Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® 020DHE Electroplated miniature hollow core drills are precision-engineered tools designed for drilling small, holes in a wide range of materials. These drills consist of a steel tube with a diamond coating applied to the tip, ensuring superior cutting ability even in the hardest and most brittle materials. Available from stock in diameters ranging from 1 mm to 3.5 mm OD.

SMART CUT® 020DHE hollow core plays an important role in enhancing stability, particularly in deep drilling applications. This feature allows for precise control, ensuring the drill remains aligned throughout the process. It also minimizes deflection and bending, common issues when using solid drills for small-diameter, deep holes. As a result, users can achieve more accurate and clean-cut drilling with reduced risks of damage to both the tool and the material.

One key advantage of these electroplated miniature hollow core drills is their ability to extract small, thin cores from materials such as rocks, ceramics, glass, composites, metals, and even biological materials like bone. This makes them an essential tool in fields such as geology, materials science, medical research, and engineering, where precision core samples or drilled channels are often required.

The shank diameter of these drills is slightly smaller than the outer diameter, allowing for easy handling and compatibility with standard drilling equipment. This design also facilitates smoother drilling operations by providing better alignment between the tool and the material.

They are ideally used with high-speed tools such as Foredom and Dremel machines, high-speed air spindles, and other equipment operating at 9,000+ RPM.. Should be used with coolant such as SMART CUT® water soluble coolant or mineral oil for optimal results.

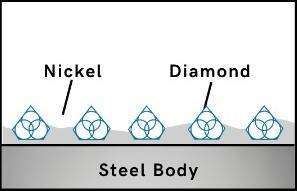

Bond Type: Nickel Bond (Plated)

Edge Type: Hollow tube

Diamond Grit Size: Medium Fine

Package Contains 3 pcs

Tube Shank Diameter is slightly smaller than diameter of diamond drill tip Overall Length:

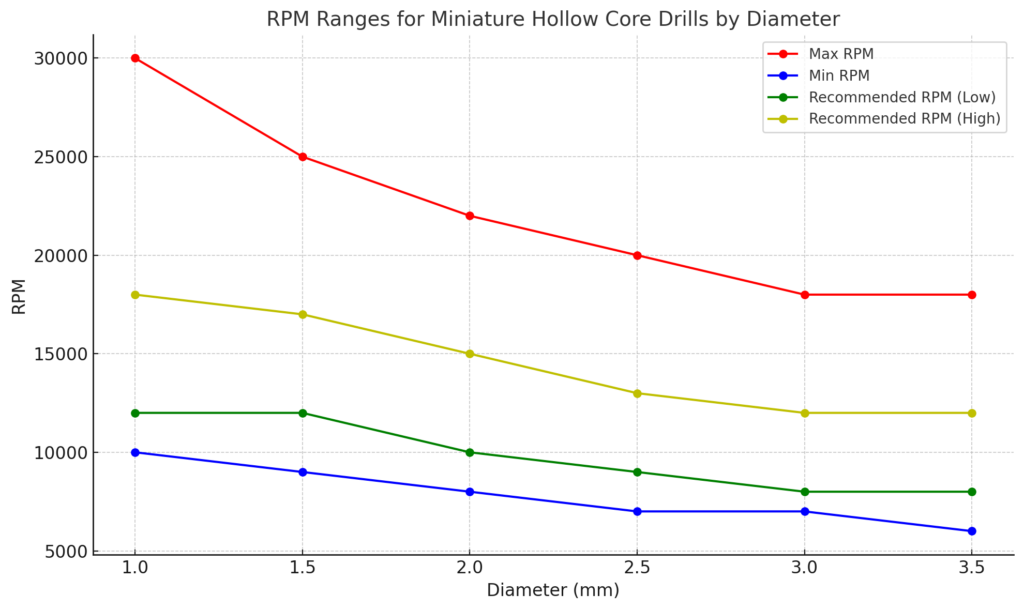

Recommended Operating Speed: 9,000-12,000

Maximum Operating Speed: 30,000

Diamond height: 5mm (.20″)

Tolerance on Outside Diameter +/- 0.05mm (.002″)

Always drill with a coolant and use submerged-pressure sensitive feed.

