-

0 items in quote

No products in the Quote Basket.

NEW GENERATION AND TECHNOLOGY

HYBRID BOND

SMART CUT® Series (SCH)

Diamond & CBN Dicing Blades

SMART CUT® HYBRID (RESIN) SCH series New Generation & Technology Dicing Blade is the highest performance dicing blade available today.

SMART CUT® SCH Series Hybrid Bond Dicing Blades are a breakthrough in dicing blade technology, combining the exceptional longevity of sintered (metal bond) blades with the superior precision, smoothness, and minimal chipping of resin bond blades. Developed in response to the need for a longer-lasting resin bond blade, this series was engineered through years of research, development, and real-world testing, resulting in a blade that delivers unparalleled performance, efficiency, and consistency.

Unlike conventional resin bond blades, which tend to wear down quickly and require frequent dressing, the SMART CUT® SCH Series is designed for extended life, lasting three to four times longer than traditional resin bond dicing blades. The hybrid bond structure provides exceptional wear resistance, maintaining its form, shape, and cutting precision throughout its lifespan. These blades excel in high-load and high-feed-rate applications while retaining their integrity and performance under demanding conditions.

The Best of Both Worlds: Longevity Precision

SMART CUT® SCH dicing blades provide the durability of metal bond blades without sacrificing the cutting quality of resin bond blades. This innovative hybrid bond formulation minimizes chipping, delivers best cut quality, and maintains tight tolerances, making it the perfect choice for applications requiring both long blade life and high cut quality.

These blades are engineered to be more universal, and are capable of handling higher loads and feed rates without degradation. The advanced diamond orientation and bond structure ensure that each diamond works at maximum efficiency, reducing unnecessary wear and optimizing cutting performance.

Unmatched Performance Features

With its self-sharpening open bond structure, the SCH Series prevents glazing, ensuring the bond renews itself naturally, minimizing dressing requirements while maintaining peak cutting efficiency. The blades feature maximum coolant absorption, allowing better heat dissipation and improved coolant retention, which prevents overheating and enhances cut quality.

The aggressive cutting action allows the SCH Series to cut faster than standard resin bond blades, yet still provides a clean, smooth finish with minimal material deformation. The superior structural integrity of the blade ensures that it maintains consistent roundness, cutting speed, and accuracy, resulting in repeatable, high-quality cuts throughout its life.

SCH Series significantly reduces blade wear, ensuring extended operation before replacement. Its robust design minimizes chipping and prevents material damage, maximizing process consistency and precision. Unlike conventional resin bond dicing blades, SMART CUT® SCH blades require minimal dressing, helping to maintain consistent cutting speed and performance while reducing downtime and operating costs.

By combining the longevity of sintered (metal bond) blades with the superior cut quality of resin bond blades, SMART CUT® SCH Series Hybrid Bond Dicing Blades set a new standard in dicing performance. These blades provide unmatched durability, efficiency, and cost savings—ensuring maximum return on investment for manufacturers seeking the best balance between blade life and cut quality.

- Outside Diameter (D): 2” (50mm) to 6” (154mm)

Blade Thickness Range

- Thickness (TE): 80 µm to 1500 µm

- Ultra-Thin Blades: Down to 45µm available for high-precision applications

- Standard Thickness Tolerances: ±0.002” (higher tolerances available upon request)

Inside Diameter (Arbor Hole)

- Standard Sizes: 40mm

- Custom Inside Diameters: Available to fit specific dicing saws or mounting requirements

