accuracy, acceptable blade life, and minimal chipping.

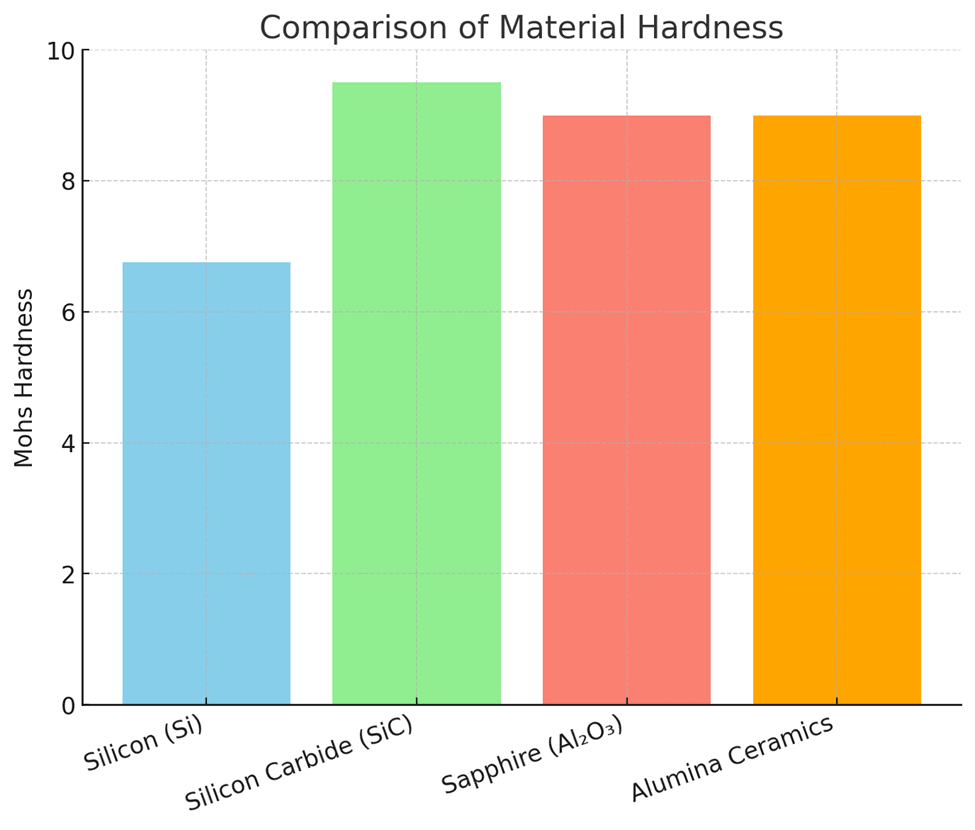

Hardness and Density

The hardness and density of the material (substrate or wafer) directly affect dicing blade performance and must be considered when selecting both the bond system and diamond grit size. Hard, dense wafers such as sapphire, SiC, or GaN place high mechanical stress on the blade. These materials require stronger Sintered (metal bond) Dicing Blades that can hold diamonds securely under load, combined with fine to medium grit sizes that minimize crack propagation and reduce back-side chipping. If grit is too coarse, subsurface fractures extend into the active die, lowering yield.

For softer or lower-density substrates like silicon or glass, smoother cutting action is more important than maximum bond strength. Resin Bond Dicing Blades or Hybrid Bond Dicing Blades paired with carefully chosen grit sizes provide cleaner kerfs, reduced edge roughness, and lower chipping risk. In these cases, slightly coarser grits can be used to improve throughput without sacrificing yield.

Optimization depends on balancing bond strength, bond hardness, and grit size with the wafer’s or substrate mechanical properties. Too soft a bond on a hard wafer causes rapid blade wear, while too hard a bond on a soft wafer increases vibration and chipping. Proper matching keeps torque stable, extends blade life, and maintains consistent cut quality across the wafer run.

Particle Size Distribution and Abrasiveness

The particle size distribution and abrasiveness of the substrate strongly affect how quickly diamonds wear and how often blades require dressing. Materials with large grains or abrasive inclusions such as alumina, quartz-filled substrates, or ceramic composites cause uneven cutting forces. This leads to accelerated diamond fracture, bond erosion, and blade loading. To maintain stable kerf quality, these materials demand more frequent dressing cycles to expose fresh diamonds and restore cutting sharpness.

In contrast, wafers with fine, uniform microstructures, such as silicon, typically cause less abrasive wear. Blades maintain sharpness longer, requiring less frequent dressing. However, if abrasiveness is underestimated and dressing intervals are extended too long, dull diamonds increase torque, generate more heat, and raise the risk of front- and back-side chipping (BSC).

Optimizing the process means setting a dressing schedule matched to the material’s grain structure and abrasiveness. This prevents excessive downtime while ensuring stable cutting performance. For highly abrasive substrates, torque monitoring provides a reliable on-line method of signaling when dressing is needed, reducing unnecessary blade changes and preserving yield.

Chemical Composition

The chemical composition of the material (wafer or substrate) can directly influence both blade bond performance and coolant behavior, making process customization essential. Certain materials contain elements that react with the bond, accelerating erosion and shortening blade life. For example, wafers with high metal content or layered metallization can wear down the bond unevenly, leading to unstable cuts and increased torque.

Coolant chemistry also plays a role. Some substrates release particles or by-products that interact with the coolant, altering its pH or lubricating ability. This can increase slurry buildup, reduce heat transfer efficiency, or leave residues on the wafer surface that affect downstream processing such as wire bonding or packaging.

To optimize the process, both bond formulation and coolant selection must be matched to the wafer’s chemistry. Metal-rich wafers may require a harder, more chemically resistant bond, while certain glass or ceramic wafers cut best with coolants formulated to reduce chemical interaction and maintain stable pH. Regular coolant monitoring and filtration further help prevent reactions that degrade performance over long runs.

Thermal Conductivity

The thermal conductivity of the wafer material plays a decisive role in process stability. High conductivity materials, such as silicon, dissipate heat away from the cut zone efficiently, allowing blades to operate at higher feed rates with lower risk of thermal stress. In contrast, low conductivity materials like glass, sapphire, or certain ceramics trap heat at the cutting interface. This localized buildup increases the risk of thermal damage, blade loading, and wafer warpage.

When heat is not removed effectively, diamonds dull faster, torque rises, and debris adheres to the blade. This not only shortens blade life but also leads to micro-cracking and back-side chipping (BSC), directly reducing yield. Warpage caused by uneven thermal expansion further complicates alignment and increases the risk of misplacement errors during dicing.

Optimization requires pairing material thermal properties with proper blade and coolant strategies. For low-conductivity wafers, operators should:

- Select bonds and diamond coatings that improve heat dissipation.

- Maintain high coolant flow rates and stable nozzle positioning to flush debris and carry heat away.

- Monitor torque values to detect early signs of thermal loading.

- Limit blade exposure to reduce friction and heat buildup.

Brittleness and Toughness

The brittleness and toughness of the material define how it responds to the stresses of dicing, whether cutting wafers, substrates, or microelectronic packages.

Brittle materials such as glass, sapphire, alumina, and some semiconductor packages are prone to micro-cracking and edge chipping. To protect yield, these materials require lower feed rates, fine-grit blades, stable coolant delivery, and minimal blade exposure. If the process is too aggressive, cracks propagate quickly into the active area of wafers or into the bond pads of packages, leading to functional failures.

Tougher materials, including silicon wafers, ceramic substrates, and composite microelectronic packages, can tolerate higher cutting loads. These applications benefit from stronger bonds and medium-grit blades, which allow faster throughput without compromising cut placement accuracy. Even so, poor mounting or vibration can still introduce internal stress that reduces device strength or reliability.

Optimization requires aligning grit size, bond type, feed rate, and coolant flow to the mechanical behavior of the material. For brittle wafers or packages, the focus is on reducing crack initiation and propagation. For tougher substrates, the goal is maximizing throughput while maintaining stable blade wear and torque levels.

Electrical Conductivity

The electrical conductivity of the material can affect downstream packaging steps, especially where residues or conductive debris may interfere with device performance. When conductive particles generated during dicing remain on the wafer surface, they can create shorts, weaken insulation, or compromise the integrity of wire bonding, flip-chip attachment, or molding compounds. Even small amounts of contamination can reduce device reliability or yield.

Maintaining cleanliness during dicing is therefore critical. Proper coolant delivery and filtration remove debris from the kerf and prevent redeposition on pads or die edges. Blades selected for conductive substrates should be paired with optimized coolant flow and chemistry to ensure debris disperses quickly and does not agglomerate in slurry.

Process optimization also includes minimizing blade loading and torque fluctuations, since these conditions release larger fragments that are more difficult to flush away. In applications where device reliability is highly sensitive, wafers may undergo additional cleaning or inspection steps, but the most cost-effective strategy is preventing contamination at the source.

Heat Generation and Management

The heat generated during dicing directly impacts both blade performance and wafer integrity. Excessive heat leads to bond softening, which weakens diamond retention and accelerates blade wear. It also promotes diamond pullout, dulling the blade and forcing higher torque that further destabilizes the process. On the wafer side, uncontrolled heat causes thermal cracking, warpage, and stress fractures, which reduce die strength and yield.

Effective heat management is therefore essential to stable dicing. The most important control factor is the coolant system. Proper delivery, flow, and pressure remove heat from the cut zone, flush away debris, and prevent slurry from baking onto the blade surface. Filtration is equally important recirculating debris increases friction, raises torque, and undermines thermal control.

Optimization requires a coordinated approach:

- Match bond thermal conductivity to the material’s heat dissipation characteristics.

- Keep blade exposure short to minimize friction and reduce localized heating.

- Ensure coolant nozzles are properly aligned and flow is stable.

- Maintain clean filters to prevent slurry recirculation.

- Use torque monitoring to detect early signs of thermal load.

Flexibility and Versatility of the Wafer / Substrate

The flexibility and versatility of the substrate influence how reliably it can be mounted and clamped during dicing. Thin or fragile wafers and substrates, including ultra-thin silicon, compound semiconductors, or laminated microelectronic packages, are especially sensitive to stress. If they are not fully supported, they can deflect under cutting forces, causing blade wobble, torque fluctuations, and misaligned cuts. Even small amounts of bending can shift the kerf away from the intended street, resulting in yield loss or die damage.

For these applications, uniform and stable mounting is critical. Dicing tapes, waxes, or vacuum chucks must provide even support across the entire substrate surface. Any voids, bubbles, or uneven clamping increase the risk of vibration, misplacement, and micro-cracking. Repeatability is equally important consistent mounting procedures ensure that every wafer or package sees the same mechanical stability, reducing variation between cuts.

Optimization strategies include using appropriate tapes and adhesives matched to substrate thickness, minimizing blade exposure to reduce mechanical load, and carefully monitoring torque to detect signs of deflection. For ultra-thin or delicate substrates, process engineers often reduce feed rate and increase coolant flow to further limit mechanical and thermal stress.

Operating Conditions for Diamond Dicing Blade Optimization

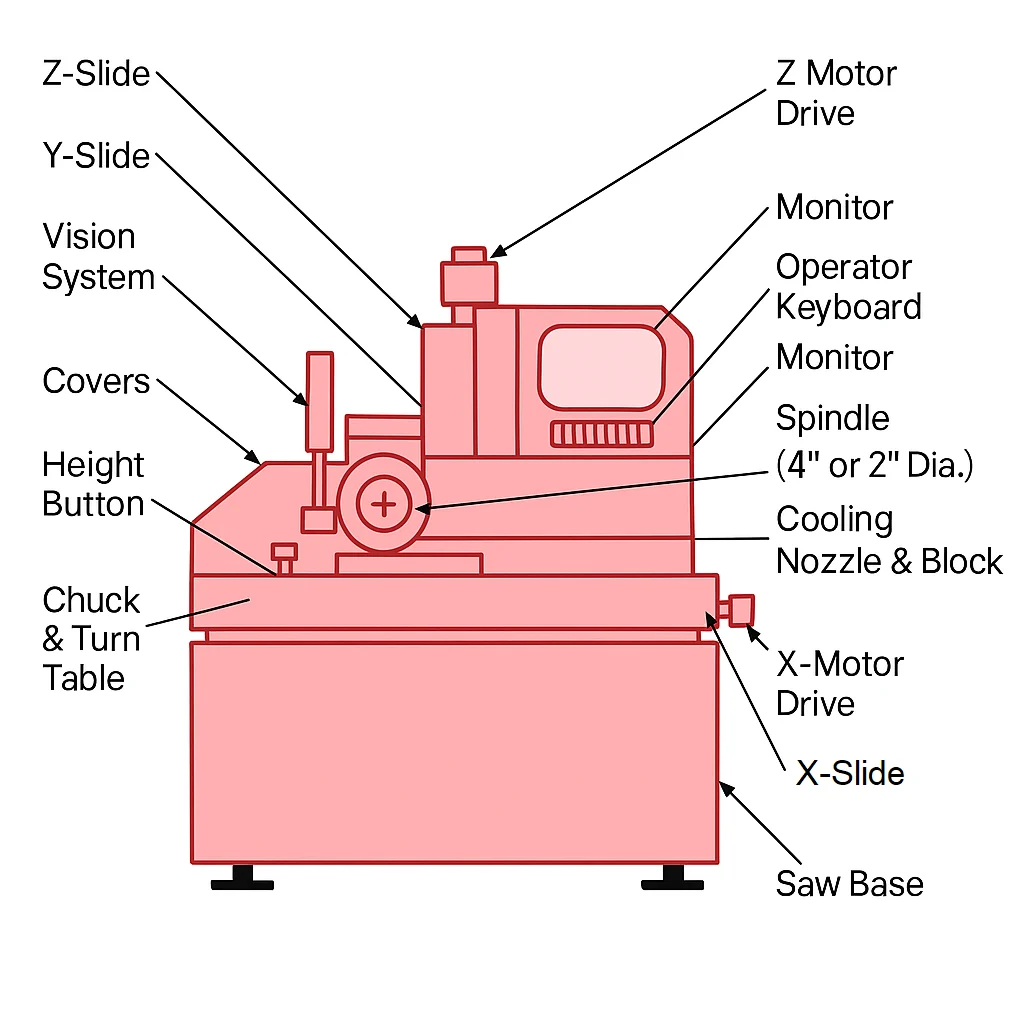

Type and Condition of the Dicing Machine

The type and condition of the dicing machine form the baseline for process stability and yield. Even the best-optimized blade cannot perform consistently if the machine introduces vibration, misalignment, or run-out. High-precision systems with rigid spindles, stable axes, and advanced alignment algorithms enable tighter tolerances, smoother cuts, and repeatable performance across wafers or packages.

Every major component plays a role. Spindle bearings must rotate smoothly at high RPM without axial or radial play. Worn bearings generate vibration that transfers directly to the blade, causing micro-cracks, uneven kerfs, and premature chipping. Guide rails and indexing systems control cut placement accuracy; any slack or backlash reduces precision and raises the risk of cutting outside the street. Calibration of optical and alignment systems ensures cuts are placed within microns, which is critical for narrow-street wafers.

Degradation in any of these areas leads to run-out, side wobble, and torque instability. These issues shorten blade life, increase front-side and back-side chipping, and reduce yield. That’s why preventive maintenance is not just a reliability task but a key process optimization strategy. Regular spindle checks, rail lubrication, vibration monitoring, and optical recalibration all help maintain consistent cut quality.

Modern dicing systems also integrate real-time monitoring of torque, vibration, and coolant flow. These signals alert operators to deviations caused by machine wear before they impact yield. By combining machine maintenance with process monitoring, manufacturers can keep the cutting environment stable, extend blade life, and optimize throughput.

