Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

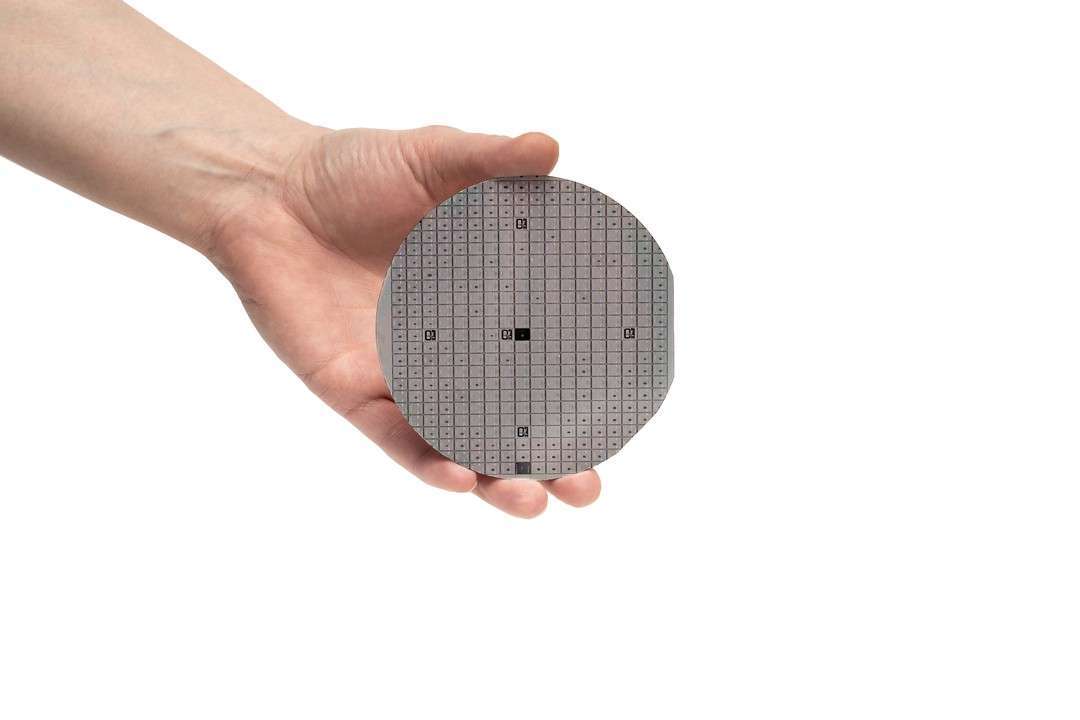

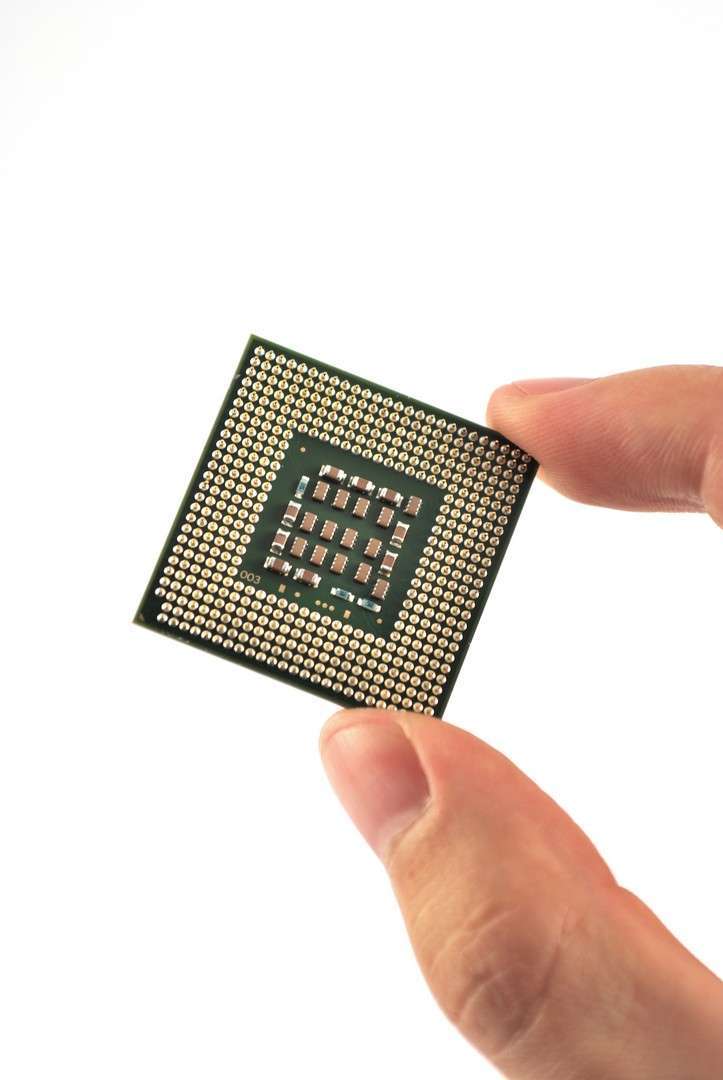

SMART CUT® Series (SC®) RESIN BOND DIAMOND & CBN DICING BLADES

Maintain excellent form & sharpness. Providing lower wear rate, longer life, and minimum level of chipping on wide variety materials.