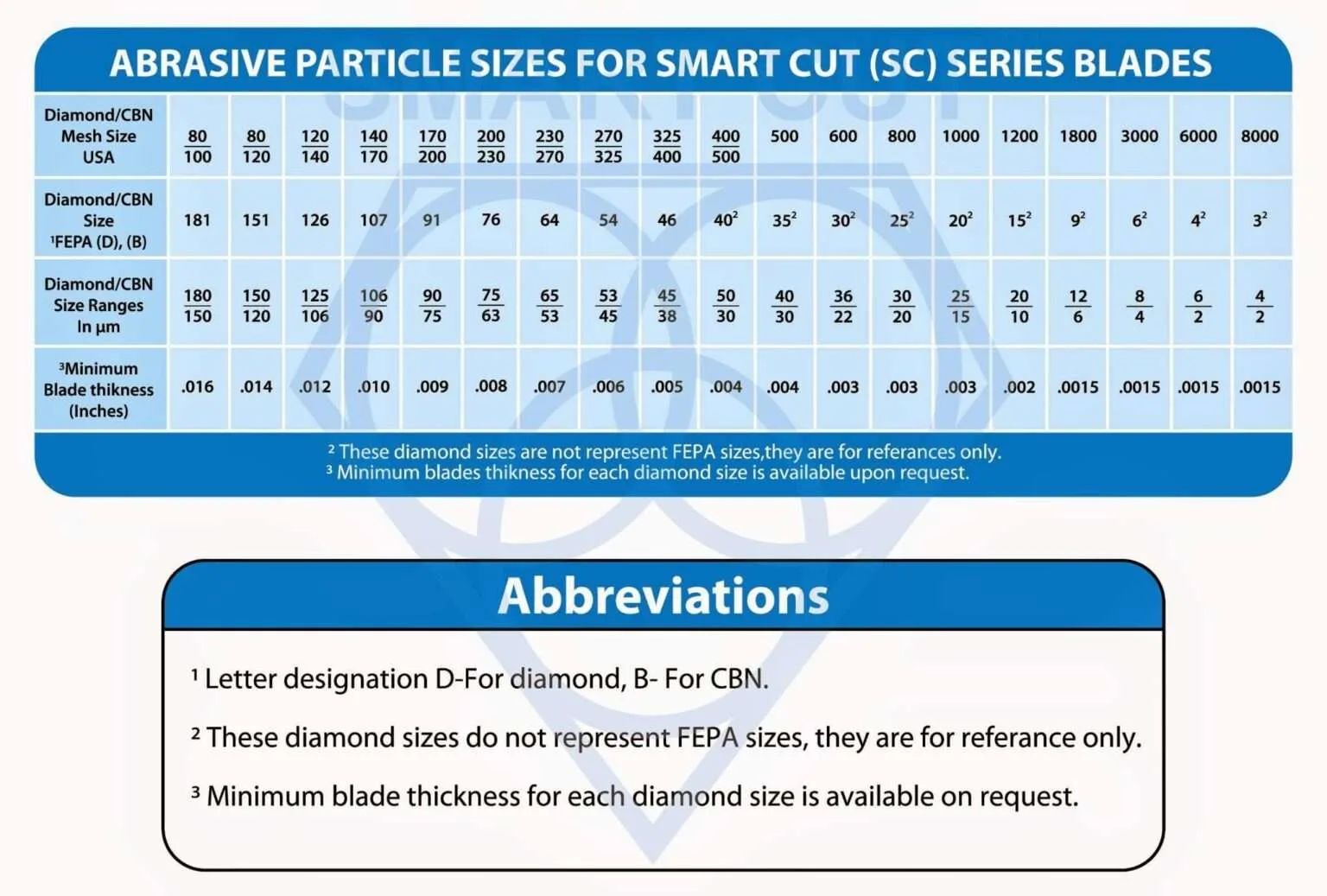

Diamond Grit Sizes

SMART CUT® Hybrid Bond Dicing Blades are available in a broad range of diamond grit sizes, enabling users to balance cutting speed, surface finish, and blade longevity:

- Diamond Grit Size Range: 2µm to 70µm

- Fine Grits (2µm - 15µm): Recommended for ultra-precise applications requiring a superior surface finish and minimal chipping

- Medium Grits (30µm - 54µm): Best for general-purpose cutting of brittle and dense materials

- Coarse Grits (D76 - D126): Ideal for aggressive material removal and faster cutting rates

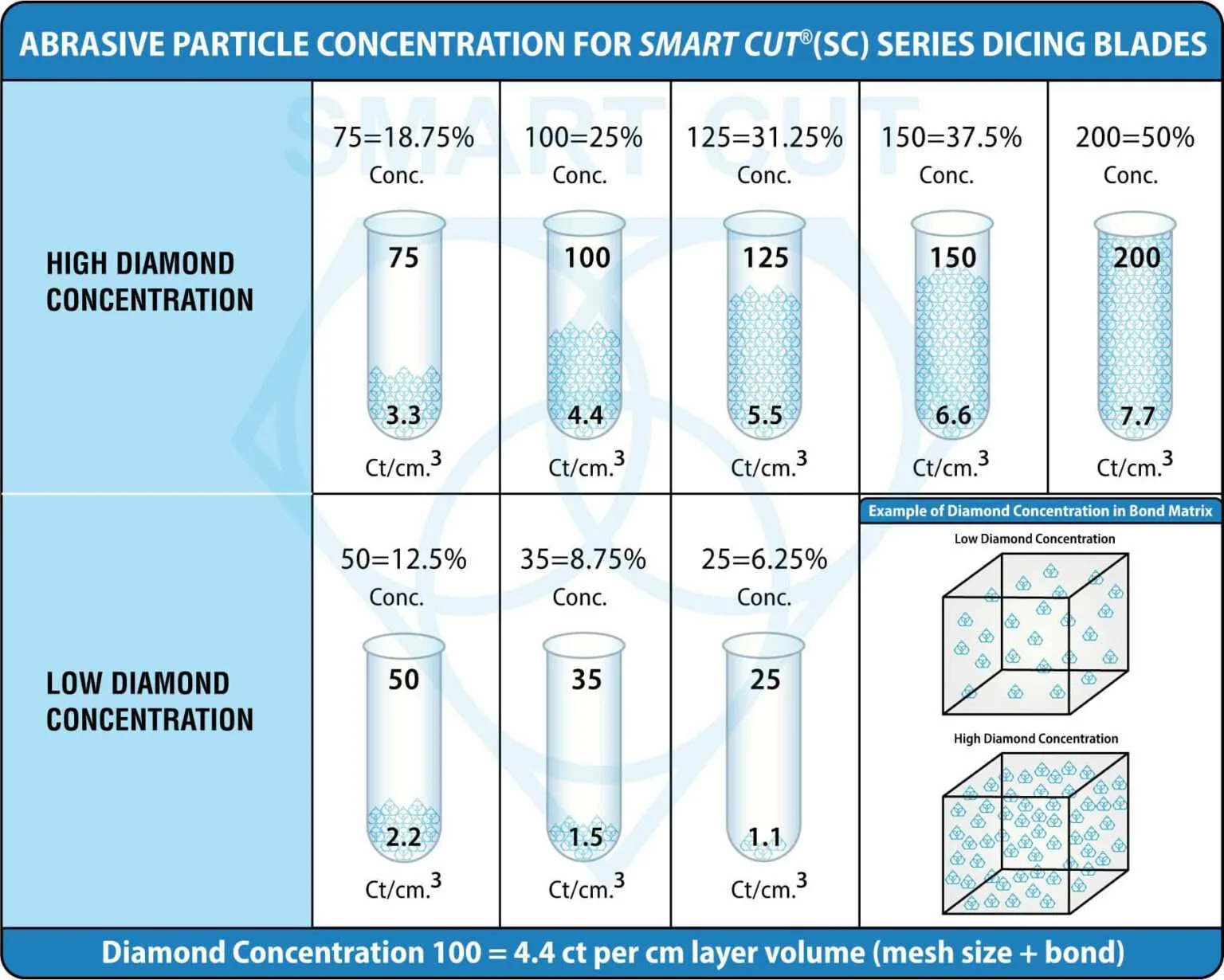

Diamond Concentration

The diamond concentration is precisely controlled to optimize blade performance based on the material being cut. Higher concentrations extend blade life, while lower concentrations improve free-cutting action.

- High Concentration: Used for cutting hard, dense materials like fiberglass (FGS), tungsten carbide (TGC), QFN packages, tool steels, Inconel, and Monel

- Low Concentration: Recommended for brittle and fragile materials such as optical glass, ceramics, lithium niobate (LiNbO₃), sapphire, quartz, and silicon carbide (SiC)

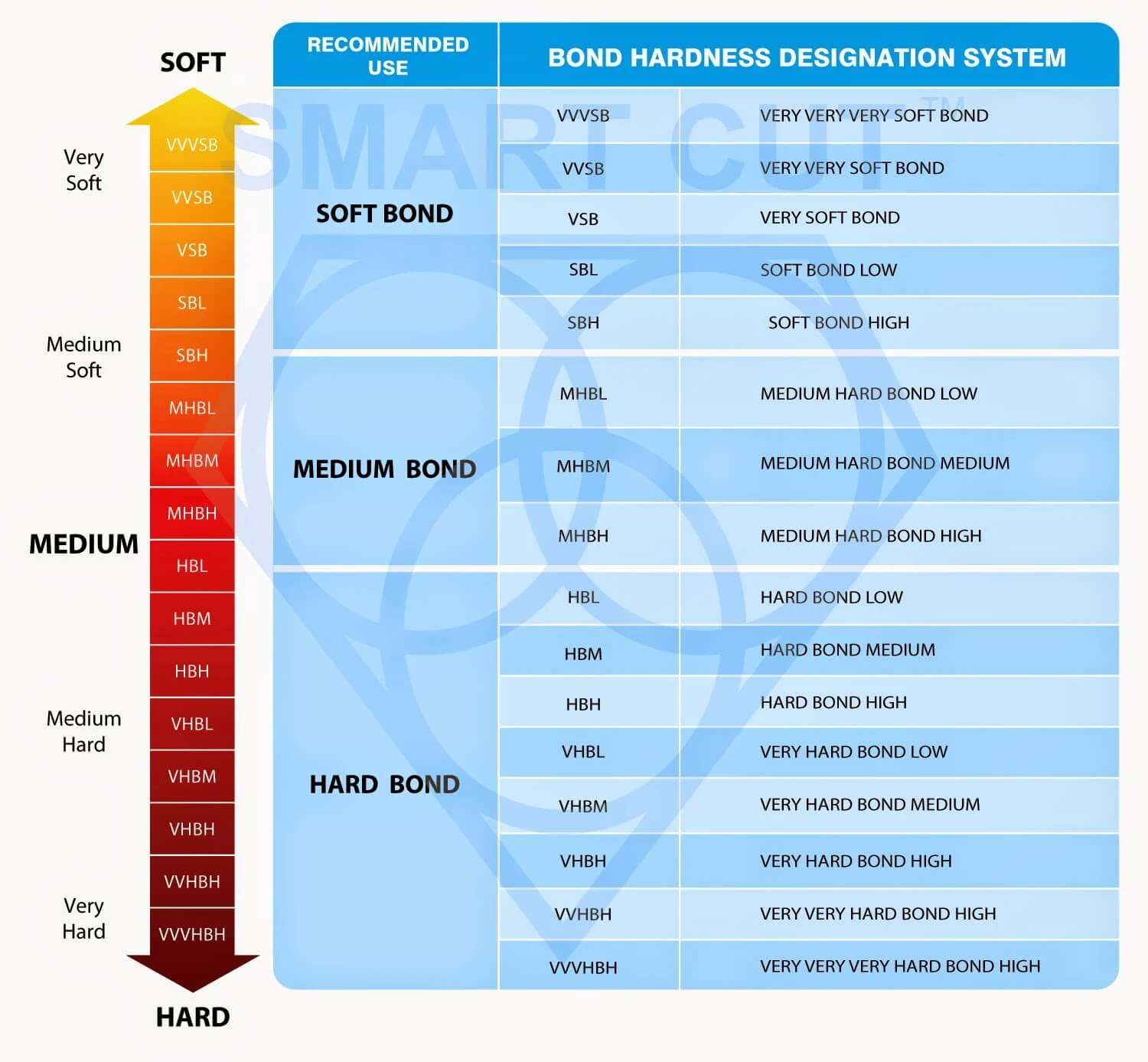

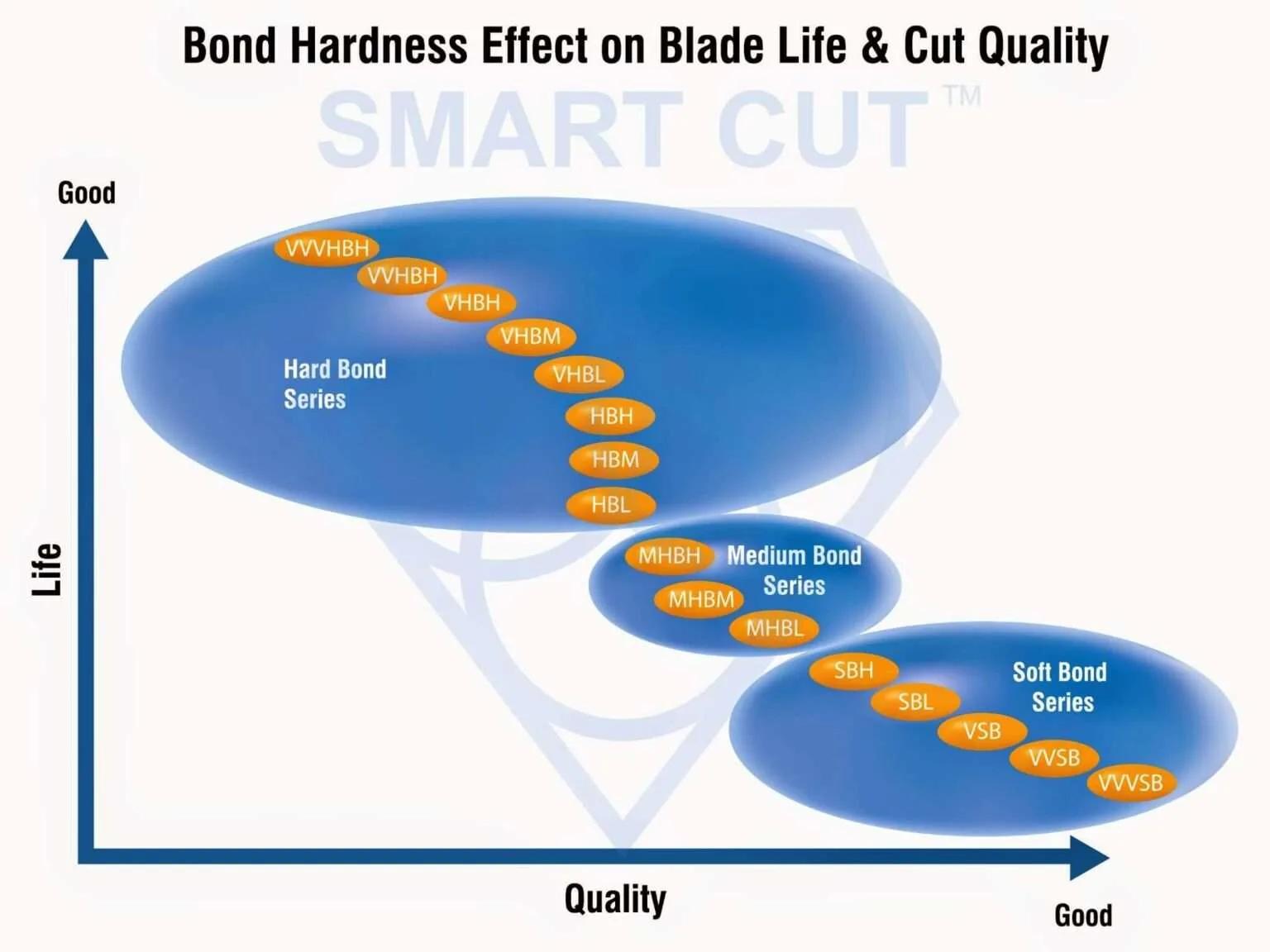

Bond Hardness Designation System

SMART CUT® sintered metal bond dicing blades come in multiple bond hardness formulations to match specific applications:

- Hard Bonds (VVVHB, VVHB, VHBH, HBH, HBM): Best suited for aggressive cutting applications requiring long blade life and high wear resistance

- Medium Bonds (SBL, MHBL, MHBM): Balanced formulation for controlled wear and stable cutting performance

- Soft Bonds (VVVSB, VVSB, VSB): Ideal for fast cutting, reduced heat generation, and minimal material deformation

Edge Profiles and Serration Options

To enhance performance in specific cutting applications, SMART CUT® offers a variety of serrated and edge profile options:

- Straight Edge: Provides smooth, clean cuts for materials with minimal chipping concerns

- Serrated Edge: Increases coolant flow and debris removal, reducing heat buildup and improving cut quality

- Custom Edge Geometries: Available upon request for specialized applications

Tolerance Standards

SMART CUT® dicing blades are manufactured to extremely tight tolerances, ensuring high precision and repeatability:

- Outside Diameter Tolerance: ±0.002”

- Blade Thickness Tolerance: ±5µm to ±15µm (depending on thickness and application)

- Runout: ≤ 0.001” (≤ 25µm) for high-precision applications

SMART CUT® Hybrid Bond Dicing Blades are a revolutionary new type of blade that combines the durability of sintered (metal bond) blades with the precision and smoothness of resin bond blades. This hybrid technology results in a blade that provides superior performance, longer lifespan, minimal chipping, and excellent cutting quality for high-precision applications.

The SMART CUT® Hybrid Bond Dicing Blade uses an innovative bond that allows the diamonds to stay sharp throughout the cutting process. The unique bonding system releases diamonds gradually during operation, allowing the blade to maintain its cutting efficiency without glazing. This feature prolongs the life of the blade and ensures consistent, high-quality cuts.

- Superior Cutting Performance: Cuts faster than conventional blades, with a smooth finish.

- Longer Blade Life: Lasts 3 to 4 times longer than traditional resin bond blades.

- Minimal Chipping: Provides cleaner cuts with reduced chipping, especially in brittle materials.

- Self-Sharpening: The bond renews itself, minimizing the need for dressing and maintaining cutting efficiency.

- Excellent Surface Finish: Delivers high-quality cuts with better surface finish quality.