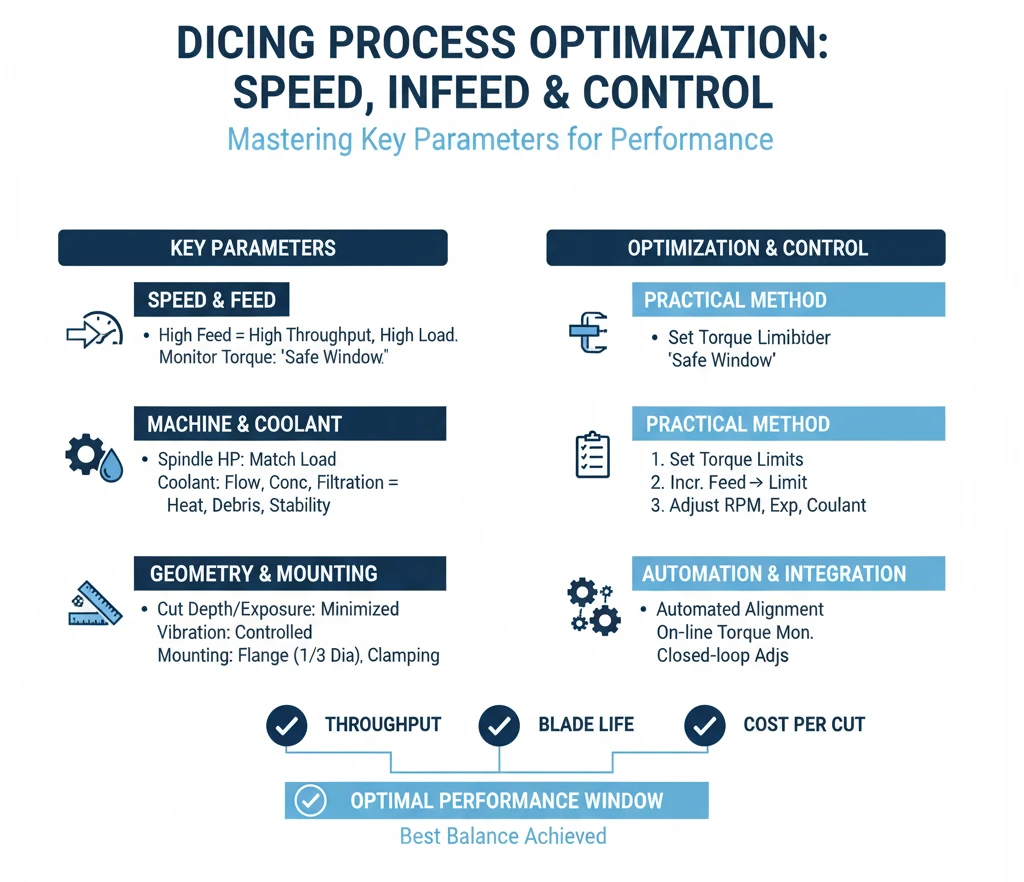

Operating Speed and Infeed Rate

The operating speed and infeed rate are two of the most influential parameters in dicing, since they directly determine throughput. Pushing the feed rate higher increases wafer or package output per hour, but it also increases the cutting load on the blade. If the load exceeds the blade’s design limit, torque rises, the bond begins to wear unevenly, and back-side chipping (BSC) develops.

Optimization requires working within a defined torque window for each blade and material. By monitoring torque in real time, operators can identify the maximum feed rate that maintains process stability. This allows production to run at the highest safe throughput without compromising cut quality or die reliability.

The spindle speed must also be balanced with the feed rate. Running at higher RPM increases cutting efficiency, but if the infeed is too aggressive, even a fast-spinning blade will overload and fracture wafers at the edges. Conversely, too slow a feed wastes production time and accelerates blade wear through unnecessary friction.

Practical optimization means:

- Establishing torque limits for each material-blade setup.

- Incrementally increasing feed until torque approaches that limit.

- Adjusting spindle speed, blade exposure, and coolant delivery to maintain stable cutting forces.

When feed and speed are optimized in this way, manufacturers achieve the best balance of throughput, blade life, and yield, keeping cost per cut under control.

The spindle horsepower determines how efficiently the blade can maintain speed under load. Adequate horsepower keeps cuts stable at higher feed rates, while insufficient power forces slower cutting and creates torque fluctuations. Matching horsepower to blade size and wafer hardness ensures consistent results.

Coolant delivery, concentration, and filtration are among the most critical factors in process optimization. Properly applied coolant removes debris from the kerf, reduces blade loading, and dissipates heat. If flow is uneven or concentration is incorrect, torque stability suffers, chipping increases, and wafer surfaces risk contamination. Filtration is equally important recirculating slurry or particles accelerates blade wear and redeposits debris on wafer surfaces. Optimized nozzle positioning, stable flow, and regular filter maintenance ensure coolant performs effectively.

Cutting depth and vibration control influence blade stability and kerf quality. Deeper cuts with excessive exposure increase blade deflection, while poor vibration control leads to micro-cracks and kerf deviation. Optimizing blade exposure to the minimum required length, combined with vibration-damping machine design, improves both yield and blade longevity.

The blade mounting method directly impacts run-out and cut precision. Proper flange size, flatness, and clamping pressure are essential for stability. For dicing blades, flanges should be at least one-third of the blade diameter to minimize wobble. Incorrect mounting increases torque variation, accelerates wear, and raises the risk of breakage.

The material clamping method also influences cut quality and wafer integrity. Adhesives, tapes, or vacuum chucks must provide uniform support to prevent wafer shifting and deflection. Poor clamping introduces stress, which magnifies chipping and reduces die strength.

Finally, automation and integration play a growing role in process optimization. Automated alignment, on-line torque monitoring, and closed-loop parameter adjustments reduce operator variability and ensure reproducibility across wafers and shifts. This stability allows dicing to be performed closer to the process limits maximizing throughput without sacrificing yield.

Diamond Dicing Blade Properties – Optimization Chart

|

Property |

Process Impact |

Optimization Benefit |

|---|---|---|

|

Diamond Grit Size |

Fine grit = smoother kerf, less chipping; coarse grit = faster cut but more BSC |

Match grit to wafer material and finish requirements to balance speed and quality |

|

Diamond Type |

Monocrystalline = sharp, fast cutting; polycrystalline = tougher, longer life |

Select type based on whether throughput or blade longevity is the priority |

|

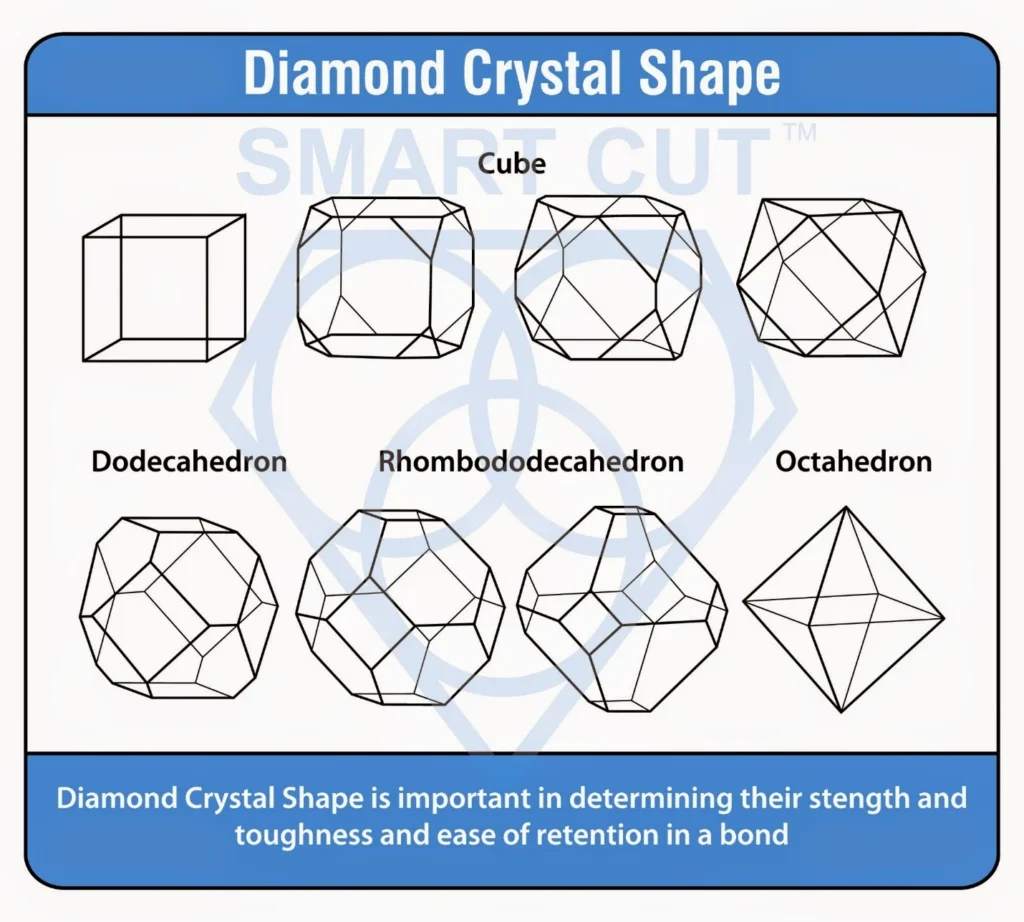

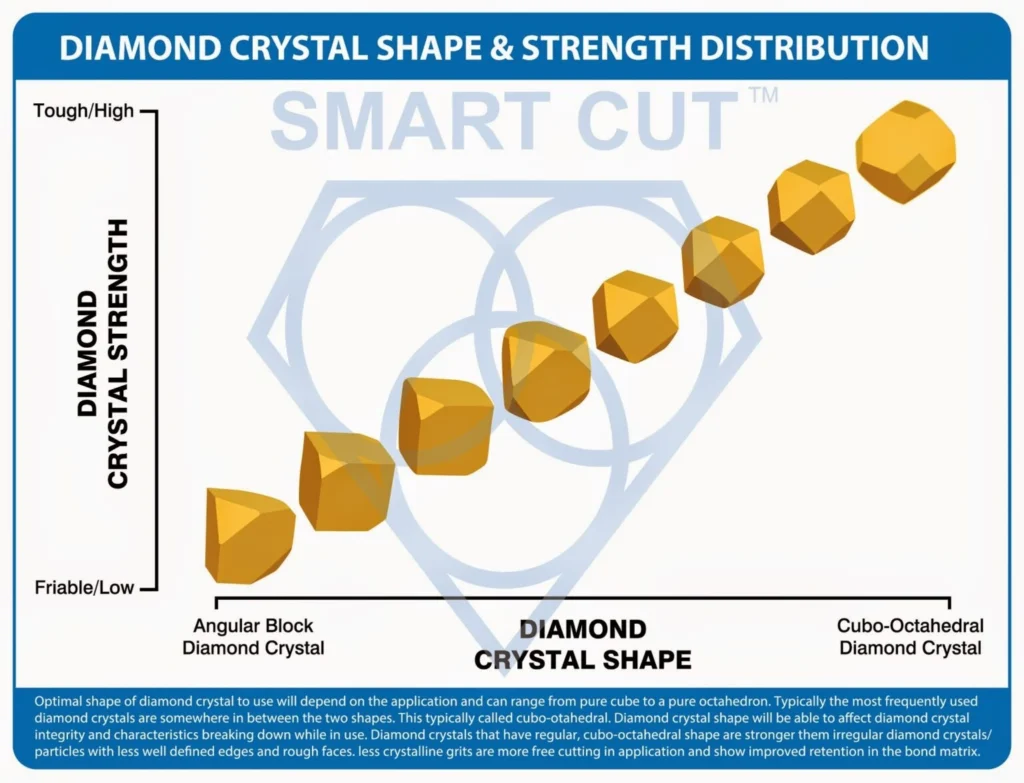

Diamond Shape |

Blocky/cubic shapes = stronger, longer life; irregular = faster wear but self-sharpening |

Improves stability and reduces dressing frequency |

|

Diamond Quality/Grade |

High-purity particles cut cleaner, reduce heat, minimize pullout |

More consistent cut quality and longer usable blade life |

|

Diamond Coating |

Nickel/titanium coatings improve bond retention, heat transfer |

Extends blade life and maintains sharpness under load |

|

Friability |

Controlled fracture exposes new sharp edges |

Reduces need for frequent dressing, stabilizes performance |

|

Thermal Stability |

Resistance to breakdown at high RPM and local heat |

Prevents premature diamond degradation and yield loss |

|

Bond Type |

Metal = rigid, durable; resin/hybrid = smoother cut, lower chipping |

Choose bond for material type and required cut quality |

|

Bond Hardness |

Softer = sharp but short life; harder = long life but needs dressing |

Balance sharpness with blade longevity to lower cost per cut |

|

Diamond Concentration |

High = efficient, less chipping, higher torque; low = less force, faster wear |

Match concentration to wafer hardness and feed rate |

|

Bond Wear Resistance |

Maintains exposure of diamonds, resists erosion |

Stabilizes cut quality across longer production runs |

|

Bond Thermal Conductivity |

Dissipates heat, prevents loading and wafer damage |

Keeps torque stable and protects wafer integrity |

|

Blade Thickness |

Thinner = higher die yield, less stiffness; thicker = stable, wider kerf |

Optimize kerf width for max yield while ensuring stability |

|

Blade Exposure |

Longer = more deflection, unstable cuts; shorter = stable |

Improves precision and reduces vibration-related chipping |

|

Run-out Stability |

Poor mounting or flange control increases wobble |

Straight, repeatable cuts with reduced micro-cracking |

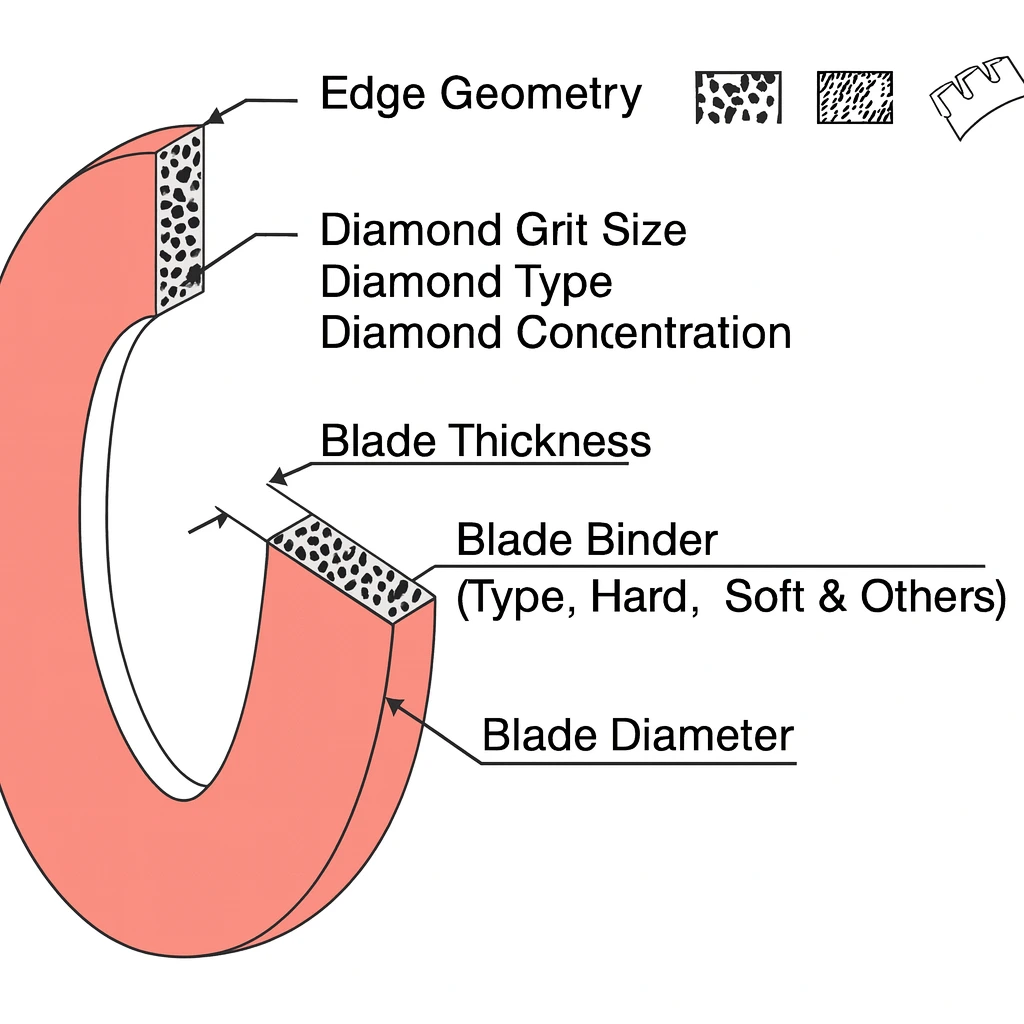

Diamond Dicing Blade Properties for Process Optimization – Diamond Properties

Diamond Characteristics

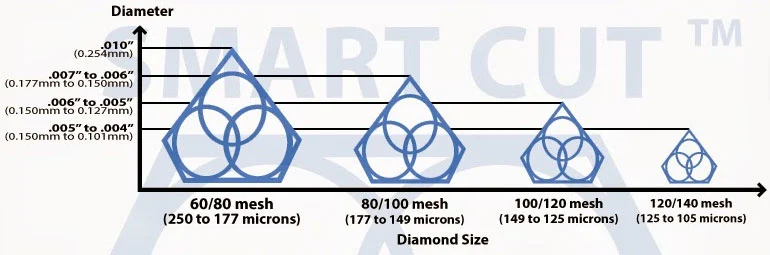

Diamond Grit size plays a defining role in process optimization. Finer grits cut slower but produce smoother kerfs with less front-side and back-side chipping (BSC), making them ideal when die strength and edge integrity are critical.