SMART CUT® Resin series New Generation & Technology Dicing Blade is the highest performance Resin Bond Dicing Blade available today! SMART CUT® Resin Dicing Blade lasts longer than any resin bond diamond dicing blade and maintains better form & shape consistently through its life. Resin Bond dicing blade are typically more forgiving, self dressing, and freer cutting. Excellent choice for Ultra Hard & Brittle Materials. Recommended for applications where cut quality and surface finish is very important.

SMART CUT® Resin series New Generation & Technology Dicing Blade are produced using phenolic resin as the binder, diamond abrasive as cutting media, ceramic & other advanced components as filler. UKAM Industrial Resin Bond Blades are manufactured with advanced molding process. available in a large variety of geometries, diamond sizes, diamond concentrations, and bond harnesses.

Resin bond dicing blades are made with high temperature phenolic resin, diamond particles, ceramic filler and often additional additives. Resin Bond is the softest of all the bonds, frequently used in applications that require a smooth surface. This type of dicing blade is used on majority of ultra hard & brittle materials. Resin bond dicing blades allow the bond matrix to wear faster, and allow for diamond particles/crystals to break out of their matrix faster, so that new sharp diamond particles become exposed. This self sharpening characteristic of resin bond dicing blades, based on faster bond wear out is what make this blade choice in almost half of all dicing application. Typical Resin Bond Diamond Blades last less than Sintered (Metal Bond) diamond blades, but more than electroplated (nickel bond) diamond blades. finish and minimum amount of chipping.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT ® Resin Bond Diamond & CBN Dicing Blades, immediately penetrate into the material, grinding and polishing as they cut.

Diamonds or CB Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

The newly exposed diamonds don't effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Will outlast conventional Resin Bond Dicing Blades SMART CUT® RESIN are more sturdy than blades manufactured with conventional technologies.

Unlike many other resin bond blades, they will not dull and maintain its firm shape and roundness all the way through the blades life.

SMART CUT® RESIN SCR Dicing Blades can accommodate higher loads and feed rates. And may be used on both low & high power saws. Exhibiting unmatched Stability, Flexibility, & Conductivity.

More universal SMART CUT® RESIN SCR Dicing Blades can accommodate higher loads and feed rates. And may be used on both low & high power saws. Exhibiting unmatched Stability, Flexibility, & Conductivity.

SMART CUT® RESIN SCR are more durable than resin bond blades. Their heavy duty construction is designed to minimize and prevent blade wreckage. And unlike conventional resin bond dicing blades, SMART CUT® RESIN SCR dicing blades require significantly less dressing. This provides 2 very distinct advantages:

SMART CUT® RESIN SCR open bond design allows diamonds to absorb excessive heat and tension generated by repeated use, promoting consistency in cut cleanness and smoothness. You will notice the difference in the quality of the cut these blades leave behind.

Blade requires minimal dressing, the bond renews itself.

More aggressive than your ordinary blades. They cut faster, still leaving behind a smooth finish as you would expect from a resin bond.

Resin bond must remain very fragile in order to expose new diamonds. Resin bond is the softest of all the dicing bond matrixes. For this reason, strong and high quality diamonds cannot be used in a resin bond. High quality diamonds are harder than a resin bond matrix. and would soon disintegrate the bond. that keeps them in place. This brings about the need for frequent blade dressing causing the cut to lose its roundness or form.

Resin bond blades provide high wear rate, lack of stiffness and thickness limitation.

Resin bond can cut hard & brittle materials fast, but will provide much shorter life. Thinnest blades that can be produced in resin bond is .004. Many of the resin bond dicing blade limitation have been resolved by utilizing different phenolic resin types, mixtures, fillers and molding techniques in our New Generation Extended Wear Resin Bond and Hybrid Bond dicing blades. Hence increasing their field or use in greater amount of applications.

The guide below will help you select the right blade to your material/application, fast and easy. Just locate the material you are working with. On right hand side of material and abbreviation you will find recommended diamond particle size, bond hardness to use for your application. Along with the SMART CUT ® bond series recommendation.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales