-

0 items in quote

No products in the Quote Basket.

SMART CUT® DIAMOND DICING / SLICING SAW

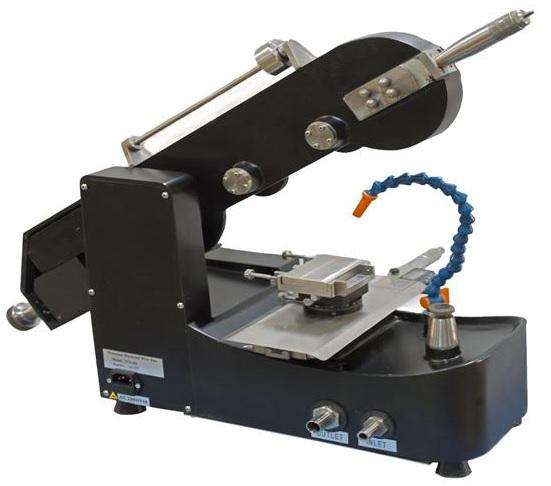

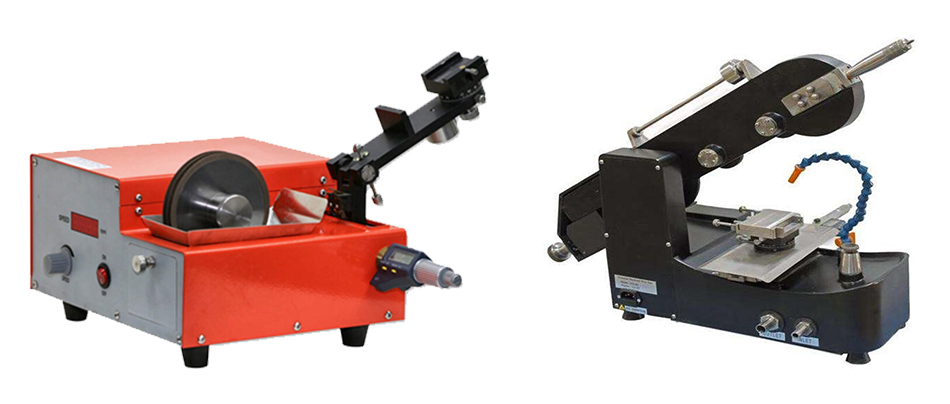

New CE certified Precision Diamond Slicing / Dicing Saw is designed for Laboratory and R & D use. This machine can be used for slicing, dicing or cutting all kinds of materials up 4″ diameter wafer or rectangular material up to 8″ length x 4″ width x 1″in depth saw is fully controlled by a computer ( any PC or Desktop computer) with position accuracy of 0.01 mm or better.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

ACCESSORIES

OPERATING MANUALS

DESCRIPTION

New CE certified Precision Diamond Slicing / Dicing Saw is designed for Laboratory and R & D use. This machine can be used for slicing, dicing or cutting all kinds of materials up 4″ diameter wafer or rectangular material up to 8″ length x 4″ width x 1″in depth saw is fully controlled by a computer ( any PC or Desktop computer) with position accuracy of 0.01 mm or better.

Machine comes with “Ready to Use” with Laptop with graphical user friendly software and USB cable are installed. As well as lexon enclosure for the machine to be used in “Lab” environment The sample stage with two-angle adjustment comes with the machine, which allows customers to cut materials at desired angle with +/- 0.5 Deg tolerance. Variable speed up to 3,000 RPM.