Recommended Coolant: water, for ultra hard materials best results will be achieved with mineral oil or synthetic water soluble coolant.

The SMART CUT 020DHE is a type of electroplated miniature hollow core drill made of a steel tube with a diamond coating on the tip. It is designed for drilling completely through various materials and is available in diameters ranging from 1mm to 3.5mm.

Hollow core drills offer extra stability for deep drilling applications. They can also be used to extract very small and thin diameter cores from materials like rocks, ceramics, glass, composites, metals, and more.

SMART CUT 020DHE drills can be used with high-speed drill presses, mounted handpiece drills (e.g., Foredom & Dremel), and high-speed air spindles.

These drills are suitable for drilling smooth and clean holes in various materials, including ceramic, tile, advanced ceramics, glass, quartz, optical materials, composites, stone (natural, synthetic, semi-precious, and precious), and many others.

The recommended operating speed for SMART CUT 020DHE drills is between 9,000 to 12,000 RPM, with a maximum operating speed of 30,000 RPM. The diamond height is 5mm (.20″), and the tolerance on the outside diameter is +/- 0.05mm (.002″).

Yes, quantity discounts are available for SMART CUT 020DHE drills, making it cost-effective to buy in larger quantities.

Electroplated diamond drills are ideal for drilling softer materials (up to 6 on the Mohs scale of hardness) and provide excellent performance. They are not recommended for very abrasive materials like sandstone and concrete. These drills offer a smooth surface finish and less thermal damage to the material being drilled.

SMART CUT 020DHE drills are designed for small and occasional use. They are commonly used by beginners and hobbyists for tasks such as drilling beads and clock faces. They may not be suitable for heavy-duty industrial use.

Electroplated diamond drills can be used dry (without coolant) in some applications, but it’s best to use coolant for optimal performance. Performance and drill life may decline when drilling thicker materials.

SMART CUT 020DHE drills offer a unique design and superior performance compared to conventional diamond solid drills. The quality and longevity of diamond drills can vary significantly between manufacturers, and SMART CUT drills are designed to provide longer life and better overall performance. The guide provides detailed information on evaluating drill performance and life.

The life of a diamond drill is influenced by various factors, including the material being drilled, drill speed and power, pressure used (feed rate), proper use of coolant, drilling depth, material holding method, operator experience, equipment condition, diamond quality, bond hardness, and manufacturer expertise.

Yes, custom manufacturing is available for SMART CUT 020DHE miniature plated hollow core drills. You can request specific diameters, drill depths, wall thicknesses, and diamond grit sizes to suit your unique requirements.

SMART CUT 020DHE drills are electroplated diamond drills, which means they have a single layer of diamonds held by a tough, durable nickel alloy. They are designed for smoother and faster drilling action with minimal heat generation, making them ideal for softer materials. However, they are not recommended for extremely abrasive materials.

While SMART CUT 020DHE drills are commonly used by beginners and hobbyists, they may not be the best choice for professional jewelers and lapidaries who require high-performance drills for intensive use. Professionals may prefer more specialized diamond drill bits.

The drill size you choose should depend on the diameter of the hole you need to create. Select a drill with a diameter slightly larger than the desired hole size to accommodate any variations. Refer to the provided item numbers and specifications to make your selection.

SMART CUT 020DHE drills can be used for precision drilling, especially in hobbyist and craft applications. However, for the highest level of precision and performance, specialized precision drilling equipment and tools may be required.

To maximize the life of your drills, it’s essential to use them within their recommended speed and pressure ranges, use proper coolant when needed, and handle them carefully to avoid damage. Regularly inspect the drills for wear and replace them as necessary.