- Reduced Blade Wear: Decreases blade wear and increases process consistency.

- Coolant Retention: Improved coolant retention reduces the risk of material deformation and contamination.

These blades are ideal for cutting hard and brittle materials, including:

- Semiconductors (Silicon, GaAs, etc.)

- Ceramic substrates

- Glass

- Quartz

- Advanced materials used in microelectronics, optics, and other precision industries.

Unlike traditional resin bond blades, which wear quickly and require frequent dressing, SMART CUT® Hybrid Bond Blades offer increased durability, longer life, and superior cutting precision. They combine the strengths of both resin and metal bonds, allowing them to cut faster while maintaining a consistent cutting speed, surface finish, and minimal chipping.

To get the most out of your SMART CUT® Hybrid Bond Dicing Blade:

- Use the recommended cutting parameters (RPM and feed rates) for your specific material.

- Ensure adequate coolant supply to manage heat buildup during the cutting process.

- Regularly inspect the blade for wear and replace it when necessary to maintain optimal performance.

Yes, these blades are designed to be compatible with most dicing saws, both low and high power machines. Ensure that the blade’s diameter and arbor size match the specifications of your equipment.

For best results, we recommend using synthetic low IFT (Interfacial Tension) coolants or lubricants specifically designed for use with dicing blades. These coolants improve the blade’s performance by reducing heat generation, minimizing friction, and ensuring consistent cutting results. SMART CUT® XP Dicing Fluid, Coolant, & Surfactant and SMART CUT water soluable coolant

While SMART CUT® Hybrid Bond Dicing Blades may have a higher initial cost compared to traditional resin bond blades, their extended lifespan, reduced wear, and superior performance make them a cost-effective choice in the long run. These blades reduce the need for frequent replacements and dressing, ultimately lowering your total cost of ownership.

Yes, we offer a free trial order guarantee. You can request a sample of the SMART CUT® Hybrid Bond Dicing Blades to evaluate their performance in your specific application. Please contact us for more details on how to place a trial order.

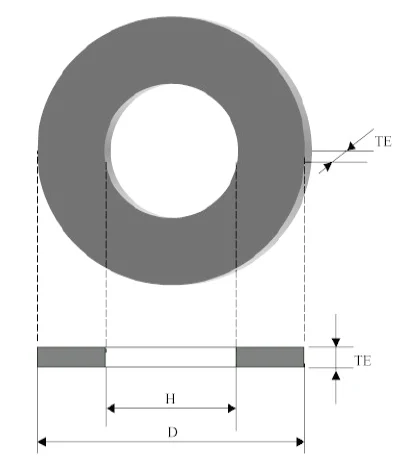

- Size Designation: The blade size is specified as D x TE x H, where D is the outside diameter, TE is the blade thickness, and H is the blade inside diameter.

- Tolerance: The standard tolerance for outside diameter is +/- 0.002″. Higher tolerances are available upon request.

For more detailed specifications, or if you need help determining the right blade for your application, please contact us directly.

Lead times typically range from 5 to 10 business days, depending on the size and customization requirements of the blade. Expedited shipping options are also available upon request.