Coarser grits increase cutting speed and throughput but create more micro-cracks and rougher edges. The optimal grit size is chosen by balancing throughput demands with acceptable chip levels for the device.

Diamond type directly affects cutting efficiency and blade life. Monocrystalline diamonds cut sharply, offering fast material removal and cleaner kerfs at the start, but they fracture more easily under stress. Polycrystalline diamonds contain many micro-crystallites, giving them superior toughness and better resistance to impact forces, which leads to longer blade life and more consistent cut quality in high-volume runs.

Diamond shape influences stability and dressing needs. Blocky or cubic particles provide greater strength, resist premature fracture, and extend blade life. Irregular particles break down more readily, creating self-sharpening edges that improve short-term sharpness but shorten overall service life. The correct shape depends on whether the process prioritizes longevity or sharpness.

Diamond quality and grade determine consistency of performance. High-purity diamonds with fewer inclusions cut more evenly, generate less frictional heat, and resist premature pullout from the bond. Lower-quality diamonds with more defects lead to erratic cutting, higher torque, and increased chipping. For critical wafer applications, high-grade, low-defect diamonds are essential to maintain tight tolerances.

Diamond coatings such as nickel or titanium are applied to improve retention within the bond. These coatings also aid heat transfer away from the cutting edge, which helps stabilize torque at high spindle speeds. Coated diamonds improve process consistency, extend blade life, and reduce the frequency of dressing.

Friability describes the ability of a diamond to fracture under load. Diamonds with controlled friability self-fracture to expose fresh cutting edges, maintaining sharpness during extended runs. Low friability particles stay intact longer but risk dulling the blade if not supported by proper dressing. Too high friability, however, results in rapid wear and shortened blade life.

Thermal stability is critical because dicing is always performed wet, but localized heat still develops at the cutting edge. Diamonds must resist graphitization and thermal breakdown under high spindle speeds and contact pressure. Thermally stable diamonds maintain sharpness longer, reduce BSC risk, and improve wafer reliability by preventing thermal stress cracks.

Properties for Diamond Dicing Blade Optimization - Bond and Geometry

Bond type is one of the most important factors in determining dicing blade performance. For wafers and substrates, the most common choices are resin bond and nickel bond. Resin bond dicing blades deliver low chipping and smooth surfaces, making them suitable for silicon, GaAs, LiNbO₃, quartz, glass, and many brittle substrates. Nickel bond dicing blades provide greater rigidity, tighter dimensional control, and ultra-thin kerfs, which are often required for advanced semiconductor wafers, multilayer substrates, and composite materials.

When it comes to microelectronic packages, bond selection becomes even more application-specific. Resin bond dicing blades are widely used for BGAs, QFNs, CSPs, and other packages where minimizing edge chipping and delamination is critical. Nickel bond dicing blades are selected when package density, metal layers, or stacked structures demand precise profile control and higher blade stiffness.

Metal bond dicing blades are generally used less in wafer singulation but remain valuable for ceramics, sapphire, and very hard packaging materials, where durability and long blade life outweigh the need for extremely low chipping. Vitrified bonds are chosen in specialized cases, such as edge trimming or very hard substrates like SiC, sapphire, and certain ceramic packages.

Selecting the proper bond type depends on the material composition, package design, required cut quality, and production priorities. The right match ensures higher yield, stable throughput, and consistent performance across both wafers and electronic packages.

Bond hardness balances sharpness with blade longevity. Softer bonds release worn diamonds quickly, exposing fresh edges and maintaining sharp cuts but shortening blade life. Harder bonds hold diamonds longer, extending life but requiring dressing to prevent dulling and torque rise. The goal is to use the softest bond that still achieves the planned blade life at the target feed rate.

Diamond concentration affects efficiency and stability. Higher concentration provides more cutting points, reducing chipping and producing more stable kerfs, but it increases torque and heat generation. Lower concentration reduces cutting forces and torque but shortens blade life. The optimal concentration is set by wafer hardness, feed rate, and coolant effectiveness.

Bond wear resistance is critical for long production runs. A wear-resistant bond maintains diamond exposure and prevents rapid kerf widening or edge roughness. Stable wear resistance reduces variation between wafers and minimizes mid-lot blade changes.

Bond thermal conductivity is essential for dissipating heat from the cutting zone. High conductivity reduces thermal loading, prevents slurry buildup, and protects wafer edges from thermal stress. This property works in combination with coolant flow and filtration to keep torque stable and kerfs clean.

Blade thickness (kerf width) directly impacts die yield and cut stability. Thinner blades maximize die count but reduce stiffness, requiring better vibration control and precision mounting. Thicker blades increase stability but widen the kerf, reducing the number of usable dice per wafer. The correct thickness depends on street width, wafer material, and tolerance requirements.

Blade exposure refers to the amount of blade protruding beyond the flanges. Excessive exposure increases deflection, vibration, and chipping. Minimizing exposure improves precision, kerf straightness, and blade stability. Always keep exposure as short as possible while still meeting cutting depth requirements.

Run-out stability is essential for repeatable, high-precision dicing. Poor flange flatness, improper mounting, or contamination between the blade and flange increases wobble, causing kerf deviation, micro-cracking, and early blade wear. Stable, clean, and properly sized flanges typically at least one-third of blade diameter—ensure straight, repeatable cuts with minimal chipping.

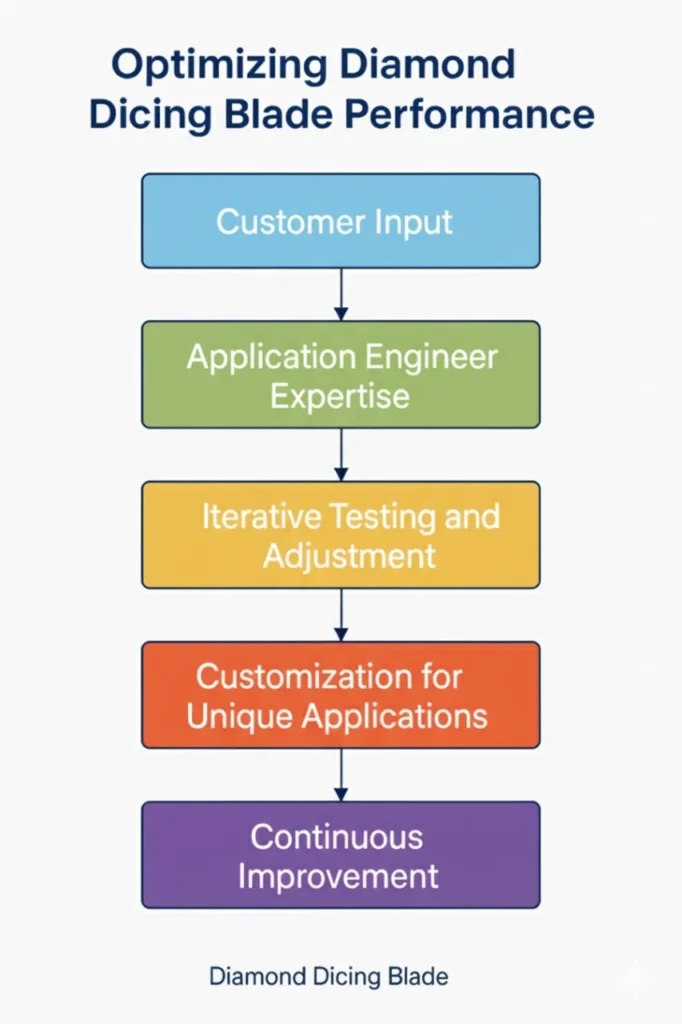

The Process of Optimizing Diamond Dicing Blade Performance

Achieving optimal performance from a diamond dicing blade requires selecting the precise combination of diamond properties, bond system, and process parameters that best fit the application. Optimization is not a one-time adjustment—it is a structured, collaborative process that balances throughput, blade life, and cut quality.

Customer Input & Operator Experience

The customer’s input is the foundation of the optimization process. Accurate, detailed data about the application ensures that blade selection and process adjustments are based on real operating conditions rather than assumptions. Critical details include material type, wafer or package thickness, street width, mounting method, and coolant setup. Each of these factors directly affects blade behavior and cutting performance.

Equally important is feedback on actual blade performance in production. Information about front- and back-side chipping, kerf width stability, cut placement accuracy, and blade wear rate provides measurable benchmarks. Without this data, optimization becomes guesswork, leading to wasted time, higher costs, and unnecessary blade trials.

Process conditions must also be clearly communicated. Changes in spindle speed, feed rate, or coolant delivery can alter torque levels and cause performance shifts. Operators should record these changes and their results so engineers can connect specific conditions to performance outcomes.

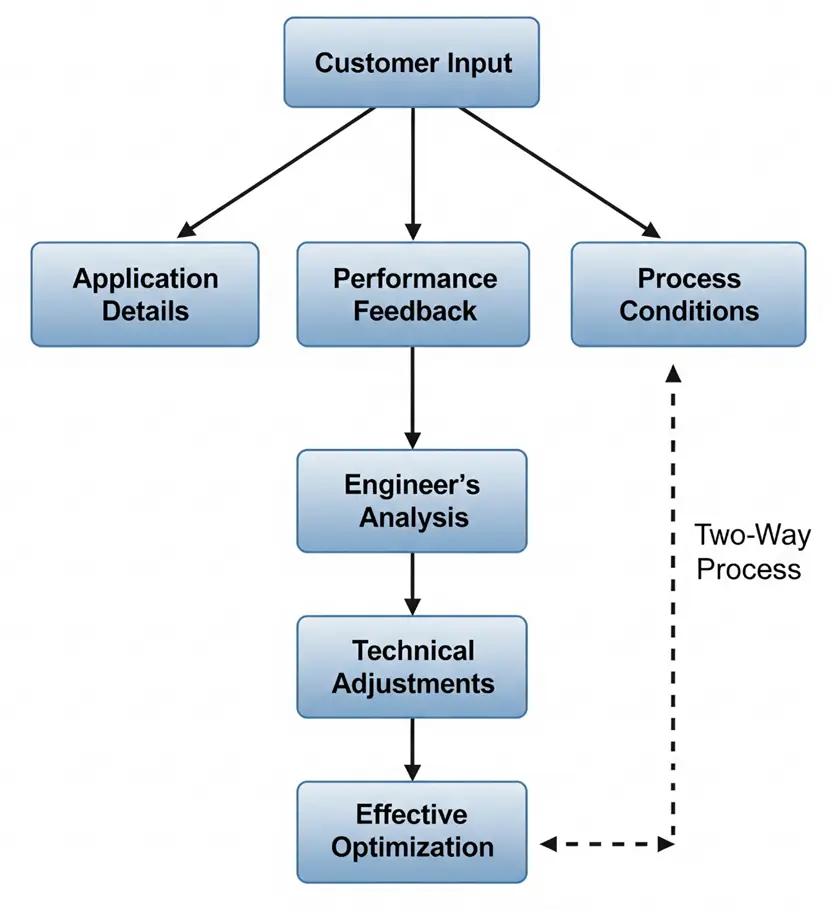

The more complete and consistent the customer’s input, the faster an application engineer can propose meaningful modifications such as adjusting diamond grit size, concentration, or bond hardness to align the blade with the target performance. Effective optimization is always a two-way process, where precise customer data drives accurate technical adjustments.

The operator’s skill and experience have a direct impact on the performance of diamond dicing blades, whether the process is carried out on fully automatic dicing saws or manually operated systems. Skilled operators who understand setup, mounting, coolant delivery, and parameter adjustments often achieve the best blade life, cut quality, and throughput. Less experienced users may see only partial results, even when using the same blade specifications.

Many end users begin the dicing process without complete or accurate knowledge of the setup steps. This often leads to mistakes such as improper blade mounting, incorrect spindle speeds, or inadequate coolant flow. When problems arise, the response is usually to address visible symptoms (such as chipping or premature wear) rather than identifying the underlying cause. This can lead to misdiagnosing issues and placing blame on the blade itself.

In practice, most performance variations can be corrected by reviewing the process. Simple adjustments such as modifying feed rates, RPMs, coolant pressure, or dressing procedures can resolve what may seem like serious blade defects. Unfortunately, few operators take the time to carefully evaluate and adjust their process, which can result in frustration and unnecessary downtime.

Proper training, documentation, and a systematic approach to troubleshooting are essential for maximizing diamond dicing blade performance. When operators are well-informed and consistent, blades reach their intended life, maintain tight tolerances, and deliver the cut quality required for demanding applications in semiconductors, optics, ceramics, and other advanced materials.

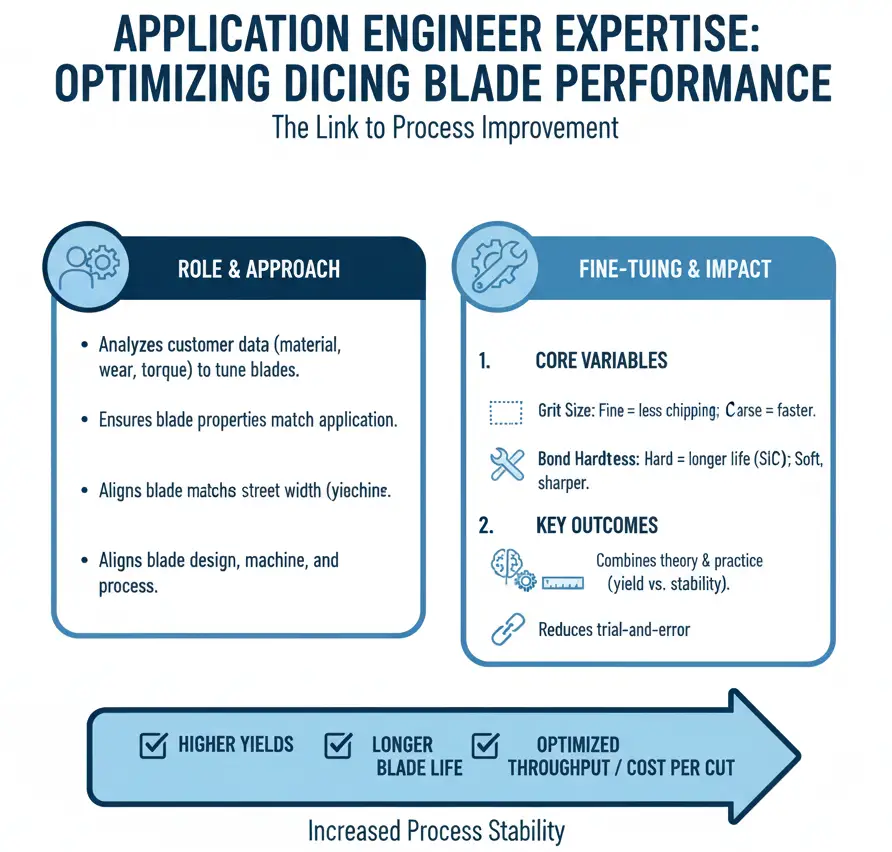

Application Engineer Expertise

Application engineer expertise is the link between customer input and real process improvements. Engineers analyze the data provided by the customer material type, street width, cut quality, blade wear, and torque behavior and translate it into specific blade design adjustments. Their role is not just recommending a blade off the shelf but ensuring that the blade’s properties are tuned to the application.

Fine-tuning begins with the core variables: diamond grit size, concentration, bond hardness, and blade thickness. Each has a direct impact on yield, throughput, and cost per cut. For instance, switching from a coarse to a fine grit reduces back-side chipping in brittle materials such as glass or sapphire. In contrast, adjusting bond hardness can significantly extend blade life when cutting hard, dense wafers like SiC. Engineers also optimize blade thickness to match street width, balancing maximum die yield with the stability needed for long production runs.