While SMART CUT 020DHE drills can work on harder materials, their life will be significantly reduced compared to softer materials. For drilling thicker or harder materials like granite, other types of diamond drills or specialized equipment may be more suitable.

The recommended maximum drill depth for SMART CUT 020DHE drills is 2.0 inches (50.8mm). Attempting to drill deeper may affect their performance and lifespan.

You can purchase SMART CUT 020DHE drills through authorized distributors or directly from the manufacturer. Quantity discounts may be available, so be sure to inquire about bulk orders if needed.

SMART CUT 020DHE drills are sold in packages of 3 pieces. The price for a package of 3 drills is $25.40. This packaging makes it convenient for users to have multiple drills on hand for various projects.

Yes, SMART CUT 020DHE drills are designed to provide a smooth and clean drilling action, making them suitable for delicate and fragile materials, such as glass, ceramics, and precious stones, without causing significant damage.

To extract small diameter cores, you can use the SMART CUT 020DHE drills to create a hole around the core you want to extract. Once the hole is drilled, gently remove the core using appropriate tools, taking care not to damage it in the process.

When using any drilling equipment, it’s important to wear appropriate safety gear, such as safety glasses and gloves, to protect yourself from potential hazards. Additionally, follow the recommended operating speeds and use coolant when necessary to minimize heat generation.

SMART CUT 020DHE drills are typically used until they wear out, and they are not commonly resharpened or reconditioned. It is more cost-effective to replace worn drills with new ones for optimal performance.

You can place an order for SMART CUT 020DHE drills by contacting the manufacturer or an authorized distributor. Be sure to specify the quantity and sizes you need, and inquire about any available discounts for bulk purchases.

Electroplated diamond drills offer advantages such as high diamond concentration, maximum diamond particle exposure, and efficient drilling action with minimal heat generation. They are particularly well-suited for softer and more ductile materials.

SMART CUT 020DHE drills can be used for jewelry making and lapidary work, especially by hobbyists and those working on smaller-scale projects. However, professionals in these fields may opt for more specialized and durable diamond tools for intensive use.

While SMART CUT 020DHE drills are typically used with coolant, including water, for some applications, it’s best to refer to the manufacturer’s recommendations and guidelines to ensure the proper use of coolant for specific materials and drilling conditions.

SMART CUT 020DHE drills typically come with shank diameters slightly smaller than the outside diameter of the drill itself. This design allows for compatibility with standard drill chucks and collets, making them easy to use with various drilling equipment.

The lifespan of SMART CUT 020DHE drills can vary depending on factors like the material being drilled, operating conditions, and user expertise. Generally, they are designed for small and occasional use. Regular inspection and replacement of worn drills will help maintain performance.

Yes, SMART CUT 020DHE drills are suitable for artistic and creative projects that involve drilling holes in various materials. They are commonly used in crafting and other creative endeavors.

While SMART CUT 020DHE drills can be used in jewelry making, their suitability depends on the specific requirements of your workshop. Professionals may opt for specialized diamond tools for precision and durability in jewelry production.

SMART CUT 020DHE drills can be used for precision drilling in glassware and scientific equipment, provided that the material is compatible with the drill and proper care is taken to maintain precision.

To clean and maintain SMART CUT 020DHE drills, ensure they are free of debris and contaminants. You can use a mild cleaning solution and a soft brush to clean the diamond-coated tips. Proper storage in a clean and dry environment is also recommended to extend their lifespan.

SMART CUT 020DHE drills are best suited for drilling holes in flat or slightly curved surfaces. Drilling on highly irregular or curved shapes may require specialized tools or techniques.

Disposing of used SMART CUT 020DHE drills should be done in accordance with local regulations for disposing of sharp objects and hazardous materials. It’s advisable to take safety precautions when handling and disposing of used drills.

Yes, SMART CUT 020DHE drills can be used for jewelry repair work, especially when precision drilling is required. They are suitable for tasks such as enlarging holes or creating small openings.