SMART CUT® Hybrid Bond Dicing Blades are designed for maximum cutting performance with their innovative open bond structure. This unique design allows the diamonds to absorb excessive heat and tension generated during the cutting process, ensuring the blade stays cooler and operates at peak efficiency. The result is faster cutting speeds, reduced wear, and consistently smooth finishes, which significantly enhance overall cutting efficiency.

No, one of the key advantages of the SMART CUT® Hybrid Bond Dicing Blade is that it prevents material contamination and deformation. Unlike other blades, the SMART CUT® Hybrid Blade does not use low-quality diamonds that could break loose and fall into the material being cut. The hybrid bond structure maintains sharp, high-quality diamonds throughout the cutting process, ensuring a clean, accurate cut without contaminating the material.

Yes, the SMART CUT® Hybrid Bond Dicing Blades are versatile and can be used on both low and high-power saws. They are designed to accommodate a wide range of cutting applications, whether you are working with a small, precision saw or a larger, high-power system.

SMART CUT® Hybrid Bond Dicing Blades offer a superior cost of ownership by providing longer blade life, fewer blade changes, and reduced dressing requirements. With their durability and minimal maintenance needs, you will experience less downtime and lower operational costs in the long run. The blade’s ability to maintain its sharpness and cutting efficiency ensures that your process remains consistent and cost-effective.

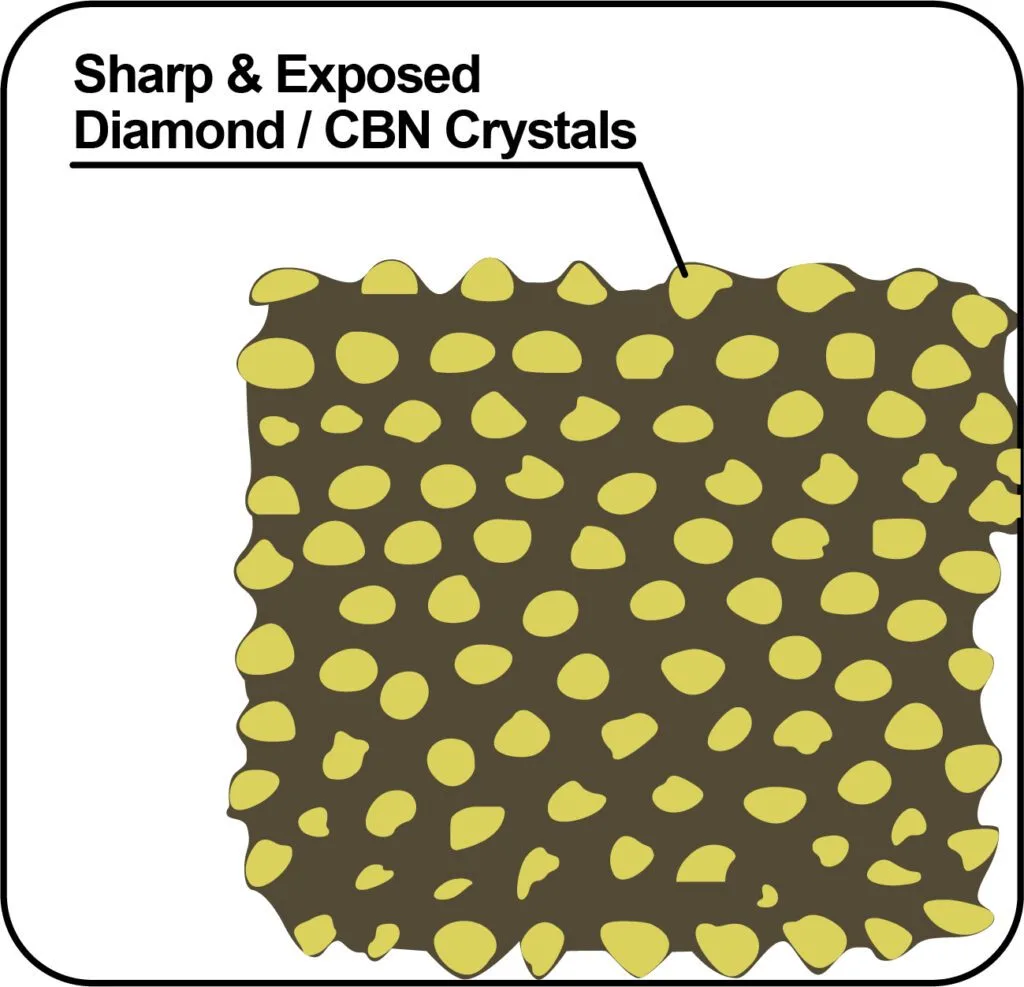

The SMART CUT® Hybrid Bond Dicing Blade is designed to provide a superior surface finish by maintaining a sharp cutting edge throughout its use. The self-sharpening bond ensures that the diamonds stay exposed and continue to perform optimally, resulting in smooth cuts with minimal chipping. This is particularly important when working with materials that require a high-quality finish, such as semiconductors and ceramics.

SMART CUT® Hybrid Bond Dicing Blades stand out from traditional resin bond and sintered (metal bond) blades by offering the best of both technologies. They combine the precision and smoothness of resin bond blades with the durability and long-lasting performance of sintered metal bond blades. This innovative hybrid technology provides faster cutting, superior surface finish, longer blade life, and reduced chipping, making SMART CUT® Hybrid Bond Blades an ideal choice for a variety of high-precision dicing applications.

Yes, SMART CUT® Hybrid Bond Dicing Blades are available in a wide range of sizes, thicknesses, and arbor diameters to suit your specific cutting needs. Custom specifications can also be accommodated, including tailored tolerances for specialized applications. Please contact our team for more information on custom options and to discuss your specific requirements.

SMART CUT® Hybrid Bond Dicing Blades offer faster cutting speeds compared to conventional resin bond blades while maintaining exceptional cut quality. The blade’s unique design provides high cutting efficiency with a smooth finish, reducing the need for secondary operations. Whether you are cutting delicate semiconductors or tough ceramics, these blades consistently deliver superior results.

The SMART CUT® Hybrid Bond Dicing Blade’s self-sharpening open bond design minimizes the need for frequent dressing, a common requirement with conventional resin bond blades. This feature allows the diamonds within the blade to continuously renew themselves, ensuring consistent cutting performance throughout the blade’s life. As a result, the blade maintains its shape and sharpness, reducing both downtime and maintenance costs.