Application engineers combine theoretical knowledge and practical experience. They understand how materials with different hardness, density, and brittleness behave under cutting forces, and they use torque monitoring data and inspection feedback to guide adjustments. Their expertise allows them to distinguish between problems caused by blade design and those caused by machine condition, mounting, or coolant delivery.

By working closely with customers, application engineers ensure that blade design, machine parameters, and process setup are aligned. This collaboration produces stable cutting conditions, reduces trial-and-error testing, and results in higher yields, longer blade life, and optimized throughput.

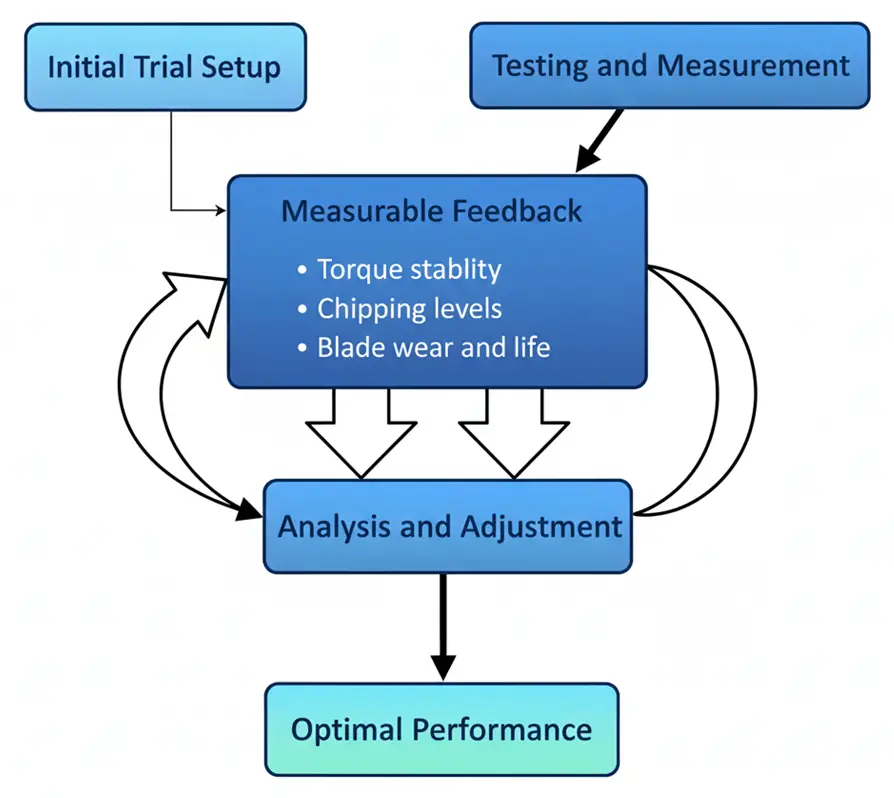

Iterative Testing and Adjustment

Iterative testing and adjustment are essential because dicing optimization rarely succeeds in a single trial. Each material, package, or wafer has its own combination of hardness, brittleness, grain structure, and thermal properties that affect how the blade performs. Standard blade configurations may work initially, but fine-tuning is almost always required to achieve both maximum throughput and acceptable yield.

This process is especially important when cutting demanding substrates such as sapphire, SiC, or multilayer microelectronic packages. These materials often reveal weaknesses in blade grit size, bond hardness, or concentration that only become apparent during real cutting. A blade that appears stable in initial trials may show rising torque, uneven wear, or increased back-side chipping after multiple wafers.

Each round of testing provides measurable feedback:

- Torque stability shows whether feed rates and exposure are within limits.

- Chipping levels reveal if grit size or bond type is appropriate for the material.

- Blade wear and life indicate if concentration or bond hardness need to be adjusted.

With each feedback cycle, specifications are refined until the process reaches a point of stability and repeatability. For example, an engineer may start with a medium grit, hard bond blade for SiC, then gradually shift toward a finer grit or softer bond after testing reveals excessive BSC.

The iterative approach reduces guesswork. Instead of relying on a one-time setup, it builds a feedback-driven optimization loop where every trial narrows the gap between current performance and the desired outcome.

Customization for Unique Applications

Customization for unique applications is often necessary because standard dicing blades cannot cover the full range of materials and requirements encountered in microelectronics and advanced packaging. Substrates with unusual hardness, multilayer structures, coatings, or extremely narrow streets present cutting challenges that require tailored solutions.

For example, ultra-hard materials such as SiC or sapphire may require blades with specialized diamond coatings to improve retention and heat dissipation. Layered substrates like ceramic packages with embedded metals or polymers may call for hybrid bonds, which combine the durability of metal bonds with the smoother cutting action of resin bonds. In cases where die count depends on ultra-narrow streets, ultra-thin blade geometries are essential, though they demand precise mounting, flange support, and torque monitoring to remain stable.

Customization is not limited to blade design. It may also involve adjusting diamond concentration, grit size, exposure length, or bond hardness to balance throughput with chipping control. Each adjustment is matched to the material’s properties and the end user’s yield requirements.

The value of customization is that it produces blades that are not just capable of cutting but optimized for the exact material and process conditions. This ensures higher yield, longer blade life, and lower cost per cut in applications where off-the-shelf solutions fall short.

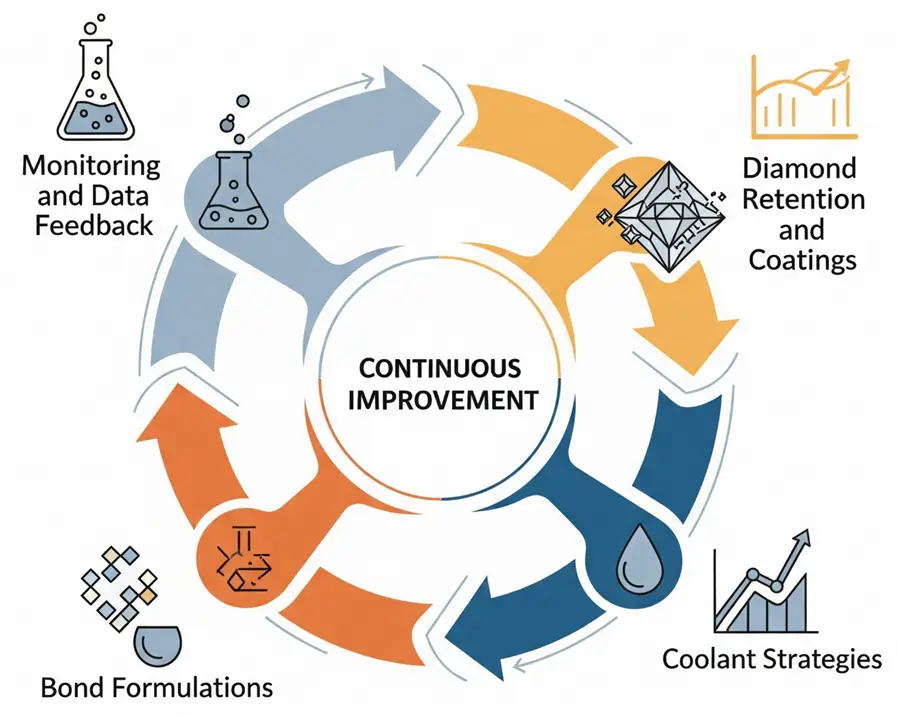

Continuous Improvement

Continuous improvement is a critical part of keeping a dicing process competitive. Optimization does not end once a blade configuration delivers stable yield and throughput. As new wafer materials, advanced packaging designs, and updated dicing equipment emerge, blade technology and process parameters must adapt.

Improvements often begin with bond formulations. Advances in metal, resin, and hybrid bonds allow better diamond retention, longer blade life, and more consistent exposure. For demanding substrates like SiC or sapphire, updated bonds can reduce torque fluctuations and extend usable life by several wafers per blade.

Another area of progress is diamond retention and coatings. Surface treatments such as nickel or titanium coatings improve adhesion, enhance thermal stability, and help control wear. Continuous testing with these new options can reduce chipping and lower cost per cut, especially for ultra-thin or multilayer packages.

Process improvement is not limited to blades. Coolant strategies including optimized nozzle geometry, flow control, and advanced filtration reduce heat, prevent slurry buildup, and improve surface cleanliness. These changes help minimize front- and back-side chipping (BSC), improve wire bonding reliability, and stabilize torque.

Finally, monitoring and data feedback drive long-term improvement. On-line torque measurement, vibration analysis, and inspection data can be used to refine dressing intervals, adjust feed rates, and validate blade modifications. Each cycle of monitoring and adjustment helps keep the process aligned with yield goals as conditions evolve.

Factors Affecting Diamond Dicing Blade Optimization

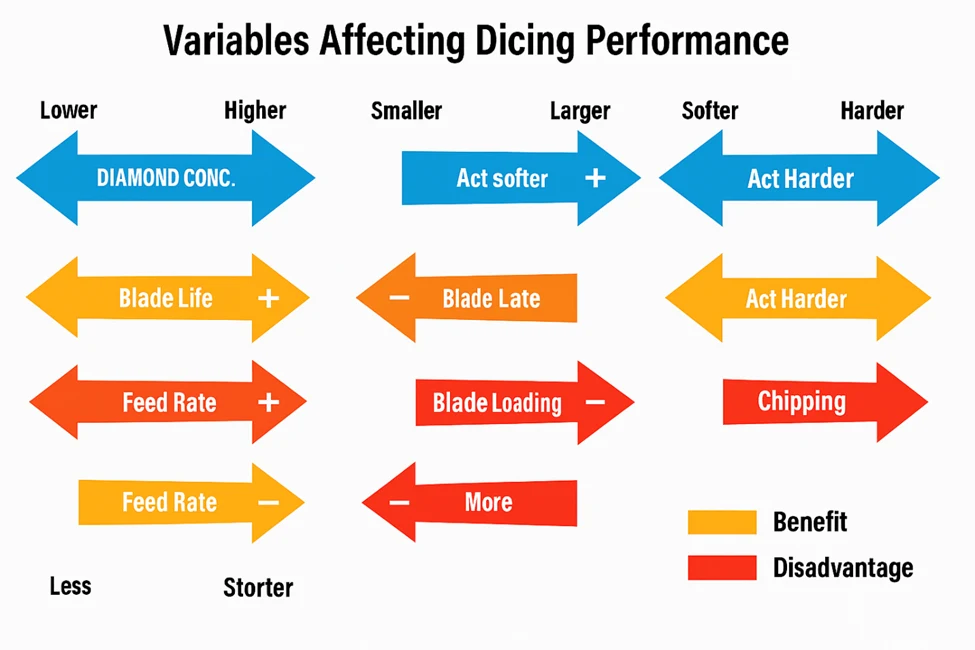

Increasing Diamond Concentration

When diamond concentration is increased, the blade behaves “harder.” With more cutting points engaged, each diamond carries less load and penetrates less deeply. This improves cut consistency and reduces chipping in brittle wafers but raises cutting torque. High concentration blades are best suited for hard, dense materials where chipping control is critical.

Increasing Diamond Mesh Size

Larger diamond particles (lower mesh numbers) reduce the number of active cutting points. This increases unit pressure per diamond, creating deeper penetration and a “softer” cutting action. Larger mesh sizes cut faster but risk higher front- and back-side chipping. Finer mesh sizes cut more slowly but improve kerf smoothness and die strength.

Increasing Bond Hardness

Harder bonds hold diamonds longer, creating a “harder” cutting action. This extends blade life on abrasive materials but can raise torque and increase the need for dressing. Softer bonds release dull diamonds sooner, maintaining sharpness but reducing overall blade life. Selecting the right hardness balances longevity with consistent cut quality.

Increasing Machine Operating Speeds (RPMs)

Higher spindle speeds reduce the time each diamond spends in contact with the wafer. This decreases penetration depth and makes the blade act harder. High RPMs improve cut accuracy and surface finish but may accelerate bond wear if not balanced with feed rate and coolant flow.

Increasing Infeed Rates (Feed Rates)

Higher feed rates make the blade act softer, since each diamond particle removes more material per pass. This increases productivity but raises cutting pressure, which can cause premature diamond loss and more back-side chipping if not kept within the torque window.

Increasing Horsepower

Machines with higher spindle horsepower can sustain higher feed rates and thicker blades, but the extra force may accelerate diamond pull-out if the bond is not matched. In these cases, harder bonds are often required to stabilize performance under heavy loads.

Increasing Coolant Volume

Higher coolant flow improves debris removal, lowers heat, and stabilizes torque. This reduces bond wear, making the blade act harder and extending its life. Optimized coolant delivery correct volume, nozzle alignment, and filtration—is one of the most effective ways to prevent blade loading and minimize chipping.

Increasing Cutting Depth

Deeper cuts increase the contact area, distributing pressure across more diamonds and reducing penetration depth per particle. This makes the blade act harder but can raise heat load. Proper depth settings and minimizing blade exposure are essential to avoid deflection or cracking.

Blade Geometry and Configuration

Blade thickness directly affects kerf width, yield, and stability. Thinner blades increase die count but reduce rigidity, demanding tight vibration control. Thicker blades provide stability and longer life but sacrifice yield and cutting speed. Proper flange support and minimized exposure are critical for thin geometries.

Material Properties

The substrate’s hardness, abrasiveness, and brittleness dictate blade choice. Hard, brittle materials like sapphire or SiC require high-concentration, fine-grit blades with harder bonds. Softer, less abrasive materials like silicon can be cut with lower concentrations, softer bonds, and slightly coarser grits to maximize throughput.

Operator Skill and Technique

Operator expertise directly influences blade life and cut quality. Proper handling, consistent feed rates, torque monitoring, and correct dressing intervals prevent unnecessary stress on the blade. Training operators in best practices reduces downtime and scrap.

Maintenance and Handling

Process optimization relies on well-maintained equipment. Regular spindle calibration, flange inspections, and coolant system cleaning ensure stable operation. Blades must also be stored, mounted, and handled correctly to avoid premature wear, cracks, or imbalance. Preventive maintenance is as critical to optimization as blade selection.

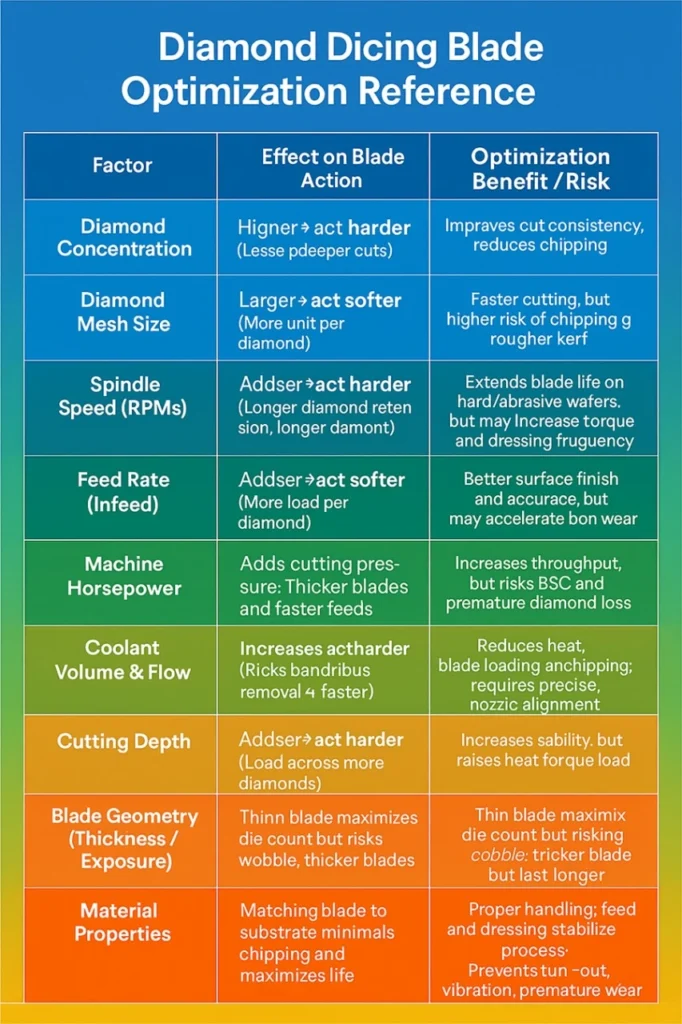

Diamond Dicing Blade Optimization Reference

|

Factor |

Effect on Blade Action |

Optimization Benefit / Risk |

|---|---|---|

|

Diamond Grit Size |

Higher concentration = harder action (less penetration per diamond) |

Improves cut consistency, reduces chipping, but raises torque |

|

Diamond Mesh Size |

Larger grit = softer action (fewer, deeper cuts per diamond) |

Faster cutting, but higher risk of chipping and rougher kerf |

|

Bond Hardness |

Harder bond = harder action (longer diamond retention) |

Extends blade life on hard/abrasive wafers, but may increase torque and dressing frequency |

|

Spindle Speed (RPMs) |

Higher RPM = harder action (shallower penetration per diamond) |

Better surface finish and accuracy, but may accelerate bond wear |

|

Feed Rate (Infeed) |

Higher feed = softer action (more load per diamond) |

Increases throughput, but risks BSC and premature diamond loss |

|

Machine Horsepower |

More horsepower = higher cutting pressure |

Enables thicker blades and faster feeds, but may cause diamond pull-out if bond not matched |

|

Coolant Volume & Flow |

Higher volume = harder action (better debris removal, less stress per diamond) |

Reduces heat, blade loading, and chipping; requires precise nozzle alignment |

|

Cutting Depth |

Deeper cuts = harder action (load spread across more diamonds) |

Increases stability, but raises heat and torque load |

|

Blade Geometry (Thickness/Exposure) |

Thinner = higher yield but less rigid; Thicker = more stable but wider kerf |

Thin blades maximize die count but risk wobble; thicker blades reduce yield but last longer |

|

Material Properties |

Hard/brittle = require fine grit & harder bonds; soft/less abrasive = allow coarser grit & softer bonds |

Matching blade to substrate minimizes chipping and maximizes life |

|

Operator Technique |

Proper handling, feed, and dressing stabilize process |

Skilled operators reduce downtime, scrap, and blade stress |

|

Maintenance & Handling |

Clean, calibrated machines and proper blade storage/mounting stabilize torque |

Prevents run-out, vibration, and premature blade wear |

Exploring Exceptions in Blade Performance Beyond Optimal Settings

In diamond dicing, following general guidelines is an effective way to optimize blade performance. However, once parameters move beyond the optimal operating window, blade behavior can shift in ways that are not always intuitive. Understanding these exceptions is essential for maintaining both yield and blade life.

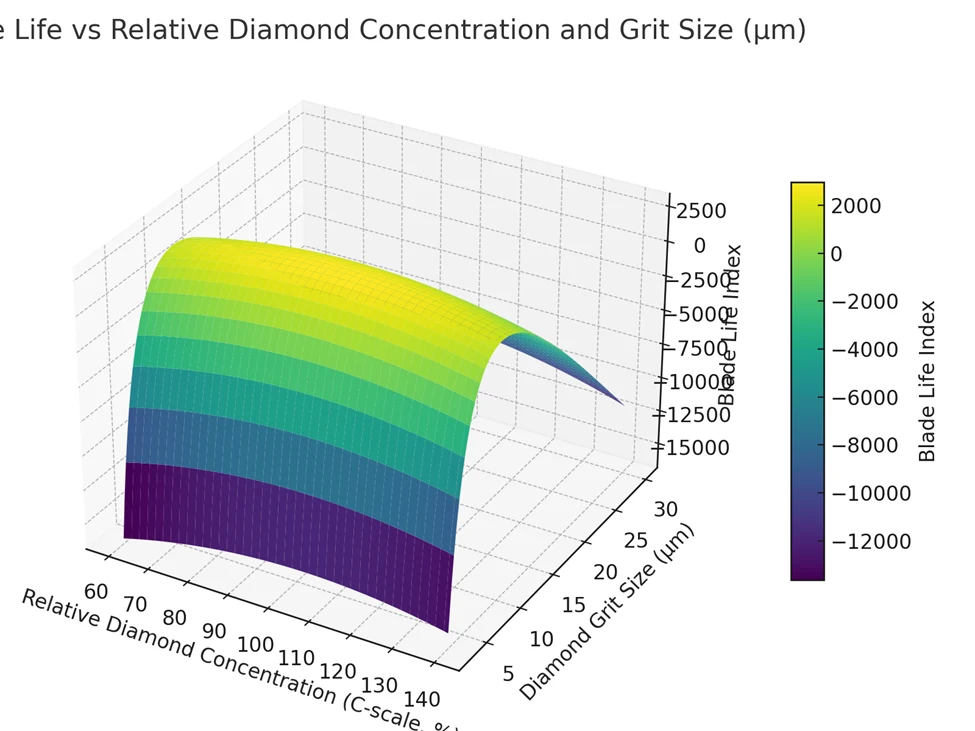

Increasing diamond concentration usually improves cut stability and reduces chipping, but beyond the optimal point this effect reverses. At very high concentrations, blades tend to act excessively hard, leading to a glazed cutting surface. When this happens, the diamonds penetrate less, the blade cuts inefficiently, and dressing is required more often to restore sharpness.

To maintain cutting rates under these conditions, operators often raise infeed pressure, which increases blade torque. While this may temporarily improve throughput, it accelerates bond breakdown and premature diamond pullout, shortening blade life and increasing the risk of front- or back-side chipping.

Experimental data shows that efficiency is not linear with diamond concentration. Heat maps or wear charts often illustrate this, where higher values represent improved efficiency and reduced wear, meaning the blade cuts cleanly with longer life. Lower values represent reduced efficiency and higher wear, requiring frequent dressing or replacement. Visualizing performance with such data helps identify the most effective balance between diamond concentration, grit size, and material type. For example, a higher concentration may be optimal for hard, brittle substrates like sapphire, but the same setup could cause excessive glazing and short blade life on softer materials like silicon.

The goal is to find the concentration sweet spot high enough to ensure consistent kerfs and minimal chipping, but not so high that the blade becomes inefficient or fragile under higher feed pressures. This balance is determined through iterative testing, torque monitoring, and close inspection of chipping and wear patterns.

Increasing the diamond grit size beyond the optimal range for a given application changes how the blade interacts with the substrate. Coarser grits create fewer cutting points, each carrying more load, which can increase penetration and cutting speed but also raise the risk of front-side and back-side chipping in brittle wafers. Finer grits create more cutting points with less load per diamond, producing smoother kerfs, tighter tolerances, and less chipping, but at the expense of slower throughput and higher blade wear.

The key trade-off is between cut quality and throughput. Very fine diamond sizes are ideal for applications requiring minimal chipping and high die strength, such as ultra-thin silicon wafers or sensitive compound semiconductors. Coarser grits may be used in applications where speed is prioritized over surface finish, such as initial singulation of less brittle substrates.

Performance maps often show a clear optimal grit size range where both blade life and cut quality are balanced. Moving toward finer grits improves yield but reduces productivity, while moving toward coarser grits improves cutting speed but reduces yield and die reliability. The correct choice depends on whether the priority is maximum wafer output or maximum die integrity.

The role of bond hardness in dicing optimization is more complex than it may appear. In theory, harder bonds should extend blade life by holding the diamonds longer and resisting erosion. However, beyond the optimal point, this does not always hold true. Excessively hard bonds can become brittle during high-speed wafer dicing and may chip or fracture instead of wearing evenly. This irregular wear leads to unstable cutting performance and premature blade failure.

When a bond acts too hard, the blade surface can glaze over, causing reduced cutting efficiency and higher torque demand. To maintain throughput, operators may increase the infeed rate or spindle pressure, which accelerates wear, increases chipping, and reduces die yield. These exceptions highlight why bond selection is not only about hardness but about balance with diamond concentration, grit size, and coolant delivery.

In practice, bond hardness must be matched carefully to substrate type and operating conditions. Harder bonds work best for dense, abrasive materials like SiC or GaN, while slightly softer or hybrid bonds improve consistency when cutting brittle wafers or microelectronic packages. Understanding these exceptions is critical, as running beyond the optimum hardness point can decrease both blade life and process stability, contrary to expectations.

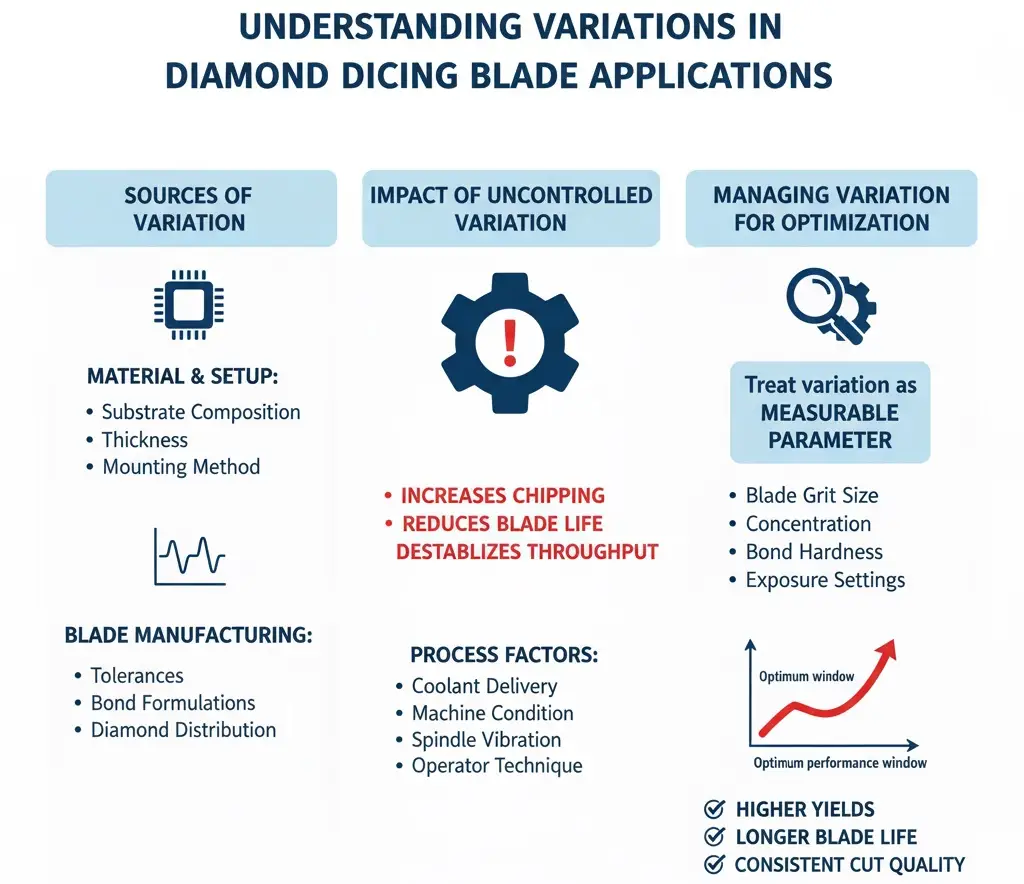

Understanding Variations in Diamond Dicing Blade Applications

Variation is one of the most important factors in diamond dicing blade performance. Even small differences in substrate composition, thickness, or mounting method can significantly change how a blade behaves during cutting. The same applies to blade manufacturing tolerances, bond formulations, and diamond distribution, all of which can shift performance outside of expected norms.

No dicing process operates without variation, but uncontrolled variation increases chipping, reduces blade life, and destabilizes throughput. Factors such as coolant delivery, machine condition, spindle vibration, and even operator technique all contribute to fluctuations in cut quality. Recognizing these variations and actively controlling them is essential for optimizing both blade selection and process stability.

By treating variation not as an error but as a measurable parameter, engineers can fine-tune blade grit size, concentration, bond hardness, and exposure settings to compensate for specific conditions. The more variation is understood and managed, the closer the process stays to its optimum performance window, ensuring higher yields, longer blade life, and consistent cut quality.

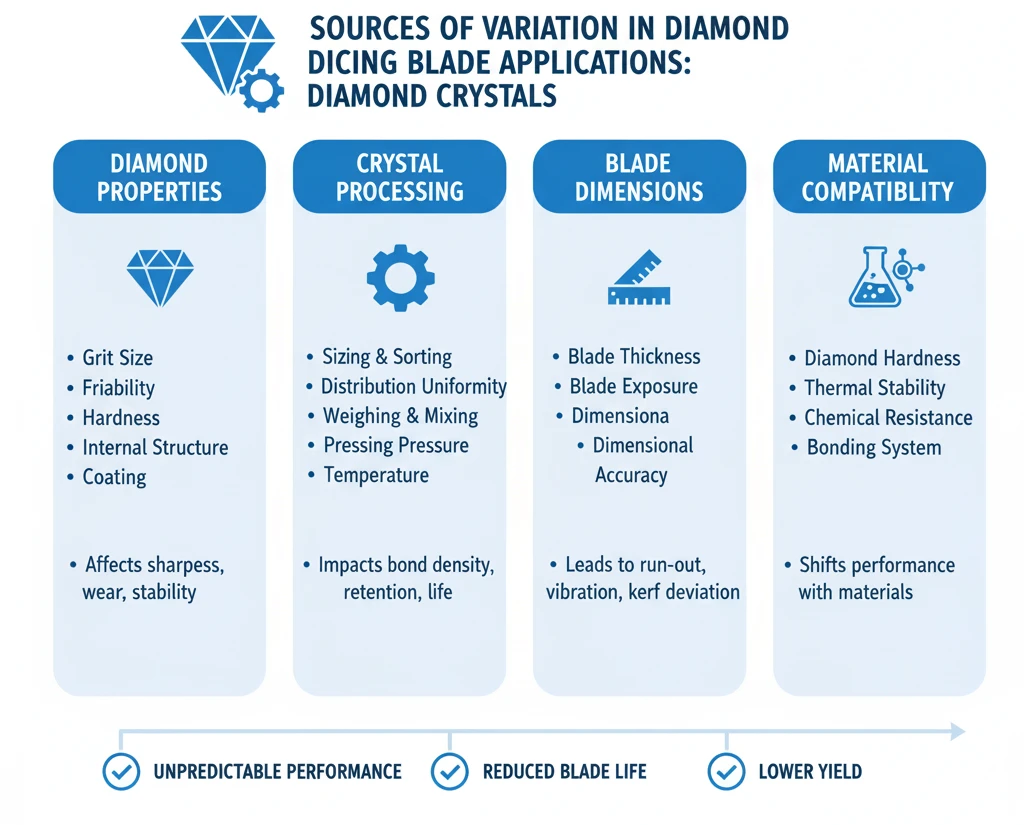

Sources of Variation in Diamond Dicing Blade Applications – Diamond Crystals

Variation in dicing blade performance begins with the diamonds themselves. Differences in diamond grit size, friability, hardness, internal structure, and coating affect sharpness, wear rate, and cutting stability. Even when blades are manufactured to the same nominal specification, inconsistencies in sizing, sorting, and distribution can change how evenly the cutting points engage the substrate.

Processing factors also introduce variation. Weighing, mixing, pressing pressure, and processing temperature all influence how uniformly diamonds are distributed in the bond and how securely they are retained. Small deviations in these steps can alter bond density, diamond exposure, and wear resistance, which in turn affect chipping levels and blade life.

Finished blade dimensions contribute as well. Blade thickness, exposure, and dimensional accuracy must be controlled within tight tolerances. Minor inconsistencies in these parameters can cause run-out, vibration, or kerf width deviations that reduce yield.

Finally, the physical and chemical properties of the diamonds and bonding system play a role. Variations in hardness, thermal stability, or chemical resistance can shift performance, particularly under aggressive feed rates or when cutting difficult materials.