SMART CUT 020DHE drills can be used in hobbyist glassblowing projects for drilling holes in glass pieces. However, it’s important to use them with care to avoid cracking or damaging the glass.

The warranty and return policy may vary depending on the manufacturer or distributor from which you purchase the drills. It’s advisable to inquire about the specific warranty and return terms before making a purchase.

SMART CUT 020DHE drills can be used for drilling holes in electronic components or PCBs, especially when precision is required. However, it’s essential to take care to avoid damaging the sensitive components or PCB traces during the drilling process.

SMART CUT 020DHE drills can be used for lapidary work on gemstones like diamonds, rubies, and sapphires. However, the choice of diamond drill bit may vary depending on the specific characteristics and hardness of the gemstone. Professional lapidaries often use specialized tools for cutting and shaping gemstones.

SMART CUT 020DHE drills can potentially be used with CNC (Computer Numerical Control) machines for automated drilling applications. However, compatibility and performance in CNC setups would depend on the machine’s capabilities and requirements.

SMART CUT 020DHE drills typically produce less dust and debris compared to some other drilling methods, making them suitable for applications where cleanliness and minimal waste are important.

SMART CUT 020DHE drills can be used for creating holes in delicate stained glass artwork. Their precision and ability to minimize chipping make them a good choice for such applications.

When drilling harder materials, it’s essential to use lower speeds, appropriate coolant, and moderate pressure to extend the life of SMART CUT 020DHE drills. Frequent inspection for wear and proper maintenance can also help maximize their longevity.

SMART CUT 020DHE drills are not specifically designed for underwater drilling. Using drills underwater may pose additional challenges and safety considerations. Consult with the manufacturer or distributor for guidance on underwater applications.

SMART CUT 020DHE drills can be used for educational purposes and in school workshops, especially for teaching students about drilling techniques and materials. They are user-friendly and can be a valuable tool for educational demonstrations.

SMART CUT 020DHE drills can be used with a variety of handheld rotary tools as long as they can accommodate the shank diameter of the drills. They are compatible with many popular rotary tool brands beyond Foredom and Dremel.

Yes, SMART CUT 020DHE drills can be used for drilling holes in plastic materials. They provide a clean and precise drilling action, which is ideal for working with plastics.

When working with fragile materials like glass, it’s important to use a controlled and gradual drilling approach. Apply consistent but gentle pressure to avoid sudden pressure changes that can cause cracking or chipping. Using a lubricant or coolant can also help dissipate heat and reduce the risk of damage.

Yes, SMART CUT 020DHE drills are suitable for DIY home improvement projects, such as drilling holes in tiles or mirrors. They are designed to provide precision and smooth drilling for such applications.

The lead time for ordering SMART CUT 020DHE drills may vary depending on factors like quantity and customization requirements. It’s advisable to inquire about lead times when placing your order to ensure timely delivery.

SMART CUT 020DHE drills are commonly used for creating holes in jewelry components like beads and pendants. They provide the precision needed for jewelry-making tasks.

When handling SMART CUT 020DHE drills, always wear appropriate safety gear, including safety glasses and gloves. Follow the manufacturer’s instructions for changing or installing drills in your specific drilling equipment to ensure safe operation.

SMART CUT 020DHE drills can be used in many drilling applications, including hard-to-reach areas or confined spaces. However, the accessibility of the drilling area will depend on the size and design of the equipment being used.

SMART CUT 020DHE drills may come with user manuals or guidelines for best practices, depending on the manufacturer or distributor. It’s advisable to review any provided documentation for specific usage instructions and tips.

SMART CUT 020DHE drills are primarily designed for straight drilling. Creating holes with specific angles or bevels may require specialized equipment or additional machining processes.

To maintain the condition of SMART CUT 020DHE drills when not in use, store them in a clean, dry environment away from moisture and contaminants. Proper storage can help prevent damage and prolong their lifespan.