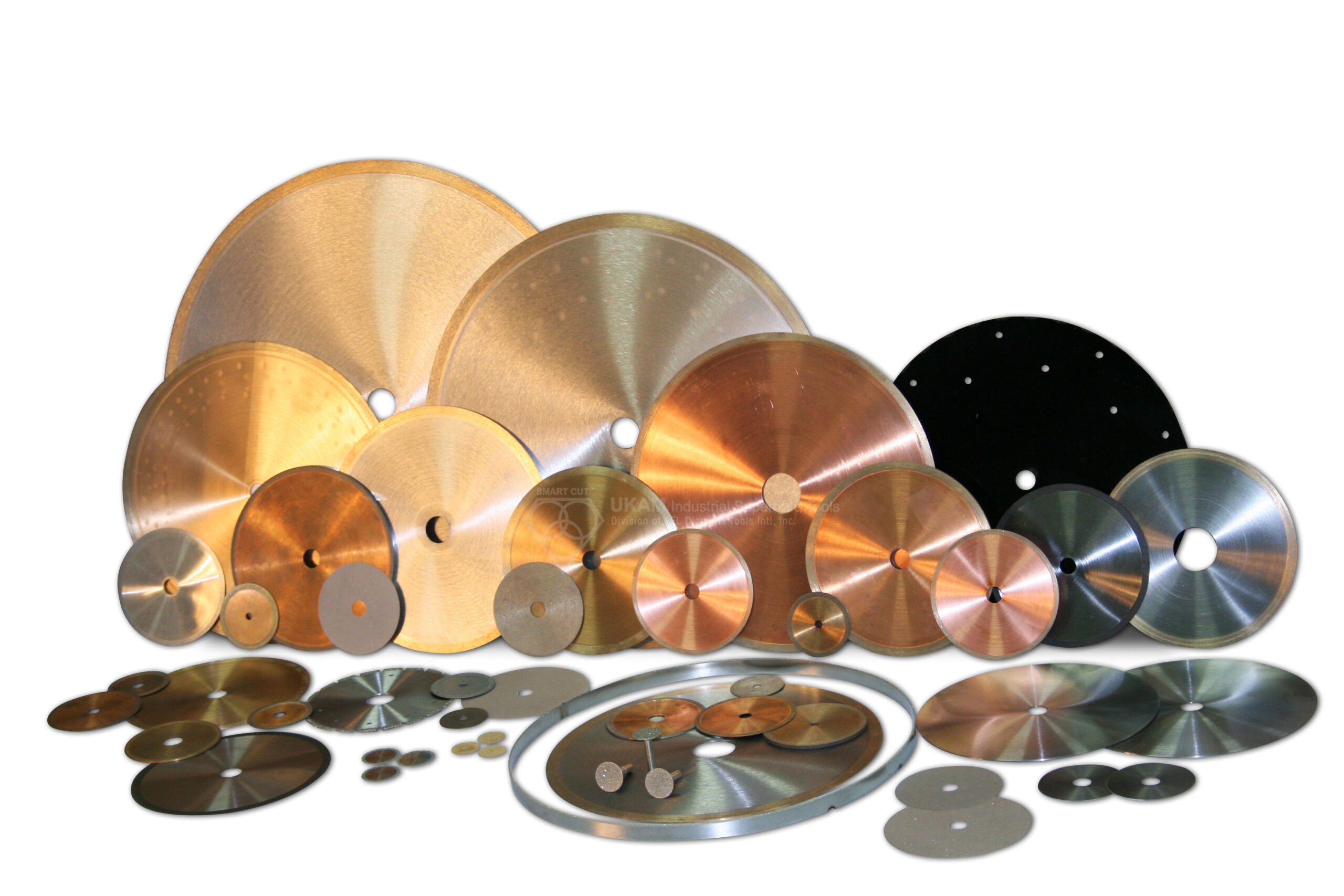

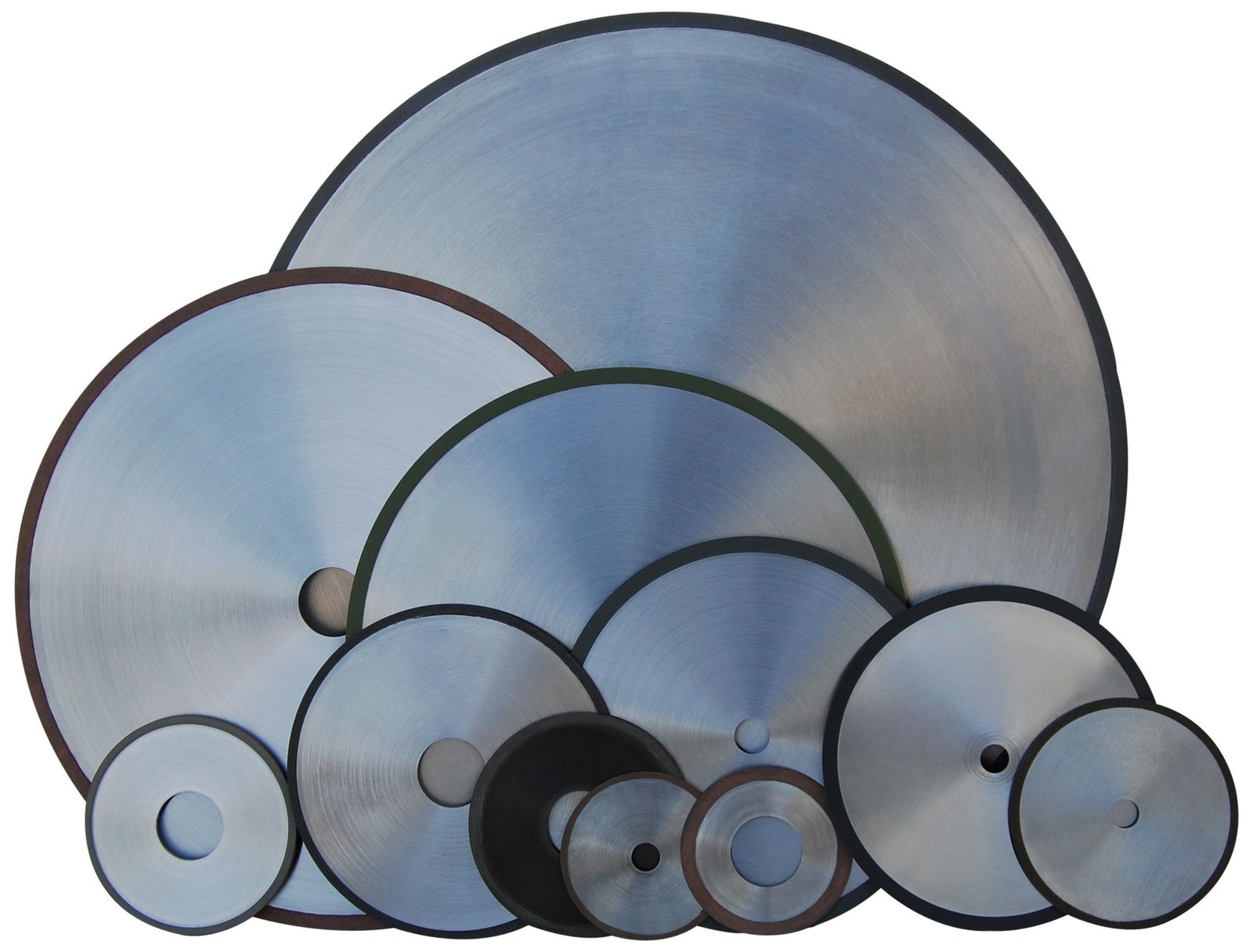

Accepts all types of blades. Including Precision Diamond Slicing, Dicing, & Wafering Blades from 3″ to 6″ in diameter. Such as Sintered (metal bond), Resin Bond, & Electroplated (nickel bond) hubless blades 1A1R, 1A8, 1A1, and etc. Affordable precision and cost effective dicing and cutting saw for R&D Labs in Materials and Micro-electronics Research. Typical applications that have benefited from the use of this machine include: wafers and sheets of optical, optoelectronic, semiconductor ceramic or related materials that need to be sectioned into smaller squares or rectangles. If this slicing/dicing

saw can meet your needs in dicing and cutting, why do you have to pay more for an expensive dicing saw?