Sources of Variation in Diamond Dicing Blade Applications

|

Category |

Specific Factors |

Impact on Dicing Process |

|---|---|---|

|

Diamond Properties |

Grit size, friability, hardness, internal structure, coating |

Controls sharpness, wear rate, and chipping. Inconsistent sizing or friability leads to uneven cutting and variable blade life. |

|

Diamond Processing |

Sizing, sorting, distribution |

Determines how evenly cutting points engage the wafer. Poor distribution creates unstable kerfs and torque fluctuations. |

|

Bond & Manufacturing |

Weighing, mixing, pressing pressure, processing temperature |

Influences bond density, porosity, and diamond retention. Small variations change blade hardness and stability. |

|

Finished Dimensions |

Blade thickness, exposure, dimensional accuracy |

Affects kerf width, stiffness, and run-out. Minor deviations can cause vibration, misplacement, and reduced yield. |

|

Material Properties |

Diamond hardness, thermal stability, chemical resistance |

Determines how well the blade holds up under heat, coolant chemistry, and aggressive feed rates. |

Table 1: Diamond Dicing Blade Characteristics

|

Category |

Details |

|---|---|

|

Diamonds |

Origin (synthetic), friability, hardness, internal structure, coating, purity |

|

Diamond Processing |

Sizing, sorting, distribution consistency |

|

Bond Properties |

Diamond concentration, bond hardness, wear resistance, thermal stability, chemical resistance |

|

Manufacturing Process |

Weighing, mixing, pressing pressure, processing temperature, sintering/curing control |

|

Finished Dimensions |

Blade thickness, diamond exposure, kerf accuracy, run-out tolerance |

Machine Operating Conditions for Diamond Dicing Blades

|

Category |

Details |

|---|---|

|

Machine |

Dicing system design, spindle accuracy, indexing precision, vibration control |

|

Speed (RPM) |

Spindle speed range and stability, matched to blade diameter and material type |

|

Feed (Infeed Rate) |

Determines throughput, torque load, and chipping risk |

|

Horsepower |

Spindle power capacity, ensuring sufficient torque for harder substrates without overloading the blade |

|

Machine Type |

Fully automatic vs. semi-automatic dicing saws, multi-axis alignment, optical magnification capability |

|

Power Source/Condition |

Electrical stability, spindle calibration, machine maintenance state |

|

Coolant Volume |

Flow rate, nozzle alignment, and pressure control to manage heat and debris removal |

|

Operator Skill |

Training in mounting, alignment, dressing, and torque monitoring |

|

Operator Practice |

Consistency in setup, parameter adjustment, and inspection feedback |

|

Purchaser/Process Flexibility |

Willingness to adapt blade specs (bond, grit, concentration) to evolving material and yield requirements |

Table 2: Machine Operating Conditions for Diamond Dicing Blades

|

Category |

Details |

|---|---|

|

Machine |

Spindle speed stability, feed (infeed rate), available horsepower, dicing saw type (automatic/semi-automatic), electrical stability, and overall machine condition (calibration, vibration control) |

|

Coolant |

Flow rate, nozzle alignment, and volume control to ensure proper heat dissipation, debris removal, and torque stability |

|

Operator |

Skill in setup, blade mounting, flange handling, dressing practices, alignment accuracy, and ability to monitor torque and chipping |

|

Process Management |

Flexibility in adjusting blade specifications, communication of results and issues, and willingness to optimize parameters for yield and throughput |

Table 3: Material Being Cut (Substrate Characteristics)

|

Category |

Details |

|---|---|

|

Particle Size & Distribution |

Grain size and homogeneity of the substrate affect how the blade engages the material. Large or uneven particles increase chipping and dressing frequency. |

|

Chemical Composition |

Certain elements or layers (e.g., metals, coatings, polymers) interact with bond systems or coolants, influencing blade wear and cut stability. |

|

Mechanical Properties |

Tensile strength, hardness, density, and brittleness determine blade grit size, bond hardness, and feed rate selection. |

|

Thermal Properties |

Refractoriness and thermal conductivity affect heat buildup at the cut zone, influencing blade wear, coolant needs, and risk of wafer warpage. |

|

Surface/Structural Properties |

Abrasiveness, porosity, and permeability impact swarf generation, coolant penetration, and kerf quality during cutting. |

Table 3: Substrate (Material Being Cut) Characteristics for Diamond Dicing

|

Category |

Details |

|---|---|

|

Physical Properties |

Grain or particle size, particle size distribution, microstructure uniformity, tensile strength, density, and porosity/permeability |

|

Chemical Properties |

Overall composition, presence of metals or coatings, abrasiveness, hardness, and reactivity with bond or coolant |

|

Processing History |

Back-grinding, thinning, coating, or deposition steps that influence residual stress and cutting response |

|

Final Product Specifications |

Thermal conductivity, brittleness, spalling tendency, surface finish requirements, and sensitivity to chipping or micro-cracks |

These tables categorize the different sources of variation that influence the performance of diamond dicing blades, showing where tighter controls or parameter adjustments may be needed to optimize both wafer and package singulation.

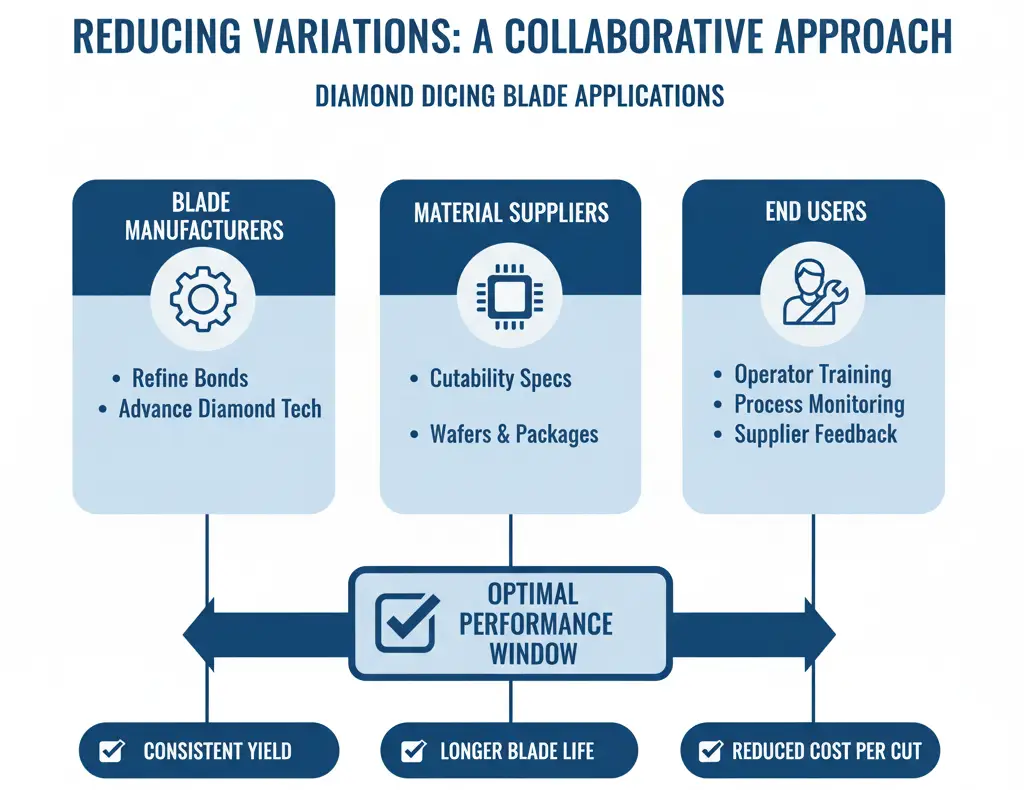

Many factors affect dicing blade performance, and controlling these variations is critical for consistent results. Blade manufacturers focus on diamond quality, sizing, concentration, and bond processing to ensure predictable behavior and repeatability in high-precision cutting. Careful control of manufacturing variables such as mixing, pressing, and thermal processing helps maintain blade stability across production runs.

On the material side, suppliers of wafers and microelectronic packages often maintain strict standards for electrical, mechanical, and thermal properties. However, the cutability of these materials is not always evaluated with the same rigor. A material may meet all design specifications for conductivity or reliability, yet still prove difficult to dice if hardness, brittleness, or abrasiveness are not considered during material development. This can directly affect chipping levels, kerf stability, and blade life.

The operating environment introduces further variation. Machine condition, coolant delivery, parameter stability, and operator skill all influence how the blade performs in practice. Unlike blade manufacturing, which is generally well controlled, the application environment is where variability most often arises. Small inconsistencies in alignment, feed rate, or coolant flow can create large differences in yield and blade wear between production runs.

Reducing these variations requires a collaborative approach. Blade manufacturers continue refining bonds and diamond technologies. Material suppliers should incorporate cutability into their specifications for wafers and advanced packages. End users must emphasize operator training, accurate process monitoring, and strong feedback loops with suppliers. Together, this ensures dicing processes remain within their optimal performance window, delivering consistent yield, longer blade life, and reduced cost per cut.

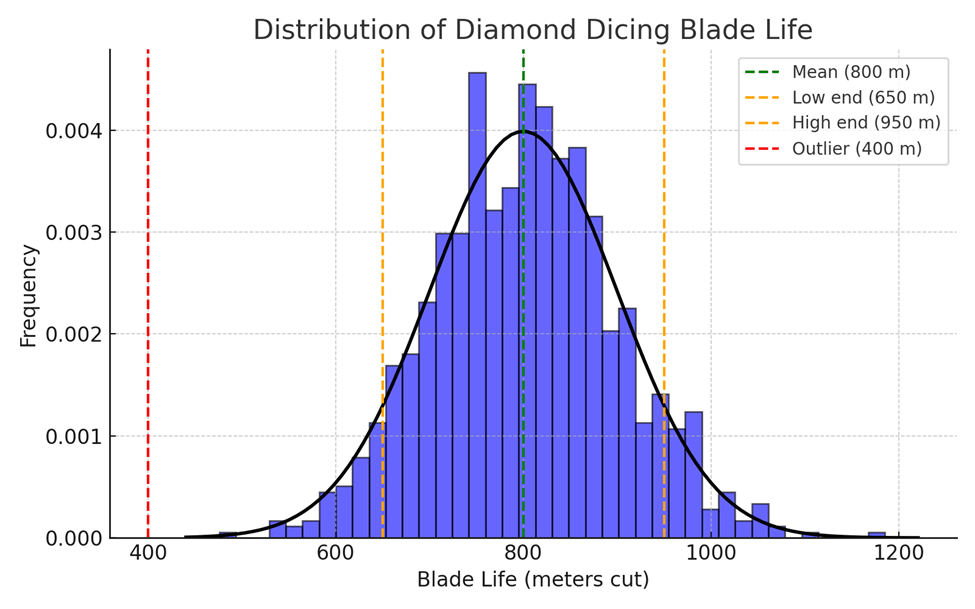

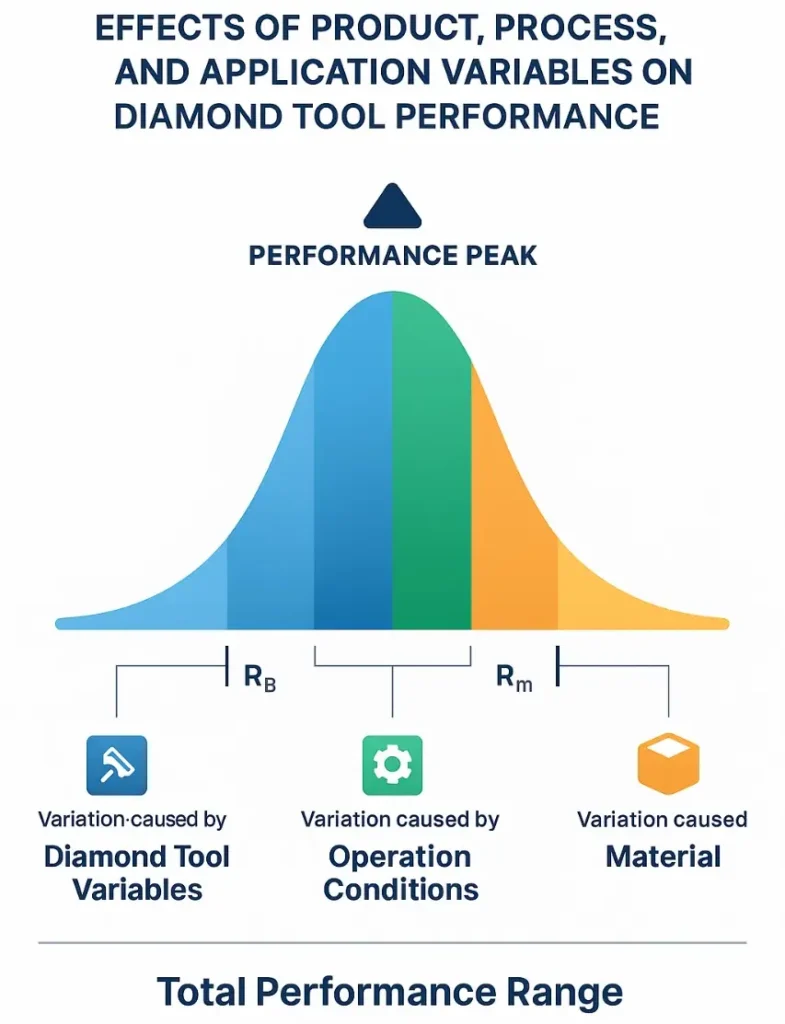

The effects of product, process, and application variables on dicing blade performance can be viewed as overlapping sources of variation. A normal variation curve represents the distribution of results for a single application. Product variation reflects differences in diamond grit and distribution, bond hardness, concentration, and finished geometry. Material variation reflects differences in wafer or package hardness, brittleness, layer stacks, residual stress, and coatings. Operating variation reflects differences in spindle speed, infeed rate, coolant flow and chemistry, exposure, flange condition, machine calibration, and operator technique. The overlap of these three ranges defines the expected performance window for blade life measured in meters.

Assume the qualified process shows an average blade life of 1,500 meters cut per blade for a specific substrate and recipe. A single blade that reaches 1,050 meters may feel disappointing. It can still be inside the expected distribution once you account for product, material, and operating variation. A low result inside the normal band does not prove a defective blade. The reverse is also true. A 1,950 meter result sits in the same distribution and is equally expected when conditions align.

This reality does not remove responsibility. It shows where to focus corrective action. Treat every outlier as a diagnosis problem, not a blame problem. First, verify the operating band. Confirm spindle speed, infeed, exposure, flange cleanliness, nozzle aim, and coolant flow. Check that torque stayed within the known limit for that blade and material.

If operation is stable, review the material band. Confirm wafer or package lot, thickness, back-grind stress, metal content in the streets, and any coating changes. If the material is unchanged, review the product band. Confirm blade lot, bond code, concentration, grit size, inspection data, and run-out at mounting.

Use data to keep results inside the expected window. Track meters cut per blade, along with torque trends, chipping measurements, and kerf width over life. Keep a fixed reference recipe and a known reference substrate. When life drops from 1,500 to 1,050 meters, run the reference to isolate whether the shift follows the blade, the material, or the machine. Change one variable at a time. If you must recover stability quickly, reduce infeed to bring torque under the limit, shorten exposure, or increase coolant flow. Avoid simultaneous changes that hide the root cause.

Set acceptance bands in meters per blade that reflect the three sources of variation. Escalate when a result falls outside the band, not simply because it is below the mean. With any blade return, request or provide torque logs, coolant settings, mounting details, and total meters cut. With any material change, provide lot identifiers, thickness, and stress history. This shared evidence lets the application engineer adjust grit size, concentration, or bond hardness with confidence.

The goal is stable, predictable output. Control the operating band with maintenance and monitoring. Reduce the material band by qualifying cutability, not only electrical or thermal properties. Tighten the product band by working with the blade supplier on lot-to-lot consistency. Managing all three keeps your process near the center of the curve, protects yield, and increases meters cut per blade.