SMART CUT 020DHE drills are more suitable for softer materials, and their effectiveness on hardened metals or alloys may be limited. For drilling hardened materials, specialized diamond or carbide tools are typically recommended.

SMART CUT 020DHE drills can be used with handheld rotary tools that have adjustable speed settings. The recommended speed settings may vary depending on the material being drilled. Refer to the manufacturer’s guidelines for specific speed recommendations for different materials.

SMART CUT 020DHE drills can be used for inlay work and creating decorative holes in wood. They offer precision and smooth drilling, making them suitable for woodworking applications.

To maintain the diamond-coated tips of SMART CUT 020DHE drills, you can use a mild cleaning solution and a soft brush to remove debris and contaminants. Avoid using abrasive or harsh cleaning agents that could damage the diamond coating.

SMART CUT 020DHE drills are suitable for making holes in ceramics for pottery and ceramic art projects. Their precision and ability to minimize chipping make them a valuable tool for such applications.

The choice of cutting fluid or coolant for SMART CUT 020DHE drills may depend on the material being drilled. Some materials may require water-based coolant, while others may benefit from specialized cutting fluids. Consult the manufacturer’s recommendations for guidance.

SMART CUT 020DHE drills can be used for creating holes in plastic components of electronic devices, but it’s essential to exercise caution to avoid damaging the electronics. Ensure that the device is powered off, and take care not to penetrate any sensitive components or circuits.

The depth accuracy or tolerance achievable with SMART CUT 020DHE drills can vary depending on factors like the material being drilled, the equipment used, and the operator’s skill. In general, they provide good depth control and accuracy for most applications.

SMART CUT 020DHE drills can be used to create holes with specific diameters within the 1mm to 3.5mm range. They are available in various standard sizes within this range for precise drilling.

SMART CUT 020DHE drills are designed to be compatible with a wide range of rotary tools and drilling equipment. However, compatibility with older or specialized equipment may vary. It’s advisable to ensure that the drills fit securely in your equipment before use.

Yes, SMART CUT 020DHE drills can be used for enlarging existing holes in materials. They can be particularly useful for precision hole enlargement tasks.

SMART CUT 020DHE drills are suitable for creating holes in plastics, including engineering polymers. However, the hardness and characteristics of the specific plastic or polymer may impact drilling performance, so it’s advisable to test the drill on a sample piece first.

SMART CUT 020DHE drills are primarily designed for creating straight holes. Adding countersinks or chamfers would typically require subsequent machining processes or specialized tools designed for those purposes.

SMART CUT 020DHE drills can potentially be integrated into automatic or robotic drilling systems for industrial applications. Compatibility and integration would depend on the specific requirements and capabilities of the automation equipment.

Yes, SMART CUT 020DHE drills can be used for drilling holes in fiberglass materials commonly used in boat building and repair projects. They provide precise drilling and are suitable for such applications.

SMART CUT 020DHE drills can be used for drilling holes in soft metals like aluminum or brass. Their efficiency and precision make them a good choice for working with these materials.

SMART CUT 020DHE drills can be used for creating holes in 3D-printed plastic or resin parts. However, take care to secure the parts properly during drilling to prevent distortion or damage.

SMART CUT 020DHE drills are well-suited for creating holes in acrylic or plexiglass sheets. They provide clean and precise drilling without causing significant chipping or cracking in the material.

SMART CUT 020DHE drills are primarily designed for drilling holes, not for engraving or etching. For jewelry engraving or etching on hard materials like metal or stone, other specialized tools or methods would be more appropriate.

SMART CUT 020DHE drills can be used with collet adapters to fit various-sized rotary tool chucks. This allows for greater versatility and compatibility with different equipment.

SMART CUT 020DHE drills can be used for creating holes in ceramics for pottery wheel applications. Their precision and smooth drilling action make them suitable for such tasks.

SMART CUT 020DHE drills are suitable for drilling holes in composite materials commonly used in aerospace and automotive applications. They offer precision and minimize delamination or damage to composite layers.