SPECIFICATIONS

Voltage |

|

Motor | Brush-less magneto DC motor (110V) with variable speed up to 3,000 rpm. Power consumption: 180W |

Effective Cutting Range |

|

Accuracy | 0.0025 mm moving resolution and 0.01 mm position accuracy. |

Cutting Blades Kits |

|

Control mode |

|

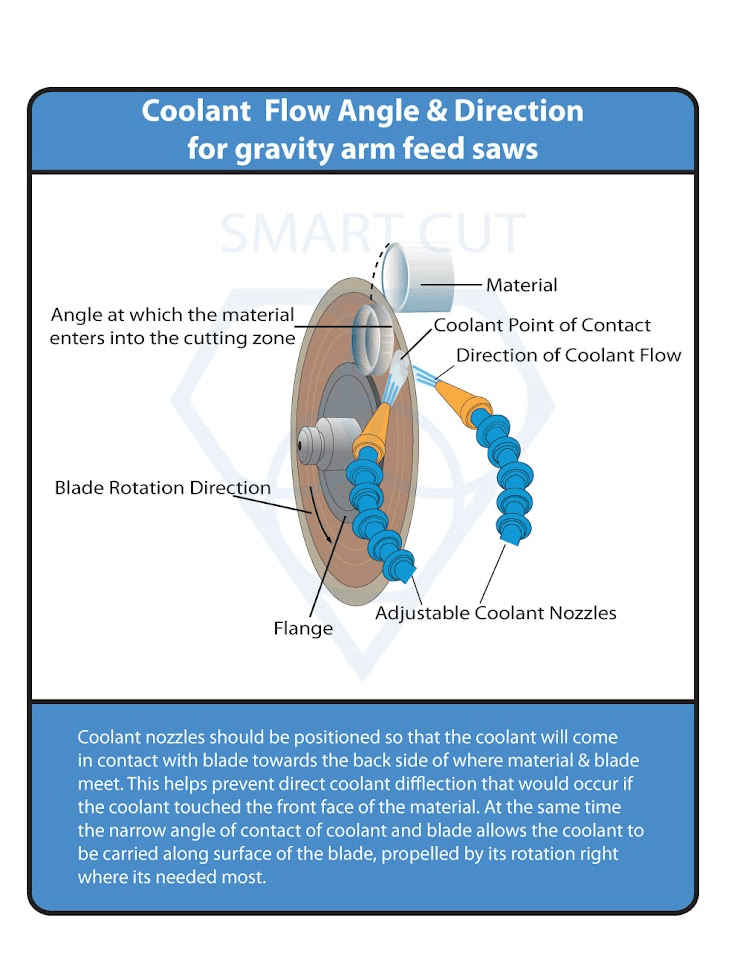

Water Cooling | Assemblies of water jetting, draining, and splashing protection are included. |

Net WT& DIMEN |

|

Shipping WT & DIMEN |

|

Warranty & Compliance | One year limited with lifetime support (warranty does not including damages caused by misuse, such as rusted parts from inadequate storage and broken parts by the user). |

Certification | CE certified |

ADVANTAGES

- Variable Speed from 100 to 3,000 RPM

- 1/2 HP motor powerful enough to almost all materials

- Fully CNC controlled by laptop computer with pre-installed windows based user friendly graphical interface software included

- CNC controlled step motor operates with 0.0025 mm moving resolution and 0.01 mm position accuracy.

- Accepts Blade Diameters from 3″ (75mm) to 6″ (154mm). Kerf thicknesses available from .004″ (125 microns) to .125″ (3.2mm)

- Unlimited number of blade specifications available from stock to fit almost any application

- Machine can be manually used with rotary hand wheels as well

- Can cut up to 4″ diameter wafers

- Can cut rectangular material 8″ L x 4″ W x 1″ depth

- Recirculation Coolant System (available)

- Enclosed(can be used in lab environment)

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

The SMART CUT® DIAMOND DICING / SLICING SAW is designed for laboratory and R&D use. It can be used for slicing, dicing, or cutting various materials, including up to 4″ diameter wafers or rectangular materials measuring up to 8″ in length, 4″ in width, and 1″ in depth.

The machine is fully controlled by a computer, which can be any PC or desktop computer. It offers a high position accuracy of 0.01 mm or better.

The machine comes “Ready to Use” with a laptop pre-installed with graphical user-friendly software and a USB cable. It also includes a Lexon enclosure for use in a laboratory environment. Additionally, a sample stage with two-angle adjustment is included for cutting materials at desired angles with +/- 0.5-degree tolerance. The machine has variable speed, with speeds of up to 3,000 RPM.

The machine accepts various types of blades, including Precision Diamond Slicing, Dicing, and Wafering Blades ranging from 3″ to 6″ in diameter. These blades can be of different bond types, including sintered (metal bond), resin bond, and electroplated (nickel bond) hubless blades, such as 1A1R, 1A8, 1A1, and more.

.004” (100 microns)

The machine can operate on AC 110V or AC 220V, with a +/- 10% tolerance. You can select and highlight the working voltage based on your requirement.

The SMART CUT® DIAMOND DICING / SLICING SAW comes with a one-year limited warranty, along with lifetime support. Please note that the warranty does not cover damages caused by misuse, inadequate storage, or user-induced breakages.

Yes, the machine is CE certified, ensuring it meets safety and quality standards.

Yes, the machine offers an optional Digital Microscope Head that allows you to monitor the cutting process in real-time on a PC screen. It can also be connected to the stereo microscope for enhanced observation.

Additional accessories available for this machine include a 4″ rotary table, a Precision Cross Mount Vise for Slicing/Dicing Saw, a Heavy Duty Coolant Circulating Tank with Pump, a 4″ Vacuum Chuck, and Wafer Bonding Tape for Vacuum Chuck. A full enclosure made from Lexon is also provided to maintain an enclosed cutting environment.

Yes, the SMART CUT® DIAMOND DICING / SLICING SAW is versatile and can be used to cut a wide range of materials, including optical, optoelectronic, semiconductor, ceramic, and related materials that need to be sectioned into smaller squares or rectangles.

The machine offers a high level of precision with a moving resolution of 0.0025 mm and a position accuracy of 0.01 mm. This ensures accurate and consistent cutting results.

Yes, the machine comes with user-friendly Windows-based software pre-installed on the included laptop. It allows you to easily set parameters such as sample shape, cut width, number of slices, cut depth, and blade kerf. The graphical interface simplifies the operation.

Yes, the machine can be manually operated using rotary hand wheels if necessary, providing flexibility in how you control the cutting process.

Yes, the machine comes with assemblies for water jetting, draining, and splashing protection. This ensures effective cooling and protection during the cutting process.

Yes, the machine includes a Lexon enclosure, making it suitable for use in a laboratory setting where environmental control is important.

The machine can cut wafers up to 4″ in diameter, providing flexibility for various applications.

Yes, the machine comes with comprehensive technical documentation and user manuals to assist with installation, operation, and maintenance.

The machine accepts an unlimited number of blade specifications, ensuring it can be tailored to fit almost any application. Additionally, it can be adapted with additional accessories and components as needed.

The shipping weight of the machine is approximately 150 lbs, and its dimensions are 43″L x 30″W x 34″H (inches). The net weight of the machine is 28.5 kg, with dimensions of 580 L x 560 W x 660 H (mm).

The machine operates on a brush-less magneto DC motor (110V) with variable speed up to 3,000 rpm. It consumes approximately 180W of power.

22. Is there an option for upgrading the microscope to digital for sample observation?

Yes, you have the option to upgrade the microscope to a digital microscope head, allowing you to observe sample cuts on a computer screen.

Yes, the machine includes a Precision Cross Mount Vise for Slicing/Dicing Saw, which is designed for cutting samples with a precision 90-degree angle (+/- 0.2 degrees) without the need for alignment.

The 4″ rotary table is used for precision rotating operations, while the vacuum chuck is used to securely hold wafers or substrates in place during the cutting process.

Yes, a 4-liter capacity heavy-duty coolant circulating tank with a pump is designed for use with the slicing/dicing saw to provide effective cooling during cutting operations.

Diamond blades are highly durable and can provide precise cuts, making them ideal for various materials. They can offer cleaner cuts and longer blade life compared to other blade types.

Yes, the machine operates with G code behind the user-friendly interface GUI. This allows the operator to program and control the machine’s operation directly if needed, offering advanced control options.

The vacuum chuck is used to securely hold wafers or substrates in place during the cutting process. When the vacuum valve is opened, the vacuum chuck creates suction, firmly gripping the material and ensuring stability during cutting.

The heavy-duty coolant circulating tank with a pump is designed to provide a continuous flow of coolant during cutting operations. It helps dissipate heat and maintains a stable cutting environment.

Yes, the machine can be used with Wafer Bonding Tape for Vacuum Chuck to bond thin substrates (less than 2.0 mm thickness) to the vacuum chuck securely, allowing for precision cutting.

A wafer or substrate is placed on removable adhesive film, which is then placed on the vacuum chuck. When the vacuum valve is opened, the vacuum chuck creates suction, firmly adhering the material through the adhesive film for cutting.

The full enclosure helps maintain an enclosed cutting environment, providing a controlled and safe workspace. It prevents debris from escaping during the cutting process and ensures operator safety.

Yes, the machine includes a sample stage with two-angle adjustment, allowing customers to cut materials at desired angles with a tolerance of +/- 0.5 degrees.

Yes, technical support is available to assist with the installation and setup of the SMART CUT® DIAMOND DICING / SLICING SAW, ensuring you can start using it effectively.

The Heavy Duty Coolant Circulating Tank operates on 208V to 240V power supply. If you need a 110V power supply, you can order a 200W transformer separately.

Yes, the machine can be used with a stereo microscope that provides 50X magnification and has a built-in reticule (scale) in nanometers and inches, making it suitable for high-magnification applications.

The 4″ rotary table is designed for precision rotating operations. It allows for accurate positioning and rotation of workpieces during cutting or other operations. It’s especially useful when precision alignment is required.

The 4″ rotary table is designed to handle small workpieces and is suitable for use with the SMART CUT® DIAMOND DICING / SLICING SAW and similar equipment. It is not designed for heavy loads.

Yes, the machine is flexible and can accept an unlimited number of blade specifications, allowing you to adapt it to various cutting applications.

You can contact the manufacturer or supplier to inquire about spare parts or additional accessories for the SMART CUT® DIAMOND DICING / SLICING SAW. They will assist you in obtaining the necessary components for your specific needs.

While primarily designed for laboratory and R&D use, it can also be used for production applications where precision cutting is required.

Yes, the machine can cut materials as thin as 1 mm with precision, making it suitable for delicate samples.

The Lexon enclosure and water cooling system help provide a safer working environment by containing debris and dissipating heat during cutting. Operators should still follow safety guidelines and wear appropriate protective gear.

Yes, the machine’s sample stage with two-angle adjustment allows for cutting materials at different angles, providing versatility in cutting various shapes.

Routine maintenance may include cleaning, blade replacement, and checking for loose parts. Detailed maintenance instructions can be found in the user manual.

Yes, the machine is suitable for research involving semiconductor materials and can help in sectioning semiconductor wafers into smaller pieces for analysis.

The machine’s G code-based software allows for customization to meet specific research needs. Users with programming skills can tailor the software to their requirements.

The machine can cut materials up to 1 inch (25.4 mm) in depth, providing ample depth for most applications.

Yes, the machine’s data can be exported and analyzed using third-party software tools for further research and analysis.

Yes, the machine can be shipped internationally, accept for countries where export is limited by US goverment

The time required to become proficient with the SMART CUT® DIAMOND DICING / SLICING SAW can vary depending on the operator’s familiarity with similar equipment and the complexity of the cutting tasks. However, with the user-friendly software and comprehensive documentation, users can typically become proficient relatively quickly.

The number of slices that can be made in one operation depends on various factors, including the material being cut and the desired slice thickness. The software allows you to specify the number of slices, and the machine can handle multiple slices in a single operation.

Yes, the SMART CUT® DIAMOND DICING / SLICING SAW is suitable for research on advanced materials such as ceramics and composites, offering precise cutting capabilities for various materials.

Yes, you can use your own laptop or computer to control the machine as long as it meets the necessary system requirements and is compatible with the machine’s software.

The machine is calibrated during the manufacturing process to ensure its accuracy. Additionally, users can fine-tune and calibrate the machine as needed using the software.

Yes, the machine’s precise control and adjustable settings allow for cutting delicate and brittle materials without causing damage, provided the correct parameters and blades are selected.

While the machine offers safety features such as the Lexon enclosure and water cooling system, it’s important to follow all safety guidelines and recommendations for safe operation.

With proper maintenance and regular use, the SMART CUT® DIAMOND DICING / SLICING SAW can have a long operational lifespan. The robust design and quality components contribute to its durability.

While primarily designed for cutting and slicing applications, it may be adaptable for certain NDT applications that involve sectioning materials for inspection.

In addition to the provided safety features, operators should wear appropriate personal protective equipment (PPE) and follow all safety guidelines for the materials being cut.

The machine can cut materials up to 1 inch (25.4 mm) in depth, making it suitable for a wide range of materials.

Yes, the machine can be used for thinning semiconductor wafers to achieve the desired thickness.

Yes, remote support is available over phone and video chat

Yes, the machine is suitable for research on materials used in microelectronics and nanotechnology, providing precise cutting capabilities for these applications.

While the machine includes a Lexon enclosure for environmental control, it is essential to operate it in a clean and controlled environment to ensure optimal cutting results.

Yes, the machine can be used for cutting materials that require a clean and contamination-controlled environment, thanks to the included Lexon enclosure.

While the machine is primarily designed for non-biological materials, it may be suitable for some applications involving biomaterials or softer biological samples if the appropriate blades and conditions are selected.

Cleaning and maintenance procedures are typically outlined in the user manual. Regular cleaning, blade inspection, and lubrication of moving parts are essential for machine longevity.

Operators should follow local regulations and guidelines for disposing of waste materials generated during the cutting process, ensuring safe and responsible disposal practices.

While the machine is designed for primarily flat or rectangular materials, it can be adapted for cutting irregular shapes or contours by carefully aligning the material and making multiple cuts.

The turnaround time for cutting operations can vary depending on factors such as material type, thickness, and desired precision. It’s advisable to perform test cuts and optimize settings for specific requirements.

The machine’s software may have options for data logging and management, allowing users to track and analyze cutting parameters and results.

The machine is primarily designed for non-metallic materials. While it may be used for some metal applications, its capabilities are better suited for materials like semiconductors, ceramics, and optics.

Ongoing costs may include blade replacement and occasional maintenance. These costs can vary depending on usage and the specific application.

Yes, the machine can be used for cutting brittle materials like glass or quartz when equipped with the appropriate blades and cutting parameters.

While the machine can accept a variety of blade types, it’s advisable to consult with the manufacturer or supplier for recommendations regarding blade compatibility and quality.

In some cases, the machine may be integrated into automated manufacturing processes, especially when precise cutting is required as part of a larger production line.

Yes, the machine can be used to create custom shapes and patterns in materials by carefully controlling the cutting path and parameters.

The machine’s software may include features for setting cutting parameters based on material type and characteristics, allowing for more efficient and precise cutting.

Yes, guidelines and recommendations for blade selection based on material type are typically provided in the machine’s documentation or by the manufacturer to help users achieve optimal cutting results.

Yes, the machine is suitable for creating thin sections of materials for microscopy and analysis, providing precise control over section thickness.

It’s important to be aware of any regional or international regulations, restrictions, or import/export requirements when shipping or using the SMART CUT® DIAMOND DICING / SLICING SAW, especially for international shipments. Compliance with local laws and regulations is essential.

The machine’s Lexon enclosure and water cooling system help control debris and fumes during cutting. However, it’s crucial to follow safety guidelines and conduct risk assessments for materials that may produce hazardous byproducts during cutting.

Depending on the software and control options, some machines may offer remote monitoring and control capabilities, allowing users to oversee cutting processes from a distance.

Yes, the machine can be adapted with custom jigs or fixtures to accommodate specific cutting tasks and workpieces. Customization options are available for tailoring the machine to your needs.

Operators should follow safety precautions for handling and disposing of diamond blades, which may include wearing protective gear and disposing of used blades according to local regulations.

Extended warranty options may be available for purchase, depending on the manufacturer or supplier. It’s advisable to inquire about extended warranty coverage when purchasing the machine.

The machine’s water cooling system helps maintain a stable cutting environment, which can be beneficial for cutting materials sensitive to temperature changes. However, it’s essential to consider the specific requirements of the material being cut.

Many machines are equipped with an emergency stop or safety shutdown feature to ensure the safety of operators in case of unexpected issues during operation.

The machine can be used for cutting abrasive materials, but it’s essential to select appropriate blade types and be prepared for more frequent blade replacements due to wear.

Yes, the machine is suitable for precision cutting in microfluidics and microfabrication applications, where accuracy and control over cut dimensions are crucial.

ACCESSORIES

Tab Content

OPERATING MANUALS

Download Operating Manuals

Features:

- Purpose: Designed for laboratory and R&D use, suitable for slicing, dicing, or cutting various materials.