What makes the SMART CUT® Hybrid Bond Dicing Blade’s bond structure superior to other dicing blades?

The SMART CUT® Hybrid Bond Dicing Blade combines the best attributes of both resin and metal bond technologies. The resin bond provides the ability to expose sharp, high-quality diamonds, ensuring a smooth and precise cut. At the same time, the metal bond component enhances durability and wear resistance, significantly extending the life of the blade compared to traditional resin bond blades. This hybrid structure allows for exceptional performance in both precision and longevity.

The SMART CUT® Hybrid Bond Dicing Blade’s construction provides improved cutting consistency by maintaining a sharp and stable cutting edge throughout its life. The blade’s design ensures that the cutting action remains stable, even under heavy loads, leading to consistent cut quality with minimal variation in results. This consistency helps improve overall process control and reduces the likelihood of defects in the final material.

One of the standout features of the SMART CUT® Hybrid Bond Dicing Blade is its ability to prevent glazing. Glazing occurs when the blade becomes clogged with material debris, which can slow cutting speeds and negatively affect cut quality. Thanks to the blade’s open bond structure, diamonds remain exposed and continue to perform optimally throughout the cutting process. This ensures that the blade remains sharp and free from material buildup, allowing it to cut faster and maintain a smooth finish.

SMART CUT® Hybrid Bond Dicing Blades are designed to perform best in a controlled cutting environment with adequate coolant application and stable feed rates. To maintain optimal performance, ensure that the cutting area is free from excessive vibration, and that the coolant is consistently applied to manage the temperature and reduce friction. Proper equipment setup, such as maintaining the correct RPM and feed rate, is crucial for achieving the best results.

The SMART CUT® Hybrid Bond Dicing Blades provide an excellent return on investment due to their longer lifespan, reduced need for dressing, and fewer blade changes. By minimizing downtime and increasing process consistency, these blades can significantly improve operational efficiency and reduce overall costs. Their superior performance also reduces scrap rates, contributing to further cost savings.

Yes, SMART CUT® Hybrid Bond Dicing Blades are versatile and can be used for dicing both thin and thick materials. The blade’s unique design ensures high performance across various material thicknesses, offering consistent cutting precision. Whether you’re working with delicate, thin films or thicker, more robust substrates, the SMART CUT® Hybrid Bond Dicing Blade provides the ideal balance of speed, durability, and cut quality.

The open bond design of the SMART CUT® Hybrid Bond Dicing Blade plays a critical role in its superior performance. This design allows diamonds to continuously release and expose fresh, sharp edges during operation, ensuring the blade maintains its cutting ability throughout its life. The open bond also helps to keep the blade cooler during use by allowing for better coolant absorption, reducing heat buildup, and preventing glazing.

The maximum cutting speed for SMART CUT® Hybrid Bond Dicing Blades depends on the material being cut, blade size, and specific application. However, the blades are designed to handle high-speed cutting without compromising performance or blade longevity. For specific recommendations, it’s best to consult with a UKAM Industrial Superhard Tools representative or refer to the technical data sheet for your blade’s optimal cutting parameters.

The lifespan of your SMART CUT® Hybrid Bond Dicing Blade depends on several factors, including material type, cutting parameters, and usage. Generally, you should replace the blade when it shows significant wear, such as when the cutting speed decreases, when the blade begins to lose its roundness, or when it starts to produce poor-quality cuts. Additionally, if dressing the blade becomes more frequent or ineffective, it may be time for a replacement.

The SMART CUT® Hybrid Bond Dicing Blades are designed to minimize chipping by ensuring that the diamonds in the blade remain sharp and exposed throughout the cutting process. The blade’s hybrid bond structure allows for controlled diamond exposure and gradual release of worn diamonds, preventing excessive wear and ensuring that the blade maintains a clean cutting edge. As a result, the blades produce clean cuts with reduced chipping, even on brittle materials.

Yes, SMART CUT® Hybrid Bond Dicing Blades can be used for cutting multi-layered materials, such as those found in semiconductor packaging or complex composites. The precision and minimal chipping of the blade allow it to cut through multiple layers with high accuracy and consistency, making it an ideal choice for multi-layer applications where precise cuts and minimal material disruption are required.

Yes, SMART CUT® Hybrid Bond Dicing Blades can be customized to meet specific bond hardness requirements based on your cutting needs. The hardness of the bond influences the blade’s performance, wear rate, and ability to handle different materials. If you require a custom bond hardness for your application, please contact UKAM Industrial Superhard Tools, and we will work with you to develop the ideal solution for your needs.

Using SMART CUT® Hybrid Bond Dicing Blades can significantly improve production throughput. Their faster cutting speeds and longer operational life reduce downtime for blade replacements and maintenance, increasing overall productivity. The consistent cutting performance also reduces the likelihood of defects or inconsistent cuts, further optimizing the manufacturing process and enhancing throughput.

SMART CUT® Hybrid Bond Dicing Blades are particularly beneficial in applications that require precision and minimal surface damage, including:

- Semiconductor dicing: Cutting thin wafers with minimal chipping and surface finish defects.

- Ceramic dicing: For cutting hard, brittle materials like advanced ceramics and piezoelectric components.

- Optical materials: Cutting glass and quartz for optical components with high precision and clean finishes.

- Microelectronics: Dicing thin, delicate materials used in microelectromechanical systems (MEMS) and other high-tech applications.

The SMART CUT® Hybrid Bond Dicing Blade technology helps reduce the environmental impact of dicing operations in several ways. Its long-lasting performance minimizes the frequency of blade replacements, reducing waste generated from discarded blades. Additionally, the efficient cutting action of the blade leads to less material loss during the dicing process, resulting in higher yields and reduced scrap. The open bond structure also allows for better coolant retention, which helps to reduce the amount of coolant needed and minimizes waste.

SMART CUT® Hybrid Bond Dicing Blades reduce the frequency of blade changeovers due to their exceptional durability and long lifespan. Unlike traditional resin bond blades that wear quickly and require frequent replacements, SMART CUT® Hybrid Bond Blades maintain their sharpness and cutting performance for a significantly longer period. This not only reduces the number of blade changeovers but also lowers downtime, leading to improved productivity and reduced operational costs.

01

Jun

Share this Article with Friend or Colleague

Dicing QFN packages presents several challenges due to the composition of materials and the precision required for clean, defect-free cuts. These challenges arise from the multi-layered structure of...

02

Jun

Dicing Blade Operations Recommendations

Share this Article with Friend or Colleague

Selecting the right dicing blade parameters often involves a trial and error process, many aspects of which can be mitigated through experience and a deep understanding of how...

02

Jun

Optimizing Dicing Blade Performance

There are many variables that affect dicing blade performance. Each variable of the dicing process is only of the many components of a larger dicing system (equation). Changing one component or variable of...

02

Jun

Trouble Shooting Dicing Problems

Guide on most common dicing problems and how to resolve them

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP YOU

CONTACT US

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge...

02

Jun

Application Recommendations

See what blade specifications we recommend to use for different applications, along with rpm's and feed rated

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP...

Tab Content

Application

-

BGA Packages

BGA Packages

-

QFN

QFN

-

Aluminum oxide (Al₂O₃)

Aluminum oxide (Al₂O₃)

-

Silicon nitride (Si₃N₄)

Silicon nitride (Si₃N₄)

-

Silicon carbide (SiC)

Silicon carbide (SiC)

-

Sapphire Boron Carbide (B₄C)

Sapphire Boron Carbide (B₄C)

-

Alsmag

Alsmag

-

LiTaO₃ & LiNbO

LiTaO₃ & LiNbO

-

FR4 and Resin

FR4 and Resin

Features

- Excellent form & corner holding characteristics

- Best tolerances in the industry

- Superior Cut Quality

- Unmatched Consistency

- Self Sharpening Open Bond

- Requires Minimal Dressing

- Maximum cutting performance

- No glazing

- Faster cutting action

- Improved surface finish quality

- Better coolant retention

- No Material Deformation

- Lasts 3 to 4 times longer than conventional resin bond blades

Why Work With Us?

Best Return

on Investment

Attractive Cost of

Ownership

Thousands of Diamond & CBN Blades in stock

Custom Manufacturer with Fast Lead times

Unmatched

Prices in North America

Unmatched Experience & Technical Support

Different Technology

SMART CUT® technology

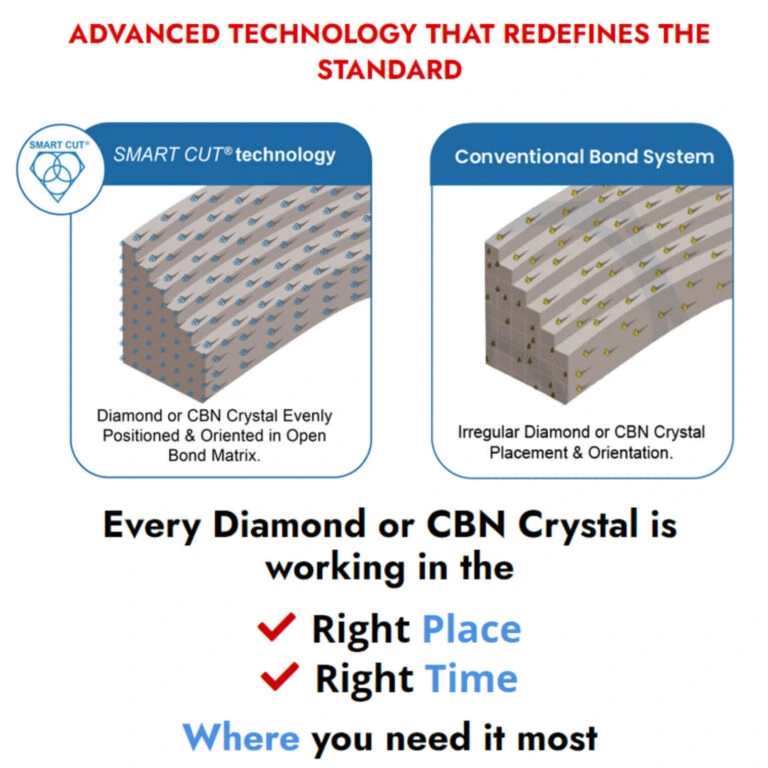

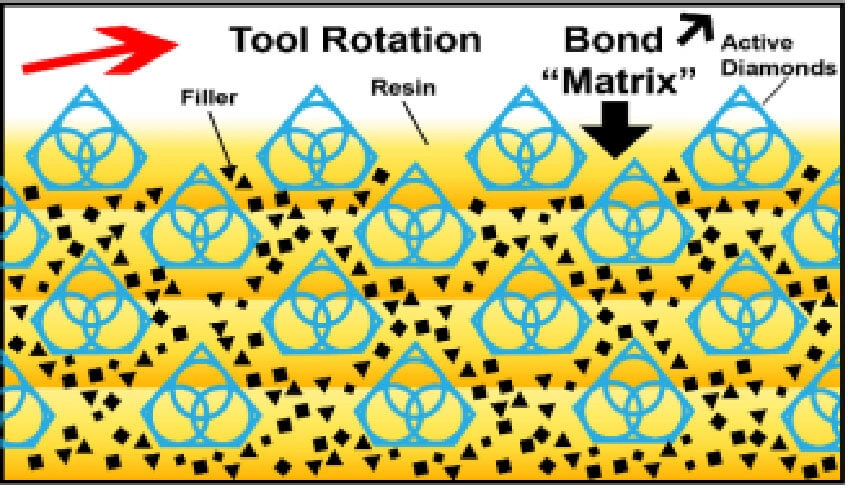

How SMART CUT® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

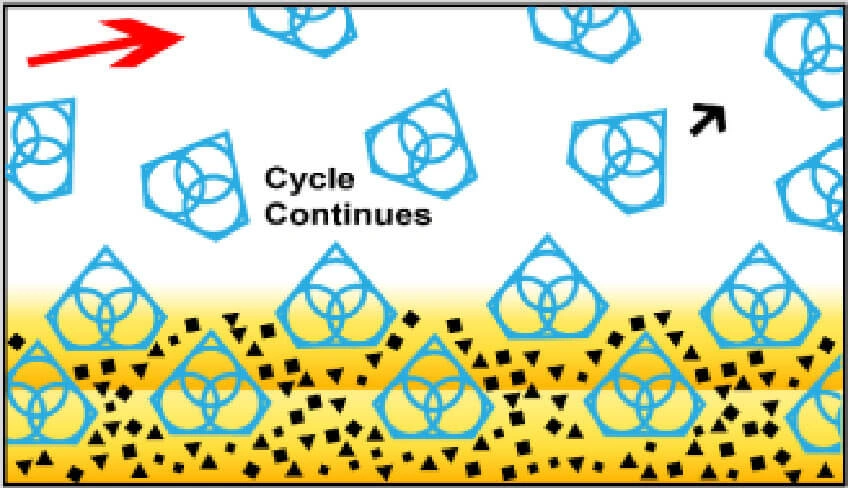

Step 2

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

SMART CUT® Difference

How SMART CUT® Dicing Blades are Different in comparison to other dicing blades.