SMART CUT 020DHE drills can be used for high-precision applications like creating holes for jewelry clasps or watch movements. They provide the necessary precision for such intricate work.

Yes, SMART CUT 020DHE drills are suitable for drilling holes in ceramic tiles for home improvement projects. They are commonly used for such applications and provide clean and precise holes.

Disposing of used SMART CUT 020DHE drills should be done in accordance with local regulations for disposing of sharp objects and hazardous materials. Consider recycling or proper disposal methods to minimize environmental impact.

SMART CUT 020DHE drills can be used for drilling holes in jewelry components made of precious metals like gold or silver. Their precision and smooth drilling action make them suitable for working with these materials.

SMART CUT 020DHE drills are suitable for creating holes in decorative glass panels or stained glass windows for artistic projects. They offer precision and minimize the risk of chipping or cracking in the glass.

Yes, SMART CUT 020DHE drills can be used for creating holes in soft stone materials like soapstone or alabaster for sculpture or carving purposes. They provide precision and control in stone drilling.

Some diamond drills may have break-in procedures or initial use guidelines recommended by the manufacturer. It’s advisable to refer to any provided documentation or consult the manufacturer for specific guidelines.

SMART CUT 020DHE drills can be used for creating holes in glass bottles for crafting or DIY projects. They are commonly used for such applications to repurpose glass bottles into various decorative items.

SMART CUT 020DHE drills can potentially be used with automatic feed systems for continuous drilling applications, depending on the specific setup and requirements of the feed system.

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

1 Gallon Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

1 Quart Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

5 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

55 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White For use on diamond tools 150 to 220 Grit Size. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $15.39 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $39.47 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $39.47 | Max: Min: 1 Step: 1 |

Tab Content

Image | Item No. | Outside Diameter | Inside Diameter | Maximum Drill Depth | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|

1.0 mm (.040") | .50 mm (.0196") | 1.5" (38.1mm) | $25.40 | Max: Min: 1 Step: 1 | |||

1.25 mm (.0492") | .75 mm (.0295") | 1.5" (38.1mm) | $25.40 | Max: Min: 1 Step: 1 | |||

1.5 mm (.059") | .90 mm (.0354") | 1.5" (38.1mm) | $25.40 | Max: Min: 1 Step: 1 | |||

1.75 mm (.069") | 1.0 mm (.040") | 2.0" (50.8mm) | $25.40 | Max: Min: 1 Step: 1 | |||

2.5 mm (.0984") | 1.75 mm (.0688") | 2.0" (50.8mm) | $25.40 | Max: Min: 1 Step: 1 | |||

3.0 mm (.118") | 2.25 mm (.0885") | 2.0" (50.8mm) | $25.40 | Max: Min: 1 Step: 1 | |||

3.5 mm (.137") | 2.50 mm (.0984") | 2.0" (50.8mm) | $25.40 | Max: Min: 1 Step: 1 |

Other more exact drill sizes & drilling depths are available upon request. Quantity Discounts are available.

Recommended RPM’s: The RPM values provided in this table serve as general guidelines for typical drilling applications. However, the optimal RPM settings will vary based on several factors including the desired cut quality, drill depth, material hardness, density, shape, and porosity. Please see our Guide on How to Properly Use Diamond Drills. To ensure the highest level of performance and safety, we advise consulting with our technical support team. They can assist in tailoring these parameters to your specific application, ensuring that you use the optimal RPM and appropriate coolant type. Properly adjusting these factors can significantly enhance the lifespan of your diamond drills and minimize the risk of tool breakage.

Recommended Feed Rate: starting at lower feed rates and gradually increasing to find the optimal drilling ratio is crucial for precision drilling. It is important to continuously clear the drill of grinding debris to prevent clogging and overheating.