- Material Capacity: Cuts materials up to 4" diameter wafers or rectangular materials up to 8" length x 4" width x 1" depth.

- Precision: Offers high precision with a position accuracy of 0.01 mm or better.

- Control: Fully computer-controlled via any PC or desktop computer; includes a laptop with pre-installed, user-friendly Windows-based software and USB cable.

- Software Features: Graphical interface allows easy setting of parameters like sample shape, cut width, number of slices, cut depth, and blade kerf.

- Versatility: Capable of cutting a wide range of materials, including optical, optoelectronic, semiconductor, ceramic, and more.

- Manual Operation: Can be operated manually using rotary hand wheels for added flexibility.

- Safety Features: Equipped with a Lexan enclosure and water-cooling system to contain debris and dissipate heat, enhancing operator safety.

- Adjustable Stage: Sample stage with two-angle adjustment enables cutting at various angles for versatility in shapes.

- Certification: CE-certified, ensuring compliance with safety and quality standards.

- Cutting Thin Materials: Suitable for delicate samples, capable of cutting materials as thin as 1 mm with precision.

- Applications: Ideal for both research (e.g., advanced materials like ceramics and composites) and production where precision cutting is required.

- Cooling System: Features a built-in coolant delivery system to maintain blade performance and prevent overheating during operation.

- Compact Design: Engineered for space efficiency, making it suitable for smaller lab environments without sacrificing functionality.

- Speed Control: Offers variable spindle speed adjustments to optimize cutting for different materials and thicknesses.

- Ease of Maintenance: Designed with accessible components for straightforward cleaning and blade replacement, minimizing downtime.

- Compact Footprint: Space-efficient design fits well in laboratory environments without sacrificing functionality.

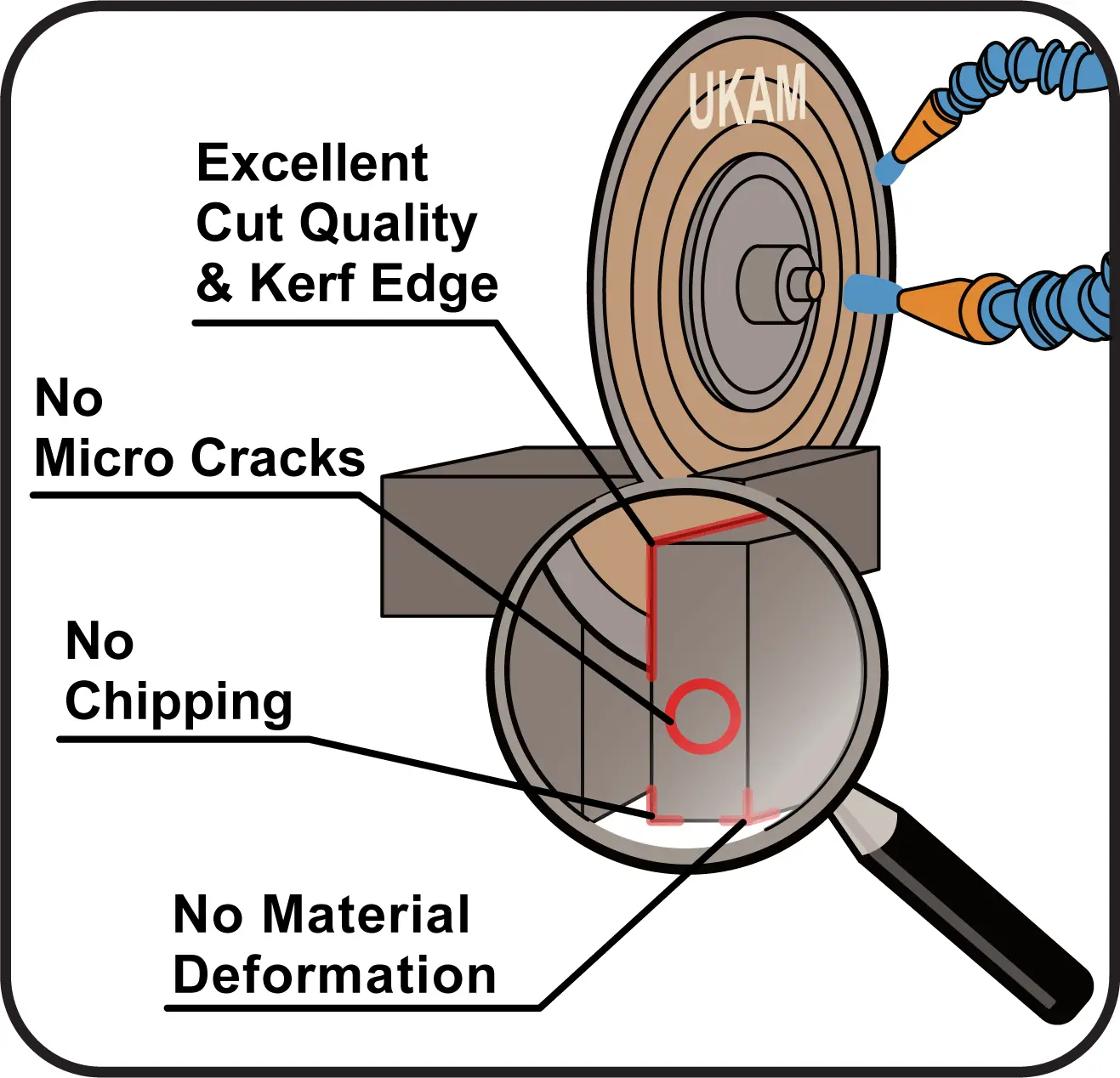

- Unmatched Selection of Diamond, CBN, & Abrasive Blades: Unmatched slection of diamond, cbn, abrasive and other wafering blade specifications (e.g., diameter, thickness, grit) to fit any specification. Best Prices & Performance in North America.