Longer Lasting

Will outlast conventional Resin Bond Dicing Blades 3 to 1 or 4 to SMART CUT® RESIN/HYBRID SCH are more durable than blades manufactured with conventional technologies. Unlike many other resin bond blades, they will not dull and maintain its firm shape and roundness all the way through the blades life. SMART CUT® RESIN/HYBRID SCH Dicing Blades can accommodate higher loads and feed rates. And may be used on both low & high power saws. Exhibiting unmatched Stability, Flexibility, & Conductivity.

No Glazing

Blade requires minimal dressing, the bond renews itself.

Faster Cutting Action

More aggressive than your ordinary blades. They cut faster, still leaving behind a smooth finish as you would expect from a resin bond.

Maximum Coolant Absorption

SMART CUT® RESIN/HYBRID SCH open bond design allows diamonds to absorb excessive heat and tension generated by repeated use, promoting consistency in cut cleanness and smoothness. You will notice the difference in the quality of the cut these blades leave behind.

More Consistent Performance

SMART CUT® RESIN/HYBRID SCH are more durable than resin bond blades. Their heavy duty construction is designed to minimize and prevent blade wreckage. And unlike conventional resin bond dicing blades, SMART CUT® RESIN/HYBRID SCH dicing blades require significantly less dressing. This provides 2 very distinct advantages:

Blade will not lose its roundness or shape

- Minimum blade dressing

- Consistent cutting speed

- Minimum chipping

- Different Product

- Different Technology

- Different Company

Expect MORE from your tools

UKAM Industrial Superhard Tools

No Material Contamination & Deformation

A resin bond must remain very fragile in order to expose new diamonds. For this reason, strong and high quality diamonds cannot be used in a resin bond. High quality diamonds are harder than a resin bond matrix, and would soon disintegrate the bond that keeps them in place. For this reason, diamonds that are used in a resin bond are poor to medium quality. Most of them disintegrate or fall out of the bond, before they have a chance of being used. The problem with this approach is these diamonds fall into the material being dicing, causing unwanted contamination. The bond most widely used with diamond dicing blades is a resin bond. It is made of a tough polymer formed to hold the diamond particles to the rim of the dicing blade. Resin-bonded dicing blades remove material quickly. However, most resin bond dicing blades wear too fast. They also require frequent dressing (truing) to hold their form. A stronger bond type is a sintered (metal bond). Metal Bond dicing blades offer longer life & better form retention than resin bond dicing blades, and can be operated at higher speeds. Yet any users find that sintered (metal bond) dicing blades cannot be utilized for their application due to their requirements for edge quality/surface finish.

Compare to any Resin Bond Dicing Blade

Contact Us for FREE Quote & Recommendation

SMART CUT® Series SCH

Hybrid bond Specifications

Size Designation: D X TE X H, Where: D-Outside Blade Diameter, TE –Blade Thickness, H- Blade Inside Diameter.

Note: Our standard Tolerance on Outside Diameter for all blades is +/-.002”, tolerance. Higher tolerances are available upon request

SMART CUT® XP Dicing Fluid, Coolant, & Surfactant

Available in 4 Different Formulas to Fit Most Dicing Applications

XP-1 is a general-purpose dicing fluid within the SMART CUT® range, designed to reduce debris, improve tool life, and prevent corrosion, while ensuring smooth cutting and protecting sensitive materials from ESD.

XP-2 enhances lubrication for demanding applications, offering superior cutting speeds, tool longevity, and advanced cleaning capabilities for tough materials like SiC and sapphire.

XP-3 is ideal for high-pressure systems, offering consistent cooling performance without foam buildup.

XP-4 specifically protects electrostatic-sensitive components by eliminating ESD, reducing defects, and extending tool life during the dicing process.

Why Work With Us?

Comprehensive Source Of Information On Dicing Blades

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

Related Products

Resin Bond Dicing Blade

Nickel Bond Hubbed Dicing Blades

Sintered (Metal Bond) Diamond & Cbn Dicing Blades

Sintered (metal bonded) diamond tools have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal bonded diamond tools are impregnated” with diamonds.

Tungsten Carbide Dicing Blades

SMART CUT® Water Soluble Dicing Coolant

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

Recently Viewed Products

ARE YOU USING RIGHT DICING BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DICING BLADES?

01

Jun

Select right Diamond Dicing Blade for your application

Selecting the right diamond dicing blade & parameters for your material/application can be a very time consuming, trial & error frustrating process. The guide below has been designed to help you better understand the most important...

02

Jun

Dicing Blade Operations Recommendations

Share this Article with Friend or Colleague

Selecting the right dicing blade parameters often involves a trial and error process, many aspects of which can be mitigated through experience and a deep understanding of how...

02

Jun

Optimizing Dicing Blade Performance

There are many variables that affect dicing blade performance. Each variable of the dicing process is only of the many components of a larger dicing system (equation). Changing one component or variable of...

02

Jun

Trouble Shooting Dicing Problems

Guide on most common dicing problems and how to resolve them

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP YOU

CONTACT US

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge...

02

Jun

Application Recommendations

See what blade specifications we recommend to use for different applications, along with rpm's and feed rated

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP...

02

Jun

Dicing Blade Case Studies

This article provides important guidelines for optimizing the dicing process in semiconductor packaging, focusing on package singulation for various technologies such as BGA, QFN, LED, CMOS, and wafer substrates. It covers key variables such as...

01

Jun

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Share this Article with Friend or Colleague

Dicing QFN packages presents several challenges due to the composition of materials and the precision required for clean, defect-free cuts. These challenges arise from the multi-layered structure of...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

02

Jun

Diamond Tool Coolants Why, How, When & Where to Use

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

17

May

Get to Know the Diamond Tool Bond Types and Which to use for your application

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools help with detailed tasks like engraving and finishing, providing good control and helping you work efficiently....

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin, high precision cutting blades, precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use