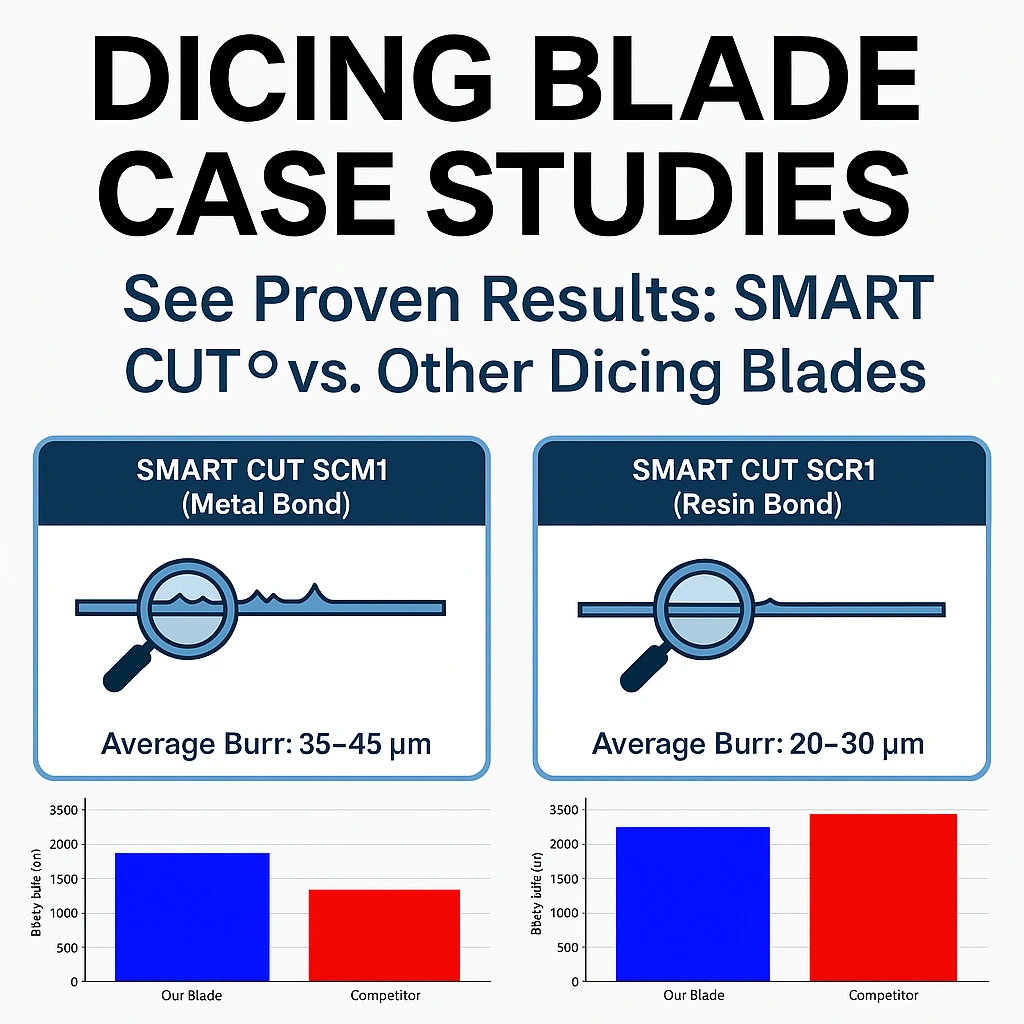

The effects of product, process, and application variables on diamond dicing blade performance are best understood through the lens of normal variation. A typical distribution curve of blade life measured in meters cut shows how results spread across influencing factors. The range labeled Rb reflects variation caused by the blade itself, including diamond grit, bond type, and concentration. Range RM represents variation from the material being cut, such as wafer hardness, brittleness, or microelectronic package structure. Range Ro captures variation from operating conditions, including feed rate, spindle speed, coolant flow, and mounting stability. While manufacturers control blade quality, these external sources of variation strongly affect performance.

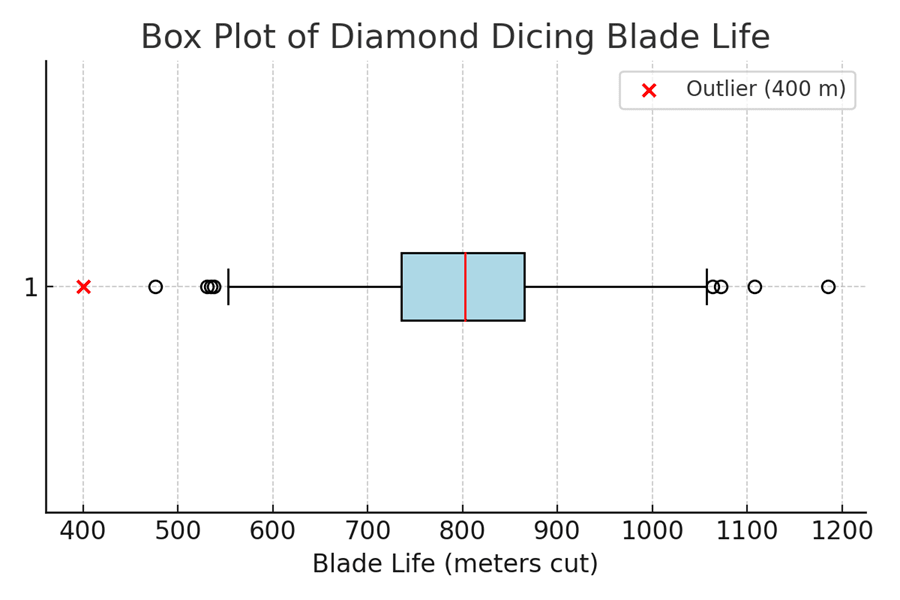

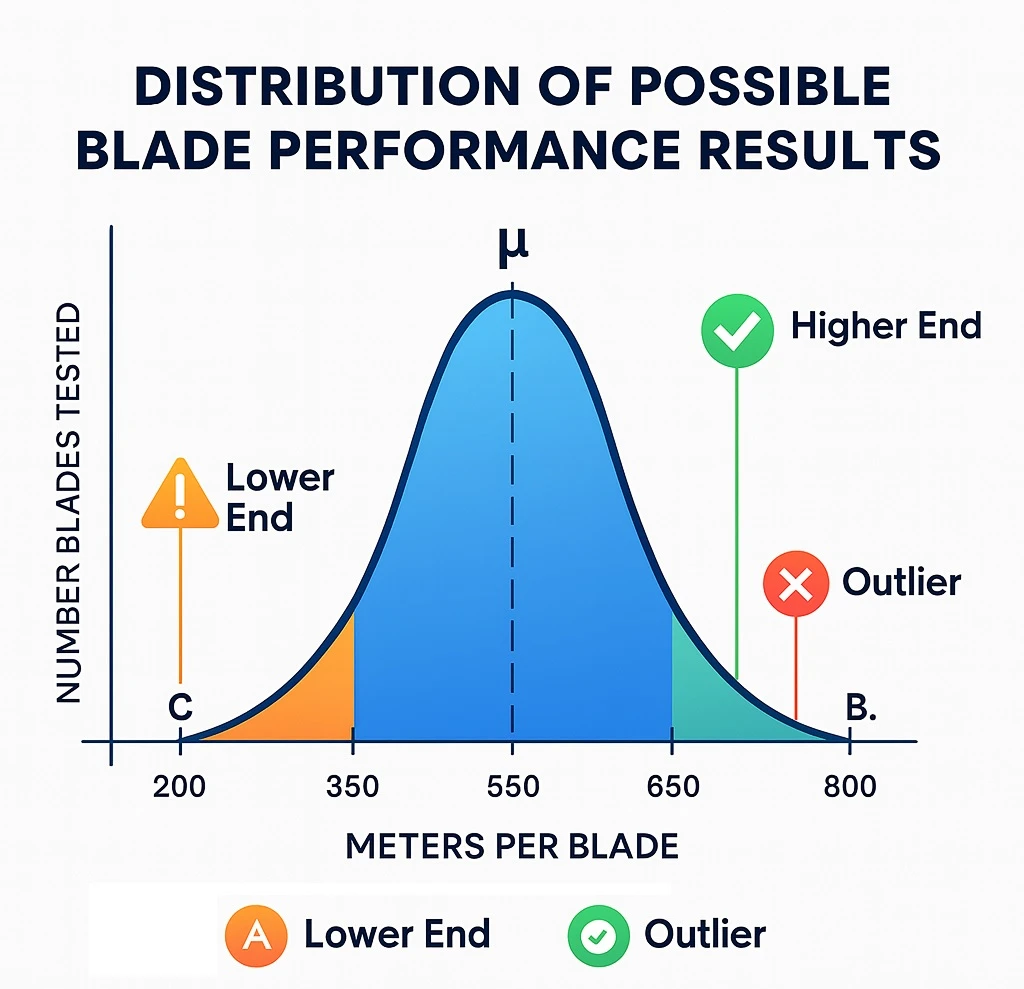

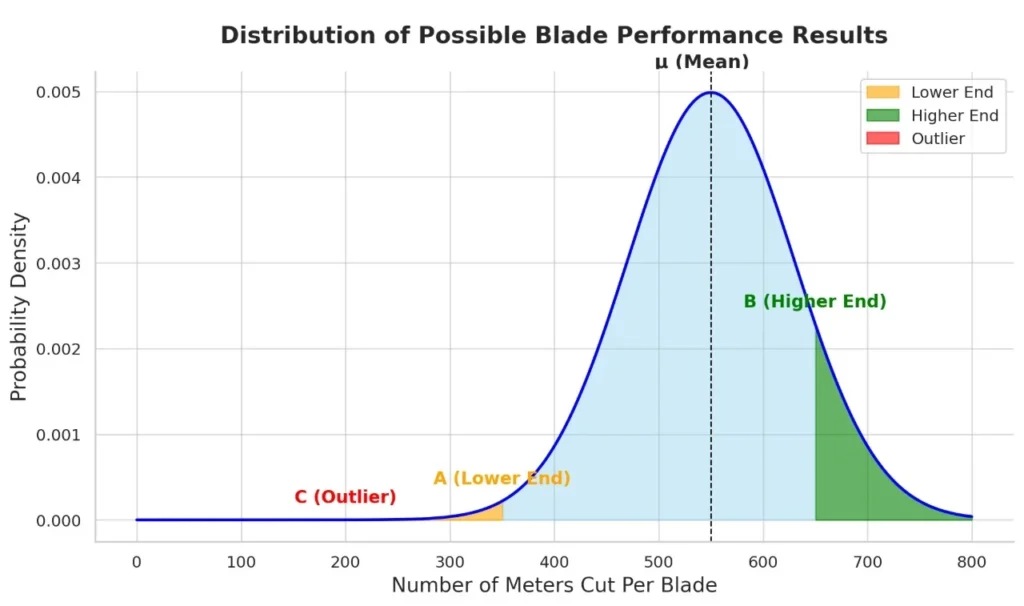

A common challenge for application engineers is addressing customer concerns when blade life appears shorter than expected. For example, in a process where the average blade life is 800 meters cut, the distribution may show normal results between 650 and 950 meters. If a blade only lasts 600 meters, it is on the low end but still within normal statistical variation. Customers may view this as unacceptable, but technically the blade is performing within the expected range.

Conversely, if a blade lasts only 400 meters cut, it falls outside the normal distribution curve. Such an outlier indicates an assignable cause, such as incorrect mounting, excessive feed rate, poor coolant delivery, or in rare cases a defective blade. Identifying the root cause requires joint investigation by the manufacturer and user, since both blade properties and process setup can produce abnormal results.

In practice, short blade life is often reported, while strong results above average, such as a blade reaching 1,000 meters cut are rarely mentioned. For true process optimization, both ends of the curve matter. Recognizing normal variation helps avoid misattributed blame, while carefully investigating outliers creates opportunities to refine process parameters, improve consistency, and maximize yield.

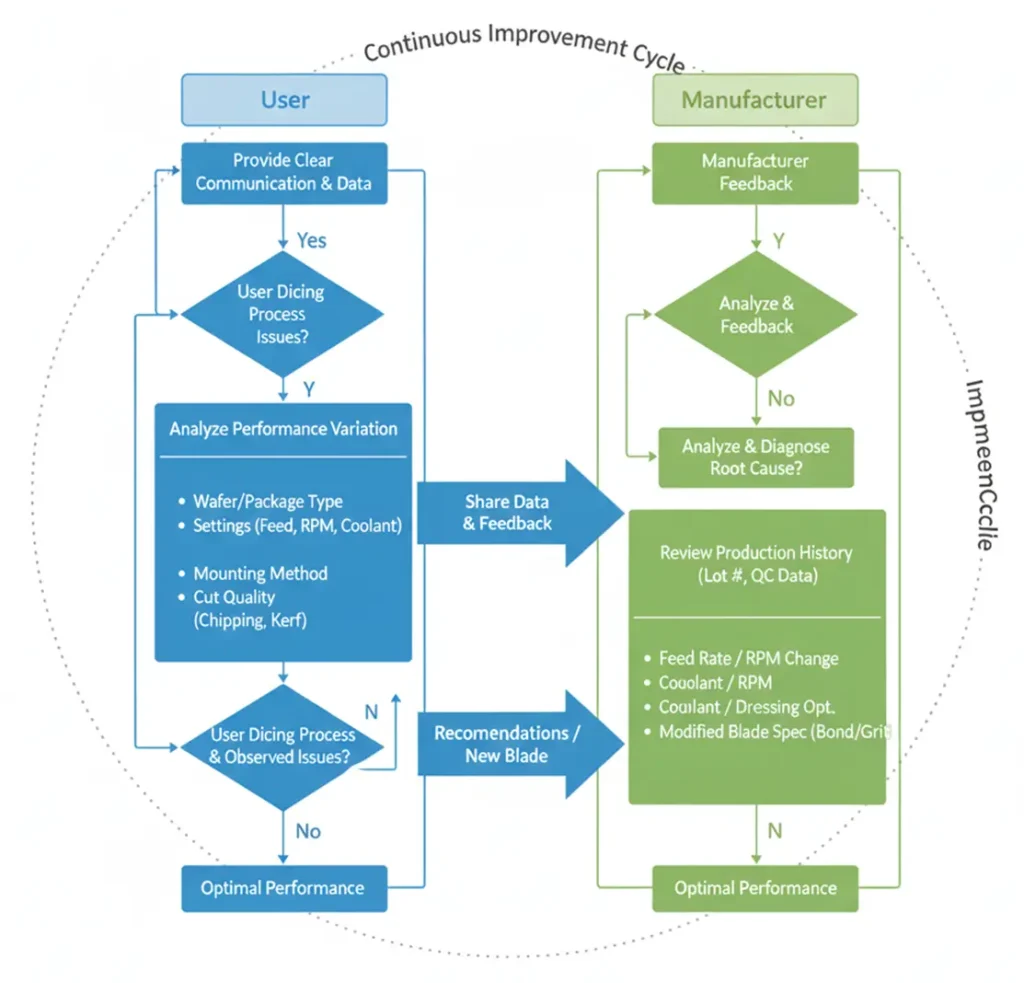

Analyzing Variation in Performance – Cooperating Between User & Blade Manufacturer

When dicing blade performance falls below expectations, it is essential for both the end user and the blade manufacturer to work together openly to identify the root cause. A cooperative approach ensures that problems are addressed quickly and effectively, rather than creating unnecessary conflict.

Clear communication from the user is critical. Without accurate details about the application such as wafer or package type, thickness, mounting method, coolant setup, feed rates, spindle speeds, and observed cut quality the manufacturer cannot provide meaningful recommendations. Missing information can delay troubleshooting and lead to higher costs in both time and yield loss.

Manufacturers, in turn, support users by analyzing feedback and recommending process adjustments. This might include changes to feed rate, spindle RPM, coolant delivery, or dressing practices, or in some cases suggesting a modified blade specification with a different bond hardness, grit size, or concentration better suited for the material.

It is important for users to recognize that while blade-to-blade variability exists, true manufacturing defects are rare. Reputable dicing blade suppliers maintain strict quality control systems, recording every stage of production. Each blade batch is typically tracked by lot or serial number, making it possible to review process history and confirm compliance with design specifications during investigations.

When yield loss or reduced blade life occurs, users often assume the blade is defective. However, the problem is just as likely to stem from variations in the wafer or package material, changes in back-grinding stress, polyimide or metallization layers, or shifts in operating conditions such as torque stability or coolant flow. Overlooking these factors can lead to misdiagnosed issues and wasted resources.

Optimization requires cooperation. By sharing complete process data and working with the blade manufacturer’s application engineers, users can ensure the right balance of blade design and operating parameters, minimizing variability and achieving consistent, high-yield results.

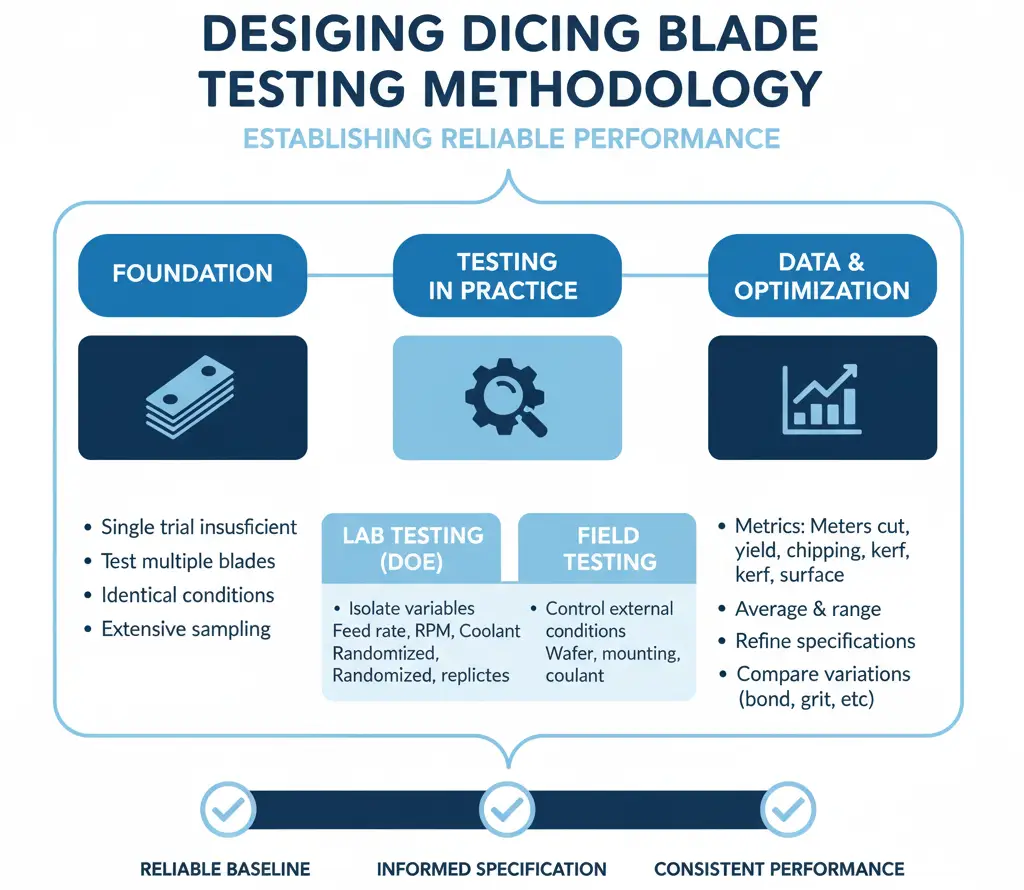

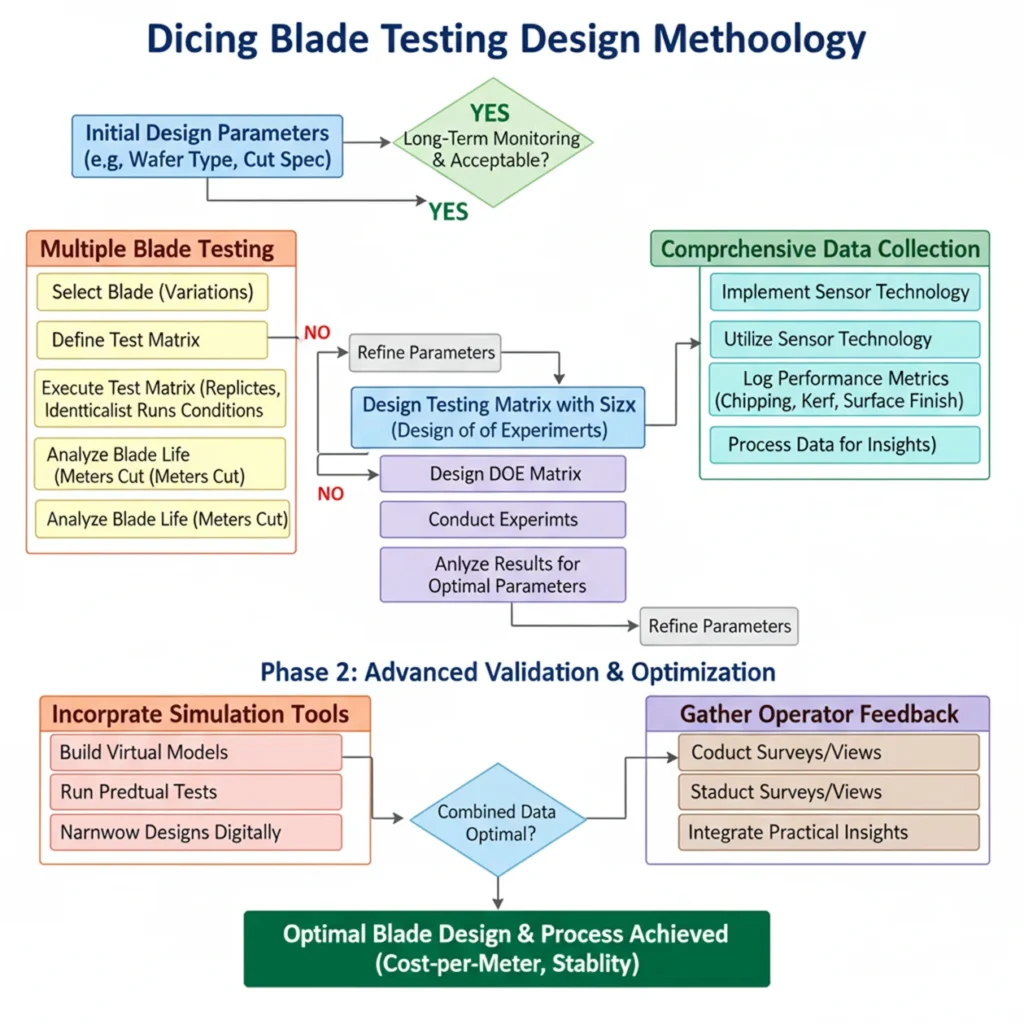

Designing Dicing Blade Testing Methodology

Identifying the optimal diamond dicing blade for a given application is rarely straightforward. Initial specifications from the manufacturer often deliver acceptable but not peak results. Even when the first tested blade appears successful, subsequent blades may show variability, highlighting that a single trial is never enough to confirm long-term optimization.

To establish a reliable performance baseline, multiple blades of the same specification must be tested under identical conditions. Measuring blade life in terms of meters cut, along with yield data such as chipping rates, kerf width, and surface finish quality, provides both the average and range of expected outcomes. This data allows users and manufacturers to refine specifications with precision.

Testing across different blade variations bond hardness, grit size, concentration, or thickness further helps to define which combinations consistently deliver the best results. Extensive sampling is critical to separate normal performance variation from true improvements.

In controlled laboratory environments, statistical methods such as DOE (Design of Experiments) help isolate the influence of individual variables. Randomized testing and replicates reduce noise and provide clarity on how feed rate, spindle RPM, or coolant delivery affect blade life and cut quality. Field testing, on the other hand, requires tight control of external conditions. Standardizing wafer thickness, mounting methods, and coolant chemistry ensures that observed differences come from the blade itself rather than uncontrolled process drift.

Incremental testing changing one parameter at a time is one of the most effective ways to identify causal relationships. Once individual effects are well understood, combinations of variables can be tested to fine-tune the process.

Modern simulation tools now allow prediction of blade performance before physical testing begins. These models save time and cost by narrowing down the most promising blade configurations. However, operator feedback remains irreplaceable. Users working directly with the blades provide insights on stability, handling, and real-world challenges that lab tests may not reveal.

As device materials evolve whether SiC wafers, GaN, polyimide-coated substrates, or multi-layer microelectronic packages testing methodologies must adapt. New materials bring unique cutting challenges, requiring modifications in both blade design and test procedures. Environmental considerations are also becoming increasingly important, with emphasis on coolant efficiency, slurry management, and sustainable materials in blade manufacturing.

Finally, performance metrics should go beyond technical outcomes. Cost-per-meter cut, downtime during blade changes, and process stability provide a complete picture of a blade’s value. A blade that reduces yield loss or minimizes operator intervention often delivers greater long-term savings than one with a lower initial purchase price.

To effectively control and minimize variation in the laboratory testing environment for diamond blades, it's essential to implement standardized and rigorous methods:

To control and minimize variation during dicing blade testing, it is essential to apply standardized and rigorous methods. Automatic dicing systems are strongly preferred whenever available, since they maintain constant spindle speed, feed rate, infeed pressure, and power consumption. These controls ensure that every cut is performed under identical conditions. When manual or semi-automatic operation is required, operators should work within fixed current (amperage) limits, and their cutting technique must be carefully monitored to reduce variability caused by inconsistent handling.

Consistency in test materials is equally important. To eliminate variability in wafer or package properties, testing should be done using a large lot of identical material that reflects the natural variation present in production. When possible, cuts should be made in different areas of the wafer or substrate to account for local hardness, coating thickness, or residual stress differences. This provides a more representative evaluation of blade performance.

When evaluating blade parameters such as diamond grit size, bond hardness, or concentration, it is best practice to use a randomized testing sequence. Instead of completing all cuts with one blade type before switching to the next, alternating between different blade specifications in short cycles reduces the impact of external influences such as machine drift, coolant temperature, operator fatigue, or environmental changes. Randomization improves accuracy by ensuring that variations in performance are linked to the blade itself rather than uncontrolled test conditions.

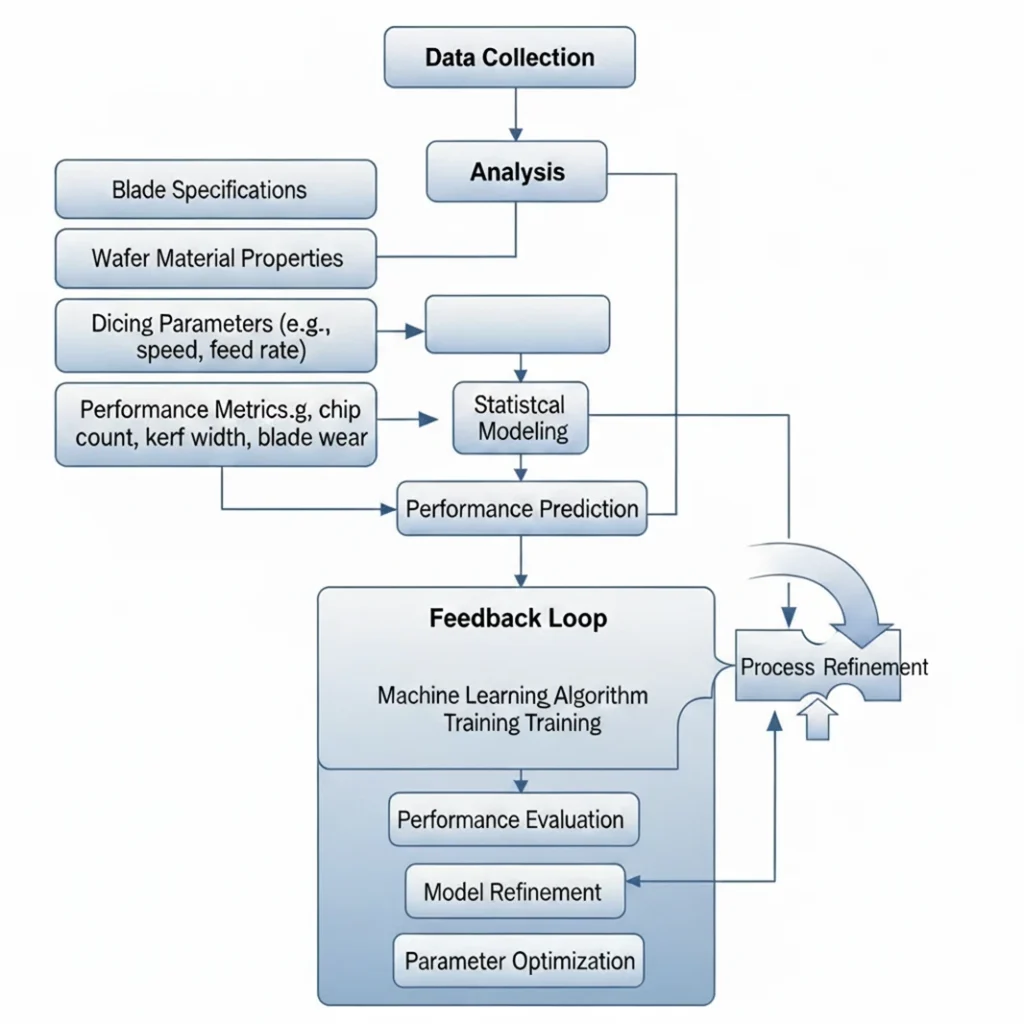

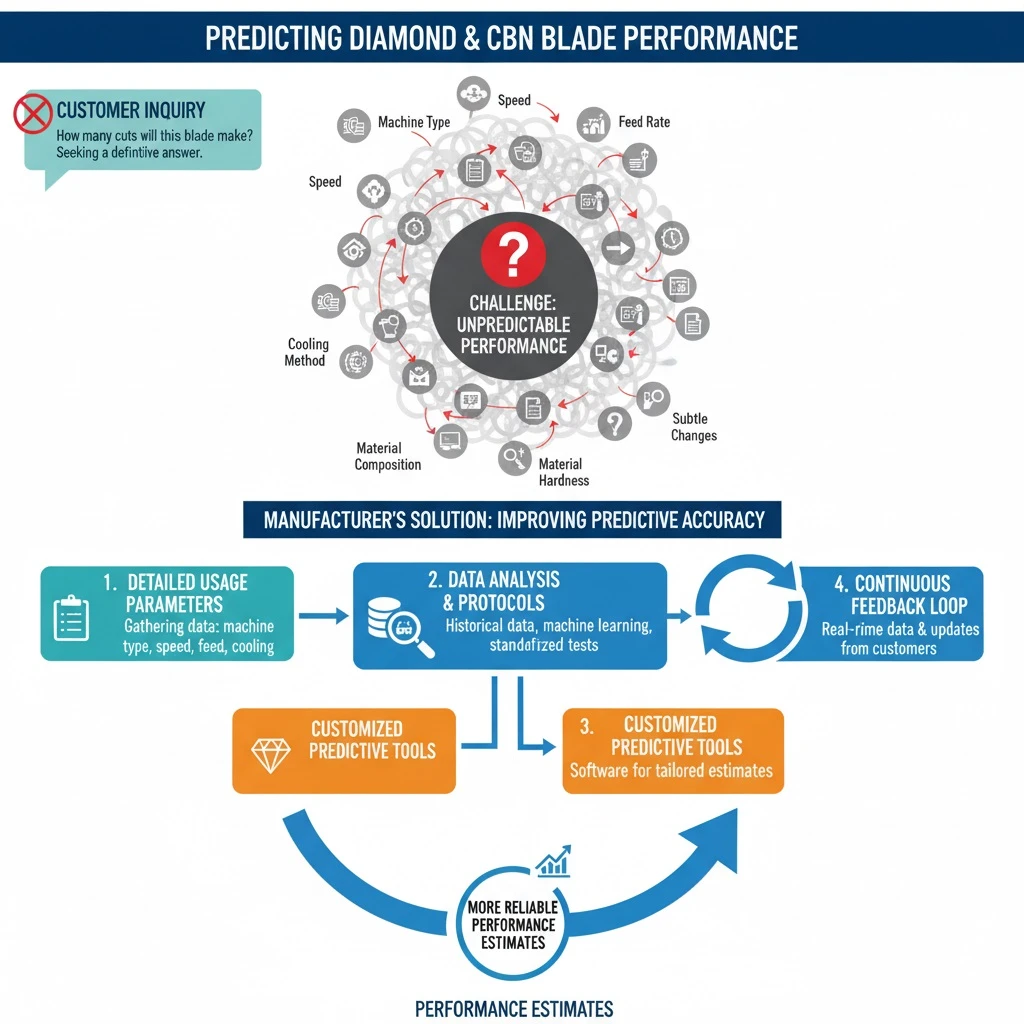

Predicting Dicing Blade Performance

One of the most common questions manufacturers receive is: “How many meters can this dicing blade cut?” Unfortunately, there is no simple answer. Blade life and cut quality depend on a wide range of variables, making accurate predictions difficult without detailed process information.

Even under seemingly identical conditions, performance can vary. One user may achieve excellent blade life with low levels of front- and back-side chipping, while another may experience premature wear or yield loss cutting the same wafer or package type. This variability often arises from differences in feed rate, spindle speed, coolant delivery, mounting method, or even wafer back-grinding stress and metallization layers.

For manufacturers, providing a numerical estimate can be problematic, as customers often treat it as a performance guarantee. Instead, accurate predictions rely on collecting and analyzing detailed usage data. This includes machine type, RPM, feed rate, coolant chemistry, and the target cut quality. With this information, blade specifications can be matched more closely to real application conditions.

Historical data analysis also improves prediction accuracy. By reviewing past results across similar materials and setups, trends can be identified. Some manufacturers now apply advanced data analytics and machine learning to large datasets of field results, improving the reliability of estimates.