Dicing Saw Vision & Optics

OPTICS & IMAGE CAPTURE

Digital Microscope Head is a digital camera professionally designed for M45 portable microscope. Displaying actual image of the material as its being cut in real time on the PC screen.

With the powerful software Scope Photo included, it is extremely convenient to do the basic and advanced image processing and measurement to the images captured. The simple operation ensures you doing all these processing works at great ease.

Digital Microscope Head employs newly designed optical system of fully coated, based on MTF (modulation Transfer Function) analysis, for improved image flatness and contrast. The images are brighter and distinct even at the periphery of the field of view. Especially, this system matches the specific characters of magnifier.

How to adapt Digital Microscope onto the Stereo Microscope?

Remove the rubber eye-cap and its plastic holder, and then mount the adapter-ring onto the eyepiece. Insert Digital Microscope Head into the adapter-ring

- The stereo microscope ( 50x) with support fixture is designed for slicing/dicing The microscope has 50X magnification and built in reticule (scale) in nm and inch.

- Can be used for aligning wafer before cutting, and observe cut width and edge chipping after

- Vise on the frame is used to mount the frame on the The optical stereo microscope can be moved vertically, horizontally, and rotated at 360 degrees. However, best position for monitoring cutting shall be installed as the picture below.

- The microscope also can be used as portable microscope when installing with plastic base (Fig. C) , and as a 5X magnifier and 10X Monocular when disassembling as Fig-D

- Note: You may choose digital microscope head , and upgrade the microscope to digital and observe sample cut under computer screen

EASY TO USE WINDOWS BASED SOFTWARE

The machine comes with Brand Name Lap Top 15″ to 16″ with pre installed windows based and user friendly software. That allows to set the sample shape, cut width, number of slices, cut depth, and account for blade kerf.

Behind the user friendly interface GUI is G code. Where the operator can program and control the machine operation without the user interface if needed.

The optional stereo microscope can also be connected, with the operator having option to view the cutting as it is being done in real time

4" Rotary table

- rotary table is a precision piece of equipment that has been designed to work with slicing/dicing saw and any precision rotating operation whenever the small 4-inch size would bean

- table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven

- table has been engraved with a laser, giving sharp and precise lines every 5”4X, numbered every 15”4X. These lines are calibrated with the 72-tooth worm gear that is driven by the

- handwheel is divided into 50 parts, making each line on the handwheel 1/10”4X. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one

- table T-slots are identical to those used on the slicing/dicing saw 6. Two hold-down clamps and T-nuts are provided with the

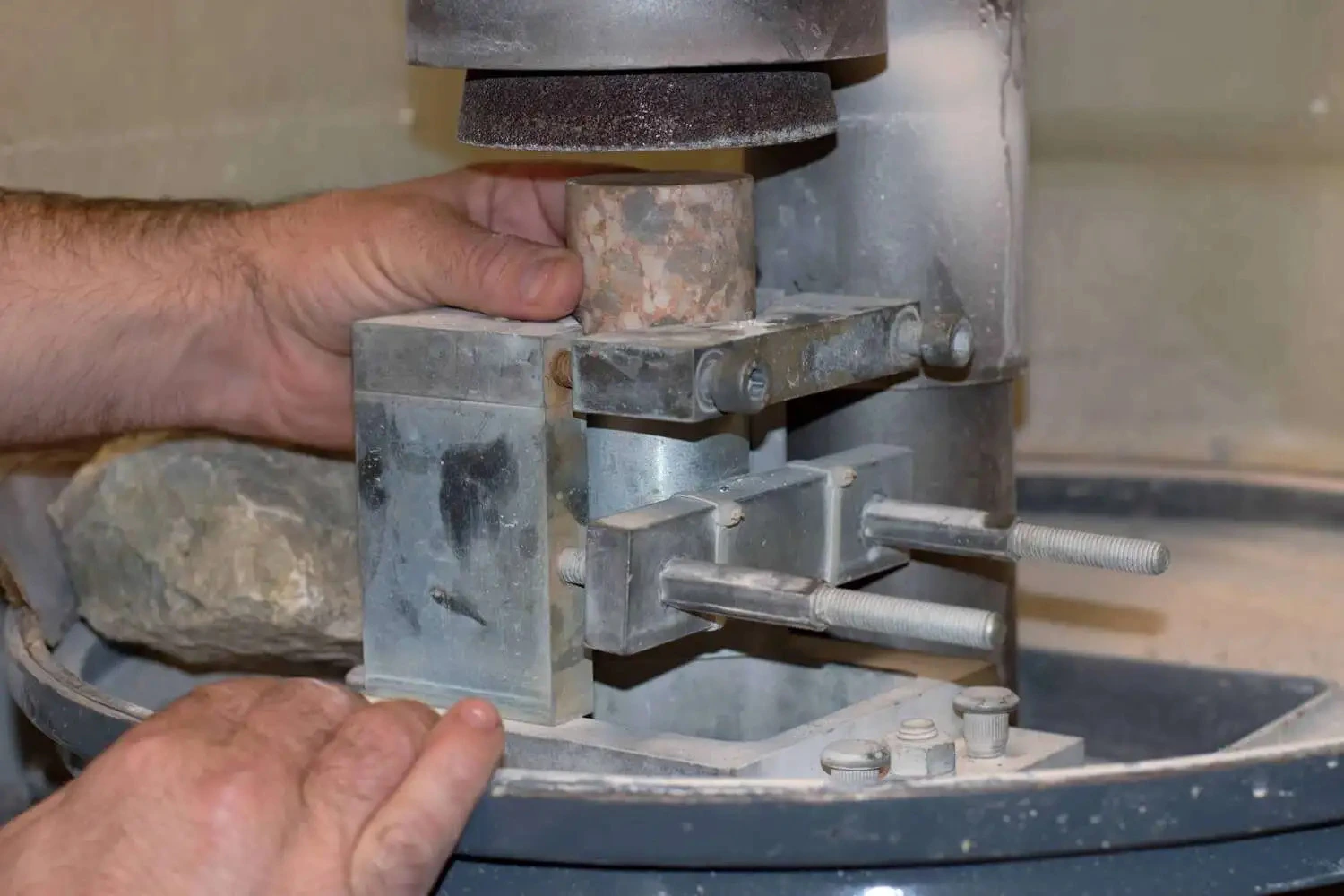

Precision Cross Mount Vise for Slicing/Dicing Saw

- The cross mount vise is designed for cutting sample with precision 90o angle (+/- 02o ) without alignment

- This crossing mounting vise can be employed and turned at 900 on the mechanical chucks

- cut square shape sample by only turning the sample at 900 without guessing and alignment

Heavy Duty Coolant Circulating Tank with Pump, 4 L

The 4 liter capacity heavy duty coolant circulating tank is designed to be used with this slicing/dicing saw

- Operation power: 208V ~240V (If you need 110V power supply, please order a 200W transformer)

- 4 Liters stainless steel tank with 1″ drain port and 1/4″ outlet port

- Built in 40W fluid pump, Flowing rate: 12L/min.

- Pumping height: 3 meters Max.

- imension: 270mm x220mm

- Plastic Hose: 05mm O.D. 2.3m Length (7.5 feet)

- Water Inlet: 4mm I.D. 31.75mm O.D.

- Weight: 3kgs

120L/min Oillless Vacuum Pump

- compact design

- Low noise and vibration

- More efficient cooling system

- Completely oil-less

- Maintenance-free

- Longer running life

- Ideal for small gas circulating system

4" Vacuum Chuck

wafer or substrate is placed on removable adhesive film which is then placed on the vacuum chuck. Open vacuum valve, vacuum chuck will suck wafer firmly and ready for cutting.

Wafer Bonding Tape for Vacuum Chuck

- High strength film is for bonding wafer (up to 6″ dia) or thin substrate (< 2.0 mm thickness ) to vacuum chunk of EC400 dicing saw or any dicing saw with< 6″ diameter vacuum chuck.

- Width: 5″

- Thickness: 25 mm

- Length: sold by 10 feet per quantity

Full Enclosure Made from Lexon

full enclosure is provide to keep the cutting area enclosed environment

Standard Package

What is included with each machine

| Item No. | Description | Items included with machine | Picture |

| 1001 | Cross mount vise | 1 pcs |  |

| 1002 | Controller w/cables & software floppy | 1 set |  |

| 1003 | Mechanical chuck | 1pcs |  |

| 1004 | Water splash guard | 1set |  |

| 1005 | Aluminum plate | 2 pcs |  |

| 1006 | Wax bulk for gluing samples | 2 pcs |  |

| 1007 | Graphite plate for holding samples | 2 pcs |  |

| 1008 | Fully sintered diamond blade 4″x 0.3mm x 1/2″ | 1 pcs |  |

| 1008A | Sintered (metal bond) diamond blade 4″x 0.3mm x 1/2″ | 1 pcs |  |

| 1009 | 1 Quart of SMART CUT™ water soluble coolant | 1 quart |  |

| 1010 | 1/2″ x 1/2″ x 6″ dressing stick (any spec) | 1 pcs |  |

| 1011 | Blade Flanges (62 mmin dia.) | 1 pair |  |

| 1012 | Blade clamps (42 mmin dia.) | 1 pair |  |

| 1013 | 4″ Steel plate for holding samples | 1 pcs |  |

| 1014 | Screw drivers | 1 set |  |

| 1015 | Water hoses | 1 set |  |

| 1016 | Plastic splash-protection cover | 1 set |  |

| 1017 | Operation manual in CD | 1 set |  |

| 1018 | 14″-15″ laptop with software installed | 1 set | |

| 1019 | 4″ Vacuum chuck | 1 pcs |  |

| 1020 | 110V or 220V Vacuum | 1 pcs |  |

| 1021 | Adhesive film for wafer holding 10ft | 1 pc |  |

1001,1002,1003,1004,1005,1006,1007,1008,1008A,1009,1010,1011,1012,1013,1014,1015,1016,1017,1018,1019,1020,1021,

SMART CUT® COOLANTS

Your choice of one (1) quart of SMART CUT™ Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT™ Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

LARGEST SELECTING OF DIAMOND &

CBN WAFERING BLADES AVAIALBLE

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

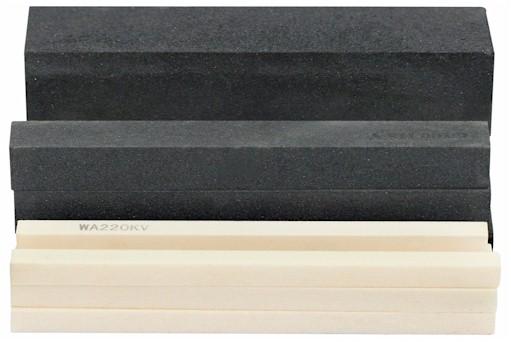

THE RIGHT DRESSING STICK FOR YOUR APPLICATION

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

SMART CUT® 6035 Diamond Wire Saw

SMART CUT® 6012 – Diamond Wire Saw (Lab)

SMART CUT® Water Soluble Dicing Coolant

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and applications....

02

Jun

Diamond Wire Advantages & Application

Diamond Wire saws provide the most accurate cutting with the least amount of material deformation and chipping of material.

Share this Article with Friend or Colleague

HOW DIAMOND WIRE WORKS

Today diamond wire sawing is preferred by majority...

02

Jun

Troubleshooting Diamond Sawing Problems

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application, we...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering blades,...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high accuracy. To...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to understand...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use