Plunge feeding is generally not recommended due to the increased risk of material damage and tool wear. Instead, we advocate for the use of a peck feed cycle. This technique involves withdrawing the drill periodically to clear debris, which helps in maintaining the integrity of both the drill and the workpiece. This method not only helps develop a better "feel" for the material and the process but also improves the overall drilling efficiency by reducing stress on the tool and preventing overheating.

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

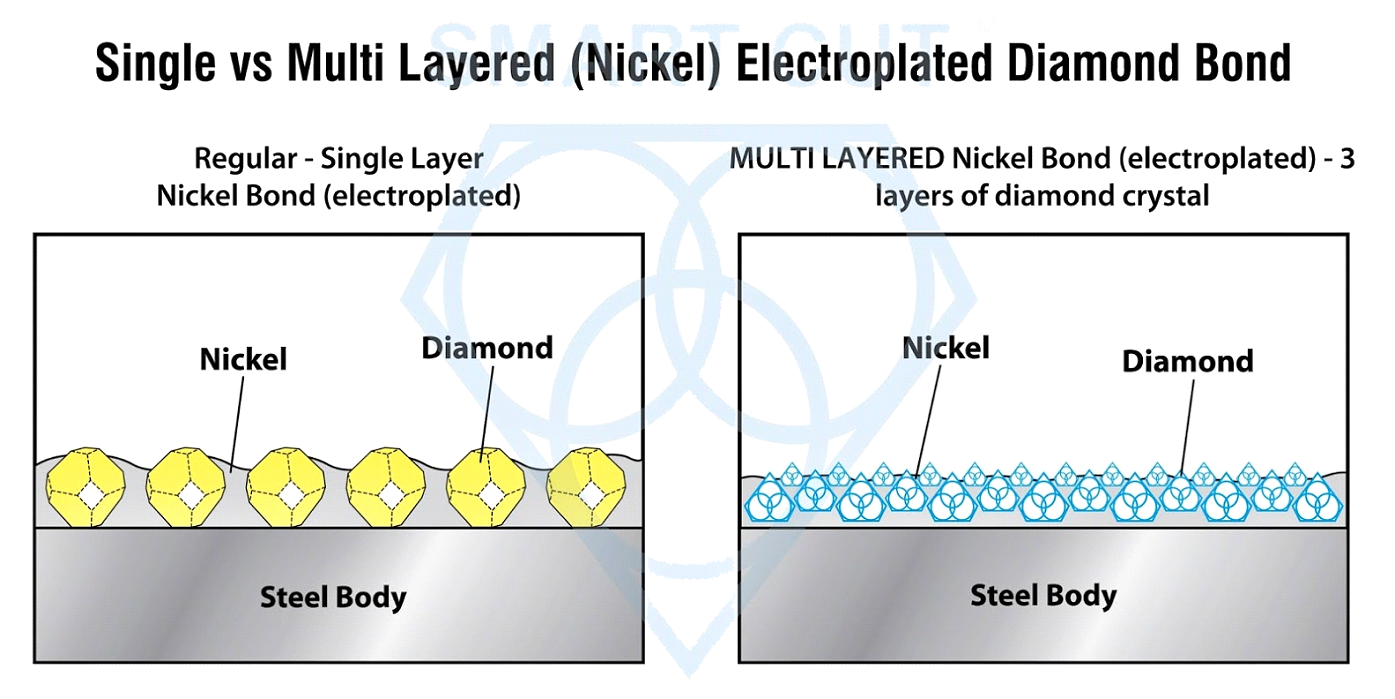

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

they have several layers of diamonds, held by a tough durable nickel alloy. Providing high diamond concentration, better diamond crystal retention and maximum diamond particle (grit) exposure/protrusion ratio. This provides freer, faster cutting action with minimum heat generation. Advantages of this type of technology include: longer tool life, more uniformity in performance, less stress to material being worked on, minimum material deformation, and better preservation of true material micro structure. This is specially important for more delicate, sensitive applications such as: glass, crystals, silicon wafers, carbon composites, sapphire, etc.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT ® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT ® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales