-

0 items in quote

No products in the Quote Basket.

Resin Bond Dicing Blade

RESIN BOND

SMART CUT® Series (SC®) RESIN BOND DIAMOND & CBN DICING BLADES

Maintain excellent form & sharpness. Providing lower wear rate, longer life, and minimum level of chipping on wide variety materials.

SMART CUT® Resin series New Generation & Technology Dicing Blade is the highest performance Resin Bond Dicing Blade available today! SMART CUT® Resin Dicing Blade lasts longer than any resin bond diamond dicing blade and maintains better form & shape consistently through its life. Resin Bond dicing blade are typically more forgiving, self dressing, and freer cutting. Excellent choice for Ultra Hard & Brittle Materials. Recommended for applications where cut quality and surface finish is very important.

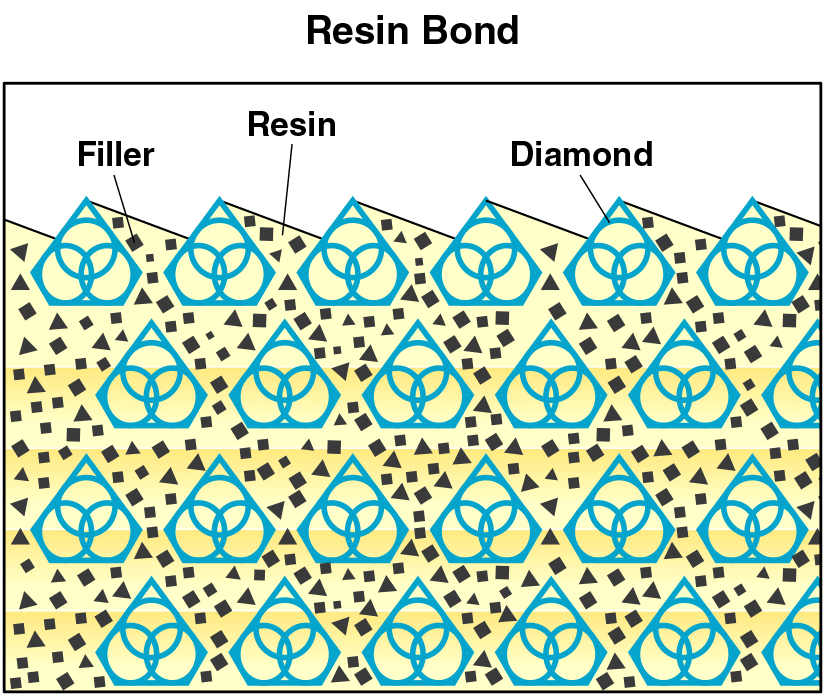

SMART CUT® Resin series New Generation & Technology Dicing Blade are produced using phenolic resin as the binder, diamond abrasive as cutting media, ceramic & other advanced components as filler. UKAM Industrial Resin Bond Blades are manufactured with advanced molding process. available in a large variety of geometries, diamond sizes, diamond concentrations, and bond harnesses.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

CASE STUDIES

DESCRIPTION

SMART CUT® RESIN SCR Dicing Blades are engineered to significantly outperform conventional resin bond blades in both durability and performance. Unlike standard resin blades that quickly dull and lose shape, SMART CUT® blades maintain their roundness, sharpness, and structural integrity throughout their life. They handle higher loads and feed rates, making them suitable for both low- and high-power dicing saws. Their heavy-duty construction and open bond design reduce the need for frequent dressing, minimize blade wreckage, and allow for superior coolant absorption—keeping the blade cool and stable during operation.

These blades cut faster and more aggressively while still delivering the smooth surface finish expected from a resin bond. They also resist glazing and maintain consistent cutting speed with minimal chipping. SMART CUT® RESIN SCR Blades use advanced phenolic resin formulations, higher grade tightly graded diamonds, and proprietary molding techniques—overcoming the limitations of conventional resin bonds and enabling use in a wider range of applications. With their self-renewing bond structure and longer life, they offer cleaner cuts, reduced downtime, and lower overall cost per cut—truly setting a new standard for what resin bond dicing blades can achieve.

SPECIFICATIONS

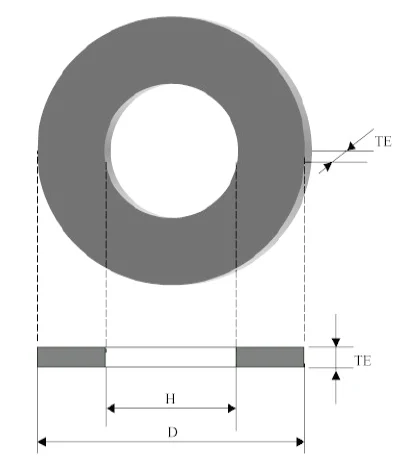

- Outside Diameter (D): 2” (50mm) to 6” (154mm)

Blade Thickness Range

- Thickness (TE): 80 µm to 1500 µm

- Ultra-Thin Blades: Down to 45µm available for high-precision applications

- Standard Thickness Tolerances: ±0.002” (higher tolerances available upon request)

Inside Diameter (Arbor Hole)

- Standard Sizes: 40mm

- Custom Inside Diameters: Available to fit specific dicing saws or mounting requirements

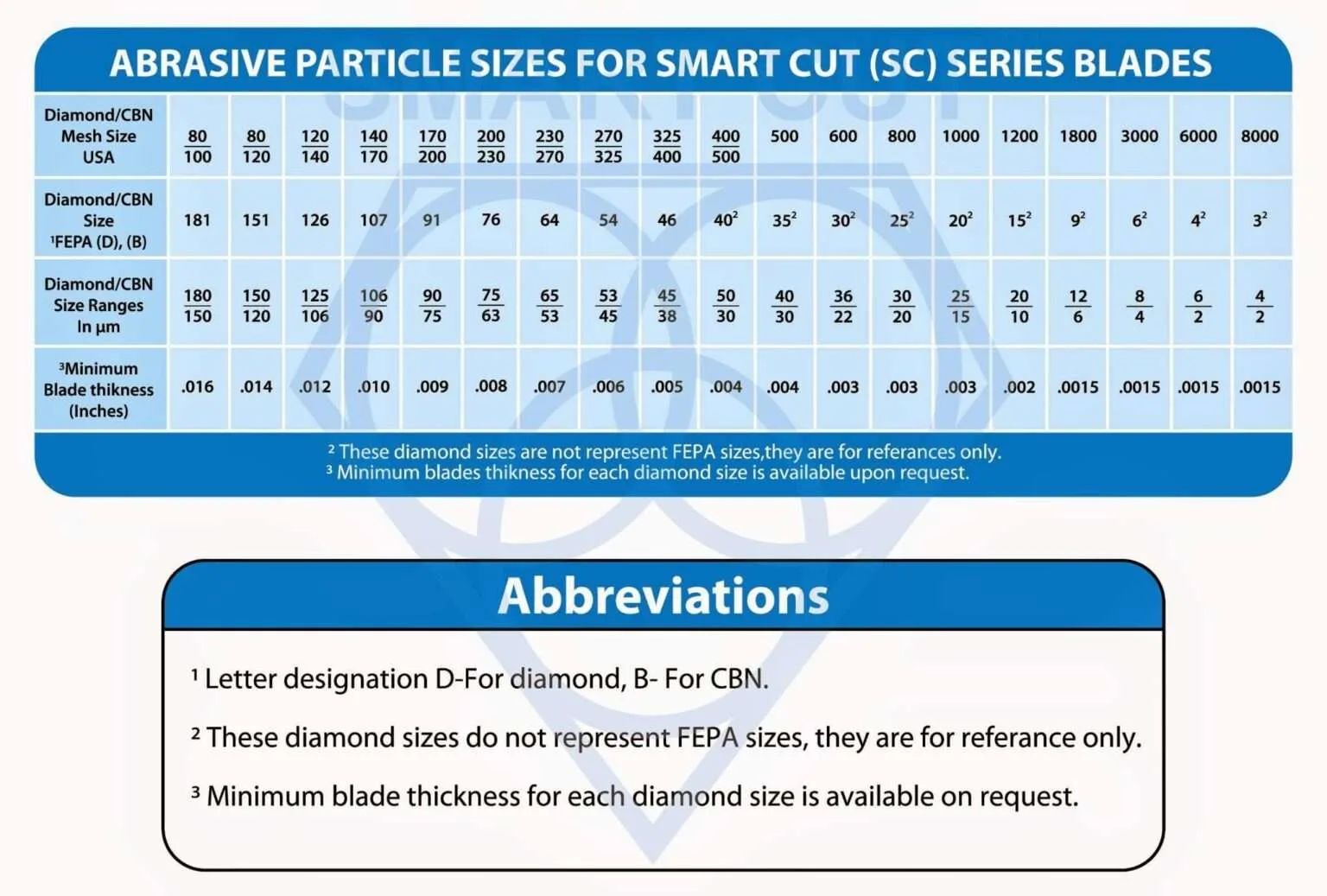

Diamond Grit Sizes

SMART CUT® Resin Bond Dicing Blades are available in a broad range of diamond grit sizes, enabling users to balance cutting speed, surface finish, and blade longevity:

- Diamond Grit Size Range: 2µm to 70µm

- Fine Grits (2µm – 15µm): Recommended for ultra-precise applications requiring a superior surface finish and minimal chipping

- Medium Grits (30µm – 54µm): Best for general-purpose cutting of brittle and dense materials

- Coarse Grits (D76 – D126): Ideal for aggressive material removal and faster cutting rates

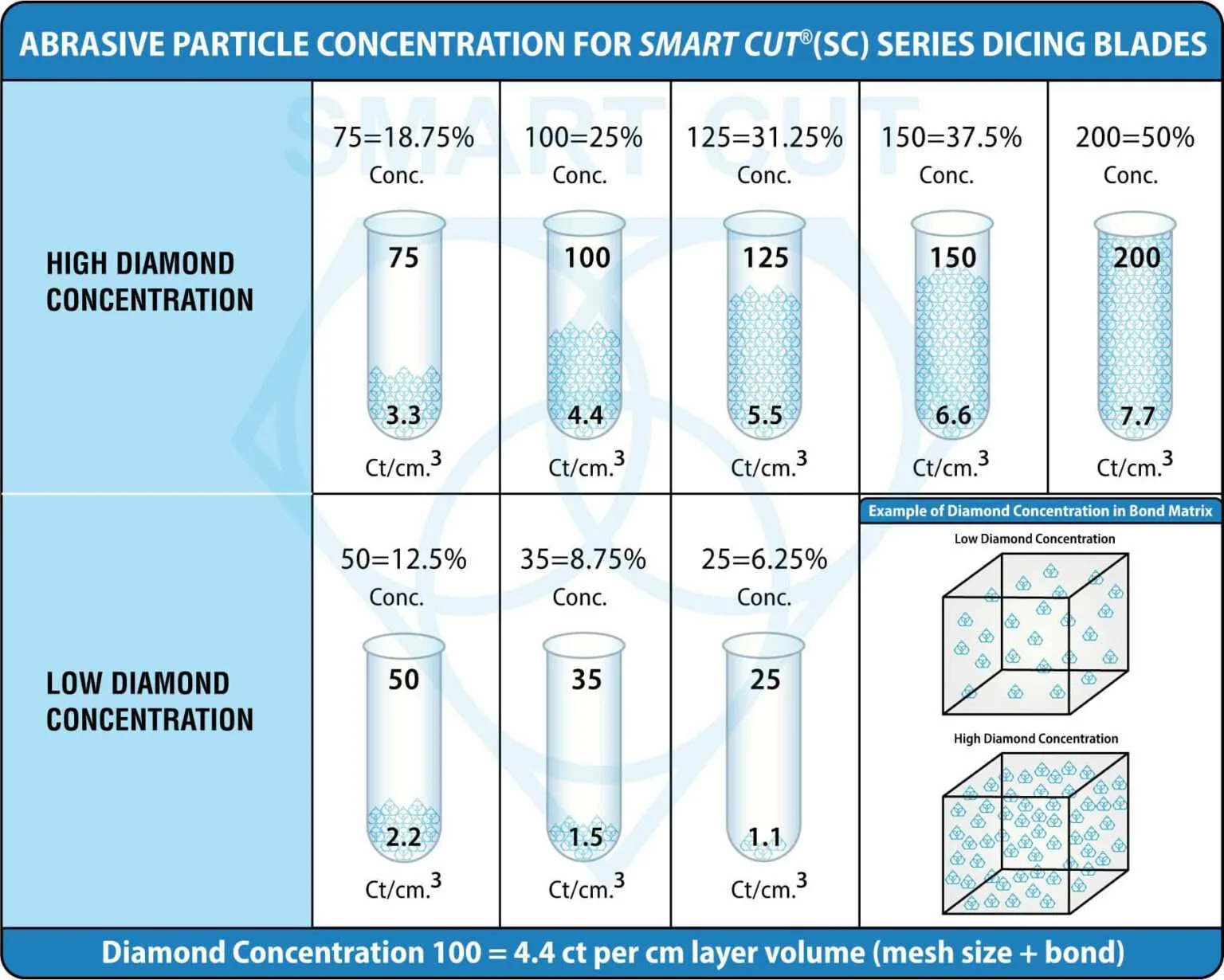

Diamond Concentration

The diamond concentration is precisely controlled to optimize blade performance based on the material being cut. Higher concentrations extend blade life, while lower concentrations improve free-cutting action.

- High Concentration: Used for cutting hard, dense materials like fiberglass (FGS), tungsten carbide (TGC), QFN packages, tool steels, Inconel, and Monel

- Low Concentration: Recommended for brittle and fragile materials such as optical glass, ceramics, lithium niobate (LiNbO₃), sapphire, quartz, and silicon carbide (SiC)

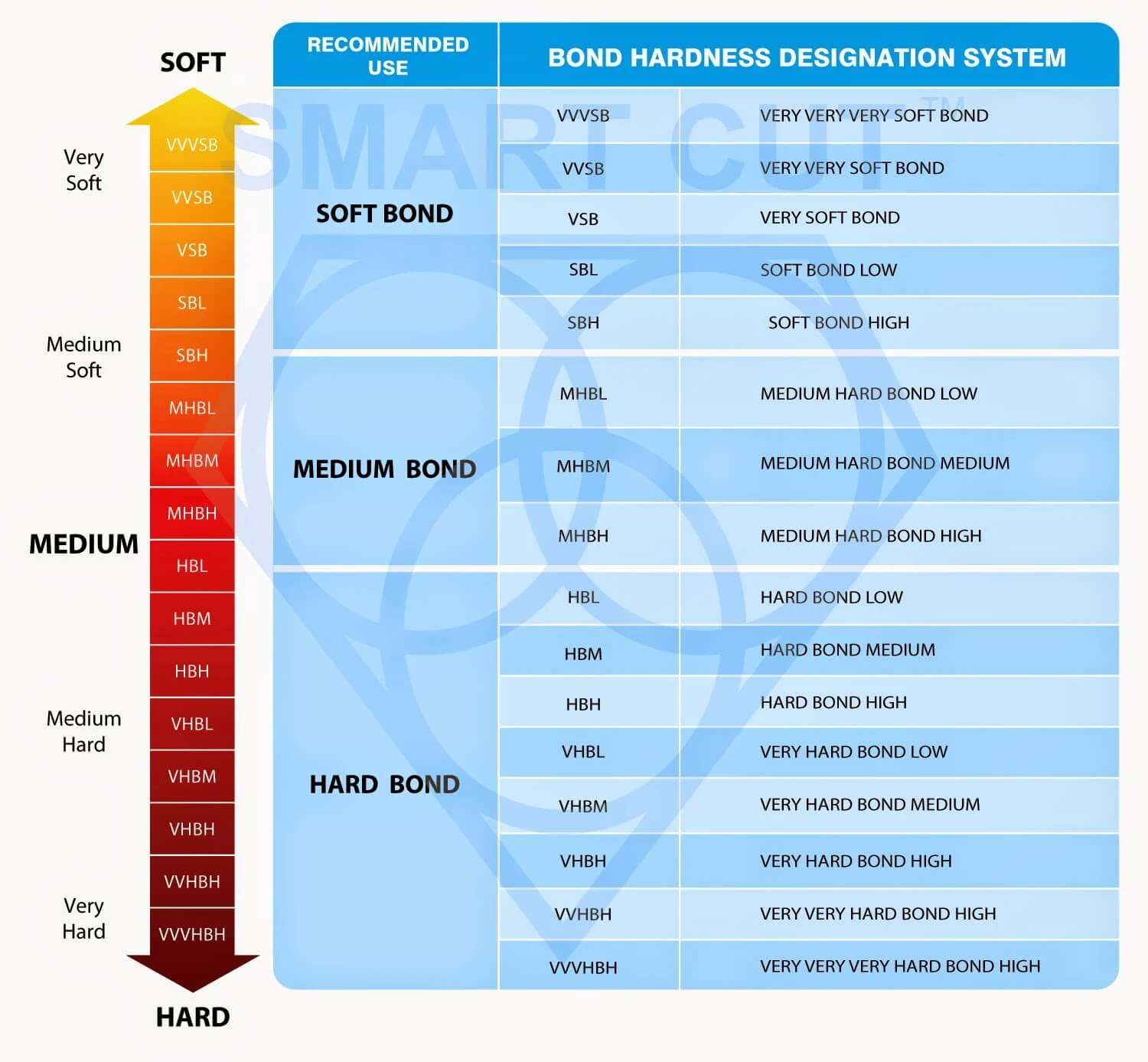

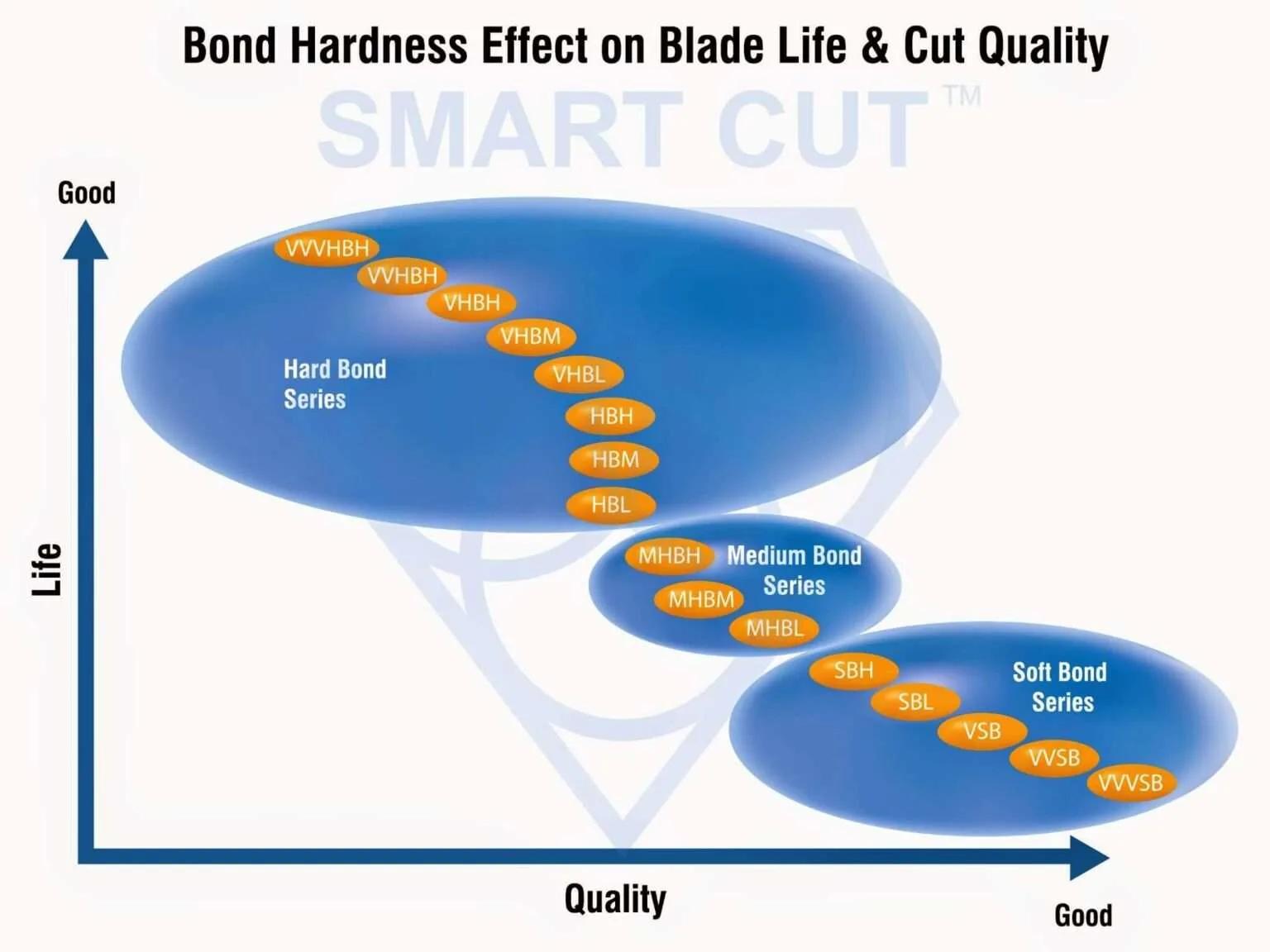

Bond Hardness Designation System

SMART CUT® sintered metal bond dicing blades come in multiple bond hardness formulations to match specific applications:

- Hard Bonds (VVVHB, VVHB, VHBH, HBH, HBM): Best suited for aggressive cutting applications requiring long blade life and high wear resistance

- Medium Bonds (SBL, MHBL, MHBM): Balanced formulation for controlled wear and stable cutting performance

- Soft Bonds (VVVSB, VVSB, VSB): Ideal for fast cutting, reduced heat generation, and minimal material deformation

Edge Profiles and Serration Options

To enhance performance in specific cutting applications, SMART CUT® offers a variety of serrated and edge profile options:

- Straight Edge: Provides smooth, clean cuts for materials with minimal chipping concerns

- Serrated Edge: Increases coolant flow and debris removal, reducing heat buildup and improving cut quality

- Custom Edge Geometries: Available upon request for specialized applications

Tolerance Standards

SMART CUT® dicing blades are manufactured to extremely tight tolerances, ensuring high precision and repeatability:

- Outside Diameter Tolerance: ±0.002”

- Blade Thickness Tolerance: ±5µm to ±15µm (depending on thickness and application)

- Runout: ≤ 0.001” (≤ 25µm) for high-precision applications

FREQUENTLY ASKED QUESTIONS

SMART CUT® SCR Series Resin Bond Dicing Blades are specifically engineered for precision dicing, singulation, slotting, and cross-sectioning of hard and brittle materials such as ceramics, quartz, semiconductor wafers, glass, optical components, sapphire, ferrites, and composites. These blades provide optimal performance in high-precision applications where cut quality, minimal chipping, and tight tolerances are critical. SMART CUT® SCR Blades are manufactured using our proprietary SMART CUT® technology, which ensures precise diamond orientation, uniform diamond distribution, and optimal diamond protrusion. This results in faster cutting speeds, longer blade life, reduced heat generation, and superior surface finishes. Our blades are custom-manufactured per application, optimizing performance and cost-effectiveness for each customer’s specific needs. These blades are ideal for cutting: SMART CUT® SCR blades are available in a wide range of diamond grit sizes, from ultra-fine (20/25 mesh) to coarse (325/400 mesh), depending on material properties and surface finish requirements. Standard diamond concentrations range from 25% to 100%, with customized concentrations available to balance cutting speed, surface finish, and blade life. The standard kerf thickness (blade thickness) ranges from 0.004″ (100 microns) to 0.100″ (2.5 mm). However, ultra-thin configurations as low as 0.001″ (25 microns) can be manufactured upon request, depending on the application and machine compatibility. SMART CUT® SCR blades are available in diameters from 1″ (25 mm) up to 6″ (154 mm) or larger upon request. Bond hardness is a critical variable that determines how quickly the matrix wears away to expose new diamonds. Softer bonds are ideal for harder, denser materials, allowing continuous diamond exposure. Harder bonds work best with softer or abrasive materials to extend blade life. SMART CUT® SCR blades are available in soft, medium, and hard bond formulations. We customize the bond matrix for each application to ensure maximum performance. Our advanced resin formulation and precision diamond placement minimize vibration, thermal damage, and lateral movement during cutting. This results in a smoother entry and exit, reduced micro-fractures, and significantly lower edge chipping, making SCR blades ideal for delicate substrates and ultra-thin materials. Yes. Our blades are designed to be fully compatible with all major precision dicing saws, including: Blade life varies depending on material hardness, thickness, coolant type, feed rate, RPM, and depth of cut. However, customers consistently report 1.5X to 3X longer blade life compared to conventional resin bond dicing blades. Longevity is further enhanced by proper dressing and optimal operating parameters. Yes. Like all precision dicing blades, SMART CUT® SCR blades benefit from periodic dressing to maintain sharpness and correct geometry. We offer dressing sticks and automated dressing solutions to restore cutting efficiency and extend overall blade life. Water-soluble dicing coolants are recommended for optimal heat dissipation, lubrication, and debris removal. For sensitive substrates or electrostatic discharge concerns, we offer specially formulated SMART CUT® XP Series dicing fluids (XP-1 through XP-4), each tailored for specific dicing environments and materials. Absolutely. Unlike off-the-shelf solutions, we specialize in engineering custom blade configurations based on your exact material type, thickness, machine type, desired surface finish, feed rate, and throughput requirements. Submit your application details and our applications engineering team will design a blade to match your exact needs. Customers consistently find that SMART CUT® SCR blades outperform leading competitors in terms of: Standard delivery is 3 to 4 weeks for most custom blades. Expedited lead times can be available depending on the blade specification. All blades are produced per your specifications and requirements and inspected for quality assurance and traceability. Our experienced applications engineering team (with over 100 years of combined experience) offers free technical consulting. We help customers select the correct blade based on material properties, machine type, cut depth, throughput requirements, and surface finish expectations. Trial blades are also available under our Guaranteed Trial Order Program. Yes. We offer hybrid resin-metal bond dicing blades, as well as multi-layer blade constructions where different bond types or grit sizes are layered to achieve specific cutting goals—such as increased durability, self-sharpening properties, or optimized surface finish in one pass. These advanced configurations are made-to-order and can significantly improve performance in challenging applications. When stored properly in a dry, cool, and dust-free environment, SMART CUT® SCR blades have a shelf life of up to 2 years. To ensure optimal performance, avoid exposing the blades to moisture, extreme temperature fluctuations, or corrosive chemicals. Blades with customized resin formulations or special coatings may have different storage guidelines, which will be specified in the product documentation. Yes. Dressing is essential to maintain blade sharpness, ensure consistent diamond exposure, and restore cutting performance. We recommend using: SMART CUT® SCR blades can be used on: Absolutely. In addition to wafer singulation and precision cut-off, SMART CUT® SCR blades are widely used for: We do not impose strict minimum order quantities. You can order as little as 3 blades, especially when prototyping or validating new materials or production methods. We encourage customers to test performance through our Guaranteed Trial Order Program, where the blade is offered free of charge if the performance feedback form is completed. Our manufacturing process allows us to maintain ultra-precise tolerances: Arbor hole tolerance: ±0.0002″ (±5 microns) Tolerances can be further customized for high-precision applications such as MEMS, microfluidics, or photonics. Yes. The resin bond matrix used in our SCR blades is specially formulated to reduce friction and heat generation at the cutting interface. Lower cutting temperatures help prevent thermal damage, preserve material integrity, and extend both blade and equipment life. For extremely heat-sensitive materials, we recommend using SMART CUT® XP Series Coolants and maintaining continuous coolant flow. Yes. Our applications engineers will evaluate your specific cutting needs—material type, dimensions, cutting machine, target surface finish, throughput requirements—and recommend a tailored solution. We often perform sample cuts in-house at no cost and provide detailed feedback on the best-performing blade configurations for your process. We offer free lifetime technical support with every blade purchased. Additionally, we provide: While the blades themselves are not recyclable in conventional municipal systems, UKAM Industrial Superhard Tools participates in industrial recycling programs for spent diamond tools. Used blades can often be returned for re-segmentation or reconditioning, extending the life of the hub and reducing waste. Ask about our Blade Recovery Program for eligible customers. Common indicators include: Need for more frequent dressing Safety is paramount. Please follow these guidelines: Inspect blades for cracks, chipping, or warping before each use. We provide full Safety Data Sheets (SDS) and operation manuals upon request. These blades are engineered for wet cutting only. Dry cutting of hard and brittle materials using resin bond blades can cause: To extend blade life and maintain performance: Reduced cutting efficiency may result from: Contact our technical support team for a blade evaluation or possible re-specification. We maintain rigorous quality control procedures, including: Internal testing protocols for grit size distribution, bond uniformity, and kerf tolerance Yes. SMART CUT® SCR blades can be used to cut multi-layered or laminated materials such as: Yes. Through our Guaranteed Trial Order Program, we offer trial blades free of charge to qualified customers who agree to provide feedback using our standard blade evaluation form. This ensures the blade meets your specific application and performance expectations before large-scale purchase. In many cases, yes. We maintain an agile manufacturing operation with the ability to make real-time changes to bond type, diamond grit, kerf thickness, or arbor size without significantly delaying production. We advise customers to confirm specification changes early in the process for fastest turnaround. Yes. For companies working on new materials, next-generation devices, or novel cutting challenges, we offer collaborative development programs including: Yes. Certain materials (such as sapphire, GaN, and semiconductor wafers) are highly sensitive to electrostatic discharge (ESD). Our SMART CUT® SCR blades can be formulated with anti-static resin systems or used in conjunction with XP-4 anti-ESD dicing fluid to: We specialize in custom-manufacturing solutions for high-mix / low-volume clients who need: Yes. For OEMs and repeat customers, we offer: Yes. We frequently reverse-engineer or replicate discontinued blades from: Yes. As a vertically integrated manufacturer, we offer:

We offer custom arbor sizes and hub mounting options to fit any machine.

If any of these symptoms are observed, we recommend retiring the blade and contacting us for a replacement recommendation or performance analysis.

Customers requiring absolute consistency for volume production can request Process Capability Index (Cp/Cpk) documentation and First Article Inspection (FAI) reports.

Blade formulation and grit size may need to be adjusted to accommodate differences in material hardness, thermal expansion, and delamination tendencies. We recommend testing in collaboration with our applications engineering team.

We regularly work with leaders in microelectronics, photonics, aerospace, medical devices, and national labs.

This makes SMART CUT® SCR blades ideal for contract manufacturers, research institutions, and small-scale device developers.

These programs improve supply chain stability, reduce lead times, and lock in preferred pricing.

We will match or enhance the original performance using SMART CUT® formulations and technology.

Bundling these products ensures optimal system performance and simplifies procurement.

INDUSTRIES USED IN

SMART CUT®Tab Content

ACCESSORIES

USAGE RECOMMENDATION

01

Jun

Share this Article with Friend or Colleague

Dicing QFN packages presents several challenges due to the composition of materials and the precision required for clean, defect-free cuts. These challenges arise from the multi-layered structure of…

02

Jun

Dicing Blade Operations Recommendations

Share this Article with Friend or Colleague

Selecting the right dicing blade parameters often involves a trial and error process, many aspects of which can be mitigated through experience and a deep understanding of how to…

02

Jun

Optimizing your Diamond Dicing Performance

Share this Article with Friend or Colleague

The performance of diamond dicing blades is influenced by a wide range of interdependent variables, and understanding these factors is essential for selecting the correct blade specifications and…

02

Jun

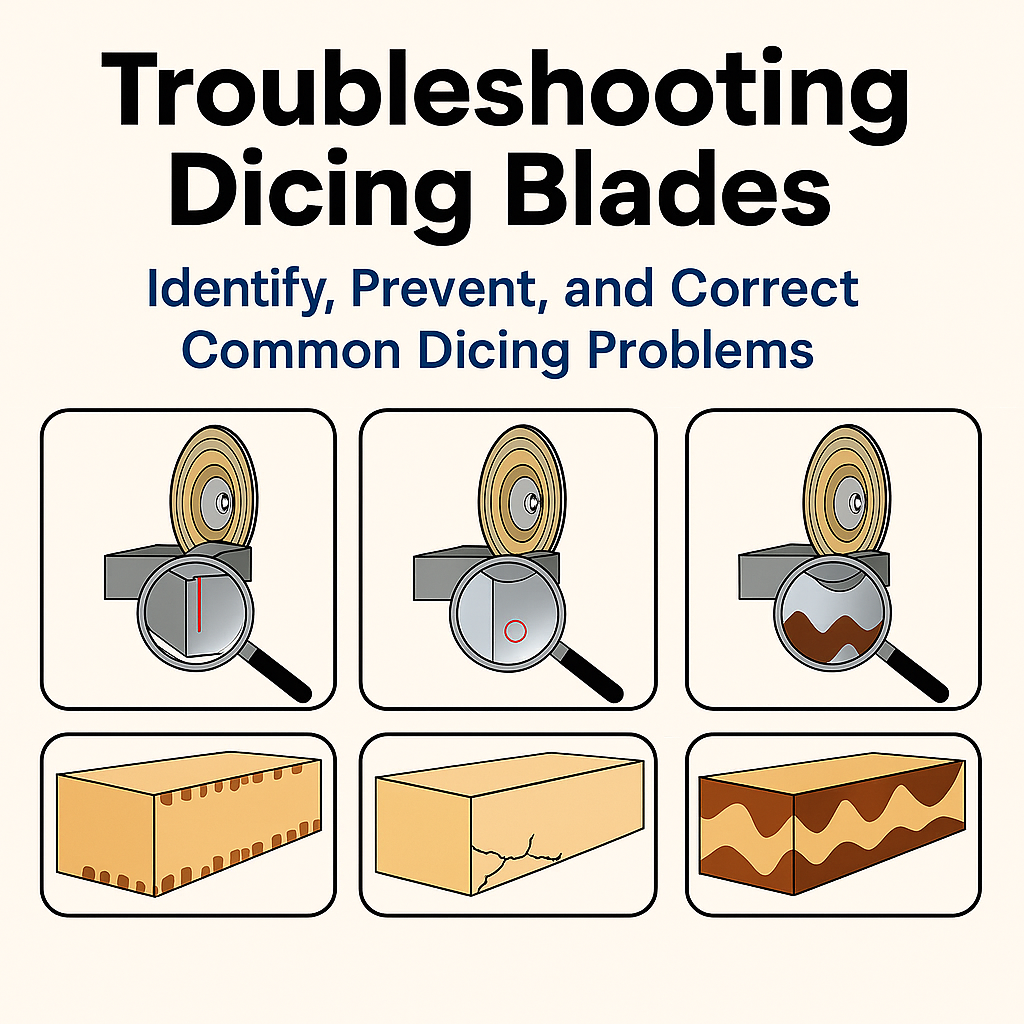

Trouble Shooting Dicing Problems

Guide on most common dicing problems and how to resolve them

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP YOU

CONTACT US

HAVING ISSUES WITH

YOUR…

02

Jun

Application Recommendations

This article provides important guidelines for optimizing the dicing process in semiconductor packaging, focusing on package singulation for various technologies such as BGA, QFN, LED, CMOS, and wafer substrates. It covers key variables such as…

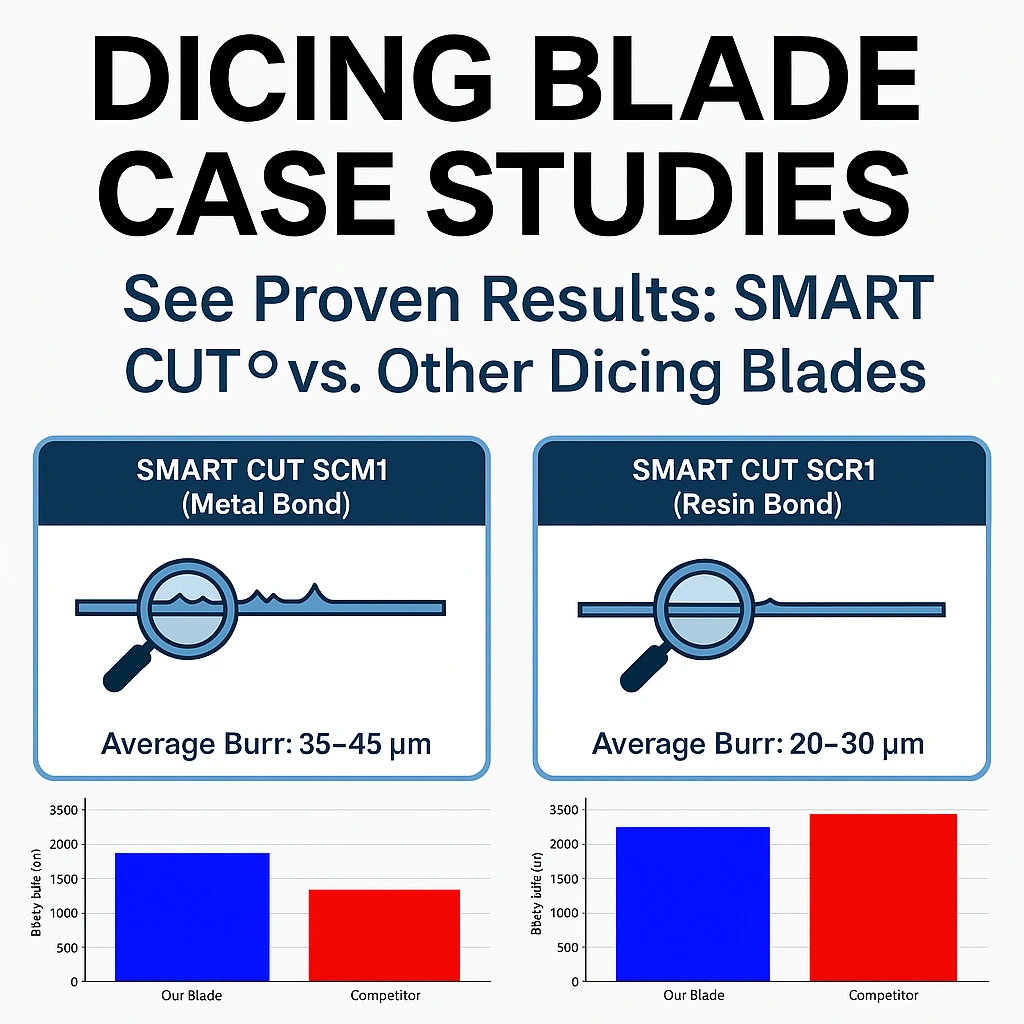

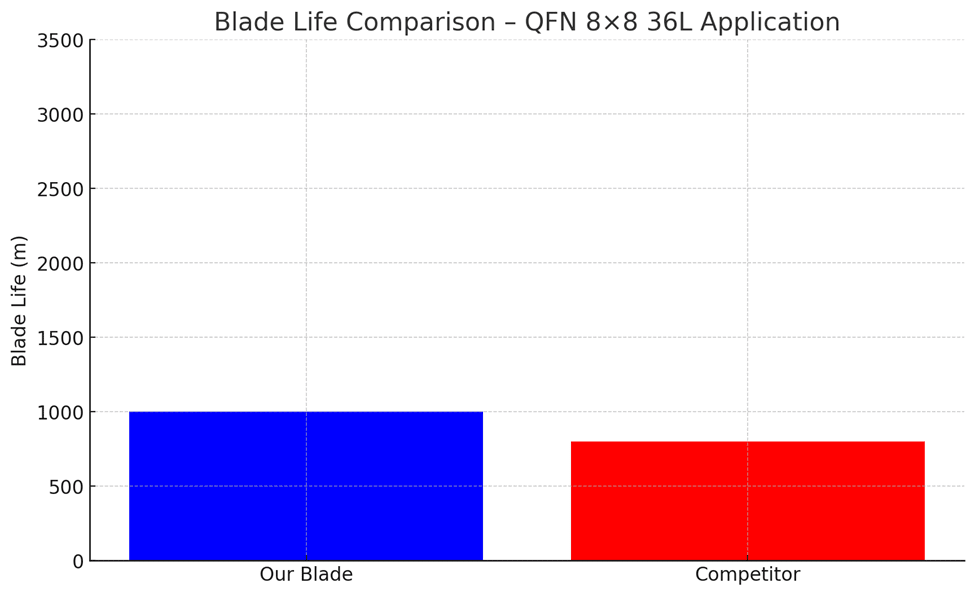

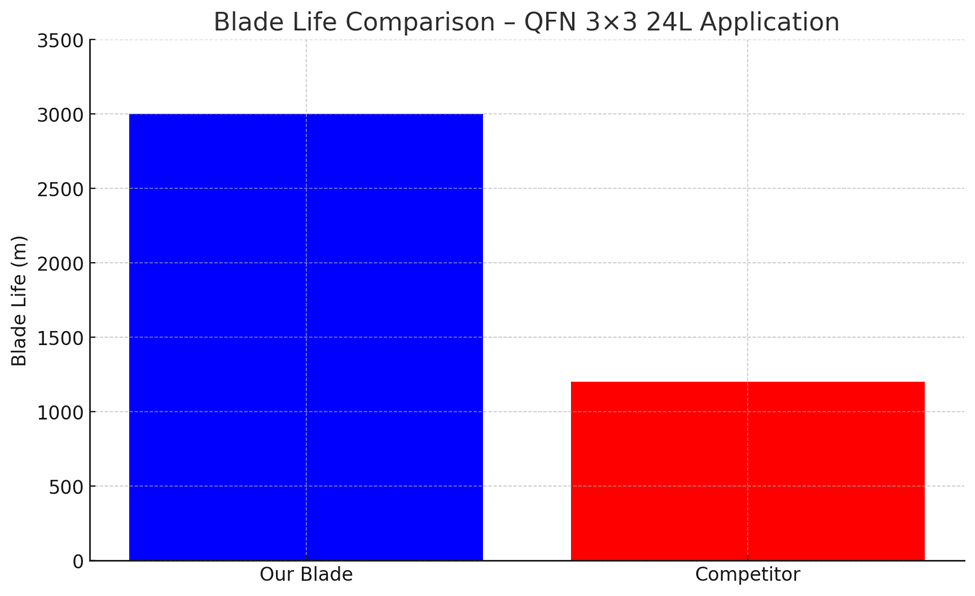

CASE STUDIES

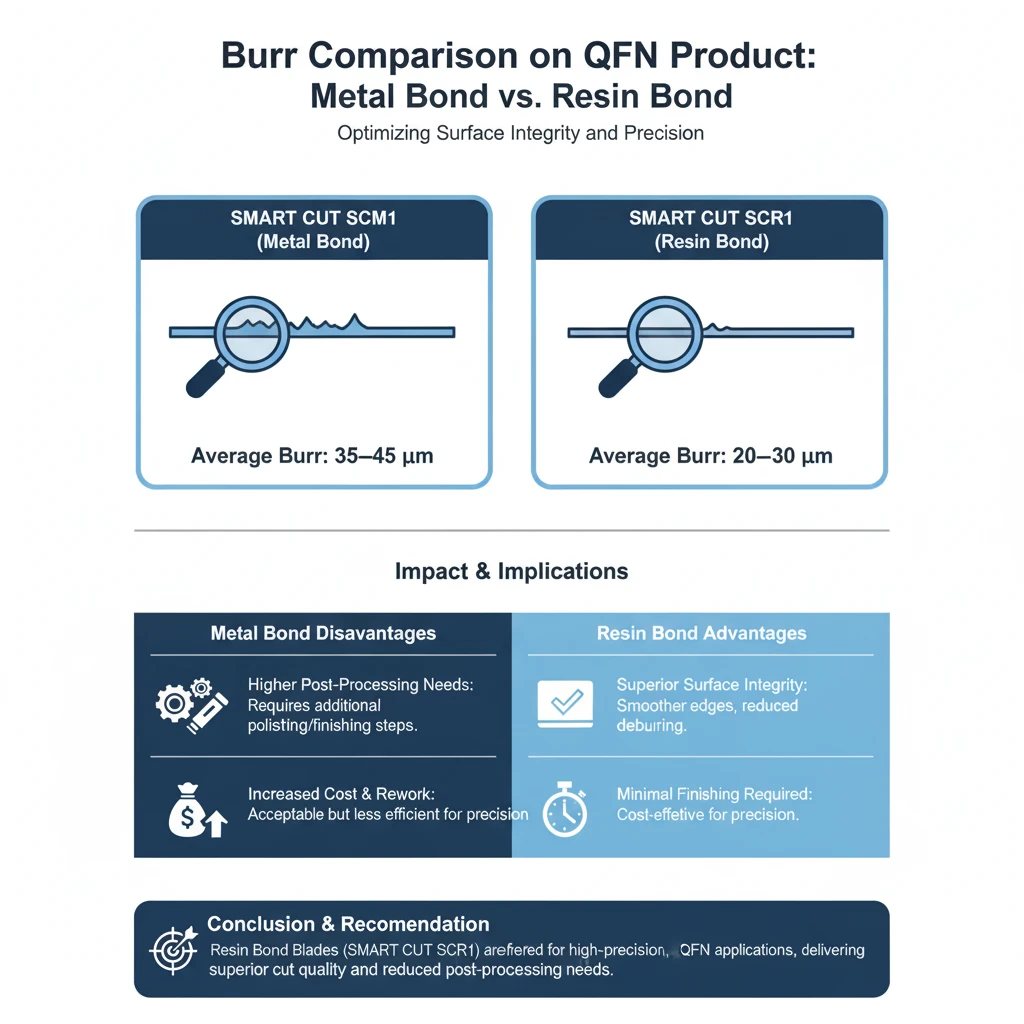

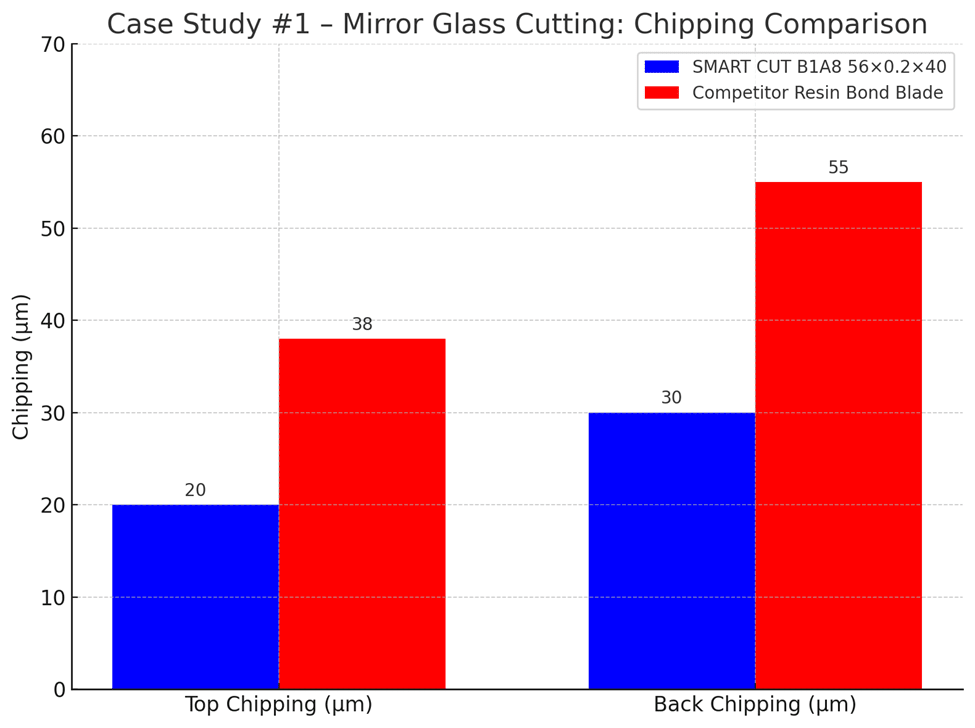

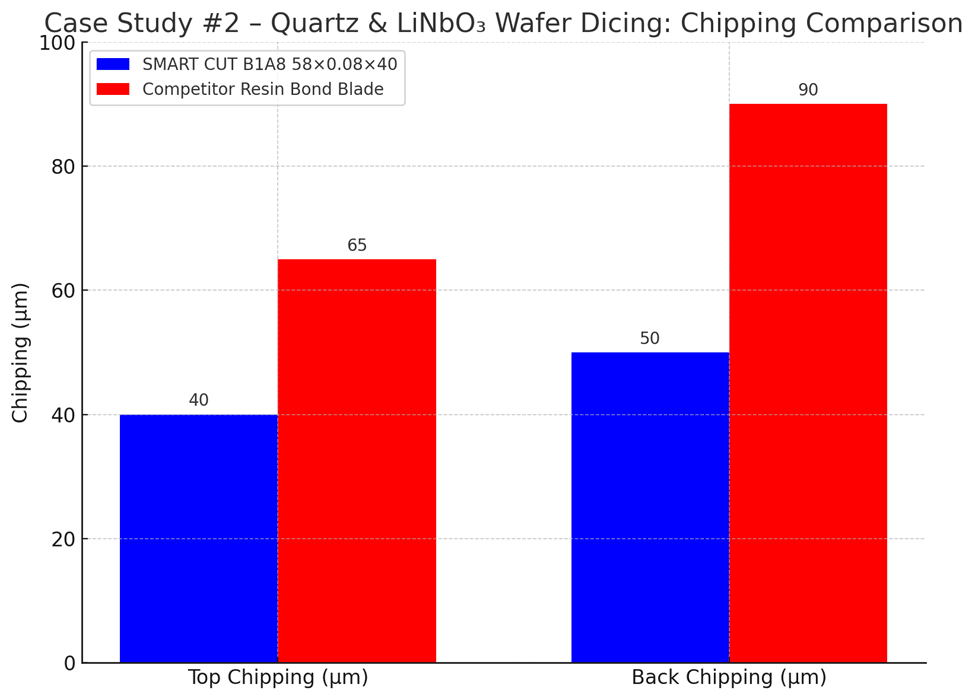

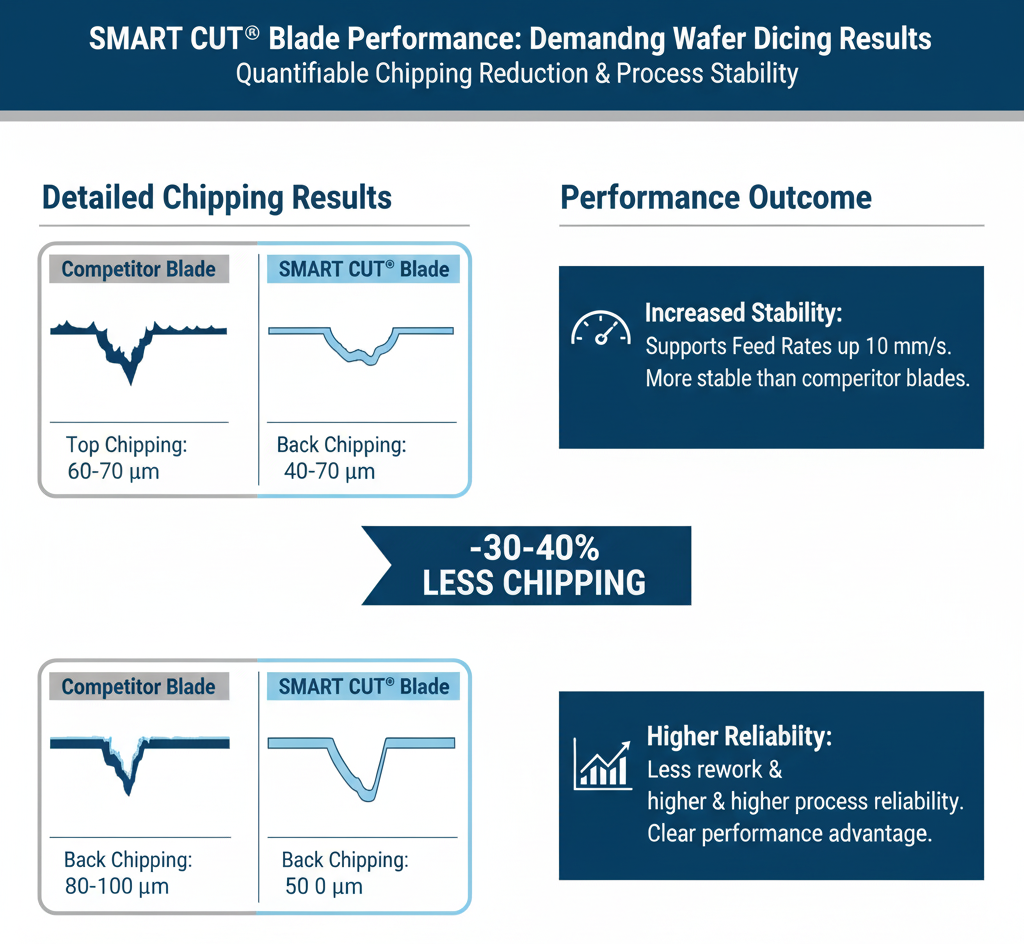

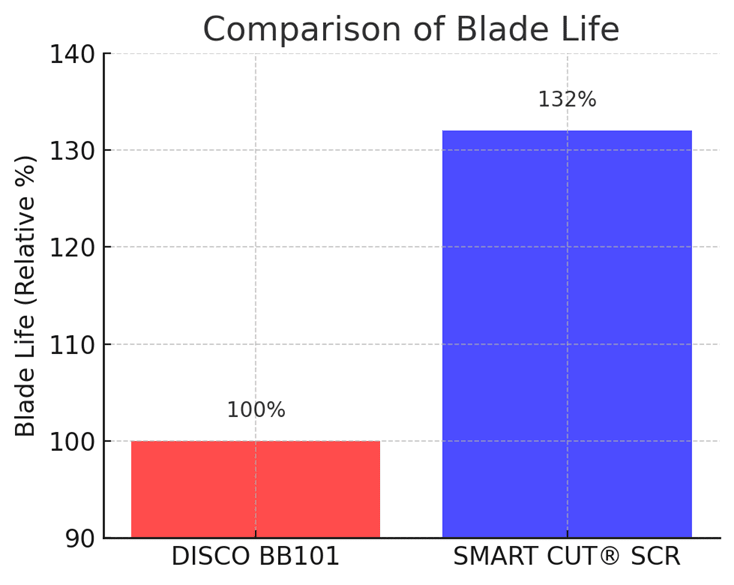

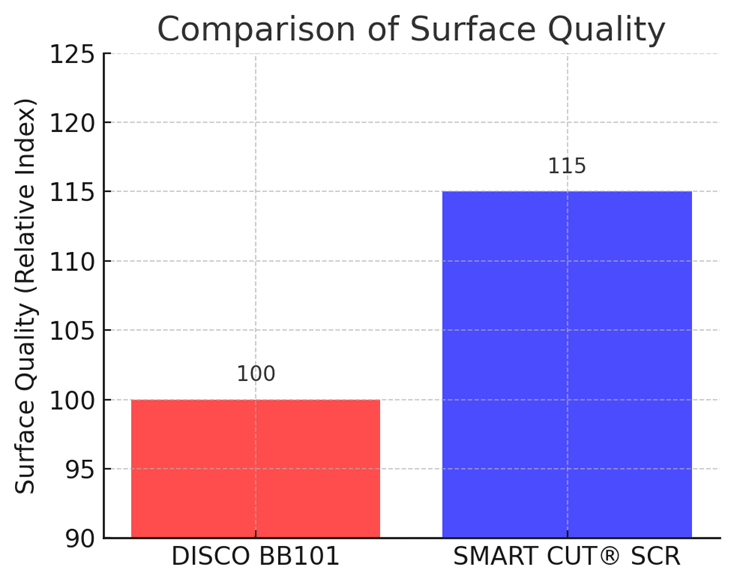

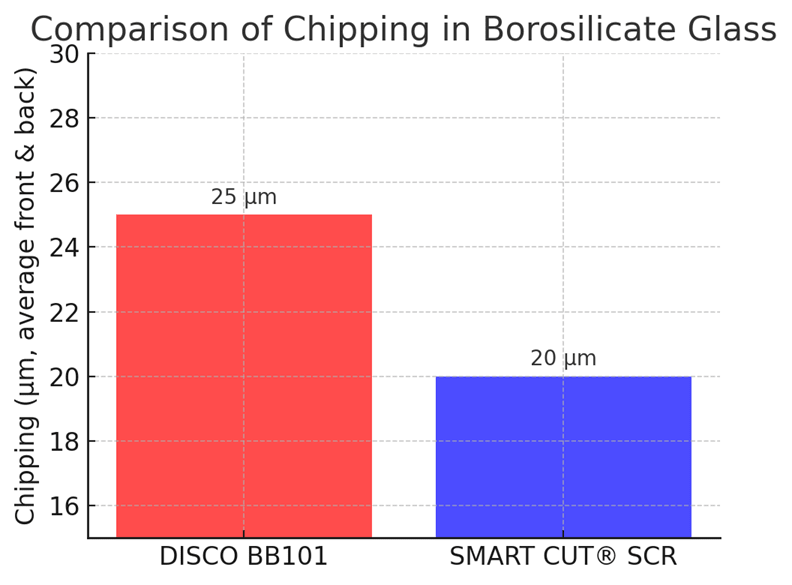

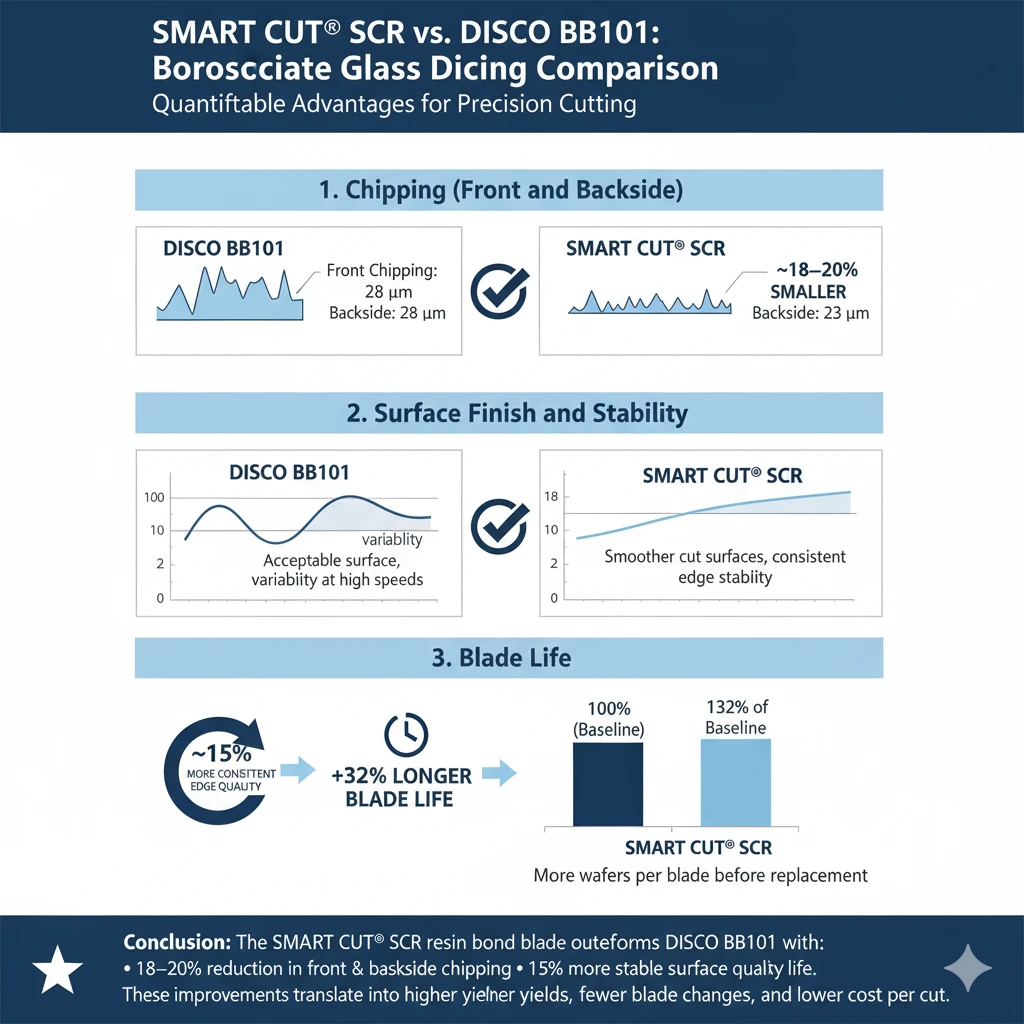

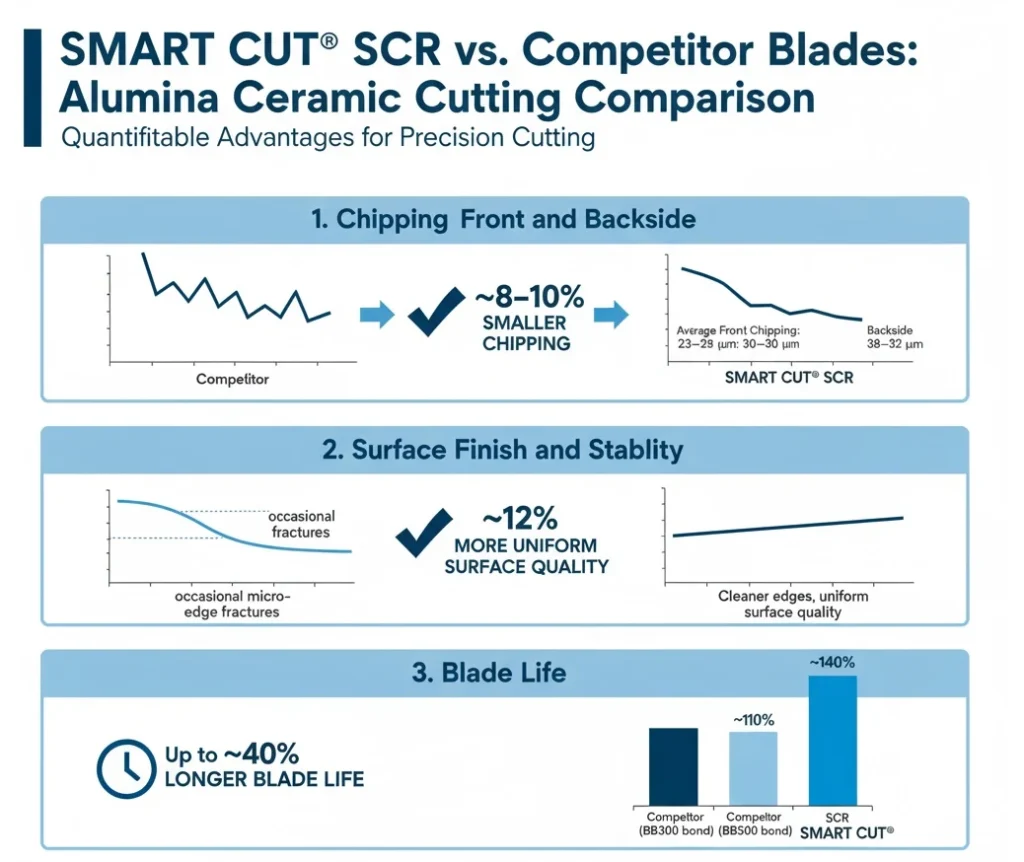

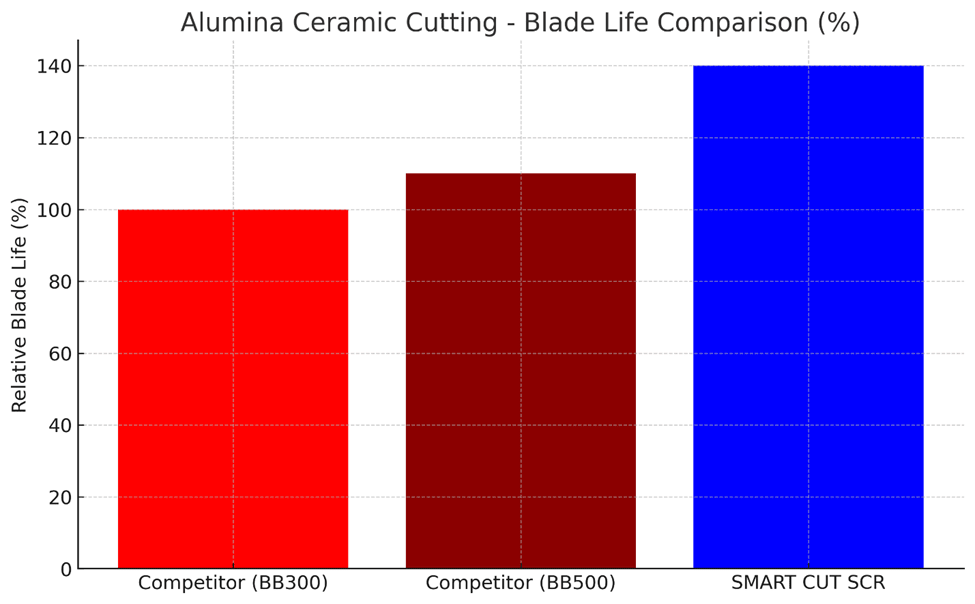

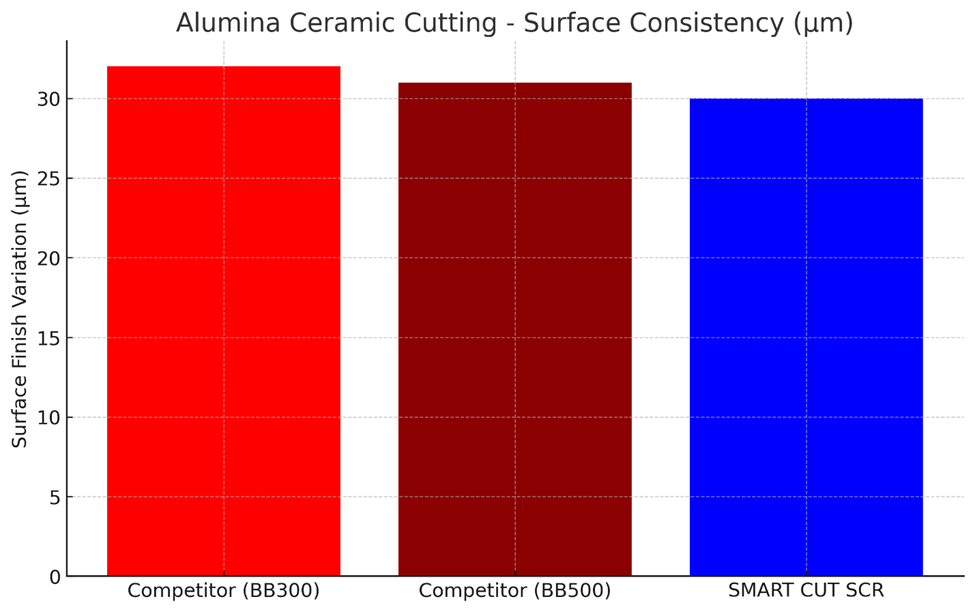

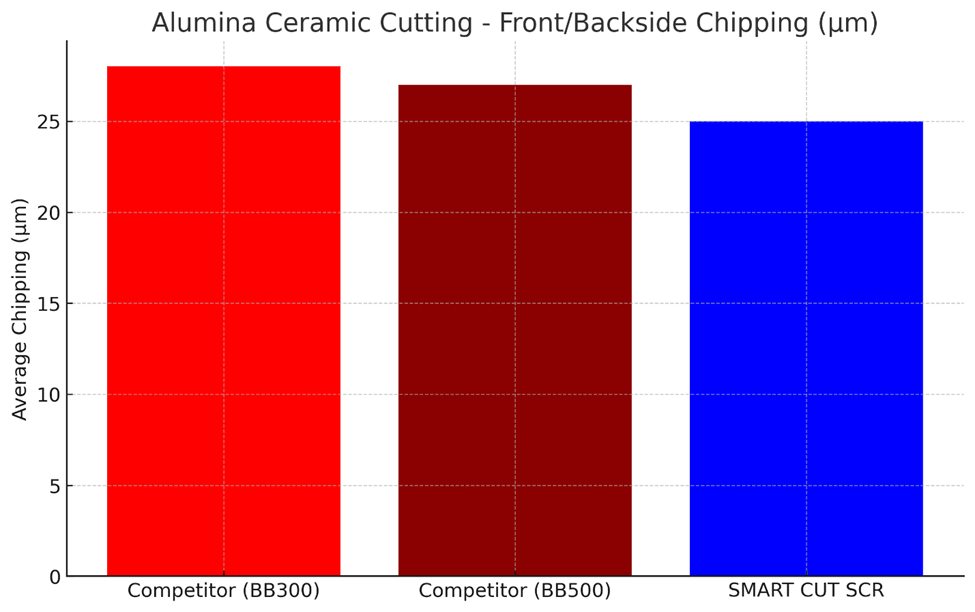

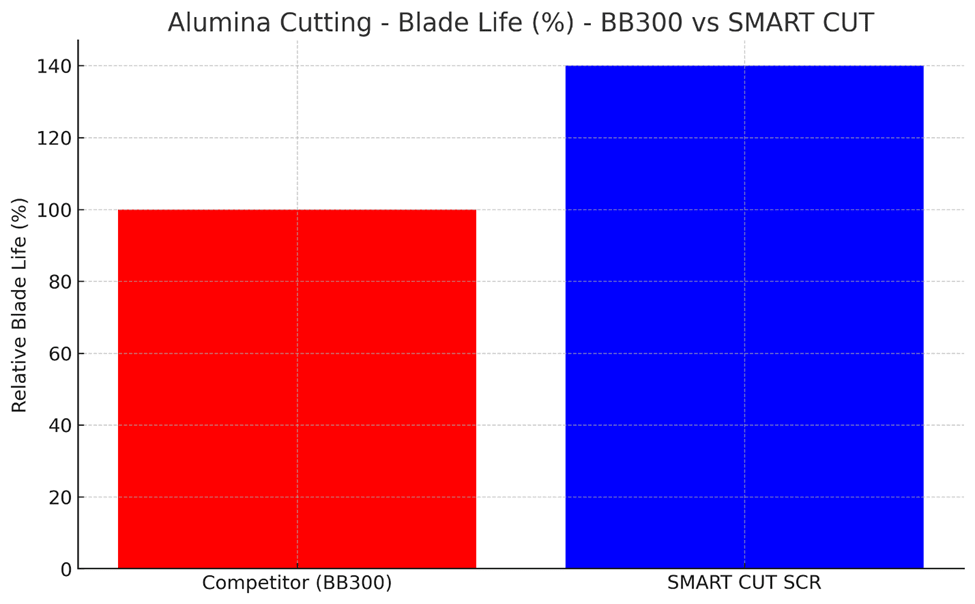

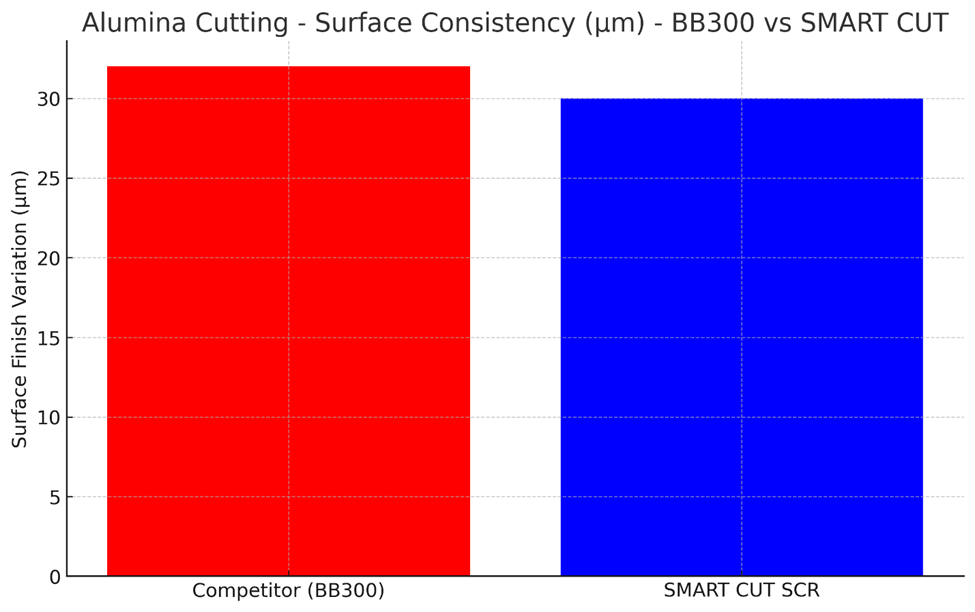

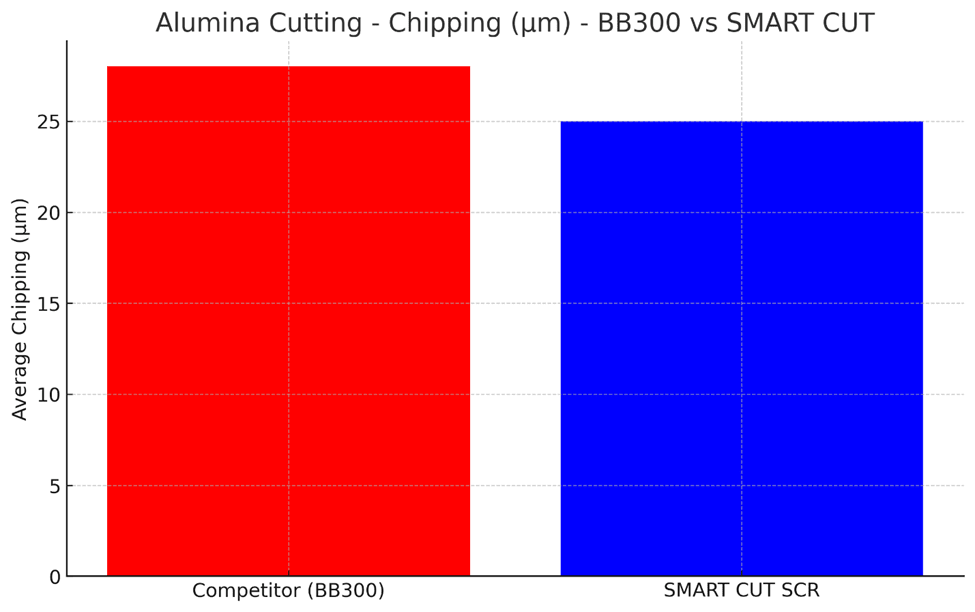

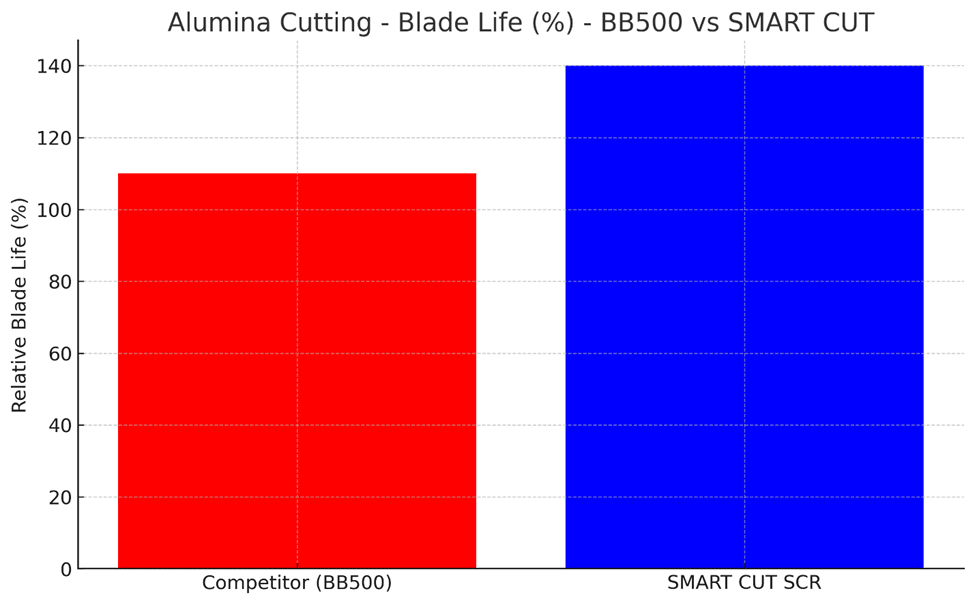

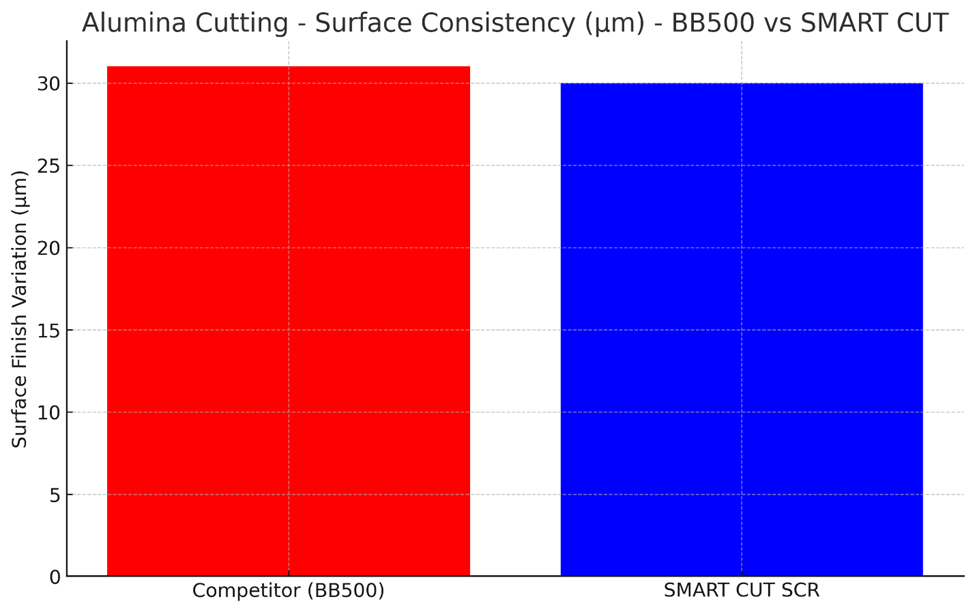

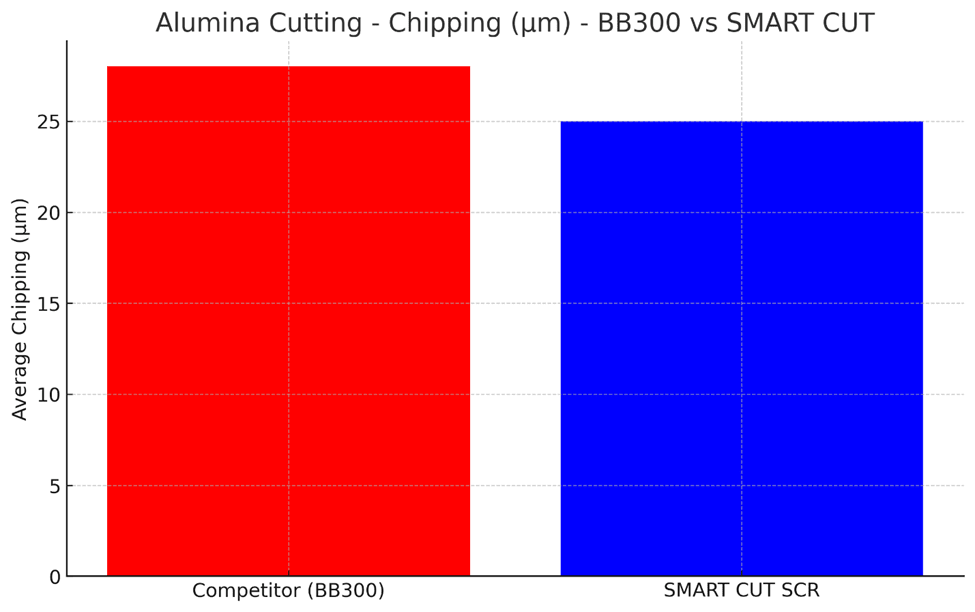

In advanced electronics manufacturing, resin bond dicing blades are widely used for cutting QFN, DFN, BGA, PCB, and glass substrates. Customers often face challenges with tool life, burr formation, tin melting, and chipping when using competitor blades. To evaluate performance differences, SMART CUT® SCR1 resin bond blades were tested head-to-head against competitor resin bond blades under identical operating conditions. SMART CUT® SCR1 resin bond blades delivered 2–3 times longer blade life, cleaner cuts with fewer burrs, and greater reliability compared to competitor blades. By reducing downtime for blade changes and minimizing defective parts, customers achieved lower overall dicing costs and higher production yields. Factor SMART CUT SCm1 (Metal Bond) SMART CUT SCR1 (Resin Bond) Average Burr Level 35–45 microns 20–30 microns Consistency Over Blade Life High burr levels remain steady Low burr levels remain consistent Surface Integrity Rougher surface, prone to defects Smoother surface with better edge quality Post-Processing Needs Requires polishing or secondary finishing Minimal or no finishing required Suitability for QFN Products Acceptable but increases cost and rework Preferred choice for precision, minimal burr applications Factor SMART CUT SCm1 (Metal Bond) SMART CUT SCR1 (Resin Bond) Smearing Level 45–55 microns, fluctuating throughout blade life 25–35 microns, consistent through blade life Edge Definition Reduced sharpness, visible deformation along cut edge Superior edge definition with minimal material drag Impact on Dimensional Accuracy Greater risk of distortion, affecting bonding and assembly Maintains high accuracy with clean cut edges Cleaning/Rework Needs Often requires additional cleaning or rework Minimizes need for secondary processing Suitability for Precision Applications Less suitable due to excessive smearing Preferred for semiconductor dicing and advanced electronics packaging Factor SMART CUT SCR1 (Resin Bond) SMART CUT SCm1 (Metal Bond) Wear Rate Rapid initial wear, reaching 1.2 mm early in blade life Gradual, linear wear, reaching 1.8 mm at end of test Bond Structure Softer bond, designed for precision but shorter lifeHarder bond, designed for durability Harder bond, designed for durability Suitability for Long Production Runs Less suitable due to faster degradation More suitable thanks to slower wear rate Surface Quality Impact Produces cleaner cuts, minimal burrs and smearing Higher burr and smear rates, rougher edges Best Application Fit Ideal for precision, high-quality surface finish applications Ideal for extended production runs and cost efficiency Based on this analysis, the choice of blade should be dictated by the specific requirements of the application: If surface quality and precision are the top priority, resin bond blades are the superior choice for cutting QFN products. However, if blade longevity and wear resistance are more critical, metal bond blades provide a longer-lasting solution but at the cost of increased burr and smearing. Precision cutting of thin mirror glass requires a stable blade capable of producing minimal chipping. Customers in optics and display manufacturing often report excessive chipping when using competitor blades, leading to lower yields and added polishing costs. Compared to competitor resin bond blades, the SMART CUT® blade cut chipping by almost 40%, producing smoother edges and reducing polishing requirements. Customers achieved higher production yields and fewer rejects, making SMART CUT® the preferred choice for precision mirror glass cutting. Quartz and Lithium Niobate wafers are brittle crystalline materials used in photonics, semiconductors, and advanced electronics. Excessive chipping can damage the wafer surface and compromise downstream assembly. Competitor blades often struggle to balance cutting speed with acceptable edge quality. SMART CUT® resin bond blades maintained lower chipping levels while supporting feed rates up to 10 mm/s, proving more stable than competitor blades. With 30–40% less chipping, manufacturers saw less rework and higher overall process reliability. SMART CUT® blades provide a clear performance advantage for demanding wafer dicing operations. Borosilicate glass is widely used in displays, optics, and precision components due to its low thermal expansion and durability. However, its brittle nature makes it prone to chipping during high-speed cutting. DISCO’s BB101 bond blades are a common choice in this application. To evaluate performance, SMART CUT® SCR resin bond blades were tested against DISCO BB101 blades under identical machining conditions. The SMART CUT® SCR resin bond blade demonstrated measurable advantages over DISCO BB101 in borosilicate glass cutting: These incremental but meaningful improvements translate into higher yields, fewer blade changes, and lower cost per cut for glass processing operations. Quartz wafers are widely used in electronics, optics, and resonator applications due to their stability and hardness. However, their brittle nature makes them prone to chipping and surface damage during high-precision cutting. DISCO’s BB200 bond blades are commonly used for this application. To evaluate performance, SMART CUT® SCR resin bond blades were compared against DISCO BB200 under identical machining conditions. The SMART CUT® SCR resin bond blade demonstrated clear advantages over DISCO BB200 in quartz cutting: These improvements translate directly into higher production yields, reduced rework, and lower cost per cut. For quartz processing applications, SMART CUT® provides a superior balance of precision, efficiency, and durability compared to conventional alternatives. Alumina (Al₂O₃) ceramics are widely used in electronics, semiconductors, and medical devices due to their hardness, thermal resistance, and electrical insulation properties. Their brittleness, however, makes them prone to chipping and edge fractures during dicing. Competitor resin bond blades are commonly applied in alumina ceramic cutting. To evaluate performance, SMART CUT® SCR blades were compared against competitor blades with similar specifications under identical machining conditions. The SMART CUT® SCR resin bond blade provided measurable advantages over competitor blades in alumina ceramic cutting: These improvements result in fewer blade changes, reduced downtime, and lower cost-per-cut. For alumina ceramic applications where durability and consistency are critical, SMART CUT® is the superior long-term choice. Alumina (Al₂O₃) ceramics are a key material in electronics, semiconductors, and medical devices. Their hardness and brittleness make them challenging to dice, as excessive chipping and edge fractures often reduce yields. Competitor BB300 bond blades are widely used for this application. This case study compares the performance of SMART CUT® SCR blades against BB300 bond blades under identical cutting conditions. SMART CUT® SCR resin bond blades achieved slightly lower chipping, smoother surfaces, and significantly longer blade life compared to BB300 competitor blades, leading to higher yields and reduced cost per cut. Alumina (Al₂O₃) is a brittle material that requires precise and stable cutting to minimize scrap. Competitor BB500 bond blades were designed for longer life compared to BB300, but often still face issues with micro-cracks and process consistency. SMART CUT® SCR blades were tested against BB500 under identical machining conditions. Compared to BB500, SMART CUT® SCR blades maintained cleaner edges and longer blade life. This reduces downtime and rework, improving overall process efficiency in alumina ceramic applications.

Case Study: Resin Bond Dicing Blades – SMART CUT® SCR1 vs. Competitor Blades

Competitor Resin Bond Blades

SMART CUT® SCR1 Resin Bond Blades

Burr Comparison on QFN Product

Findings:

Analysis:

Smearing Comparison on QFN Product

Findings:

Analysis:

3. Wear Rate Comparison on QFN Product

Findings:

Analysis:

Use Resin Bond Blades When:

Use Metal Bond Blades When:

Case Study 1: SMART CUT® Resin Bond Blade for Mirror Glass

Background

Blade Specification

Results

Outcome

Case Study 2: SMART CUT® Resin Bond Blade for Quartz and LiNbO₃

Background

Blade Specification

Results

Outcome

Case Study: SMART CUT® SCR Resin Bond Blade vs DISCO BB101 in Borosilicate Glass Cutting

Background

Experimental Setup

Results

1. Chipping (Front and Backside)

2. Surface Finish and Stability

3. Blade Life

Conclusion

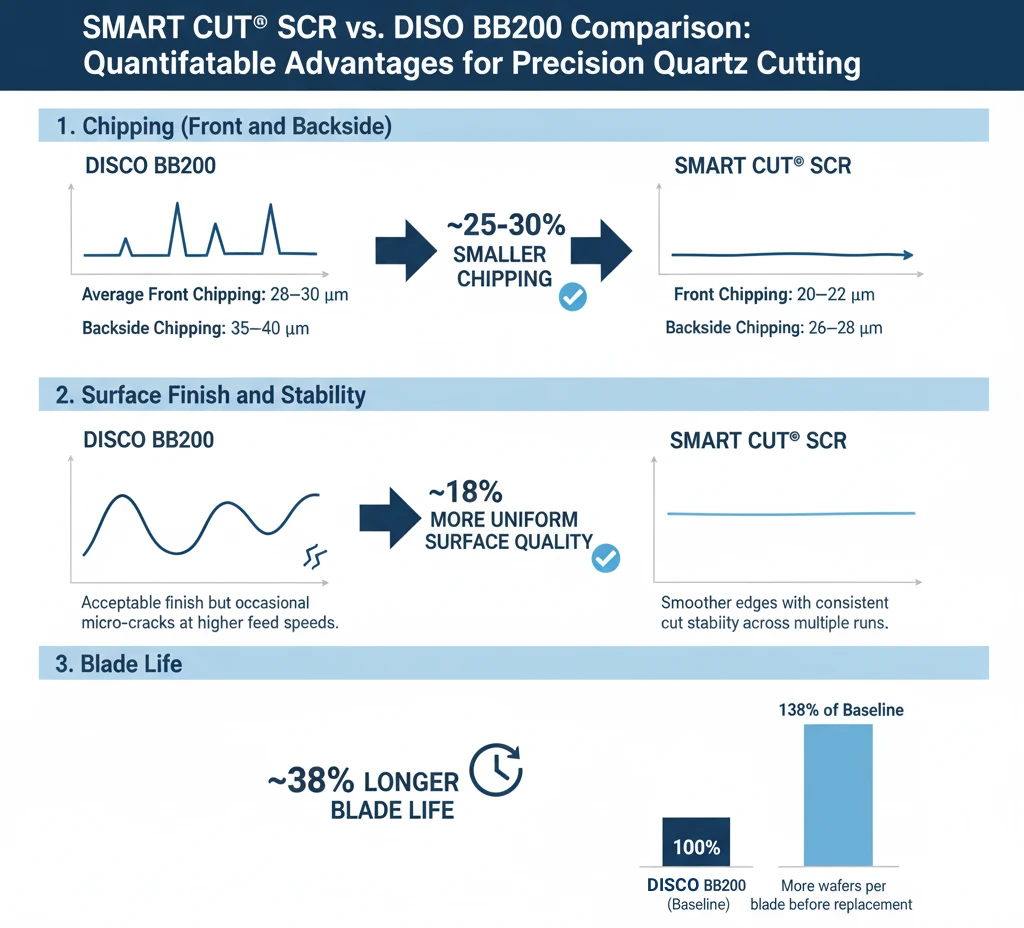

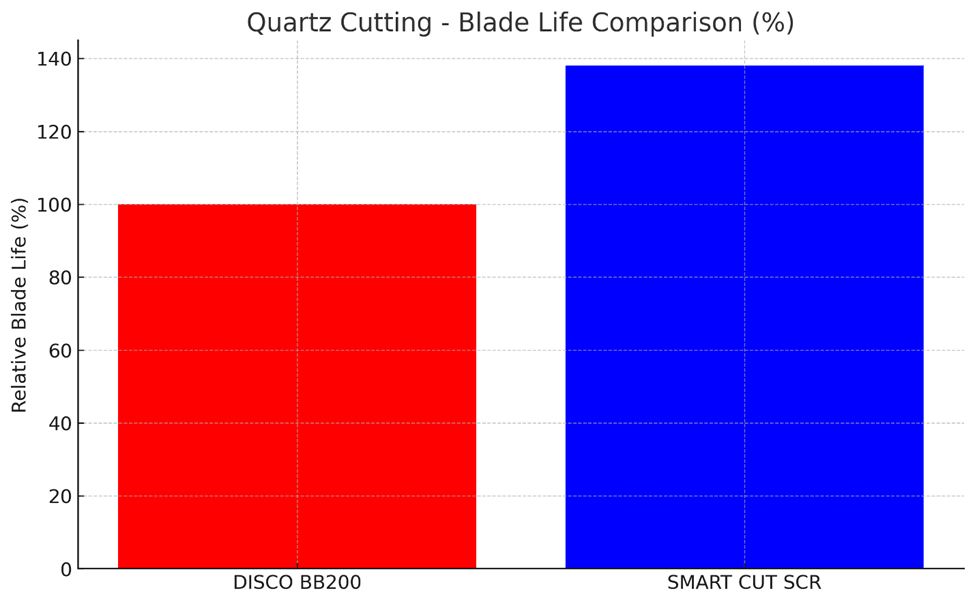

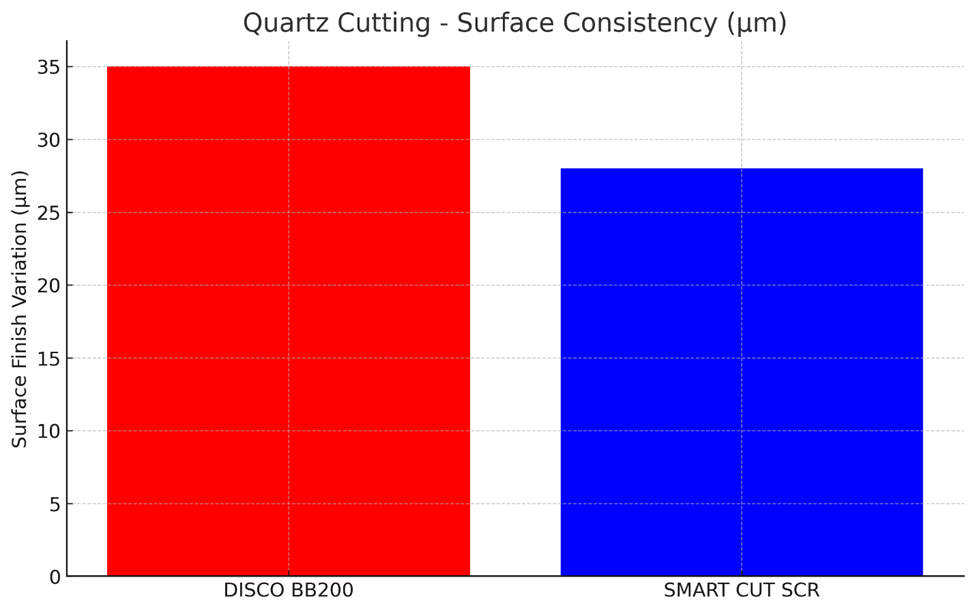

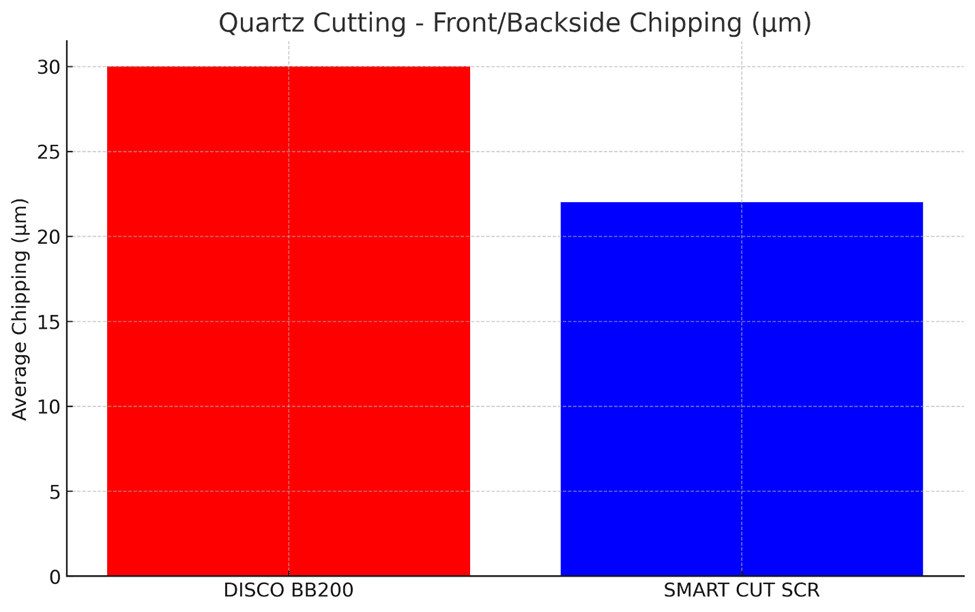

Case Study: SMART CUT® SCR Resin Bond Blade vs DISCO BB200 in Quartz Cutting

Background

Experimental Setup

Results

1. Chipping (Front and Backside)

2. Surface Finish and Stability

3. Blade Life

Conclusion

Case Study: SMART CUT® SCR Resin Bond Blade vs Competitor Blades in Alumina Ceramics Cutting

Background

Experimental Setup

Results

1. Chipping (Front and Backside)

2. Surface Finish and Stability

3. Blade Life

Conclusion

Case Study 1: SMART CUT® SCR Resin Bond Blade vs Competitor (BB300 Bond) in Alumina Ceramics Cutting

Background

Experimental Setup

Results

Conclusion

Case Study 2: SMART CUT® SCR Resin Bond Blade vs Competitor (BB500 Bond) in Alumina Ceramics Cutting

Background

Experimental Setup

Results

Conclusion

Features:

- Highly Customizable

- Improved Precision

- Versatility in Applications

- Resistant to Wear

- Low Vibration

- High Strength and Rigidity

- Extended Blade Life

- Minimal Deflection

- Ideal for Deep or Aggressive Cutting

- Available in Various Grit Formulas

Advantages

- Maximum cutting performance

- No glazing

- Faster cutting action

- Improved surface finish quality

- Better coolant retention

- No Material Deformation

SMART CUT® Resin Bond Dicing / Slicing Blades with a Steel Core

SMART CUT® Resin bond dicing / slicing blades with a steel core offer exceptional strength and rigidity, making them well-suited for high-precision applications. The resin bond is known for its controlled wear properties, which means the abrasive particles remain exposed and sharp for longer periods, ensuring a consistent cut throughout the blade's life. This results in a smooth, even cut with reduced thermal buildup, helping to preserve the material being cut and avoid damage such as microfractures or heat distortion. The combination of the resin bond and the steel core provides added durability, ensuring that the blade maintains its form during demanding cutting operations. These blades are perfect for deep or aggressive cutting, grooving, and slicing of a variety of materials, The added rigidity minimizes blade deflection, which is critical for maintaining consistent performance and protecting the workpiece from damage.

The reduced deflection helps lower operational costs by decreasing the likelihood of material defects and reducing the need for frequent blade replacements. These blades are available in diamond, CBN, and custom grit formulations, offering versatility to meet a wide range of cutting requirements. The blade sizing and shape are highly customizable to suit specific applications, ensuring optimal performance across different materials and cutting conditions.

One of the key benefits of SMART CUT® resin bond blades are less likely to clog or load up, which improves chip removal and reduces the potential for blade binding during operation. Since they are made with a steel core they have extended lifespan. This design allows for longer periods of use, improving productivity and reducing downtime. Additionally, the blades can be equipped with or without water slots, depending on the cooling and lubrication requirements of the application. The edge design/radius can abrasive edge be customized enabling precise control over the depth, width, and shape of the cut.

Why Work With Us?

Best Return

on Investment

Attractive Cost of

Ownership

Thousands of Diamond & CBN Blades in stock

Custom Manufacturer with Fast Lead times

Unmatched

Prices in North America

Unmatched Experience & Technical Support

About Resin Bond

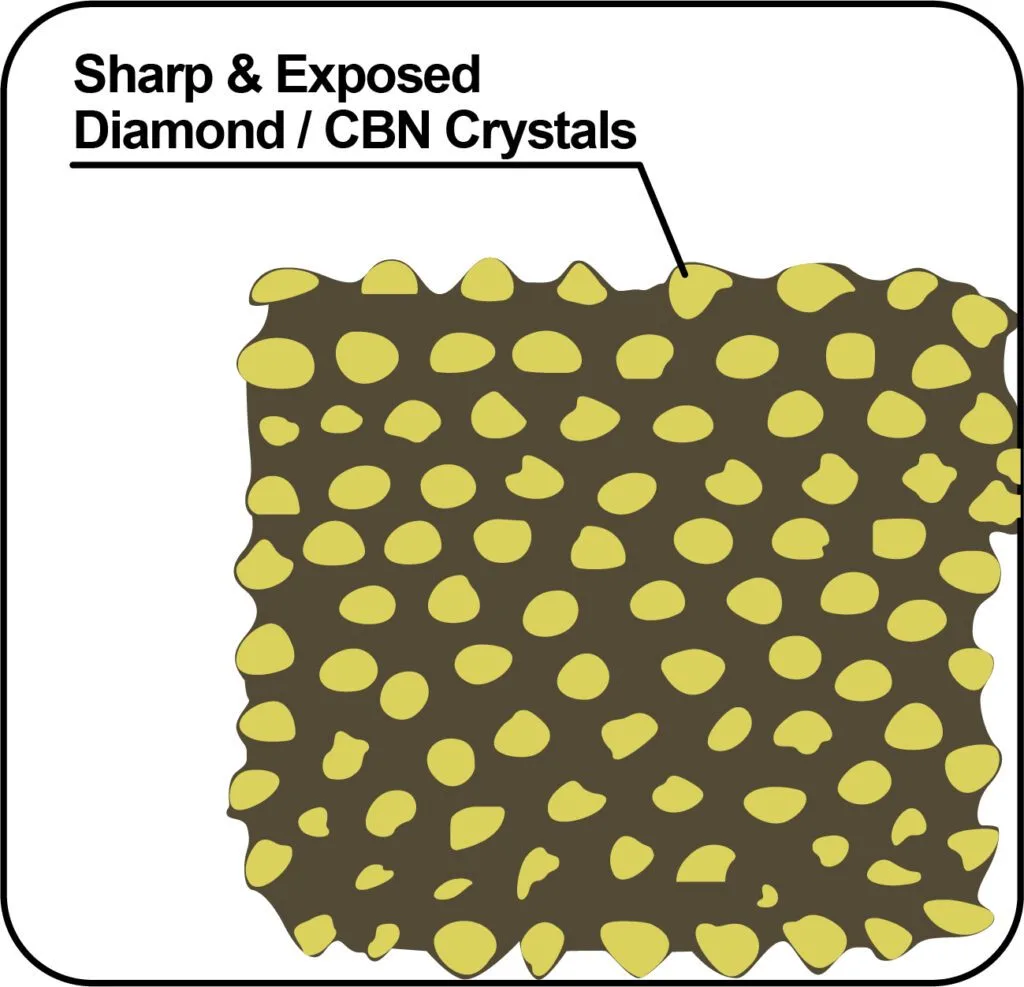

Resin bond dicing blades are made with high temperature phenolic resin, diamond particles, ceramic filler and often additional additives. Resin Bond is the softest of all the bonds, frequently used in applications that require a smooth surface. This type of dicing blade is used on majority of ultra hard & brittle materials. Resin bond dicing blades allow the bond matrix to wear faster, and allow for diamond particles/crystals to break out of their matrix faster, so that new sharp diamond particles become exposed. This self sharpening characteristic of resin bond dicing blades, based on faster bond wear out is what make this blade choice in almost half of all dicing application. Typical Resin Bond Diamond Blades last less than Sintered (Metal Bond) diamond blades, but more than electroplated (nickel bond) diamond blades. finish and minimum amount of chipping.

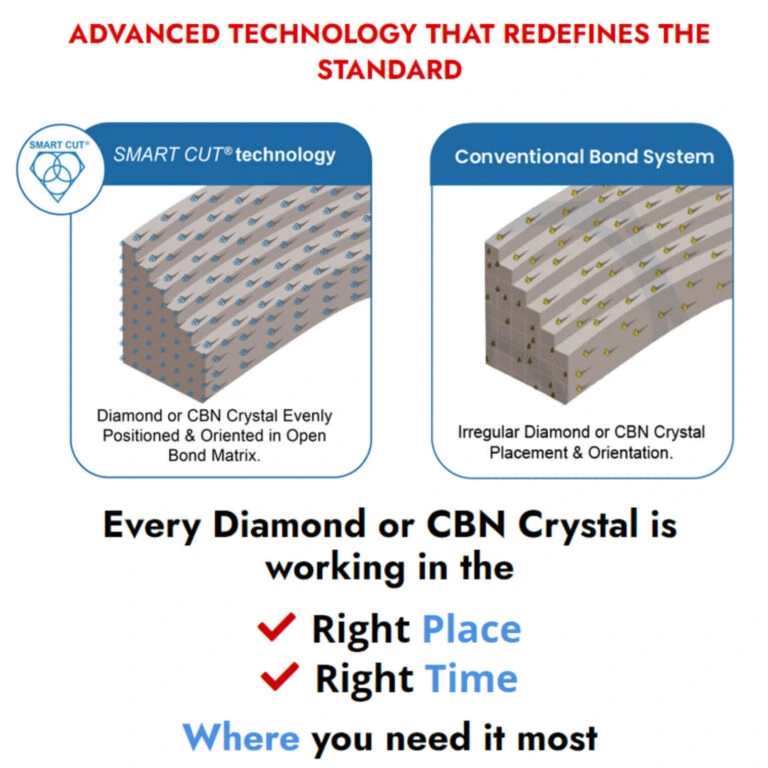

Its what you cant see that makes all the Difference

SMART CUT® technology

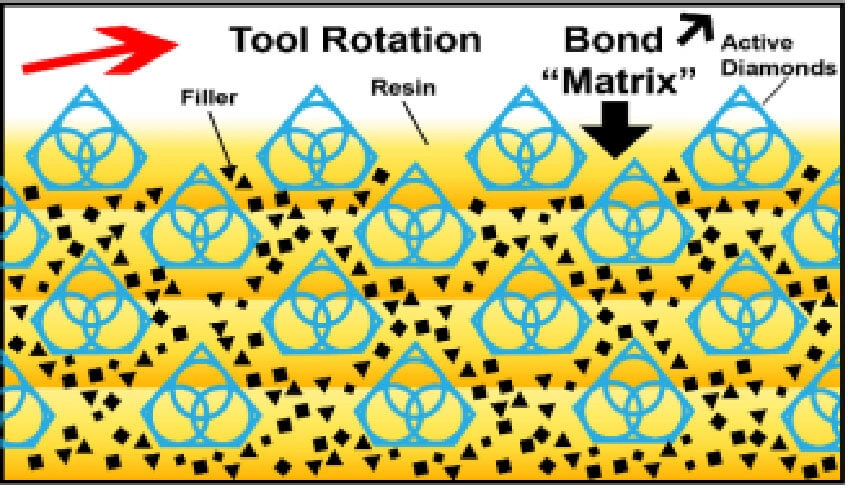

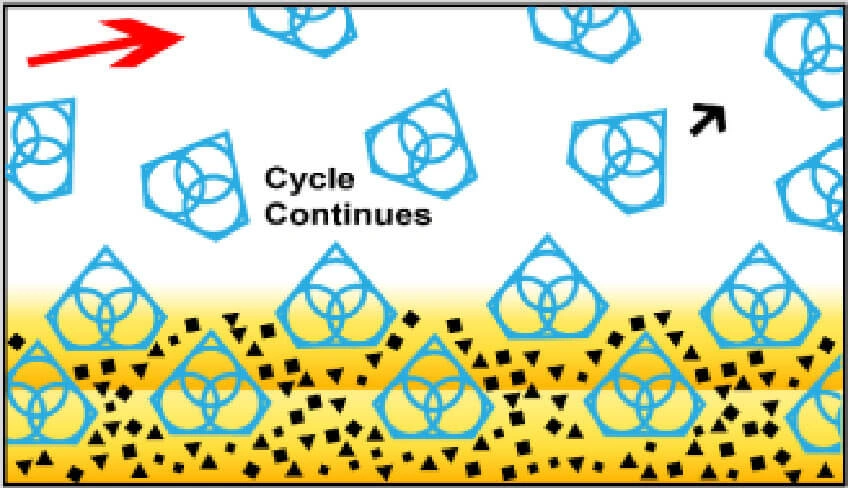

How SMART CUT® Bond Works?

Step 1

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Step 2

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

How SMART CUT® Resin Bond Works?

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT ® Resin Bond Diamond & CBN Dicing Blades, immediately penetrate into the material, grinding and polishing as they cut.

Diamonds or CB Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

The newly exposed diamonds don't effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

SMART CUT® Difference

How SMART CUT® Dicing Blades are Different in comparison to other dicing blades.

Longer

Lasting

Will outlast conventional Resin Bond Dicing Blades SMART CUT® RESIN are more sturdy than blades manufactured with conventional technologies.

Unlike many other resin bond blades, they will not dull and maintain its firm shape and roundness all the way through the blades life.

SMART CUT® RESIN SCR Dicing Blades can accommodate higher loads and feed rates. And may be used on both low & high power saws. Exhibiting unmatched Stability, Flexibility, & Conductivity.

More universal SMART CUT® RESIN SCR Dicing Blades can accommodate higher loads and feed rates. And may be used on both low & high power saws. Exhibiting unmatched Stability, Flexibility, & Conductivity.

More

Consistent Performance

SMART CUT® RESIN SCR are more durable than resin bond blades. Their heavy duty construction is designed to minimize and prevent blade wreckage. And unlike conventional resin bond dicing blades, SMART CUT® RESIN SCR dicing blades require significantly less dressing. This provides 2 very distinct advantages:

Maximum

Coolant Absorption

SMART CUT® RESIN SCR open bond design allows diamonds to absorb excessive heat and tension generated by repeated use, promoting consistency in cut cleanness and smoothness. You will notice the difference in the quality of the cut these blades leave behind.

More

Universal

Blade requires minimal dressing, the bond renews itself.

NO

Glazing

Blade requires minimal dressing, the bond renews itself.

Faster

Cutting Action

More aggressive than your ordinary blades. They cut faster, still leaving behind a smooth finish as you would expect from a resin bond.

Blade

Will not lose its roundness or shape

- Minimum blade dressing

- Consistent cutting speed

- Minimum chipping

- Different Product

- Different Technology

- Different Company

Expect MORE from your tools

Disadvantages of Conventional

Resin Bond Dicing Blades

High Quality Diamond is not used

Resin bond must remain very fragile in order to expose new diamonds. Resin bond is the softest of all the dicing bond matrixes. For this reason, strong and high quality diamonds cannot be used in a resin bond. High quality diamonds are harder than a resin bond matrix. and would soon disintegrate the bond. that keeps them in place. This brings about the need for frequent blade dressing causing the cut to lose its roundness or form.

High Wear Rate

Resin bond blades provide high wear rate, lack of stiffness and thickness limitation.

Short Life

Resin bond can cut hard & brittle materials fast, but will provide much shorter life. Thinnest blades that can be produced in resin bond is .004. Many of the resin bond dicing blade limitation have been resolved by utilizing different phenolic resin types, mixtures, fillers and molding techniques in our New Generation Extended Wear Resin Bond and Hybrid Bond dicing blades. Hence increasing their field or use in greater amount of applications.

Contact Us for FREE Quote & Recommendation

SMART CUT® Series SCH

RESIN BOND SPECIFICATIONS

Size Designation: D X TE X H, Where: D-Outside Blade Diameter, TE –Blade Thickness, H- Blade Inside Diameter.

Note: Our standard Tolerance on Outside Diameter for all blades is +/-.002”, tolerance. Higher tolerances are available upon request

SMART CUT® SERIES (SCR) RESIN BOND DIAMOND DICING BLADE – SELECTION GUIDE

The guide below will help you select the right blade to your material/application, fast and easy. Just locate the material you are working with. On right hand side of material and abbreviation you will find recommended diamond particle size, bond hardness to use for your application. Along with the SMART CUT® bond series recommendation.

|

Material |

Material Code |

SMART CUT |

Diamond |

Bond |

Diamond Concentration |

|---|---|---|---|---|---|

|

FIBERGLASS |

FGS |

SCR1 ® |

D126, D107, D91, D76, D54, D46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

CARBON |

CN |

SCR4® |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

CERAMICS |

D126, D107, D91, D76, D54, D46FRP, CS |

SCR5® |

D54, D46, 45µm, 30µm, 15µm |

SBL, MHBL, MHB |

LOW CONCENTRATION |

|

CARBIDE TGC |

CE |

SCR3 |

D91, D76, D54 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

QUARTZ |

QZ |

SCR5 |

D54, D46, 45µm, 30µm, 15µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

OPTICAL GLASS |

OG |

SCR5 |

D54, D46, 45µm, 30µm, 15µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

PHOTONICS GLASS |

PG |

SCR5 |

D54, D46, 45µm, 30µm, 15µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

MULTI-LAYER CERAMIC CAPACITORS |

BGA CSP MLCC |

SCR6 |

30µm, 15µm, 9µm, 6µm, 45µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

THIN FILM DISC DRIVE HEADS ALUMINUM TITANIUM CARBIDE |

PZT; TFDHH |

SCR5 |

D54, D46, 45µm, 30µm, 15µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

SAPPHIRE AL2O3 + Fe + Ti |

SE |

SCR5 |

D54, D46, 45µm, 30µm, 15µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

RUBY AL2O3 + CR |

RY |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

LITHIUM NEOBYTE LiNbO3 |

D126, D107, D91, D76, D54, D46LN |

SCR6 |

30µm, 15µm, 9µm, 6µm, 45µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

LITHIUM TANTALITE LiTaO3 |

LT |

SCR6 |

30µm, 15µm, 9µm, 6µm, 45µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

ALUMINA (HYBRID SUBSTRATES AND CERAMIC PACKAGES) |

AL |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

QFN, COPPER + EPOXY MOLDING |

QFN |

SCR1 |

D126, D107, D91, D76, D54, D46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

ALUMINUM NITRIDE |

ALN |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

ZIRCONIA (ZrO2) |

ZA |

SCR5 |

D54, D46, 45µm, 30µm, 15µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

BORON CARBIDE (B4C) |

BC |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

TITANIUM DIBORIDE (TiB2) |

TD |

SCR4H |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

GLASS + SIO2 |

GSI |

SCR6 |

30µm, 15µm, 9µm, 6µm, 45µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

SILICON |

SI |

SCR5 |

D54, D46, 45µm, 30µm, 15µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

SILICON-CARBIDE SiC |

SC |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

ZINK-SELENIDE ZnSe |

ZS |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

BARIUM-TITINATE |

BTI |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

BISMUTH-SILICATE Bi2Si22 |

BS |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

BISMUTH-TELLURIDE |

BTE |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

GGGNdGd (W04)2 |

G2 |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

GARNET |

G |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

KOVAR NiFeCo |

K |

SCR6 |

30µm, 15µm, 9µm, 6µm, 45µm |

SBL, MHBL, MHBM |

LOW CONCENTRATION |

|

SILICON NITRIDE Si3N4 |

SN |

SCR4 |

D91, D76, D54, D46, 45µm, 30µm, 15µm |

VVVSB, VSB, VSB |

LOW CONCENTRATION |

|

STONE |

SE |

SCR2 |

D107, D91, D76 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

NON-FERROUS ABRASION RESISTANT MATERIALS |

NFARS |

SCR2 |

D107, D91, D76 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

DIE STEELS |

DS |

SCR7 |

B126, B107, B91, B76, B54, B46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

HARDENED CARBON STEEL |

HCS |

SCR7 |

B126, B107, B91, B76, B54, B46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

INCONEL |

IL |

SCR7 |

B126, B107, B91, B76, B54, B46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

MONEL |

ML |

SCR7 |

B126, B107, B91, B76, B54, B46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

RE |

RE |

SCR7 |

B126, B107, B91, B76, B54, B46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

WASP ALLOY |

WY |

SCR7 |

B126, B107, B91, B76, B54, B46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

HARD FERROUS SUPERALLOYS |

HFS |

SCR7 |

B126, B107, B91, B76, B54, B46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

|

HIGH SPEED TOOL STEELS |

HSTS |

SCR7 |

B126, B107, B91, B76, B54, B46 |

VVVHB, VVHB, VHBH, HBH, HBM |

HIGH CONCENTRATION |

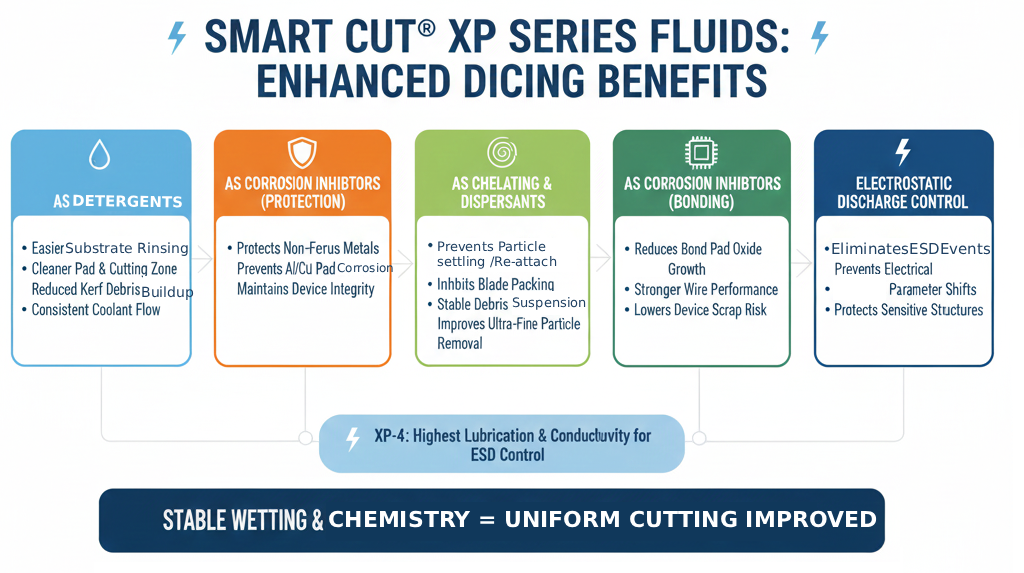

SMART CUT® XP Dicing Fluid, Coolant, & Surfactant

Available in 4 Different Formulas to Fit Most Dicing Applications

XP-1 is a general-purpose dicing fluid within the SMART CUT® range, designed to reduce debris, improve tool life, and prevent corrosion, while ensuring smooth cutting and protecting sensitive materials from ESD.

XP-2 enhances lubrication for demanding applications, offering superior cutting speeds, tool longevity, and advanced cleaning capabilities for tough materials like SiC and sapphire.

XP-3 is ideal for high-pressure systems, offering consistent cooling performance without foam buildup.

XP-4 specifically protects electrostatic-sensitive components by eliminating ESD, reducing defects, and extending tool life during the dicing process.

Related Products

SMART CUT® Water Soluble Dicing Coolant

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

Tungsten Carbide Dicing Blades

Nickel Bond Hubbed Dicing Blades

Sintered (Metal Bond) Diamond & Cbn Dicing Blades

Sintered (metal bonded) diamond tools have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal bonded diamond tools are impregnated” with diamonds.

Hybrid Bond Dicing Blades

Recently Viewed Products

Resin Bond Dicing Blade

SMART CUT® Diamond Edge Grinding Wheels (Electroplated)

SMART CUT® Diamond Edge Grinding Wheels are engineered to deliver exceptional performance for precision grinding applications, providing superior results in both rough and fine grinding. These wheels are ideal for use in industries that require highly accurate EDM processing and consistent wafer-to-wafer results. Manufactured with synthetic diamond grit, SMART CUT® wheels offer improved surface roughness and extended tool life due to their tightly controlled diamond distribution and uniform bond structure.

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

01

Jun

Select right Diamond Dicing Blade for your application

Selecting the right dicing blade for your application requires careful consideration of several key variables that influence both performance and cost. The type of material being cut, the depth of the required cuts, the level...

02

Jun

Dicing Blade Operations Recommendations

Share this Article with Friend or Colleague

Selecting the right dicing blade parameters often involves a trial and error process, many aspects of which can be mitigated through experience and a deep understanding of how to...

02

Jun

Optimizing your Diamond Dicing Performance

Share this Article with Friend or Colleague

The performance of diamond dicing blades is influenced by a wide range of interdependent variables, and understanding these factors is essential for selecting the correct blade specifications and...

02

Jun

Trouble Shooting Dicing Problems

Guide on most common dicing problems and how to resolve them

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP YOU

CONTACT US

HAVING ISSUES WITH

YOUR...

02

Jun

Application Recommendations

This article provides important guidelines for optimizing the dicing process in semiconductor packaging, focusing on package singulation for various technologies such as BGA, QFN, LED, CMOS, and wafer substrates. It covers key variables such as...

02

Jun

Dicing Blade Case Studies

Selecting the right dicing blade is important to achieving high yields, superior edge quality, and consistent reliability in microelectronics and optics manufacturing. Across industries such as semiconductors, electronics packaging, photonics, and precision optics, even small...

01

Jun

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Share this Article with Friend or Colleague

Dicing QFN packages presents several challenges due to the composition of materials and the precision required for clean, defect-free cuts. These challenges arise from the multi-layered structure of...

27

Aug

Selecting the Right Wafer Dicing Saw Practical Guide

Selecting the proper wafer dicing saw is a important decision for manufacturers, researchers, and engineers working with large variety of materials. Whether processing silicon wafers in microelectronics, ceramics in materials science, or glass substrates in...

26

Nov

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

Semiconductor wafers are the foundation of nearly all modern electronics, from integrated circuits and photonic devices to advanced power components. As device geometries shrink and packaging density increases, the requirements placed on wafer dicing processes...

17

Sep

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

Many companies still judge diamond dicing blades by purchase price alone. At first, the cheapest blade may appear to be the best choice. However, price does not equal cost. The real economics of diamond dicing...

18

Sep

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

The making of the integrated circuit is a long and complex process that involves many critical steps. In most cases, the wafer travels to multiple facilities before it is completed and turned into the final...

19

Sep

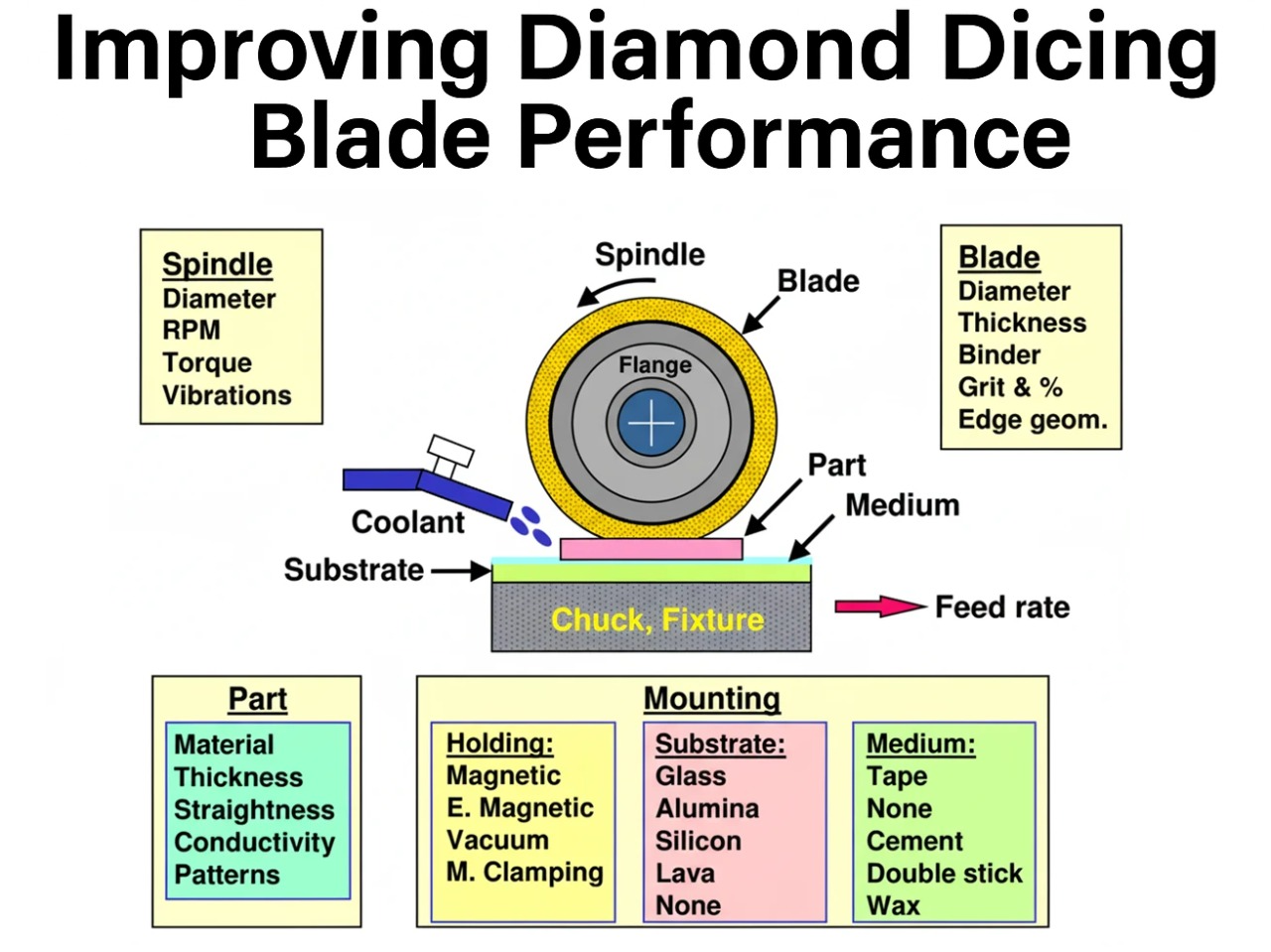

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

Diamond dicing is one of the most important step in semiconductor & microelectronics manufacturing package. Although the process itself does not add direct value to the finished device, it has a decisive impact on yield,...

08

Dec

Selecting the Right Dicing Surfactant / Fluid for Your Application

Selecting the correct dicing surfactant / fluid is essential for stable cutting, consistent kerf quality, and long blade life. Each operation places specific demands on lubrication, cooling, foaming control, and electrostatic behavior. You must choose...

09

Dec

How to Use SMART CUT XP Dicing Surfactants

SMART CUT® XP dicing surfactants should be introduced into the saw water supply in a controlled and consistent manner to ensure proper dilution, stable chemical performance, and uniform delivery to the cutting zone. Correct dosing equipment and proper...

09

Dec

Dicing Surfactants Guide

Dicing surfactants support stable and consistent wafer dicing. You use them as part of a complete dicing fluid designed to cool the blade, flush debris, and protect exposed device surfaces. Modern semiconductor wafers contain smaller...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

02

Nov

Diamond Tool Coolants Why, How, When & Where to Use

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...